Calibration-Free Current Measurement with Integrated Quantum Sensor †

Abstract

1. Introduction

2. Materials and Methods

2.1. Measurement Setup

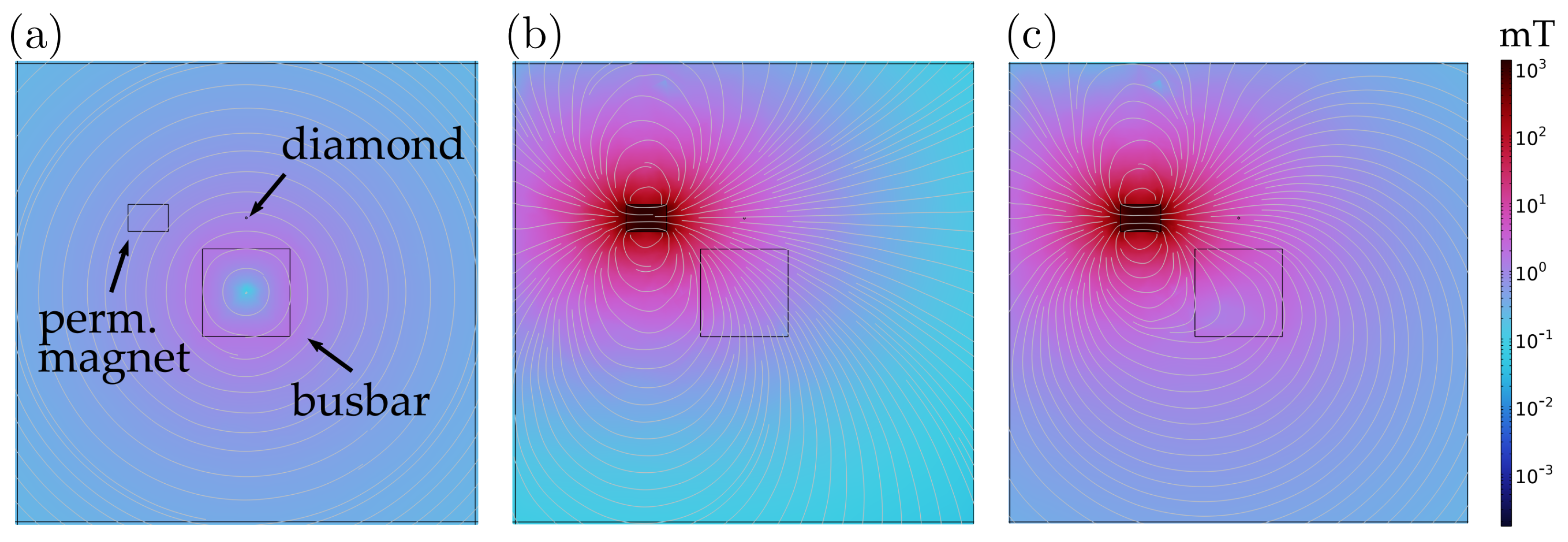

2.2. Simulation of Magnetic Field Distribution

2.3. Extraction of Magnetic Field Information from ODMR Measuremnts

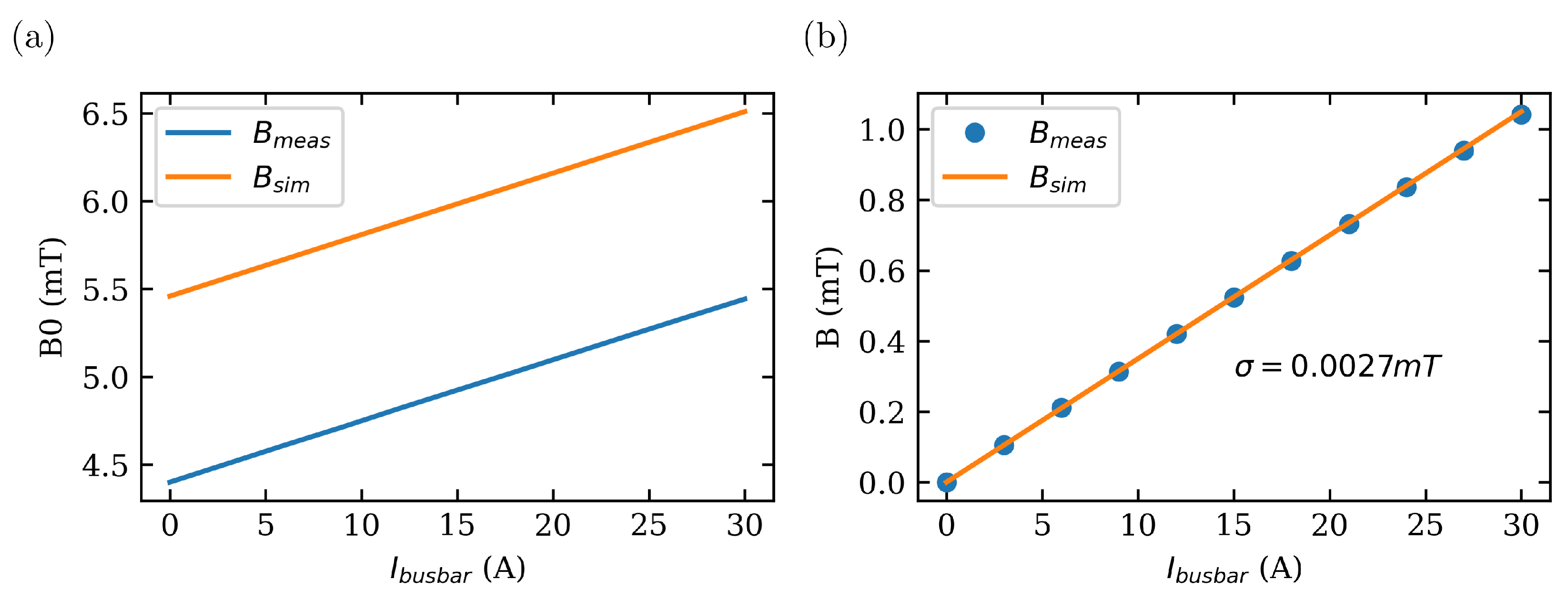

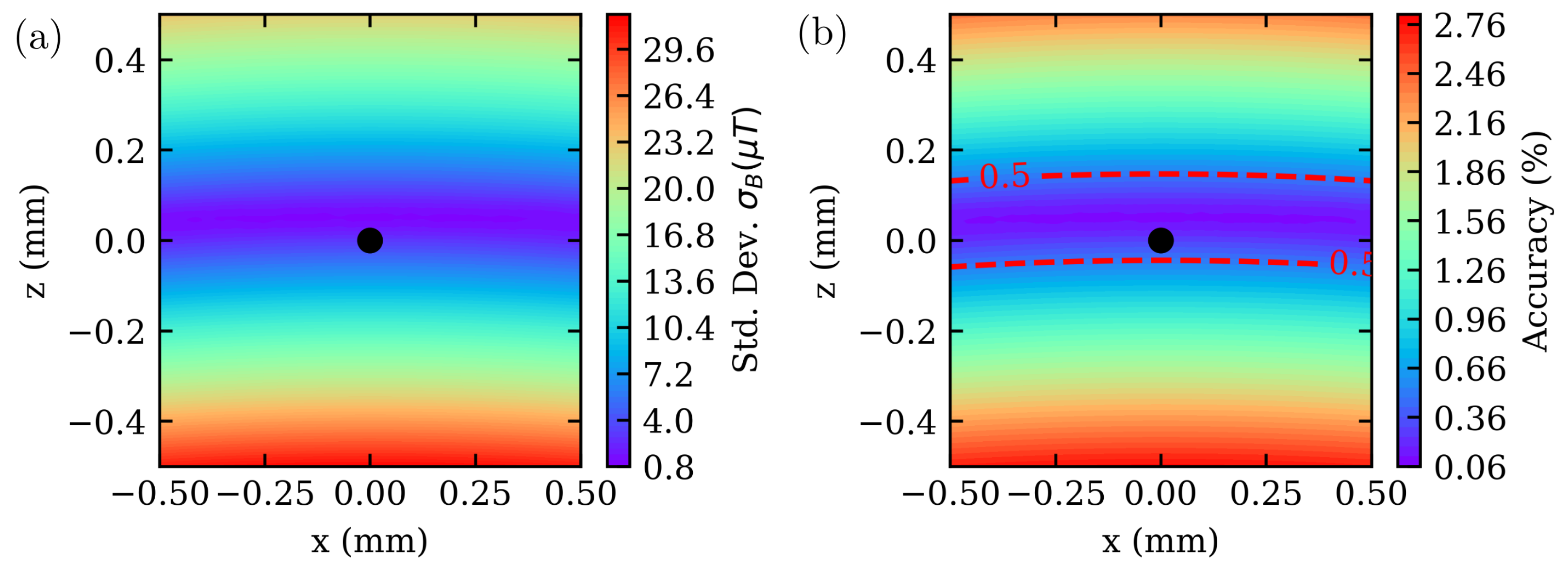

3. Results and Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| NV | Nitrogen vacancy |

| LED | Light emmitig diode |

| DC | Direct current |

| ODMR | Optical detected magnetic resonance |

| ZFS | Zero field splitting |

| PCB | Printed circuit board |

| MW | Microwave |

| PD | Photodiode |

| SLA | Stereolithography |

| TIA | transimpedance amplifier |

| FWHM | Full width half maximum |

References

- Stürner, F.M.; Brenneis, A.; Buck, T.; Kassel, J.; Rölver, R.; Fuchs, T.; Savitsky, A.; Suter, D.; Grimmel, J.; Hengesbach, S.; et al. Integrated and Portable Magnetometer Based on Nitrogen-Vacancy Ensembles in Diamond. Adv. Quantum Technol. 2021, 4, 2000111. [Google Scholar] [CrossRef]

- Xie, Y.; Yu, H.; Zhu, Y.; Qin, X.; Rong, X.; Duan, C.K.; Du, J. A hybrid magnetometer towards femtotesla sensitivity under ambient conditions. Sci. Bull. 2021, 66, 127–132. [Google Scholar] [CrossRef] [PubMed]

- Silani, Y.; Smits, J.; Fescenko, I.; Malone, M.W.; McDowell, A.F.; Jarmola, A.; Kehayias, P.; Richards, B.A.; Mosavian, N.; Ristoff, N.; et al. Nuclear quadrupole resonance spectroscopy with a femtotesla diamond magnetometer. Sci. Adv. 2023, 9, eadh3189. [Google Scholar] [CrossRef]

- Zhou, T.X.; Stöhr, R.J.; Yacoby, A. Scanning diamond NV center probes compatible with conventional AFM technology. Appl. Phys. Lett. 2017, 111, 163106. [Google Scholar] [CrossRef]

- Rondin, L.; Tetienne, J.P.; Spinicelli, P.; Savio, C.D.; Karrai, K.; Dantelle, G.; Thiaville, A.; Rohart, S.; Roch, J.F.; Jacques, V. Nanoscale magnetic field mapping with a single spin scanning probe magnetometer. Appl. Phys. Lett. 2012, 100. [Google Scholar] [CrossRef]

- Hong, S.; Grinolds, M.S.; Pham, L.M.; Sage, D.L.; Luan, L.; Walsworth, R.L.; Yacoby, A. Nanoscale magnetometry with NV centers in diamond. Mrs Bull. 2013, 38, 155–161. [Google Scholar] [CrossRef]

- Balasubramanian, G.; Chan, I.Y.; Kolesov, R.; Al-Hmoud, M.; Tisler, J.; Shin, C.; Kim, C.; Wojcik, A.; Hemmer, P.R.; Krueger, A.; et al. Nanoscale imaging magnetometry with diamond spins under ambient conditions. Nature 2008, 455, 648–651. [Google Scholar] [CrossRef]

- Zhang, C.; Shagieva, F.; Widmann, M.; Kübler, M.; Vorobyov, V.; Kapitanova, P.; Nenasheva, E.; Corkill, R.; Rhrle, O.; Nakamura, K.; et al. Diamond Magnetometry and Gradiometry Towards Subpicotesla dc Field Measurement. Phys. Rev. Appl. 2021, 15, 064075. [Google Scholar] [CrossRef]

- Acosta, V.M.; Bauch, E.; Ledbetter, M.P.; Waxman, A.; Bouchard, L.S.; Budker, D. Temperature Dependence of the Nitrogen-Vacancy Magnetic Resonance in Diamond. Phys. Rev. Lett. 2010, 104, 070801. [Google Scholar] [CrossRef] [PubMed]

- Neumann, P.; Jakobi, I.; Dolde, F.; Burk, C.; Reuter, R.; Waldherr, G.; Honert, J.; Wolf, T.; Brunner, A.; Shim, J.H.; et al. High-Precision Nanoscale Temperature Sensing Using Single Defects in Diamond. Nano Lett. 2013, 13, 2738–2742. [Google Scholar] [CrossRef]

- Abrahams, G.J.; Ellul, E.; Robertson, I.O.; Khalid, A.; Greentree, A.D.; Gibson, B.C.; Tetienne, J.P. Handheld Device for Noncontact Thermometry via Optically Detected Magnetic Resonance of Proximate Diamond Sensors. Phys. Rev. Appl. 2023, 19, 054076. [Google Scholar] [CrossRef]

- Xu, R.; Zhang, Z.; Du, B.; Zhang, Y.; Huang, K.; Cheng, L. Ultra-Sensitive Two-Dimensional Integrated Quantum Thermometer Module Based on the Optical Detection of Magnetic Resonance Using Nitrogen-Vacancy Centers. IEEE Sens. J. 2022, 22, 15316–15322. [Google Scholar] [CrossRef]

- Dolde, F.; Fedder, H.; Doherty, M.W.; Nöbauer, T.; Rempp, F.; Balasubramanian, G.; Wolf, T.; Reinhard, F.; Hollenberg, L.C.L.; Jelezko, F.; et al. Electric-field sensing using single diamond spins. Nat. Phys. 2011, 7, 459–463. [Google Scholar] [CrossRef]

- Pezzagna, S.; Meijer, J. Quantum computer based on color centers in diamond. Appl. Phys. Rev. 2021, 8, 011308. [Google Scholar] [CrossRef]

- Kennedy, T.; Charnock, F.; Colton, J.; Butler, J.; Linares, R.; Doering, P. Single-Qubit Operations with the Nitrogen-Vacancy Center in Diamond. Phys. Status Solidi (B) 2002, 233, 416–426. [Google Scholar] [CrossRef]

- Pogorzelski, J.; Horsthemke, L.; Homrighausen, J.; Stiegekötter, D.; Gregor, M.; Glösekötter, P. Compact and Fully Integrated LED Quantum Sensor Based on NV Centers in Diamond. Sensors 2024, 24, 743. [Google Scholar] [CrossRef] [PubMed]

- Fujiwara, M.; Sun, S.; Dohms, A.; Nishimura, Y.; Suto, K.; Takezawa, Y.; Oshimi, K.; Zhao, L.; Sadzak, N.; Umehara, Y.; et al. Real-time nanodiamond thermometry probing in vivo thermogenic responses. Sci. Adv. 2020, 37, eaba9636. [Google Scholar] [CrossRef]

- Hatano, Y.; Shin, J.; Tanigawa, J.; Shigenobu, Y.; Nakazono, A.; Sekiguchi, T.; Onoda, S.; Ohshima, T.; Arai, K.; Iwasaki, T.; et al. High-precision robust monitoring of charge/discharge current over a wide dynamic range for electric vehicle batteries using diamond quantum sensors. Sci. Rep. 2022, 12, 13991. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Xie, F.; Peng, X.; Hu, Y.; Wang, N.; Zhang, Y.; Wang, Y.; Li, L.; Chen, H.; Cheng, J.; et al. Millimeter-Scale Temperature Self-Calibrated Diamond-Based Quantum Sensor for High-Precision Current Sensing. Adv. Quantum Technol. 2023, 6, 2300210. [Google Scholar] [CrossRef]

- Kubota, K.; Hatano, Y.; Kainuma, Y.; Shin, J.; Nishitani, D.; Shinei, C.; Taniguchi, T.; Teraji, T.; Onoda, S.; Ohshima, T.; et al. Wide temperature operation of diamond quantum sensor for electric vehicle battery monitoring. Diam. Relat. Mater. 2023, 135, 109853. [Google Scholar] [CrossRef]

- Zhao, L.; Wang, L.; Sun, F.; Xu, K.; Wang, X.; Wang, Y. Design of Current Sensor based on Quantum Precision Measurement. In Proceedings of the 2020 11th International Conference on Prognostics and System Health Management (PHM-2020 Jinan), Jinan, China, 23–25 October 2020; IEEE: Piscataway, NJ, USA, 2020. [Google Scholar] [CrossRef]

- Homrighausen, J.; Horsthemke, L.; Pogorzelski, J.; Trinschek, S.; Glösekötter, P.; Gregor, M. Edge-Machine-Learning-Assisted Robust Magnetometer Based on Randomly Oriented NV-Ensembles in Diamond. Sensors 2023, 23, 1119. [Google Scholar] [CrossRef] [PubMed]

- Homrighausen, J.; Hoffmann, F.; Pogorzelski, J.; Glösekötter, P.; Gregor, M. Microscale Fiber-Integrated Vector Magnetometer with On-Tip Field Biasing using NV Ensembles in Diamond Microcystals. arXiv 2024, arXiv:2404.14089. [Google Scholar] [CrossRef]

- Doherty, M.W.; Dolde, F.; Fedder, H.; Jelezko, F.; Wrachtrup, J.; Manson, N.B.; Hollenberg, L.C.L. Theory of the ground-state spin of the NV- center in diamond. Phys. Rev. B 2012, 85, 205203. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pogorzelski, J.; Horsthemke, L.; Homrighausen, J.; Stiegekötter, D.; Hoffmann, F.; Bülter, A.-S.; Gregor, M.; Glösekötter, P. Calibration-Free Current Measurement with Integrated Quantum Sensor. Eng. Proc. 2024, 68, 58. https://doi.org/10.3390/engproc2024068058

Pogorzelski J, Horsthemke L, Homrighausen J, Stiegekötter D, Hoffmann F, Bülter A-S, Gregor M, Glösekötter P. Calibration-Free Current Measurement with Integrated Quantum Sensor. Engineering Proceedings. 2024; 68(1):58. https://doi.org/10.3390/engproc2024068058

Chicago/Turabian StylePogorzelski, Jens, Ludwig Horsthemke, Jonas Homrighausen, Dennis Stiegekötter, Frederik Hoffmann, Ann-Sophie Bülter, Markus Gregor, and Peter Glösekötter. 2024. "Calibration-Free Current Measurement with Integrated Quantum Sensor" Engineering Proceedings 68, no. 1: 58. https://doi.org/10.3390/engproc2024068058

APA StylePogorzelski, J., Horsthemke, L., Homrighausen, J., Stiegekötter, D., Hoffmann, F., Bülter, A.-S., Gregor, M., & Glösekötter, P. (2024). Calibration-Free Current Measurement with Integrated Quantum Sensor. Engineering Proceedings, 68(1), 58. https://doi.org/10.3390/engproc2024068058