Experimental Investigation on Abrasive Flow Finishing of FDM-Printed Polymeric Y-Shaped Nozzle †

Abstract

1. Introduction

2. Materials and Method

3. Experimental Setup and Procedure

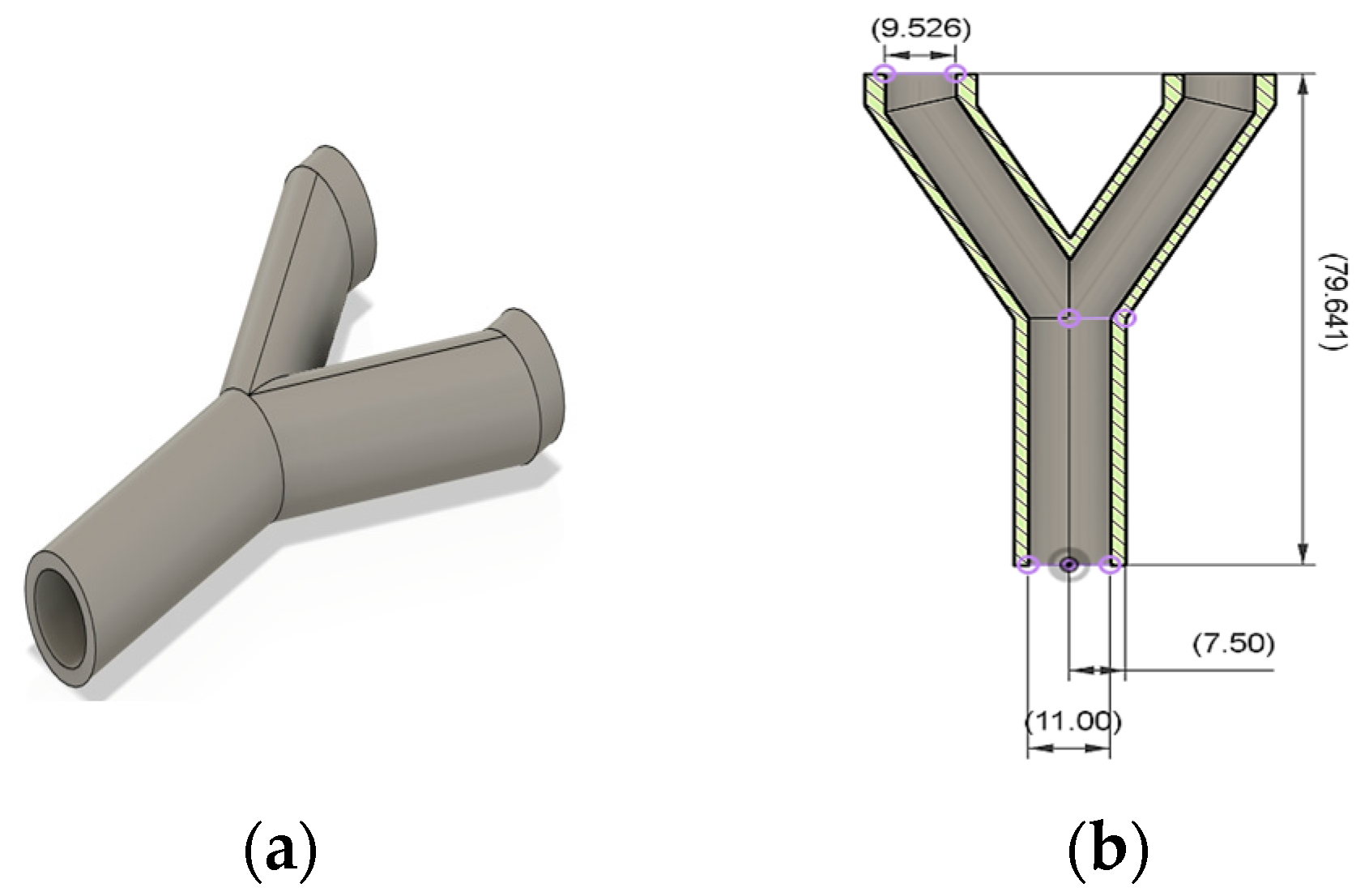

3.1. Printing of Y-Shaped Nozzles

3.2. Fabrication of AFM Fixtures

3.3. Preparation of AFM Medium

3.4. Abrasive Flow Machining Process

3.5. Parameter Optimization

3.6. Surface Roughness Measurement

3.7. Experimental Trials

4. Results and Analysis

4.1. Surface Roughness Outcomes

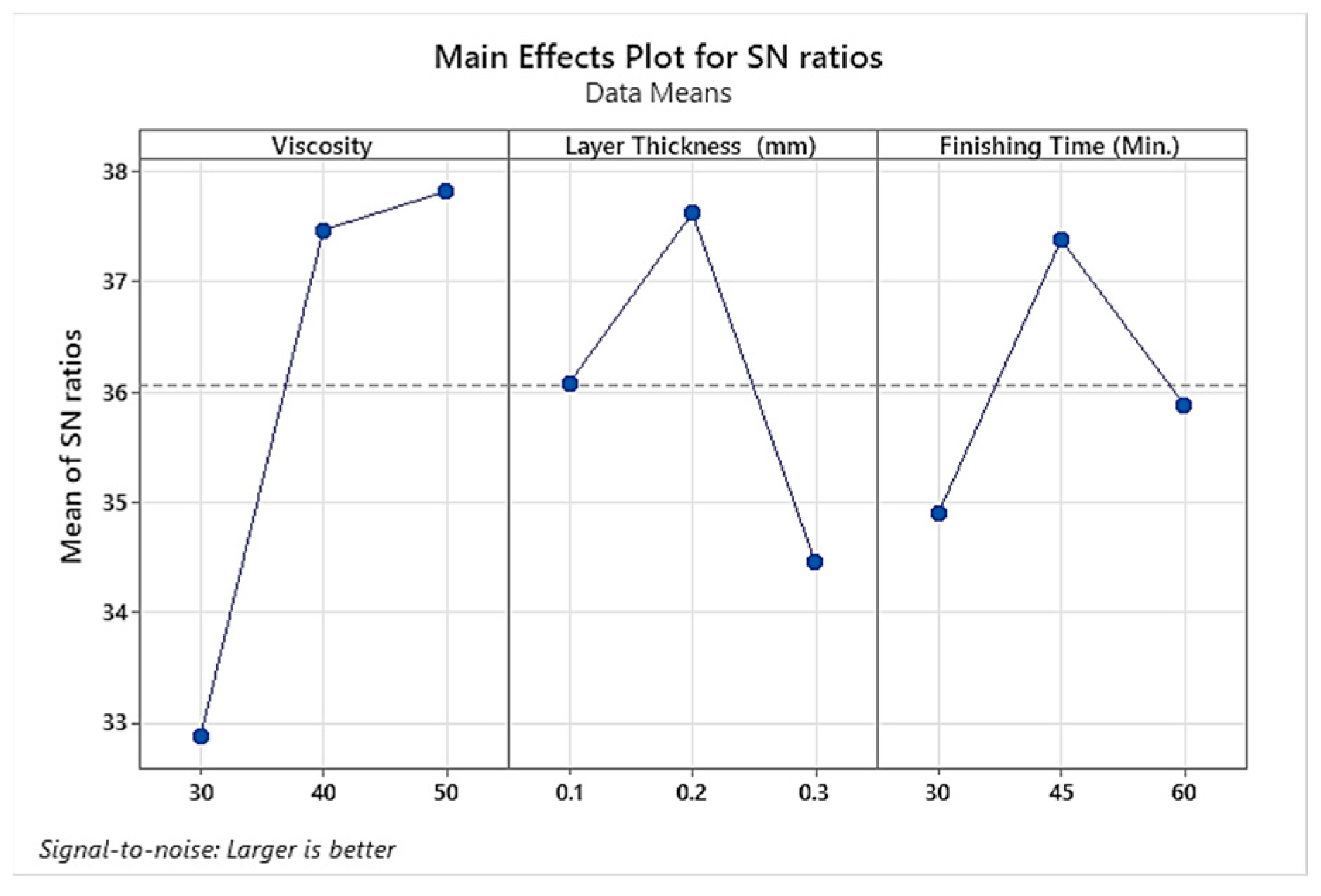

4.2. Influence of AFM Parameters

4.3. Viscosity’s Role in AFM Efficiency

4.4. Statistical Analysis of Results

4.5. Comparison with Control Samples

4.6. Process Reproducibility

4.7. Optical Image Analysis

5. Conclusions

- AFM significantly improves the surface roughness of FDM-printed ABS Y-shaped nozzles.

- Optimal AFM parameters were identified for achieving the best surface finish.

- The study’s optimized AFM process is applicable across various manufacturing sectors.

- The utilization of waste rubber in AFM media aligns with sustainable manufacturing practices.

- Future research should explore AFM’s effects on different materials and process automation.

- AFM-treated FDM parts exhibit a potential increase in viable applications for 3D-printing technologies.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Additive Manufacturing Technologies, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2021; ISBN 9783030561260. [Google Scholar]

- Jyothish Kumar, L.; Pandey, P.M.; Wimpenny, D.I. 3D Printing and Additive Manufacturing Technologies; Springer: Singapore, 2018; ISBN 9789811303050. [Google Scholar]

- Dave, H.K.; Davim, J.P. Fused Deposition Modeling Based 3D Printing; Springer: Berlin/Heidelberg, Germany, 2021; ISBN 978-3-030-68024-4. [Google Scholar]

- Kumbhar, N.N.; Mulay, A.V. Post Processing Methods Used to Improve Surface Finish of Products Which Are Manufactured by Additive Manufacturing Technologies: A Review. J. Inst. Eng. (India) Ser. C 2018, 99, 481–487. [Google Scholar] [CrossRef]

- Pandey, P.M.; Reddy, N.V.; Dhande, S.G. Improvement of Surface Finish by Staircase Machining in Fused Deposition Modeling. J. Mater. Process. Technol. 2003, 132, 323–331. [Google Scholar] [CrossRef]

- Hashmi, A.W.; Meena, A.; National, M. Improving the Surface Characteristics of Additively Manufactured Parts: A Review. Mater. Today Proc. 2023, 81, 723–738. [Google Scholar] [CrossRef]

- Hashmi, A.W.; Mali, H.S.; Meena, A. A Comprehensive Review on Surface Quality Improvement Methods for Additively Manufactured Parts. Rapid Prototyp. J. 2023, 29, 504–557. [Google Scholar] [CrossRef]

- Hashmi, A.W.; Mali, H.S.; Meena, A. Surface quality improvement methods of additively manufactured parts: A review. Solid State Technol.. 2020, 63, 23477–23517. [Google Scholar] [CrossRef]

- Hashmi, A.W.; Mali, H.S.; Meena, A.; Ahmad, S.; Puerta, A.P.V.; Kunkel, M.E. A critical review of mechanical-based post-processing techniques for additively manufactured parts. In Post-Processing Techniques for Additive Manufacturing; Alam, Z., Iqbal, F., Khan, D.A., Eds.; CRC Press: Boca Raton, FL, USA, 2024; pp. 99–127. [Google Scholar] [CrossRef]

- Hashmi, A.W.; Mali, H.S.; Meena, A. The Surface Quality Improvement Methods for FDM Printed Parts: A Review. In Fused Deposition Modeling Based 3D Printing; Dave, H.K., Davim, J.P., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 167–194. ISBN 978-3-030-68024-4. [Google Scholar]

- Hashmi, A.W.; Mali, H.S.; Meena, A.; Puerta, V.; Kunkel, M.E. Surface Characteristics Improvement Methods for Metal Additively Manufactured Parts: A Review. Adv. Mater. Process. Technol. 2022, 8, 4524–4563. [Google Scholar] [CrossRef]

- Hashmi, A.W.; Mali, H.S.; Meena, A.; Saxena, K.K.; Ahmad, S.; Agrawal, M.K.; Sagbas, B.; Puerta, A.P.V.; Khan, M.I. A Comprehensive Review on Surface Post-Treatments for Freeform Surfaces of Bio-Implants. J. Mater. Res. Technol. 2023, 23, 4866–4908. [Google Scholar] [CrossRef]

- Hashmi, A.W.; Mali, H.S.; Meena, A.; Saxena, K.K.; Puerta, A.P.V.; Rao, U.S.; Buddhi, D.; Mohammed, K.A. Design and Modeling of Abrasive Flow Finishing of Freeform Surfaces of FDM Printed Femoral Component of Knee Implant Pattern. Int. J. Interact. Des. Manuf. (IJIDeM) 2022, 17, 2507–2526. [Google Scholar] [CrossRef]

- Hashmi, A.W.; Mali, H.S.; Meena, A.; Saxena, K.K.; Puerta, A.P.V.; Buddhi, D. A Newly Developed Coal-Ash-Based AFM Media Characterization for Abrasive Flow Finishing of FDM Printed Hemispherical Ball Shape. Int. J. Interact. Des. Manuf. (IJIDeM) 2022, 17, 2283–2298. [Google Scholar] [CrossRef]

- Hashmi, A.W.; Mali, H.S.; Meena, A.; Ahmad, S.; Tian, Y. A Novel Eco-Friendly Abrasive Media Based Abrasive Flow Machining of 3D Printed PLA Parts Using IGWO and ANN. Rapid Prototyp. J. 2023, 29, 2019–2038. [Google Scholar] [CrossRef]

- Mali, H.S.; Hashmi, A.W.; Jangid, M.K.; Meena, A. Experimental Investigation on AFF of FDM Printed Pattern for Extrusion Die Insert. In Advances in Micro and Nano Manufacturing and Surface Engineering; Springer: Berlin/Heidelberg, Germany, 2023; pp. 199–211. [Google Scholar]

- Wahab Hashmi, A.; Singh Mali, H.; Meena, A. Experimental Investigation on Abrasive Flow Machining (AFM) of FDM Printed Hollow Truncated Cone Parts. Mater. Today Proc. 2022, 56, 1369–1375. [Google Scholar] [CrossRef]

- Hashmi, A.W.; Mali, H.S.; Meena, A. An Experimental Investigation of Viscosity of a Newly Developed Natural Polymer-Based Media for Abrasive Flow Machining (AFM) of 3D Printed ABS Parts. J. Eng. Res. 2021, 1–18. [Google Scholar] [CrossRef]

- Wahab Hashmi, A.; Singh Mali, H.; Meena, A. Design and Fabrication of a Low-Cost One-Way Abrasive Flow Finishing Set-up Using 3D Printed Parts. Mater. Today Proc. 2022, 62, 7554–7563. [Google Scholar] [CrossRef]

- Chohan, J.S.; Singh, R. Pre and Post Processing Techniques to Improve Surface Characteristics of FDM Parts: A State of Art Review and Future Applications. Rapid Prototyp. J. 2017, 23, 495–513. [Google Scholar] [CrossRef]

- Boparai, K.S.; Singh, R.; Singh, H. Development of Rapid Tooling Using Fused Deposition Modeling: A Review. Rapid Prototyp. J. 2016, 22, 281–299. [Google Scholar] [CrossRef]

- Singh, D.; Singh, R.; Boparai, K.S. Development and Surface Improvement of FDM Pattern Based Investment Casting of Biomedical Implants: A State of Art Review. J. Manuf. Process. 2018, 31, 80–95. [Google Scholar] [CrossRef]

| Parameters | Level 1 | Level 2 | Level 3 |

|---|---|---|---|

| Abrasive mesh size | 120 | 220 | 320 |

| %Abrasive concentration | 33 | 50 | 67 |

| Layer thickness | 0.1 | 0.2 | 0.3 |

| Finishing time (min) | 30 | 45 | 60 |

| S. N. | Viscosity | Layer Thickness (mm) | Finishing Time (Min.) | Initial Surface Roughness (Ra in µm) | Post-Finishing Surface Roughness (Ra in µm) | % Improvement in (ΔRa) |

|---|---|---|---|---|---|---|

| 1 | 30 | 0.1 | 30 | 13.80 | 09.16 | 33.62 |

| 2 | 40 | 0.2 | 45 | 23.13 | 02.20 | 90.49 |

| 3 | 60 | 0.3 | 60 | 28.60 | 12.83 | 55.14 |

| 4 | 30 | 0.2 | 60 | 22.90 | 11.43 | 50.09 |

| 5 | 40 | 0.3 | 30 | 29.03 | 13.73 | 52.70 |

| 6 | 50 | 0.1 | 45 | 16.90 | 02.03 | 87.99 |

| 7 | 30 | 0.3 | 45 | 30.00 | 14.76 | 50.80 |

| 8 | 40 | 0.1 | 60 | 14.00 | 01.76 | 87.43 |

| 9 | 50 | 0.2 | 30 | 23.33 | 00.70 | 97.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hashmi, A.W.; Ahmad, S.; Iqbal, F.; Yusuf, M.; Ibrahim, H. Experimental Investigation on Abrasive Flow Finishing of FDM-Printed Polymeric Y-Shaped Nozzle. Eng. Proc. 2024, 76, 107. https://doi.org/10.3390/engproc2024076107

Hashmi AW, Ahmad S, Iqbal F, Yusuf M, Ibrahim H. Experimental Investigation on Abrasive Flow Finishing of FDM-Printed Polymeric Y-Shaped Nozzle. Engineering Proceedings. 2024; 76(1):107. https://doi.org/10.3390/engproc2024076107

Chicago/Turabian StyleHashmi, Abdul Wahab, Shadab Ahmad, Faiz Iqbal, Mohammad Yusuf, and Hussameldin Ibrahim. 2024. "Experimental Investigation on Abrasive Flow Finishing of FDM-Printed Polymeric Y-Shaped Nozzle" Engineering Proceedings 76, no. 1: 107. https://doi.org/10.3390/engproc2024076107

APA StyleHashmi, A. W., Ahmad, S., Iqbal, F., Yusuf, M., & Ibrahim, H. (2024). Experimental Investigation on Abrasive Flow Finishing of FDM-Printed Polymeric Y-Shaped Nozzle. Engineering Proceedings, 76(1), 107. https://doi.org/10.3390/engproc2024076107