Abstract

As amine-based post-combustion capture is adopted in numerous projects, aligning projected equipment performance with the operational requirements of Carbon Capture and Storage (CCS) facilities is imperative. This study highlights the methodology in using data from the operation of an amine-based CCS facility to provide essential Reliability, Availability and Maintainability (RAM) parameters for some key equipment including a Booster Fan, Compressor, and Lean–rich heat exchanger. The performance of the equipment was evaluated using key indicators such as the mean time between failures and mean time to repair. The analysis shows the need to combine different data sources within the plant to identify opportunistic maintenance and critical failure points to assess equipment reliability. These findings can be used as a tool for maintaining operational efficiency in future CCS plants, empowering decision-makers to identify bottlenecks and make informed equipment redundancy decisions.

1. Introduction

The high cost associated with maintaining equipment in industrial facilities can represent a major operating cost and can also lead to excessive downtimes for facilities and negatively impact revenue. Therefore, establishing the appropriate level of redundancy of equipment in new CCS projects requires careful analysis.

Based on the experience gained from previous operational projects, the cost associated with developing new projects can be significantly reduced by applying the lessons learned from operating existing facilities. This is evident in large-scale carbon capture utilization and storage (CCUS) projects. One study found that the cost of CO2 capture has decreased by 35% in the power sector between the first (SaskPower’s BD3) and second (Petra Nova) major facilities, with further reduction projected for future facilities [1].

One factor that will play a major role in achieving this reduction in upcoming projects is the insights gained from the performance and maintenance of existing equipment. A Reliability, Availability and Maintainability (RAM) analysis of major CCS equipment can further reduce the cost associated with operating and maintaining these projects, increase equipment safety and optimize process performance. RAM analysis aims to pinpoint areas within a system or process where improvement can be implemented across various design stages considering both safety and operational constraints. The parameters ascertained from a RAM analysis are included in decision-making tools to inform managers to take necessary actions in enhancing operational, maintenance and safety methods, ensuring optimum equipment function [2].

In order to maintain operational equipment performance throughout the lifespan of CCS facilities using amine-based technologies, it is imperative to provide a novel RAM analysis baseline for forthcoming projects to incorporate into their design process. Many analyses for the development of CCS facilities typically draw upon RAM parameters conducted during design, as highlighted in the Shell Quest CCS Project RAM study report, as well as other industries such as power stations and oil and gas plants [3].

The International CCS Knowledge Centre conducted a study of real performance data sourced and adapted from an operational amine-based CCS facility. For confidentiality reasons, the owner of this facility is referred to as “MZ” in this paper. This work included the establishment of methodologies for estimating crucial RAM study indicators. This information was provided to a client in the United States that is a major power producer engaged in the front-end engineering design (FEED) stage of integrating carbon capture at a large power generation facility. For confidentiality reasons, this client is referred to as “HZ” in this paper. HZ is using this information as input for the base case analysis model for conducting a comprehensive RAM analysis of the proposed new facility.

The equipment performance data from MZ are confidential and will not be shared as part of this paper or elsewhere. However, the methodologies used for the analysis, as well as conclusions reached, will be demonstrated in this paper, allowing for an understanding of how RAM analysis could be applied to CCS projects in development. The data presented as part of this paper were generated and informed by the CCS project development experience internal to the International CCS Knowledge Centre.

This study aims to provide insights into data sources, the steps to consider for conducting a detailed RAM analysis of a CCS facility and the methodology in refining historical data to facilitate meaningful analysis.

2. Materials and Methods

2.1. Materials

MZ provided all details of the maintenance executed on the various equipment for this study via an Excel file extracted from their SAP records. The Excel files provided details of the work order type, activity carried out, equipment or equipment component worked on, work scheduled duration and the actual start and finish times. The maintenance process used by the company is similar to that outlined by [4], which adheres to a structured routine of tackling equipment failure to ensure good record keeping.

Given that each maintenance process is initiated by a work order, our initial step was to request work orders for the capture facility. The work order types were distinctly categorized within the SAP record, clearly delineating whether a particular work order was a corrective maintenance event aimed at resolving existing issues or preventive maintenance intended to proactively address potential issues before they escalate. This was instrumental to the compilation of failures associated with each piece of equipment considered for this study to provide lucid inputs to ascertain their performance.

The SAP record provided by the company details when the work order was created, following issue identification. Assessing equipment downtime solely from the SAP record did not reflect the actual duration; hence, another data source was required to provide real-time insights into occurrences in the CCS plant. To overcome this challenge, PI ProcessBook data were juxtaposed with the SAP records to extract and confirm realistic equipment downtimes using the performance metric of the equipment.

MZ also supplied us with the primary reasons for the capture plant downtimes, which were used to determine the main cause associated with each instance of downtime experienced by the plant. This was conducted to differentiate between issues occurring at MZ’s capture plant and those originating from their flue gas source plant.

We also made use of equipment data sheets together with SAP records and PI ProcessBook to acquire specifications for normal operation. These specifications were used to ascertain the operational thresholds distinguishing between normal and faulty operation.

2.2. Procedure

The analysis was aimed at focusing on work orders which contributed as major precursors to unplanned shutdowns in the CCS facility. To initiate the analysis, we collected data from the resources described in the Materials Section above. Subsequently, we extracted dates within the operational years designated for planned maintenance to filter out work orders in the SAP system that were categorized as planned orders. This filtering process was conducted in Excel by selecting only unplanned maintenance work orders for later analysis.

Following the selection of unplanned work orders for the specific equipment, the next step involved retrieving the hourly output from MZ’s flue gas flowrate in PI ProcessBook. These data were crucial for analyzing the operational timelines of the flue gas source, providing essential insights into the operational status of the CCS flue gas source plant. The aim of this step was to decouple the downtime of the CCS facility from the independent events and downtimes of the upstream flue gas source plant.

Unplanned work orders in the CCS facility below the minimum flue gas flowrate required for the CCS plant to operate were tagged as opportunistic, indicating that they were performed when the flue gas source plant was not operational. However, it is worth noting that the flue gas source plant is the main or only supplier of flue gas and energy to the capture plant in the system we considered for our analysis. During periods when the flue gas source plant was non-operational, any work order generated for equipment was classified as opportunistic maintenance and was excluded from the analysis.

Additionally, work orders for specific pieces of equipment were further verified to determine whether the equipment was in operation, using performance metrics. This meticulous approach ensured that the analysis accurately distinguished between planned and unplanned maintenance activities while also confirming the operational status of individual equipment within the plant. For example, we assessed how well the Booster Fan was working by checking the RPM of its fan, which we obtained from PI ProcessBook. We compared this RPM against the set threshold for normal operation. The Excel IF function was employed to return 1 to show normal operation and 0 to indicate equipment failures when the normal operational limit was not met. This additional step was essential to help filter out major failures that occurred unexpectedly and were driven by only the CCS facility and not the flue gas source plant.

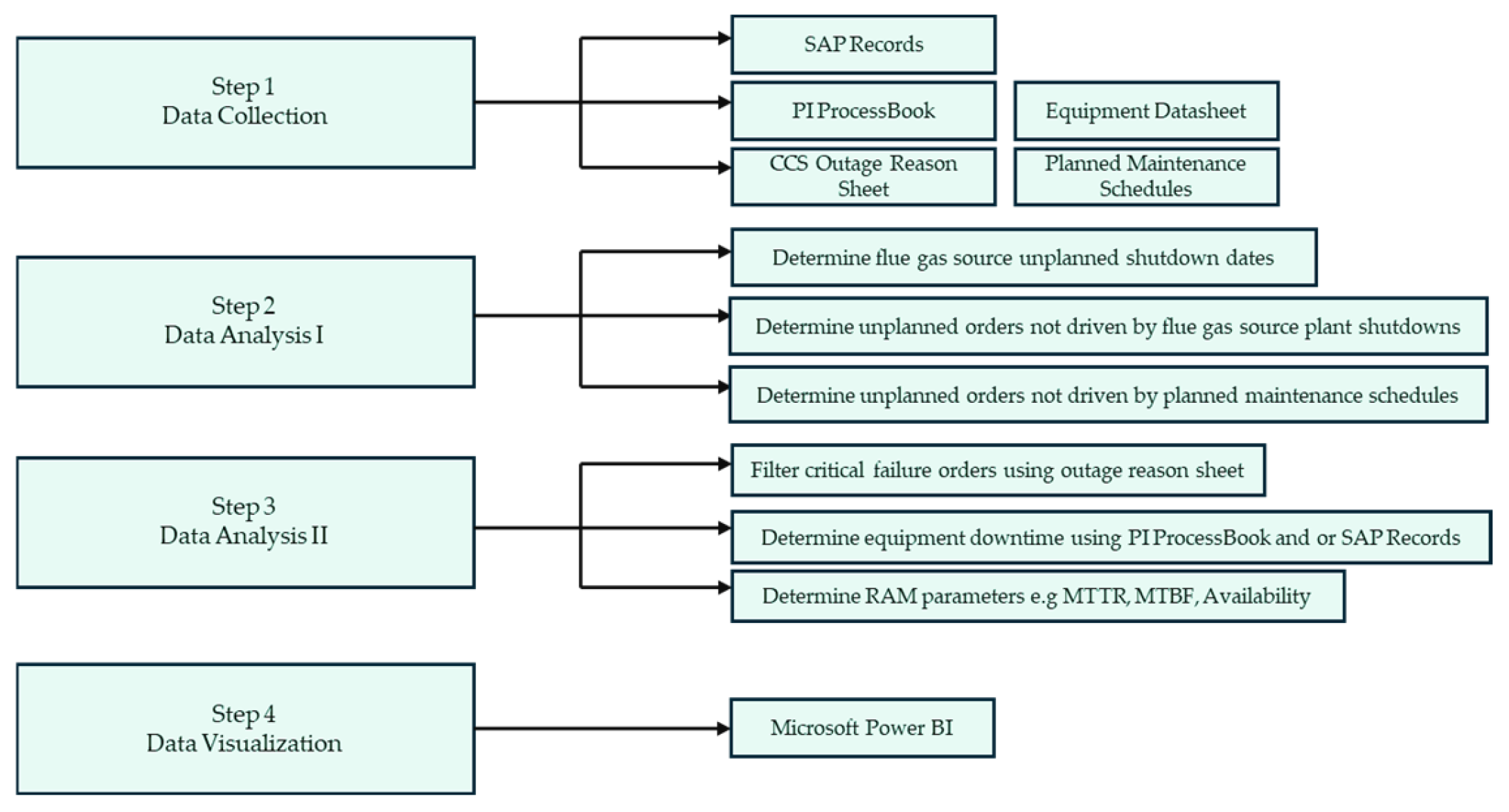

The decisive step of the analysis involved determining whether the unplanned work orders were the primary initiators for CCS plant outages. This critical assessment was conducted using the outage reason sheet generated by MZ, which records the equipment responsible for causing unplanned downtime in the CCS plant. This step was essential to confirm if the major unplanned downtime, identified in the previous analysis, aligned with the recorded reasons for unplanned outages. Additionally, further analysis was carried out using CO2 product flowrate data extracted from the PI process to ascertain if unplanned failures contributed to the plant outages. The final dataset, compiled in an Excel Workbook, was utilized as an input to calculate and visualize the RAM parameters—MTBF, MTTR and equipment availability—using Microsoft Power BI (Version: 2.138.1004.0 64-bit). The methodology used to analyze the data is summarized in Figure 1.

Figure 1.

Road map to RAM analysis.

3. Data Analysis

The previous sections detailed the methodology used to analyze MZ’s data for the benefit of HZ’s large-scale CCS facility development. For this paper, we randomly generated data to demonstrate what the results of such an analysis would look like to maintain the confidentiality of MZ’s data, as well as the information provided to HZ.

The RAM analysis only focused on unplanned maintenance that resulted in CCS plant outages. The CCS plant considered for this study undergoes planned maintenance for 14 days for every 2 years of operation, which is the same for the flue gas source plant. The data in Table 1 represent summarized work orders for the units considered, ready to be analyzed using the procedure described above.

Table 1.

CCS plant work orders.

Table 1 shows sample unplanned maintenance (UM) and planned maintenance (PM) orders of the Booster Fan (MZBF-001), Lean–rich heat exchanger (MZHX-101) and Compressor (MZCOMP-001) for an 8-year operational period. Table 1 represents sample data generated to demonstrate some scenarios encountered when analyzing the real data obtained from MZ. For example, row one shows that a work order generated with an ID of 1 in the first year of operation on the 7th day of April was tagged as unplanned maintenance caused by the Booster Fan (MZBF-001) with a downtime of 48 h.

The downtime for each work order was originally sourced from PI ProcessBook during the actual analysis. However, for this paper’s purpose, the downtimes were generated randomly. Table 1 was used in collaboration with an outage reason sheet, as shown in Table 2, which details the main reasons for the CSS plant outages.

Table 2.

Downtime reasons for work orders.

From our actual analysis, the outage reason sheet was provided by the process engineers and maintenance team running MZ’s CCS plant. In many instances, multiple work orders were generated on the same day or dates close to those of other equipment downtimes. This required extensive data analysis aimed at extracting and identifying the initial major work orders from the SAP data to determine which work order was the major precursor in a CCS facility outage.

The outage reason data obtained were instrumental in establishing major failures for this study and were integral in distinguishing opportunistic maintenance and actual unplanned failures. In this paper, we also generated a sample outage reason sheet to capture most of the events we encountered in the actual analysis and highlight its significance in capturing critical failure points.

To capture only the major failures using the outage reason sheet, we compared unplanned work order dates from the SAP data with the outage reason sheet to identify the key influencers in the CCS plant’s downtimes. For example, the outage reason sheet indicates that the CCS plant in the first year was down due to an issue related to the booster on the 7th of April. Comparing that to the work orders in Table 1, there are two different orders generated for the Lean–rich heat exchanger and the Booster Fan on the same day with different downtimes. This is a typical issue that was encountered throughout our analysis. To establish the main downtime propeller in this case, the outage reason sheet indicates that the reason for the CCS shutdown on the 7th of April during the first year was driven by a Booster Fan-related issue which took 48 hrs to return to normal operation.

Looking at order ID 2, which occurred on the same day as order ID 1, there was an opening to work on the Lean–rich heat exchanger during the Booster Fan-driven downtime. This indicates that this maintenance conducted on the Lean–rich heat exchanger resulted from an opportunity which was provided by the Booster Fan issue and hence not considered as a major failure. This exercise was conducted using various Excel functions including IF, VLOOKUP, INDEX, MATCH, ISNUMBER to match unplanned failure work orders with the CCS outage reason sheet. Order ID 2 was then considered as opportunistic maintenance (OM) and was excluded from our analysis. Subsequently, order ID 3 was also not considered a major failure that led to the CCS plant outage since order ID 1 had a downtime of 48 hrs, providing room for order IDs 2 and 3 to be performed within its repair time. In addition to this, order ID 5 was also tagged as OM due to the opportunity provided by the Compressor-related shutdown on the 5th of Oct. Moreover, this exercise helps to filter relevant critical equipment point failures that provided room for other maintenance work to be performed.

Order IDs 7, 10, 15 and 19 represent planned maintenance dates which were incorporated into Table 1 to aid in filtering all work orders which are tagged as unplanned that were carried out within the scheduled maintenance timeframe. One typical scenario is when order ID 20 was generated and tagged as unplanned maintenance in Table 1. This order and its associated downtimes could have escaped the filtering using the outage reason sheet. By looking at the downtime duration of order 19, it becomes very evident that order ID 20 was not a CCS failure but opportunistic maintenance during the planned maintenance period on 26 November.

Another contributory parameter to consider is the configuration between the flue gas source plant and the CCS plant. As mentioned, for the system considered for this analysis, the flue gas source plant is the only plant that supplies flue gas to the CCS plant. In situations where the flue gas source plant encounters an issue, the capture plant would have to shut down. When conducting CCS plant analysis, it is essential to consider the dates and durations of flue gas source plant downtimes to identify the relevant sources of failure. Order IDs 8, 9 and 13 belong to this category. During this phase, these orders were triggered due to outages in the flue gas source plant and were not deemed as failures. In the real study, PI ProcessBook was used to determine flue gas flow trends in the CCS plant; this can also be used as a data source to determine flue gas source plant downtimes.

The analysis discussed was used to filter the dataset in Table 1 to capture only relevant failures that were directly related to CCS equipment leading to unplanned outages of the entire CCS facility (see Table 3).

Table 3.

Distinct work orders after analysis.

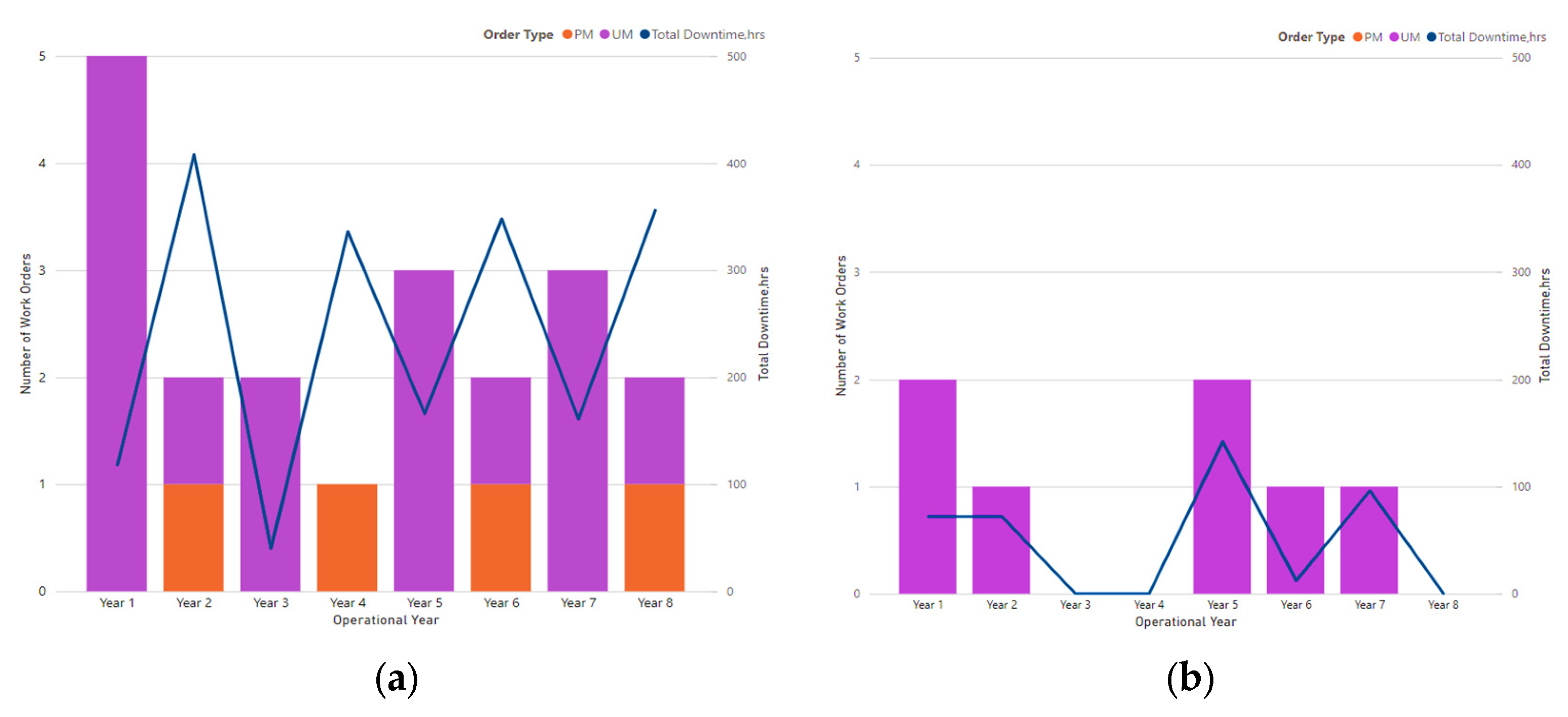

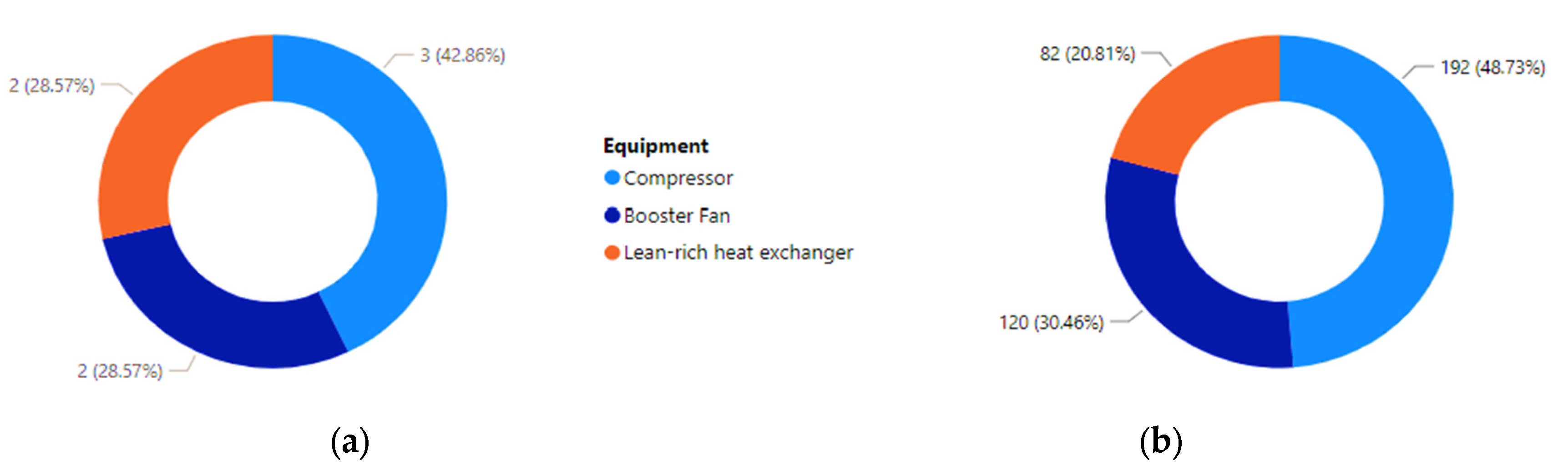

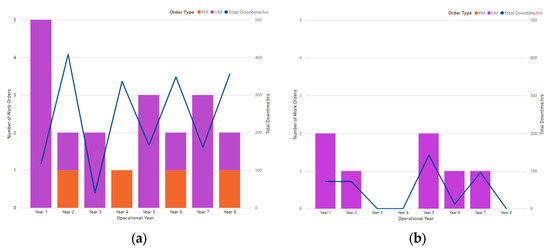

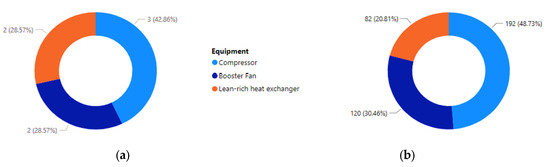

Figure 2 shows the annual distribution of planned and unplanned maintenance before and after the data analysis, respectively. The number of unplanned maintenance actions associated with CCS outages was corrected from 16 to only 7 distinct actions, as indicated in Table 3 and Figure 3 based on the data analysis. In addition to this, the remaining maintenance actions were categorized as opportunistic maintenance (OM).

Figure 2.

Annual maintenance distribution and downtimes before (a) and after data analysis (b).

Figure 3.

Unplanned unit contribution to CCS outages after data analysis: (a) failure count and (b) downtime contribution.

4. RAM Parameter Analysis

The final work orders obtained from the analysis (see Table 3) with its associated downtimes were then used as inputs to estimate RAM parameters. The parameters estimated were the mean time between failures (MTBF), mean time to repair (MTTR) and equipment availability (EA). The total operational duration for the plant spans 8 years, with biennial shutdowns lasting 14 days each. It is worth noting that the duration for planned maintenance was duly accounted for in the 8-year period to estimate the expected uptime of each unit.

During the actual analysis, the downtime estimated incorporates the time the equipment went below its normal performance metric, indicating a decrease in efficiency, and the time when it was fully functional again. The MTTR for each piece of equipment was estimated by dividing the total downtime during the 8-year period by the number of failures.

The MTBF was calculated by dividing the total expected uptime during the 8- year period by the number of failures.

MTTR = Total downtime/Number of failures,

MTBF = Total uptime/Number of failures,

Equipment availability was assessed by expressing the mean time between failures (MTBF) as a fraction of the sum of the MTBF and mean time to repair (MTTR).

EA = MTBF/(MTBF + MTTR),

The total uptime was determined by subtracting the time allocated for planned maintenance and the downtime associated with the equipment. The RAM parameters were obtained using Equations (1)–(3) over the 8-year period and are presented in Table 4.

Table 4.

Summary of RAM parameters for critical failures over 8-year operational period.

Based on our analysis, the Booster Fan experienced two failure events over an 8-year operational period. The average interval between these failures was approximately 4 years, indicating a stable performance with long durations between incidents.

When a failure occurred, the average duration required to repair the blower and restore it to operation was found to be 60 h (about 2 and a half days). However, this efficient repair process contributed to a high availability rate of 99.83% throughout the 8-year period. This trend can be used to explain the RAM parameters obtained for the Compressor and Lean–rich heat exchanger in Table 4.

5. Conclusions

In summary, this study delves into the methodology used to estimate RAM parameters while highlighting various data sources and analyses to consider, helping to better understand equipment performance across a project’s life. Future research will delve into analyzing additional equipment beyond the scope of this paper, shedding light on typical failures encountered in operating equipment within a CCS plant and assessing the contribution of equipment components to overall reliability. Our major contribution is providing a road map to properly analyze CCS plant data efficiently and the necessary conclusions that can be drawn from the analysis. However, it is important to note that the data presented in this study are simulated to reflect real-world operational scenarios in a CCS plant, serving mainly as a guide for conducting RAM analysis in such facilities.

The RAM analysis can inform process developers to make better estimates in including redundancy in some piece of equipment to ensure high performance for the facility as a whole across project life. Maintenance schedulers can also rely on the RAM analysis data to ensure that planned maintenance is scheduled within reasonable timelines to ensure high equipment reliability.

Author Contributions

Conceptualization, C.N. and R.A.; methodology, C.N., E.R. and R.A.; validation, E.R., Y.F. and R.A.; formal analysis, C.N.; investigation, C.N.; resources, C.N. and Y.F.; data curation, C.N.; writing—original draft preparation, C.N.; writing—review and editing, E.R., Y.F. and R.A.; visualization, C.N.; supervision, E.R., Y.F. and R.A.; project administration, C.N. and E.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are available in this manuscript.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Adam, B.-S.; Niels, B. Is Carbon Capture Expensive? 2021. Available online: https://www.iea.org/commentaries/is-carbon-capture-too-expensive (accessed on 18 March 2024).

- Qingfeng, W.; Wenbin, L.; Xin, Z.; Jianfeng, Y.; Qingbin, Y. Development and Application of Equipment Maintenance and Safety Integrity Management System. J. Loss Prev. Process Ind. 2011, 24, 321–332. [Google Scholar] [CrossRef]

- Stephens, R.M. Quest CCS Project RAM Study—Final Report; Shell Global Solutions: London, UK, 2010; pp. 1–55. [Google Scholar]

- Corvaro, F.; Giacchetta, G.; Marchetti, B.; Recanati, M. Reliability, Availability, Maintainability (RAM) Study, on Reciprocating Compressors API 618. Petroleum 2017, 3, 266–272. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).