Abstract

This paper offers a brief insight into predicting the State of Health (SOH) of lithium-ion batteries in EVs using machine learning. Accurate SOH assessment is crucial for optimizing electric vehicles (EVs’) performance and longevity. Employing supervised machine learning on a diverse battery dataset, the research develops a robust SOH estimation method. Various algorithms are compared for efficacy, considering factors like temperature and charging patterns. Feature selection enhances model accuracy and efficiency. The proposed methodology offers promising real-world results, indicating high SOH prediction accuracy. This research contributes to EV battery management, applying machine learning for SOH estimation, which is vital for intelligent battery management systems, and enhancing EVs’ sustainability and efficiency.

1. Introduction

In an era dominated by the need for sustainable energy solutions, lithium-ion batteries have emerged as the linchpin of modern technological progress because they are more affordable than other batteries and have greater electrical densities, reduced self-discharge rates, and longer lifespans [1,2]. Their ubiquitous presence in portable electronics, electric vehicles, and renewable energy systems underscores their pivotal role in shaping our contemporary world [3,4]. As we harness the power of lithium-ion batteries to propel us into an electrified future, understanding and predicting their aging processes become paramount. This paper delves into the critical importance of lithium-ion batteries, exploring their diverse applications and the pressing need for effective aging estimation methodologies.

The pervasive influence of lithium-ion batteries extends far beyond the confines of our smartphones and laptops. These compact powerhouses have become the heartbeat of electric mobility, driving the transition from fossil fuel dependence to cleaner and more sustainable alternatives [5,6]. From powering electric cars to storing renewable energy generated by solar panels and wind turbines, lithium-ion batteries stand as the backbone of a green energy revolution. This paper seeks to underscore the indispensability of these energy storage devices and the urgency of addressing the challenges posed by their inevitable aging.

As we become increasingly reliant on lithium-ion batteries to fuel our technological advancements, the question of their longevity becomes central to ensuring the reliability and efficiency of our energy systems. The aging of lithium-ion batteries, characterized by a gradual loss of capacity and performance, poses challenges that demand meticulous investigation. This paper aims to shed light on the intricacies of battery aging and the methodologies employed to estimate and mitigate its impact on the functionality and sustainability of lithium-ion energy storage.

By comprehending the intricate relationship between the applications of lithium-ion batteries and the aging phenomena they undergo, we pave the way for enhanced performance, longevity, and sustainability in the realm of energy storage. The insights gained from this exploration are not merely theoretical; they hold the key to optimizing the lifespan of lithium-ion batteries and, consequently, advancing the frontiers of our electrified future.

Lithium-ion (Li-ion) batteries have emerged as the preferred energy storage solution for a wide range of applications, with electric vehicles (EVs) being a prominent example. Understanding the State of Health (SOH) and State of Charge (SOC) of these batteries [7] is essential for ensuring their optimal performance and longevity.

State of Health (SOH) refers to the overall health or condition of a battery over time [7]. It provides insights into the battery’s capacity to store and deliver energy compared to its original design capacity. The degradation of a lithium-ion battery over its lifespan is inevitable, influenced by factors such as temperature, charging/discharging cycles, and usage patterns. Monitoring SOH helps assess the remaining useful life of the battery and informs decisions related to maintenance, repair, or replacement. This represents the SOH [8], as shown in Equation (1):

SOH = Qmax/Qrated × 100%

SOC shows the battery’s current charge level as a proportion of its overall capacity. It reflects the immediate energy availability for use. Precise SOC measurements are crucial for ensuring accurate range estimation in EVs, as the driver relies on this information to plan journeys and gauge when recharging is necessary.

Calculating SOH and SOC in EVs has several important functions:

- Optimizing battery life: Monitoring SOH allows manufacturers and users to implement strategies to optimize battery life. By identifying degradation patterns, one can adjust charging and discharging parameters to mitigate factors contributing to wear and tear.

- Range estimation and planning: Accurate SOC measurements are vital for estimating the driving range of an EV. Drivers need reliable information about how much charge is remaining in order to plan their journeys effectively. Inaccuracies in SOC readings could lead to unexpected range anxiety and inconvenience.

- Preventing overcharging and over discharging: Precise SOC data help prevent overcharging (which can degrade the battery) and over discharging (which can damage cells). Maintaining the SOC within recommended limits ensures the battery operates within a safe and efficient range.

- Cost efficiency: Understanding SOH aids in predicting the end of life of the battery. This knowledge allows for proactive maintenance or replacement, preventing unexpected failures and contributing to cost-efficient operation of EV fleets.

- Avoiding fire hazards determined by accurate SOH measurements: The primary issue with today’s Li-ion batteries is their potential to catch fire if damaged, and this risk grows with age, particularly when the batteries are charging. This could result in fire events in private or public structures.

In conclusion, accurate calculation and monitoring of SOH and SOC are integral aspects of managing lithium-ion batteries in electric vehicles. These parameters not only impact the performance and reliability of EVs but also play a crucial role in maximizing the efficiency and sustainability of electric transportation systems.

Machine learning, a subset of artificial intelligence [9,10], is a dynamic field that empowers computers to learn and improve from experience without explicit programming. At its core, machine learning involves the development of algorithms and statistical models that enable systems to recognize patterns, make decisions, and adapt over time. Various methods within machine learning include supervised learning, where models are trained on labeled data, unsupervised learning for exploring patterns in unlabeled data, and reinforcement learning, which involves learning through interaction with an environment.

1.1. State-of-the-Art Review

This paper is grounded in the research conducted by Ethelbert Ezemobi for his 2022 master’s thesis [7], which delves into the testing of lithium-ion batteries under various loads and the estimation of their State of Health (SOH). Additionally, this work draws inspiration from a 2021 study [11] by Sunkyu Jung and Taemoon Roh, wherein machine learning techniques were employed for SOH estimation based on the relative State of Charge. Furthermore, insights from a 2019 study by William C. Chueh and Richard D. Braatz, showcasing their ability to predict battery life cycles using machine learning [12], are incorporated into the paper. The primary focus of this paper is to explore how variations in operating temperature impact the behavior, particularly the State of Health, of the battery.

Rui Xiong’s 2017 identification of Open Circuit Voltage (OCV) [13] using the H infinity filter (HIF) in real operating conditions is also discussed. Alagar Karthick’s 2021 paper [14] presents SoC estimation for EV’s battery systems, utilizing six machine learning algorithms: artificial neural network (ANN), support vector machine (SVM), linear regression (LR), Gaussian process regression (GPR), etc. Error analysis is incorporated into the study to maximize the battery’s efficiency factor. Furthermore, the 2015 study by Peter Keil and Andreas Jossen offers guidance on how to best operate Li-ion batteries in electric cars by taking into account variables like temperature, regenerative braking, and State of Charge (SoC) to determine the best operating tactics that will maximize battery life [15].

The automated machine learning algorithm known as linear regression [8] is emphasized for its capacity to forecast numerical outcomes based on distinct variables and uncover correlations between them. It is characterized by its versatility, offering various models based on the nature and number of variables. The dependent variable (outcome) is forecasted using independent variables (predictors). Linear regression is noted for its interpretability, simplicity, speed, and robustness, making it effective for a broad range of prediction tasks, even in the presence of noisy or imperfect data. Additionally, in 2022, in the presence of battery cycle profiles with quick charging conditions, the author offers battery aging simulations according to high-current, gradually increasing characteristics [16].

1.2. Structure and Contributions

This research proposes a novel approach to estimating the SOH of EV batteries by measuring and testing the battery at various temperatures and utilizing the data to predict the remaining life via machine learning.

The cell’s maximum usable capacity is predicted using connected feed-forward liner regression with these data. Consequently, this paper’s contributions are as follows:

- Design integrated circuit to test & measure the battery performance at different temperatures.

- Analysis the battery parameters during the testing period (at zero temperature and high temperature).

- Collect this data and use them in MATLAB machine learning.

- Extremely precise approximations are produced from a small set of measurements.

2. Methodology

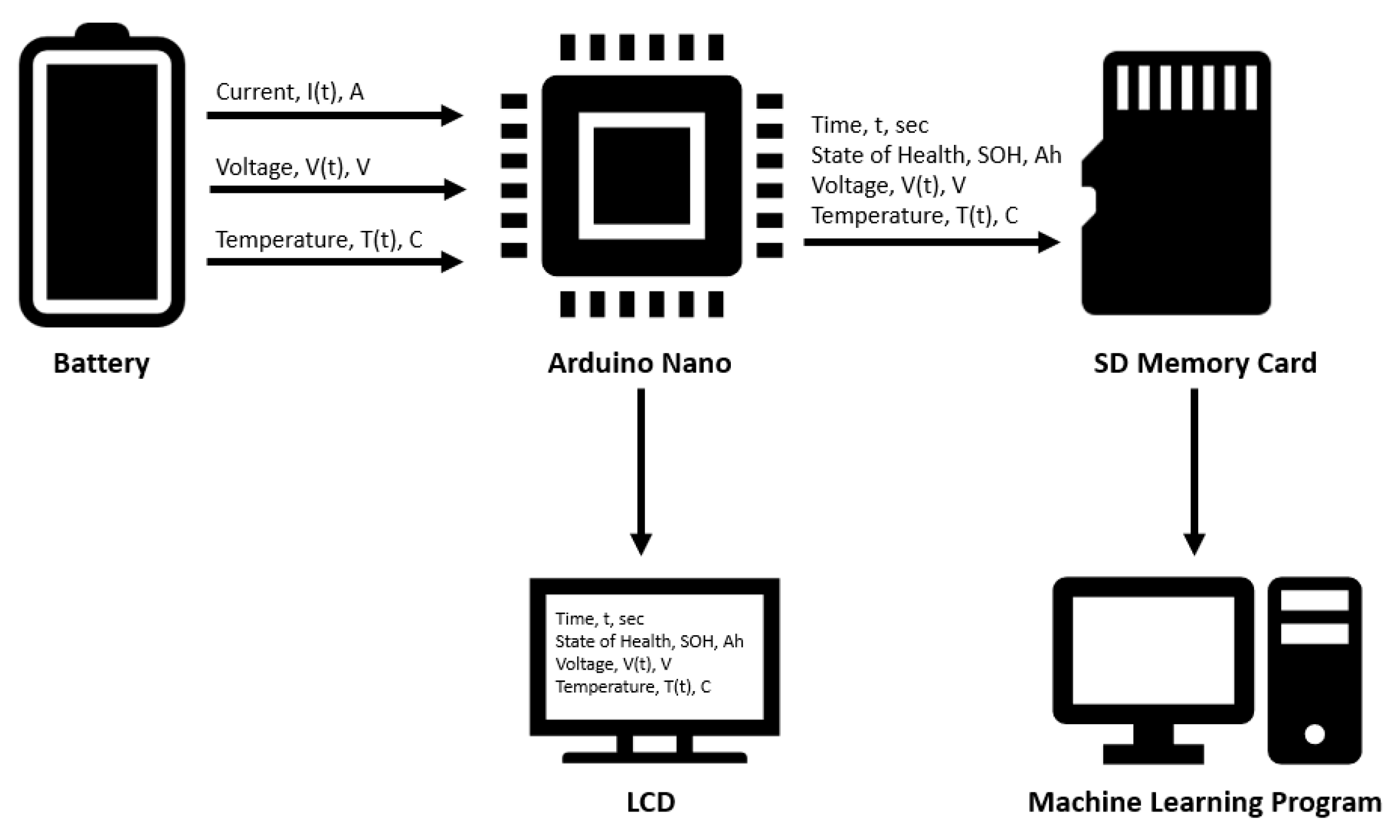

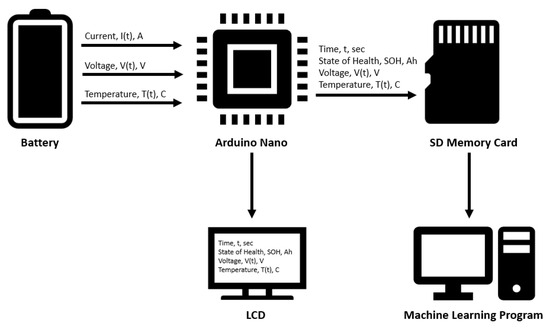

Figure 1 depicts the design of the system-level SOH calculation. It functions as follows: As soon as the cell sends a load request, the system obtains the measured voltage and current. Using the proper functions, the State of Charge (SOC) and State of Energy (SOE) are calculated. The SOH estimate algorithm operates on a regular basis without depending on previous estimation logs. A 30 s time buffer is used by a feature extraction method to recover the voltage, SOC, and SOE when it is triggered.

Figure 1.

SOH estimation architecture.

The objective of the proposed approach is to assess the State of Health (SOH) of the battery across differentiating load circumstances. In this investigation, State of Charge (SOC) and State of Energy (SOE) are determined through analytical calculations. The study utilizes a Samsung 18650 lithium-ion cell, which manufactured by SAMSUNG SDI Co., Ltd., Energy Business Division located in Yongin, Gyeonggi-do, South Korea, with a capacity of 2800 mAh as a representative example, and its characteristics are outlined in Table 1. The methodology has been specifically tailored for a singular cell [16].

Table 1.

Nominal characteristics of cylindrical Samsung 18650—28 A lithium-ion cell.

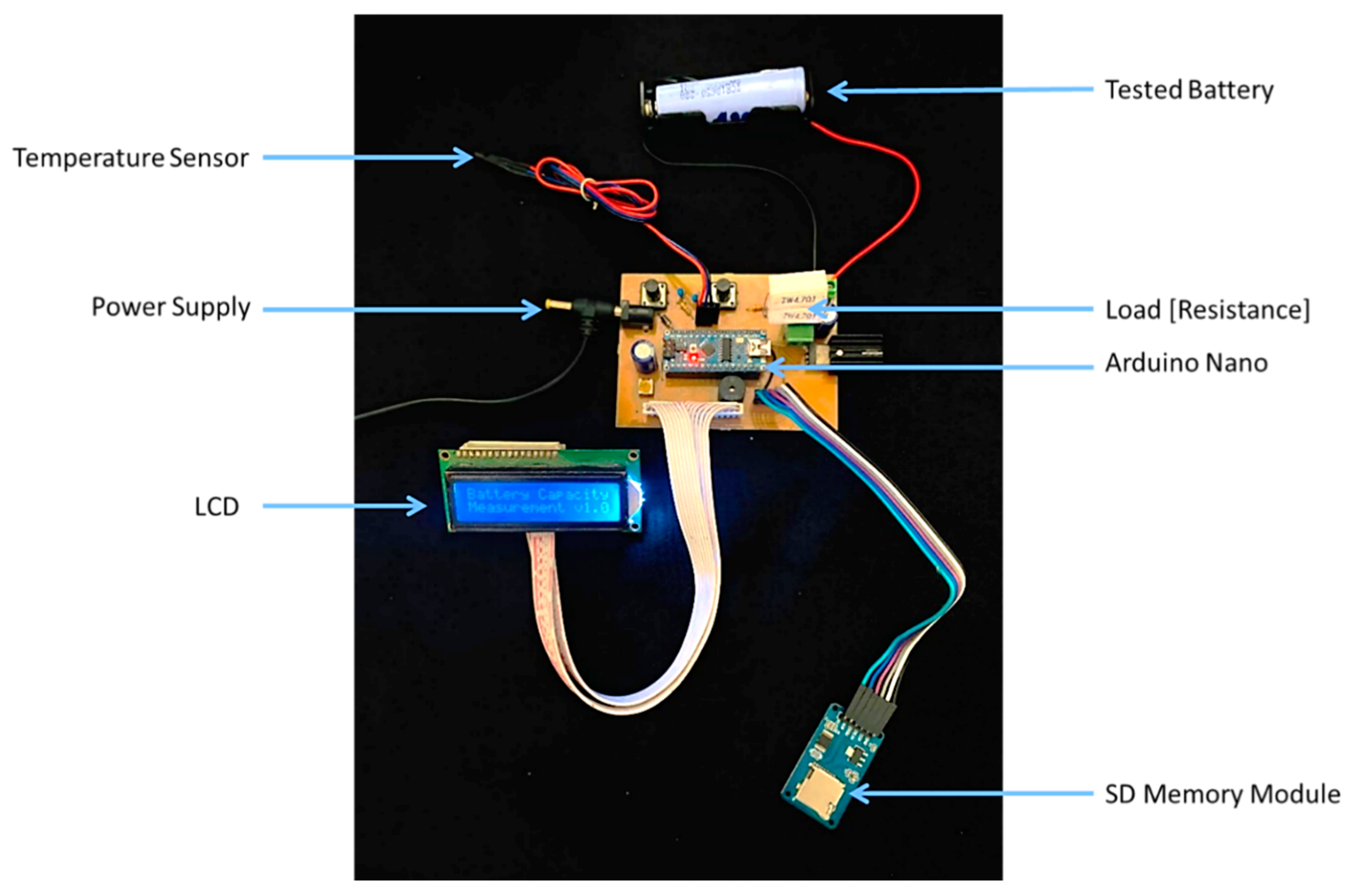

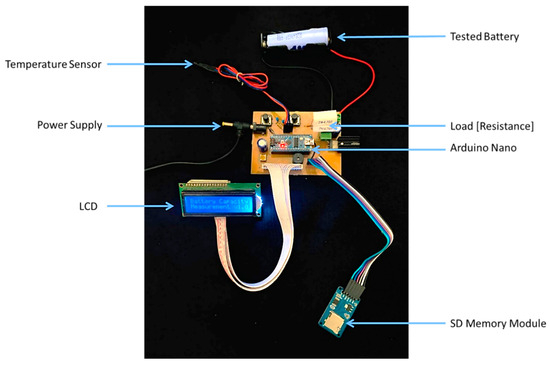

The experimental data utilized in this study were obtained from a proprietary test bench developed in-house. Illustrated in Figure 2, the test bench comprises a single cell, with cell voltages being monitored through an Arduino Nano board. The surface temperatures of the cells were measured using LM35 temperature sensors. Subsequently, an Arduino Nano board facilitated the storage of these data onto an SD memory card. These stored data were later transferred to a dedicated personal computer for further analysis and utilization to acquire the measured parameters.

Figure 2.

Experimental setup for data acquisition from lithium-ion batteries.

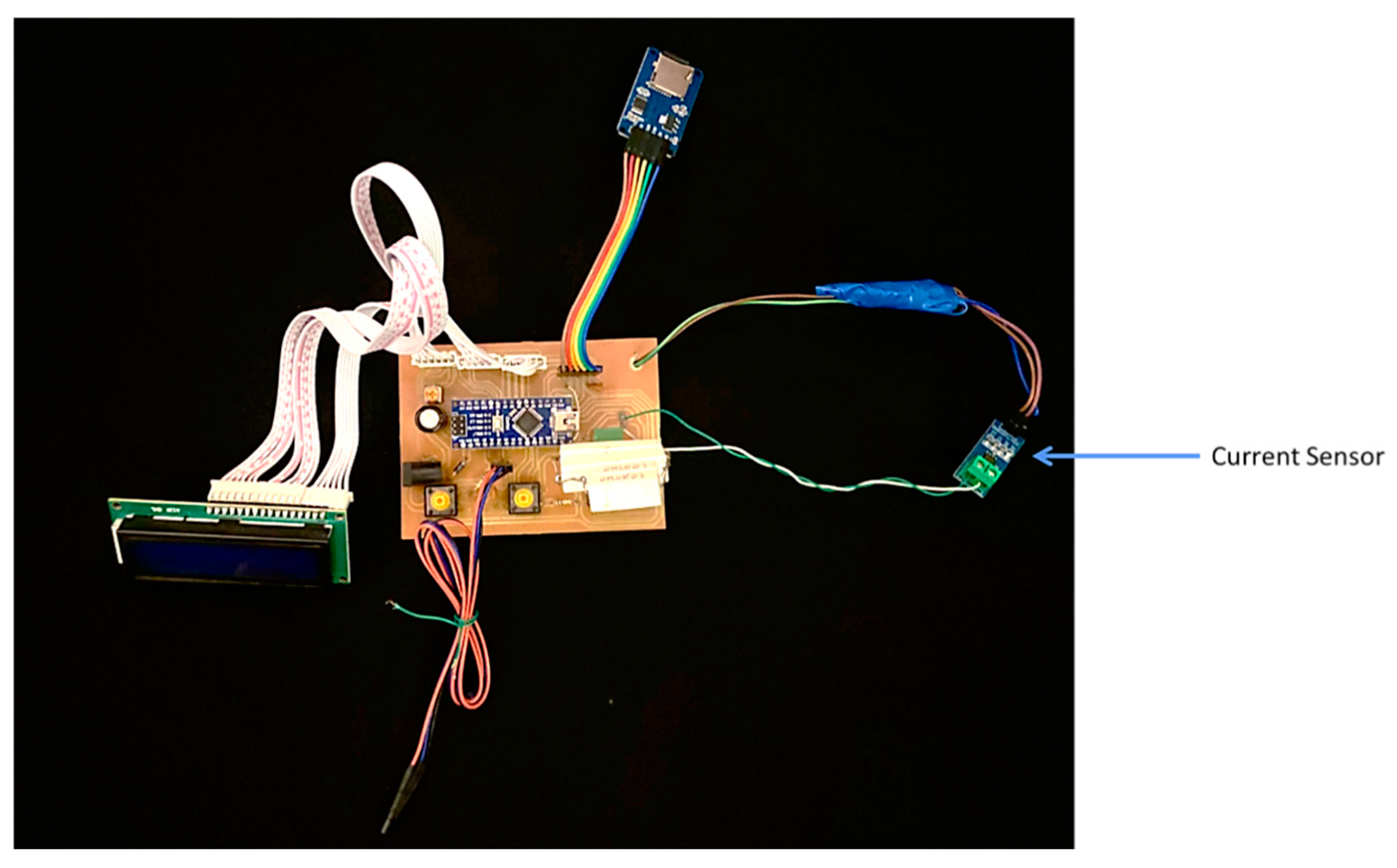

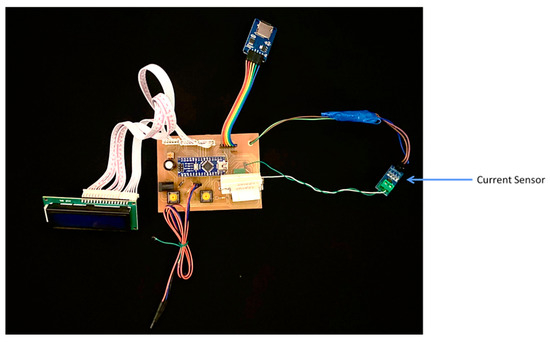

The accuracy of the State of Health (SOH) evaluation was impacted by a problem with the initial determination and continued maintenance of an unchanged current amount on the board. A current sensor was added to the discharge circuit to solve this problem (shown in Figure 3). The accuracy of the SOH evaluation is increased by this innovation, which enables continuous tracking of the current discharge fluctuations during the procedure.

Figure 3.

Experimental setup for data acquisition from lithium-ion batteries with current sensor.

Following collection, battery cells’ charging and discharging processes provided the datasets utilized in this project. Discharge capacity is a crucial component that can reveal a battery’s condition and indicates an electric vehicle’s driving range. The datasets, which are related to one another, will be put into a MATLAB table. A cell’s remaining cycle life can be estimated using a regularized linear model. High interpretability and minimal computing cost are two benefits of linear models [13]. Equation (2) represents the linear model in this format:

where w and xi are the vectors, β is a scalar capture, and yi is the number of loops. Elastic net regularization is used to address excessive correlations between features in the linear model. Elastic net firmly solves the problem laid out Equation (3) for α from 0 to 1 as well as positive λ, the regularization coefficient [13]:

according to Pα(w) = (1 − α)/2 ‖w‖22 + α‖w‖1. The elastic net is like lasso regularization when α = 1 and resembles ridge regression when α is near 0. The coefficient, w, and the hyperparameters, α and λ, are selected using training data. For each α and λ value, the lasso function yields fitted minimal-squares regression coefficients and details on the model’s fit. For the λ parameter, the lasso function takes a vector of values. Thus, the variables w and λ that produce the lowest RMSE value are calculated for each value of α.

yi = wTxi + β,

w = minw‖y − Xw − β‖22 + λPα(w),

3. Results

Within this section, we delve into the outcomes derived from the training and validation processes. The classifier undergoes training using diverse load profiles, each characterized by a maximum current amplitude of 1.5 A during discharge phases and is subjected to various temperatures. Subsequently, the model’s applicability is scrutinized through validation across multiple cells operating under distinct load conditions.

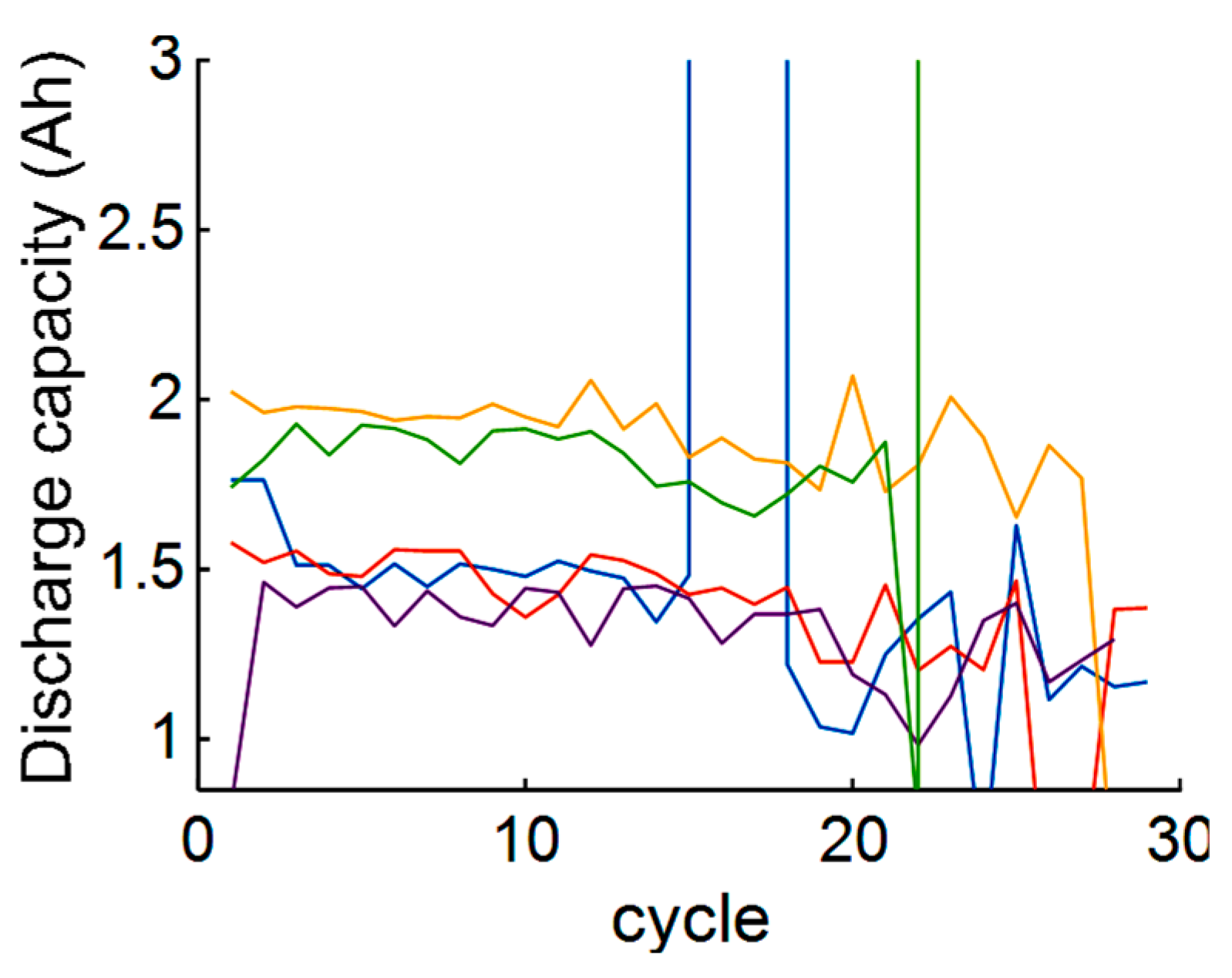

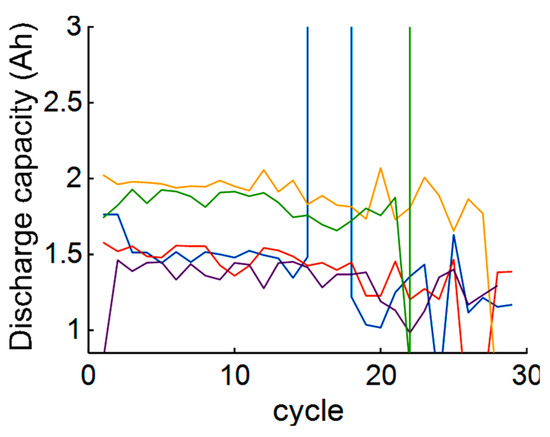

Discharge capacity, a crucial indicator, visually represents a battery’s health and directly influences the electric vehicle’s driving behavior. Plotting the discharge capacity over the initial 30 cycles in the training data provides insight into evolution throughout the lifespan. As shown in Figure 4 (Every colored line corresponds to a test lithium-ion cell.)

Figure 4.

Graph showing the discharge capacity with the number of cycles.

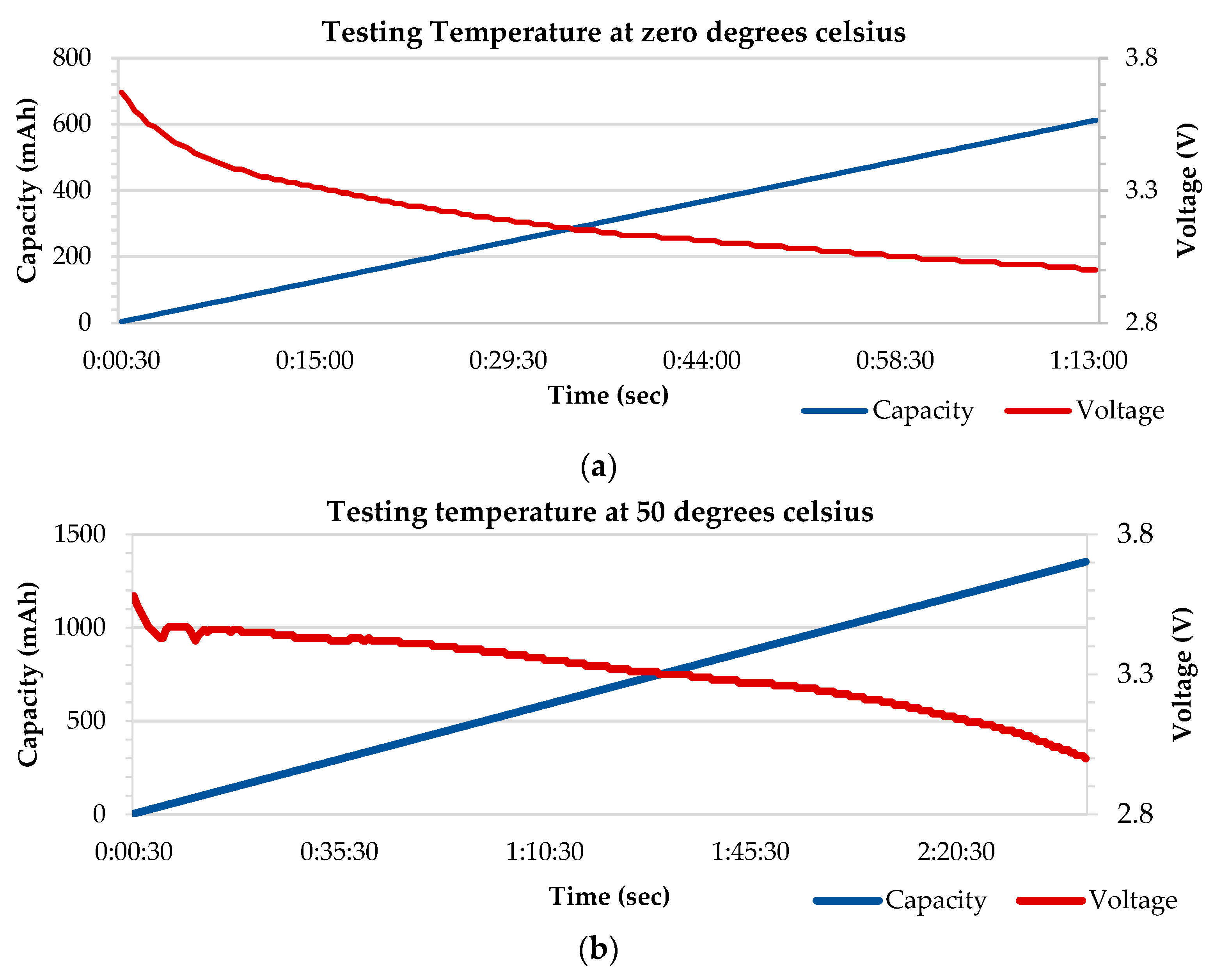

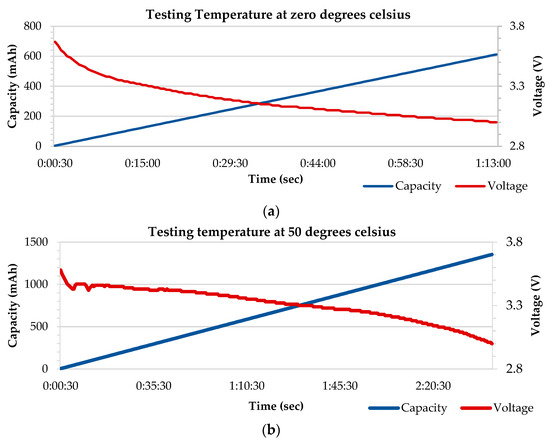

The battery was thoroughly tested in a variety of climatic settings in order to simulate the many use cases of an electric car. Illustrated in Figure 5, The results of the investigation showed that temperature has a major impact on the behavior of the battery, particularly on its State of Health (SOH). In order to replicate the effects of temperature, first secure the battery in a glass jar and place it inside a plastic vessel filled with ice (cooled to approximately zero degrees Celsius) or boiling water (heated to approximately fifty degrees Celsius). Next, run the testing presets, but first seal the jar to stop any water leakage.

Figure 5.

A comparison of the SOH of the same battery under different temperature conditions: (a) at 0 degrees Celsius; (b) at 50 degrees Celsius.

Examining the plot depicting the predicted versus actual cycle life for test data from a linear regression model serves as a crucial tool for evaluating the model’s accuracy in estimating the remaining useful life of a battery. This visual representation showcases predicted cycle life values along the y-axis and actual cycle life values along the x-axis, enabling a clear assessment of the model’s predictive capability. A strong linear relationship observed in the plot, with most data points closely aligned with the diagonal line of equality, signifies precise predictions by the model. Conversely, a weak or nonlinear relationship, with data points scattered widely from the diagonal line, indicates inaccuracies in the model’s predictions, necessitating refinement or enhancement. Overall, visualizing the predicted versus actual cycle life plot offers valuable insights into the linear regression model’s performance and helps to pinpoint areas for potential improvement.

The chosen metrics for assessing model performance are the RMSE along with the mean error in percentages [12]. Equation (4) defines the RMSE as follows:

where n is the entire number of samples, is the observed cycle life, and is the projected cycle life [12].

The resulting RMSE is 6.23.

The average error% is known as Equation (5):

where all variables are defined as shown above.

The resulting error percentage is 30%.

To encapsulate our process, we initially separate the data into sets for training and testing. After that, we use the elastic net to simulate the model on the training set, producing a linear model with down-selected features and coefficients. Lastly, we use many test sets to apply the model.

4. Conclusions

The proposed machine learning algorithm (linear regression) has demonstrated impressive performance in challenging scenarios, striking a commendable balance between minimal estimation errors and low computational costs. The efficiency of the algorithm is particularly noteworthy, requiring only seven complex impedance measurements and a compact model. However, this study acknowledges the limitation imposed by the scarcity of recorded data, emphasizing the negative impact on overall performance. Despite this constraint, the research underscores the potential of data-driven modeling for diagnosing and predicting lithium-ion battery behavior, offering valuable insights for development, manufacturing, and optimization processes.

Specifically, the study focuses on cycle life prediction models using early-cycle discharge data from commercial lithium-ion batteries. In a regression setting, a test error of 30% is achieved, influenced partly by the limited number of cycles analyzed, encompassing 12 lithium-ion batteries over only 30 cycles. Nonetheless, the collected data highlight the discernible impact of operational temperature variations on battery behavior. This research serves as a steppingstone, emphasizing both the accomplishments and the need for expanded data collection to further enhance the accuracy and applicability of predictive models in the realm of lithium-ion battery performance analysis.

Author Contributions

M.Z. and M.A. (Mohamed Abdelaziz) proposed the idea; M.Z. and M.A. (Mohamed Abdelwahab) designed the research; M.Z. drew and output the figures; M.Z. and M.A. (Mohamed Abdelwahab) wrote the paper; M.Z. substituted the data into each operating condition for simulation. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Whittingham, M.S. Electrical energy storage and intercalation chemistry. Science 1976, 192, 1126–1127. [Google Scholar] [CrossRef] [PubMed]

- Nishi, Y. Lithium ion secondary batteries; past 10 years and the future. J. Power Sources 2001, 100, 101–106. [Google Scholar] [CrossRef]

- Stan, A.I.; Świerczyński, M.; Stroe, D.I.; Teodorescu, R.; Andreasen, S.J. Lithium ion battery chemistries from renewable energy storage to automotive and back-up power applications—An overview. In Proceedings of the 2014 International Conference on Optimization of Electrical and Electronic Equipment (OPTIM), Bran, Romania, 22–24 May 2014; pp. 713–720. [Google Scholar]

- Goodenough, J.B.; Kim, Y. Challenges for rechargeable Li batteries. Chem. Mater. 2010, 22, 587–603. [Google Scholar] [CrossRef]

- Dunn, J.B.; Gaines, L.; Kelly, J.C.; James, C.; Gallagher, K.G. The significance of Li-ion batteries in electric vehicle life-cycle energy and emissions and recycling’s role in its reduction. Energy Environ. Sci. 2015, 8, 158–168. [Google Scholar] [CrossRef]

- Huo, H.; Cai, H.; Zhang, Q.; Liu, F.; He, K. Life-cycle assessment of greenhouse gas and air emissions of electric vehicles: A comparison between China and the US. Atmos. Environ. 2015, 108, 107–116. [Google Scholar] [CrossRef]

- Ezemobi, E.; Silvagni, M.; Mozaffari, A.; Tonoli, A.; Khajepour, A. State of Health Estimation of Lithium-Ion Batteries in Electric Vehicles under Dynamic Load Conditions. Energies 2022, 15, 1234. [Google Scholar] [CrossRef]

- Barragán-Moreno, A.; Schaltz, E.; Gismero, A.; Stroe, D.-I. Capacity State-of-Health Estimation of Electric Vehicle Batteries Using Machine Learning and Impedance Measurements. Electronics 2022, 11, 1414. [Google Scholar] [CrossRef]

- Girijaprasanna, T.; Dhanamjayulu, C. A Review on Different State of Battery Charge Estimation Techniques and Management Systems for EV Applications. Electronics 2022, 11, 1795. [Google Scholar] [CrossRef]

- Wang, X.; Gao, Y.; Lu, D.; Li, Y.; Du, K.; Liu, W. Lithium Battery SoC Estimation Based on Improved Iterated Extended Kalman Filter. Appl. Sci. 2024, 14, 5868. [Google Scholar] [CrossRef]

- Jo, S.; Jung, S.; Roh, T. Battery State-of-Health Estimation Using Machine Learning and Preprocessing with Relative State-of-Charge. Energies 2021, 14, 7206. [Google Scholar] [CrossRef]

- Severson, K.A.; Attia, P.M.; Jin, N.; Perkins, N.; Jiang, B.; Yang, Z.; Chen, M.H.; Aykol, M.; Herring, P.K.; Fraggedakis, D.; et al. Data-driven prediction of battery cycle life before capacity degradation. Nat. Energy 2019, 4, 383–391. [Google Scholar] [CrossRef]

- Xiong, R.; Yu, Q. Open circuit voltage and state of charge online estimation for lithium ion batteries. Energy Procedia 2017, 142, 1902–1907. [Google Scholar] [CrossRef]

- Chandran, V.; Patil, C.K.; Karthick, A.; Ganeshaperumal, D.; Rahim, R.; Ghosh, A. State of charge estimation of lithium-ion battery for electric vehicles using machine learning algorithms. World Electr. Veh. J. 2021, 12, 38. [Google Scholar] [CrossRef]

- Keil, P.; Jossen, A. Aging of lithium-ion batteries in electric vehicles: Impact of regenerative braking. World Electr. Veh. J. 2015, 7, 41–51. [Google Scholar] [CrossRef]

- Available online: https://www.google.com.eg/url?sa=i&url=https%3A%2F%2Fwww.dnkpower.com%2Fwp-content%2Fuploads%2F2018%2F04%2FSamsung-ICR18650-28A-Datasheet.pdf&psig=AOvVaw3f29QLTVoQSHtpIWJm-283&ust=1723003965278000&source=images&cd=vfe&opi=89978449&ved=0CAQQn5wMahcKEwiAp4iOwN-HAxUAAAAAHQAAAAAQBA (accessed on 1 December 2008).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).