Winter-Safe Slip Prevention Rim for E-Scooter: Design to Production Lifecycle Analysis †

Abstract

1. Introduction

2. Related Work

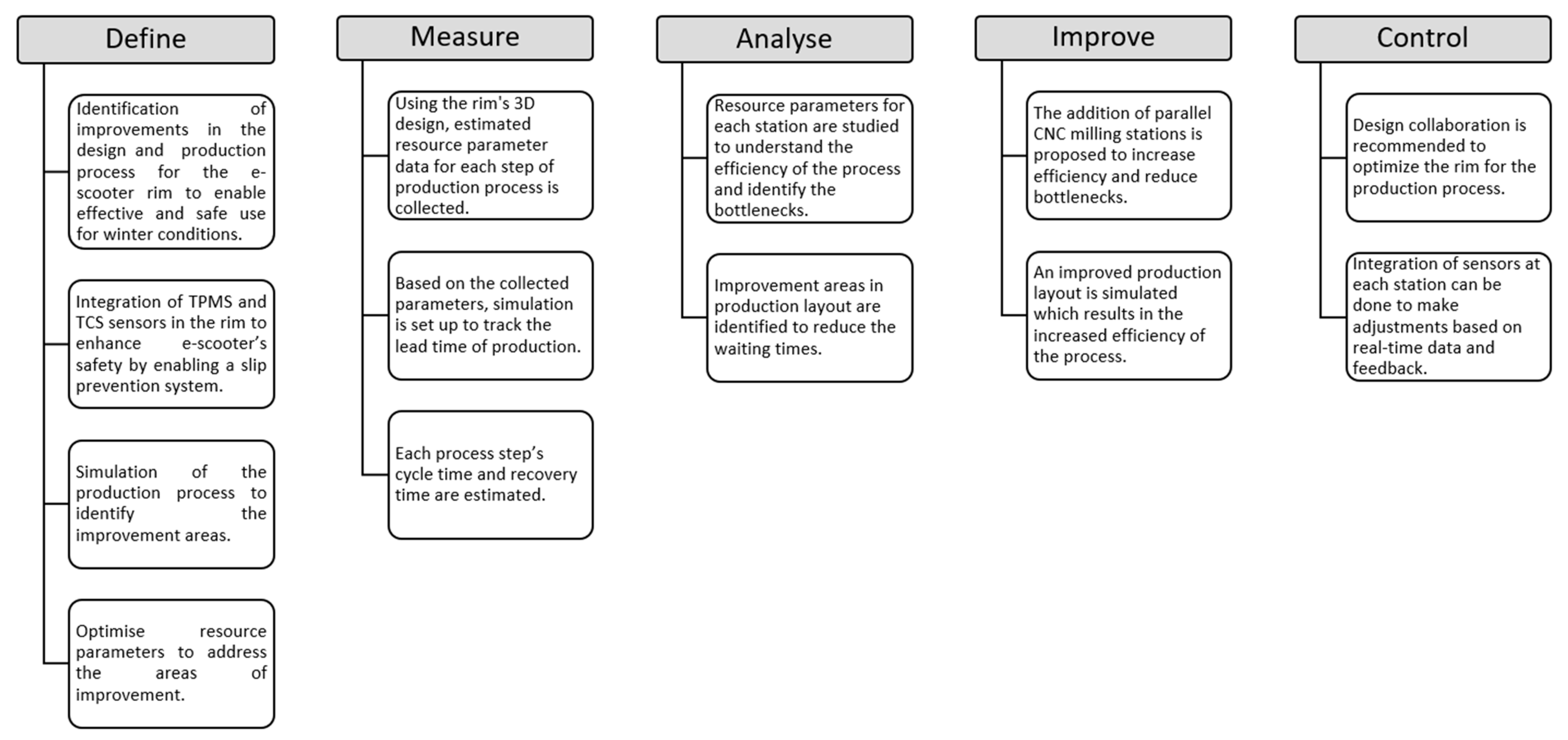

3. Methodology: DMAIC

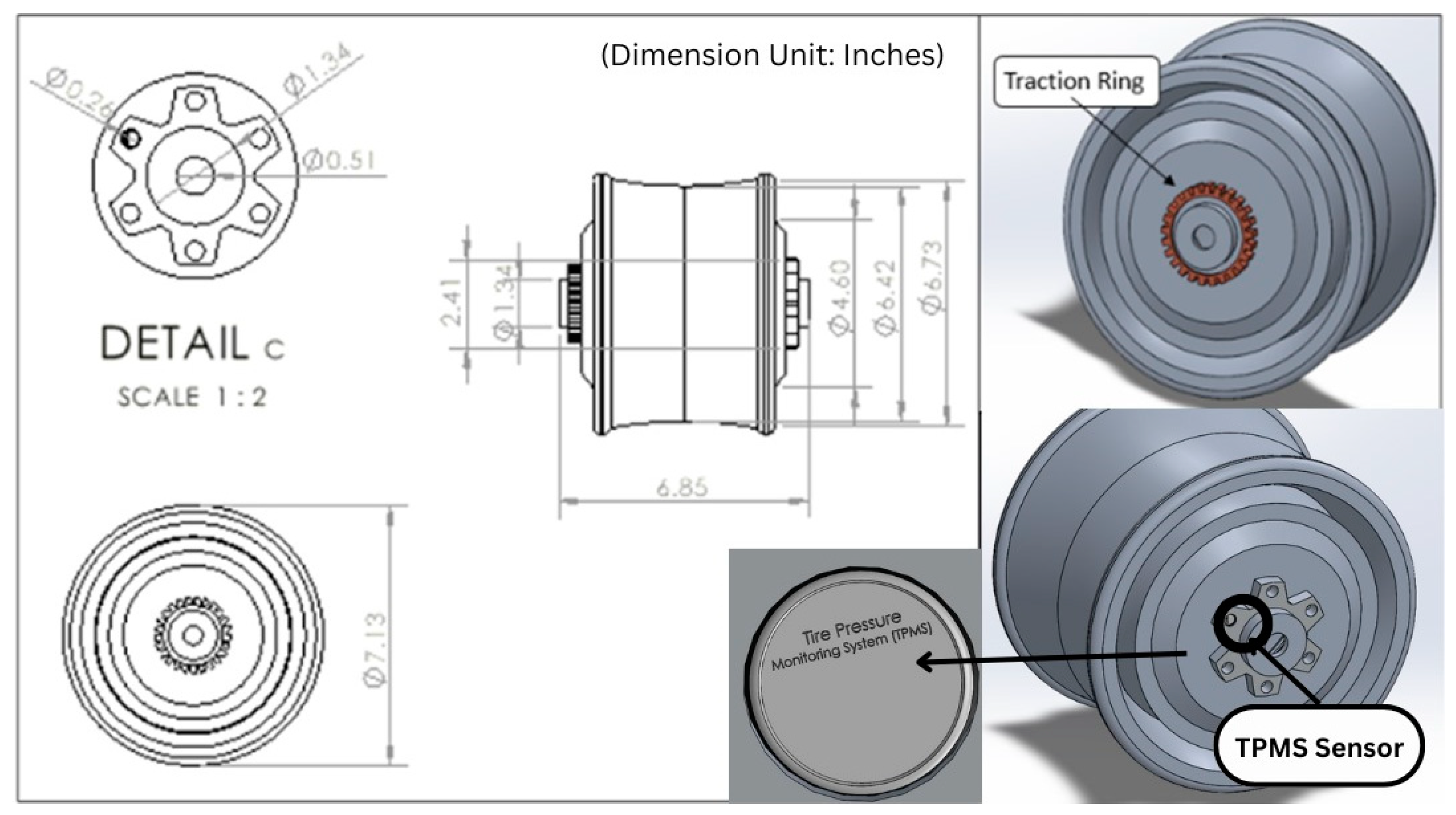

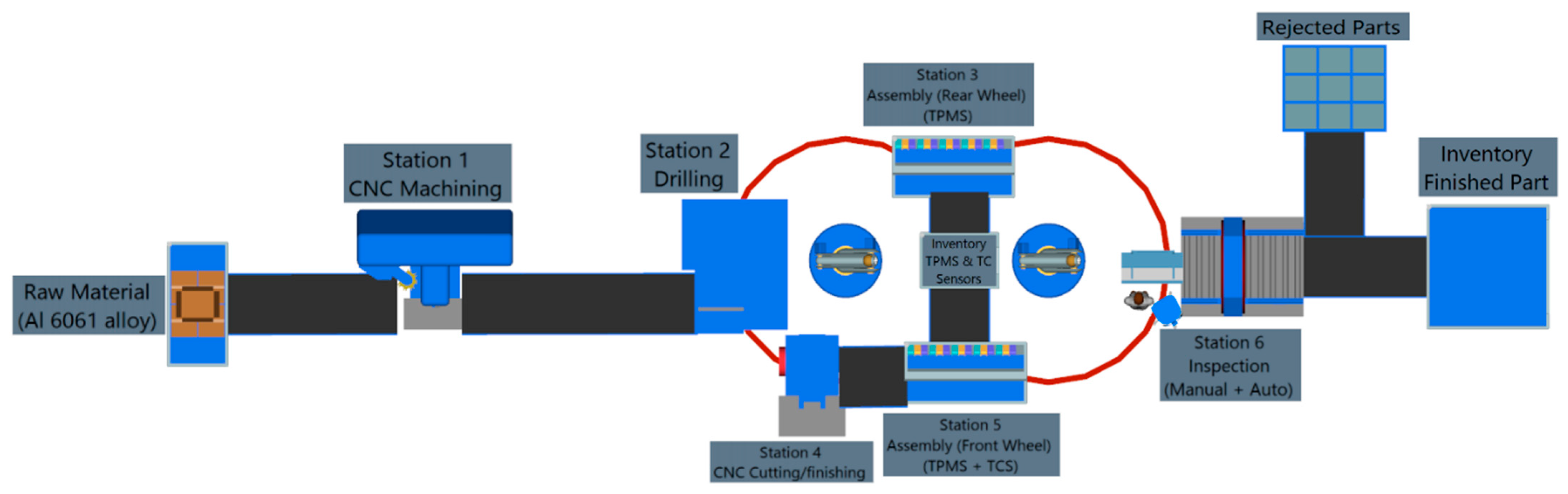

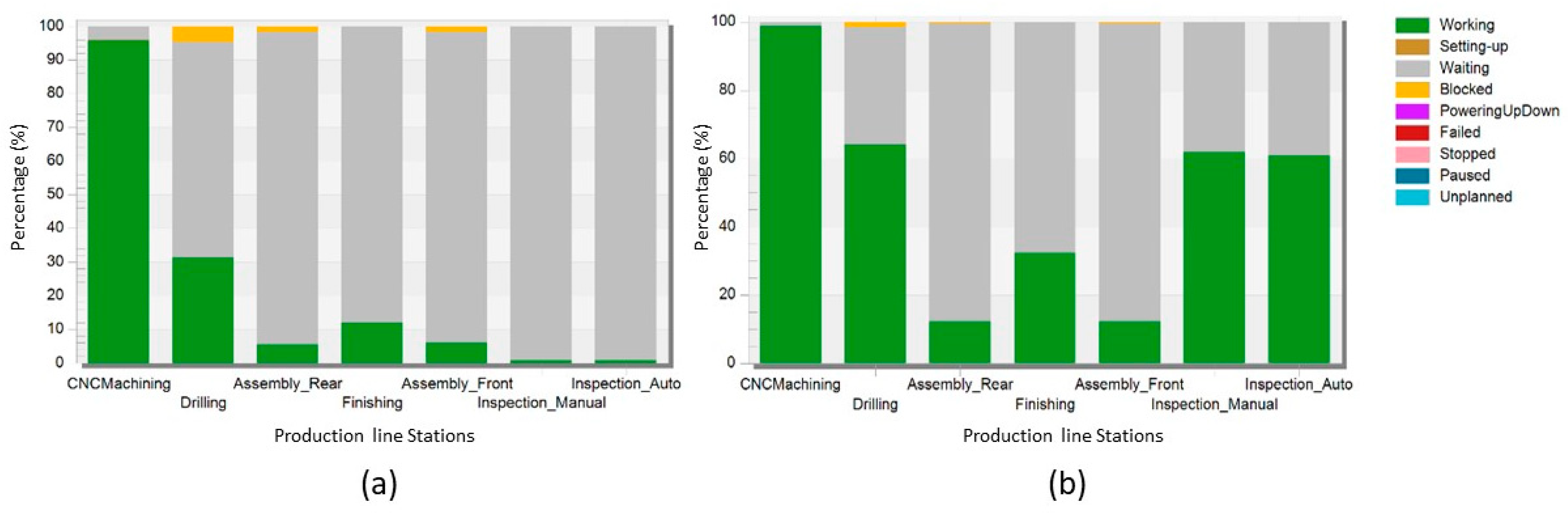

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Montgomery, R.E.; Li, Y.; Dutta, T.; Holliday, P.J.; Fernie, G.R. Quantifying Mobility Scooter Performance in Winter Environments. Arch. Phys. Med. Rehabil. 2021, 102, 1902–1909. [Google Scholar] [CrossRef] [PubMed]

- Trivedi, T.K.; Liu, C.; Antonio, A.L.M.; Wheaton, N.; Kreger, V.; Yap, A.; Schriger, D.; Elmore, J.G. Injuries Associated With Standing Electric Scooter Use. JAMA Netw. Open 2019, 2, e187381. [Google Scholar] [CrossRef] [PubMed]

- Puzio, T.J.; Murphy, P.B.; Gazzetta, J.; Dineen, H.A.; Savage, S.A.; Streib, E.W.; Zarzaur, B.L. The electric scooter: A surging new mode of transportation that comes with risk to riders. Traffic Inj. Prev. 2020, 21, 175–178. [Google Scholar] [CrossRef] [PubMed]

- Ma, Q.; Yang, H.; Mayhue, A.; Sun, Y.; Huang, Z.; Ma, Y. E-Scooter safety: The riding risk analysis based on mobile sensing data. Accid. Anal. Prev. 2021, 151, 105954. [Google Scholar] [CrossRef] [PubMed]

- Yuniarto, M.N.; Wiratno, S.E.; Nugraha, Y.U.; Sidharta, I.; Nasruddin, A. Modeling, Simulation, and Validation of An Electric Scooter Energy Consumption Model: A Case Study of Indonesian Electric Scooter. IEEE Access 2021, 10, 48510–48522. [Google Scholar] [CrossRef]

- García-Vallejo, D.; Schiehlen, W.; García-Agúndez, A. Dynamics, Control and Stability of Motion of Electric Scooters. In Advances in Dynamics of Vehicles on Roads and Tracks: Proceedings of the 26th Symposium of the International Association of Vehicle System Dynamics, IAVSD 2019, Gothenburg, Sweden, 12–16 August 2019; Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2020; pp. 1199–1209. [Google Scholar] [CrossRef]

- Garman, C.; Como, S.G.; Campbell, I.C.; Wishart, J.; O’Brien, K.; McLean, S. Micro-Mobility Vehicle Dynamics and Rider Kinematics during Electric Scooter Riding; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2020. [Google Scholar] [CrossRef]

- Paudel, M.; Fah Yap, F. Front steering design guidelines formulation for e-scooters considering the influence of sitting and standing riders on self-stability and safety performance. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2020, 235, 2551–2567. [Google Scholar] [CrossRef]

- Chen, T.H.; Tu, C.H.; Lin, C.L.; Hsu, S.P. Advanced stabilizing control for electric scooters. Asian J. Control 2021, 23, 1121–1134. [Google Scholar] [CrossRef]

- Jeon, S.M.; Kim, G. A survey of simulation modeling techniques in production planning and control (PPC). Prod. Plan. Control 2016, 27, 360–377. [Google Scholar] [CrossRef]

- Pham, T.T.; Kuo, T.C.; Tseng, M.L.; Tan, R.R.; Tan, K.; Ika, D.S.; Lin, C.J. Industry 4.0 to accelerate the circular economy: A case study of electric scooter sharing. Sustainability 2019, 11, 6661. [Google Scholar] [CrossRef]

- Severengiz, I.; Finke, S.; Schelte, N.; Wendt, N. E-TEMS 2020: 2020 IEEE European Technology & Engineering Management Summit: 5–7 March, 2020, Dortmund University of Applied Sciences and Arts; IEEE: Piscataway, NJ, USA, 2020. [Google Scholar]

- Mittal, A.; Gupta, P.; Kumar, V.; Al Owad, A.; Mahlawat, S.; Singh, S. The performance improvement analysis using Six Sigma DMAIC methodology: A case study on Indian manufacturing company. Heliyon 2020, 9, e14625. [Google Scholar] [CrossRef] [PubMed]

- Sharma, A.; Yadav, R.; Sharma, K. Optimization and investigation of automotive wheel rim for efficient performance of vehicle. Mater. Today Proc. 2021, 45, 3601–3604. [Google Scholar] [CrossRef]

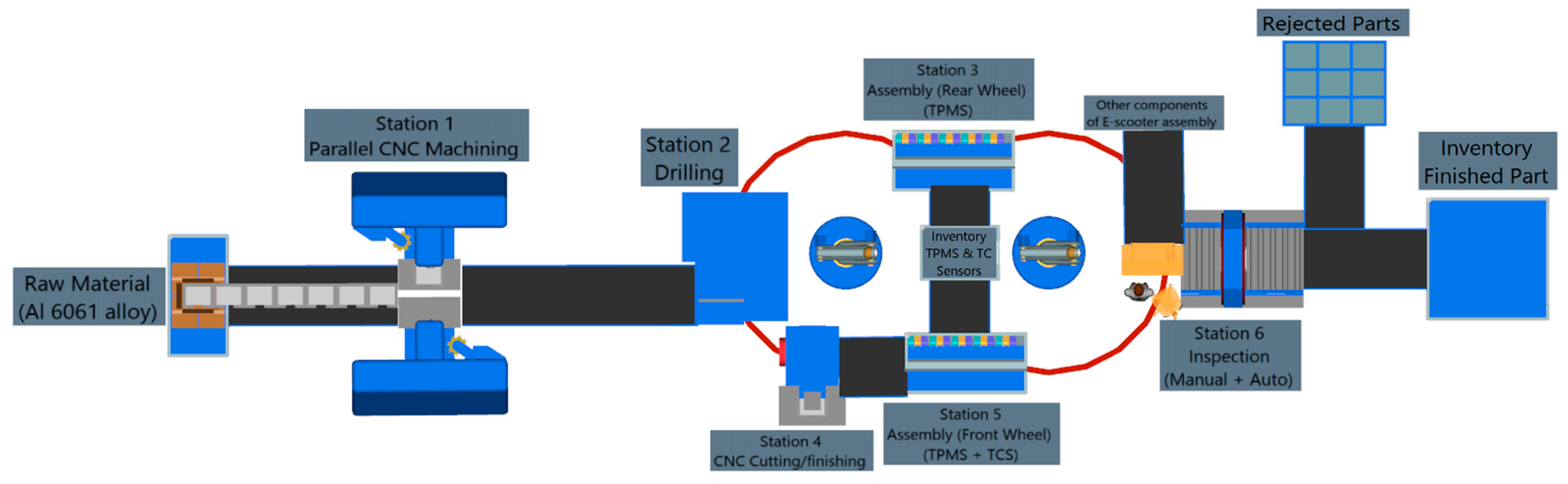

| Station No. | Station Name | Process Time | Recovery Time |

|---|---|---|---|

| 1 | CNC Milling | 30 min | 5 min |

| 2 | Drilling | 10 min | 2 min |

| 3 | Assembly (TPMS) | 15 s | 1 min |

| 4 | CNC cutting/finishing | 5 min | 2 min |

| 5 | Assembly (TPMS + TCS) | 30 s | 1 min |

| 6 | Quality Control | 30 s | 1 min |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rasool, A.; Satsangee, G.R.; Arickswamy, L.; Ashfaq, M.M.; Ahmad, R. Winter-Safe Slip Prevention Rim for E-Scooter: Design to Production Lifecycle Analysis. Eng. Proc. 2024, 76, 88. https://doi.org/10.3390/engproc2024076088

Rasool A, Satsangee GR, Arickswamy L, Ashfaq MM, Ahmad R. Winter-Safe Slip Prevention Rim for E-Scooter: Design to Production Lifecycle Analysis. Engineering Proceedings. 2024; 76(1):88. https://doi.org/10.3390/engproc2024076088

Chicago/Turabian StyleRasool, Afia, Guru Ratan Satsangee, Leander Arickswamy, Muhammad Mohsin Ashfaq, and Rafiq Ahmad. 2024. "Winter-Safe Slip Prevention Rim for E-Scooter: Design to Production Lifecycle Analysis" Engineering Proceedings 76, no. 1: 88. https://doi.org/10.3390/engproc2024076088

APA StyleRasool, A., Satsangee, G. R., Arickswamy, L., Ashfaq, M. M., & Ahmad, R. (2024). Winter-Safe Slip Prevention Rim for E-Scooter: Design to Production Lifecycle Analysis. Engineering Proceedings, 76(1), 88. https://doi.org/10.3390/engproc2024076088