Abstract

This text describes a study that investigates the mechanics, environmental benefits, and potential challenges of paper recycling machines. It highlights the importance of these machines in promoting a more sustainable future, and how they align with the United Nations’ Sustainable Development Goals (SDGs). The SDGs aim to address issues such as climate change, land use, responsible consumption and production, and poverty alleviation by promoting sustainable economies. This study explores the transformative potential of the recycling industry and its impact on the economy of Papua New Guinea (PNG).

1. Introduction

In an era marked by the relentless advance of technology and the inexorable transition towards a paperless society, the issue of waste paper and its environmental implications remains a challenge of significant magnitude. This paper embarks on a journey to explore the transformative potential of the Paper Recycling Machine—while simultaneously addressing pressing environmental concerns.

The ubiquity of technology has undoubtedly reshaped our world, steering it towards a digital future. Paradoxically, this digital revolution has exacerbated the issue of waste paper, which continues to accumulate unabated in our local townships. This paper pollution not only poses a visual blight but also perpetuates a grave environmental challenge that demands immediate attention.

Our investigation into the paper recycling machine aims to shed light on its mechanics, environmental benefits, and potential challenges. In doing so, we emphasize the profound significance of this technology as a beacon of hope for a more sustainable future. Beyond merely reshaping the paper industry, this innovative machine plays a pivotal role in the global effort to safeguard our planet.

In a world increasingly attuned to the imperatives of sustainability, this machine emerges as an ally in the fight against climate change, deforestation, ground acidification, and soil erosion. By recycling paper [1,2,3] through this design of technology, we align ourselves with the Sustainable Development Goals (SDGs) of the United Nations, particularly those concerning life on land, climate action, and responsible consumption and production.

Beyond its environmental merits, this study also delves into the transformative potential of paper recycling machine making as an industry sector within the country. It not only revolutionizes paper production but also plays a critical role in poverty alleviation, fostering sustainable economic growth, and generating employment opportunities in underserved communities.

Deforestation, a global menace, disrupts ecosystems, threatens biodiversity, and exacerbates climate change. This transformative machine helps combat deforestation by reducing the demand for virgin timber, thus contributing substantively to SDG 15.

Moreover, the conventional paper production process often involves the use of chemicals that exacerbate ground acidification upon release into the environment. By opting for paper recycling through this machine, we curtail the need for these harmful chemicals; as a result, it reduces contamination of both terrestrial and aquatic habitats, aligning with SDGs 15 and 14 and decreasing ground acidification.

Unsustainable forestry and land use practices can give rise to soil erosion, adversely affecting agriculture and ecosystems. The promotion of paper recycling design methods, by reducing pressure on forests, contributes tangibly to soil erosion prevention, in line with sustainable cities and communities (SDG 11) and SDG 2 (Zero Hunger) as it indirectly supports food security and sustainable urban development by preserving land quality [4,5,6,7].

By squarely addressing these critical environmental issues and aligning with multiple Sustainable Development Goals, this technology exemplifies commitment to a sustainable future. In the pages that follow, we will delve deeper into the mechanics, benefits, and potential challenges associated with this innovative solution, ultimately showcasing its profound potential to transform the paper industry and safeguard the future of our planet.

As a response to this problem, paper recycling has become a better alternative than the modern methods of creating paper. By recycling paper, we save trees, cut the cost of transporting newly made paper, and also limit carbon emissions by burning paper.

This paper also utilizes the existing methods of recycling paper but with a few added downscaled modifications to the process. This is to ensure that the process meets the above-stated goals without compromising quality.

To achieve the goal of being mobile and easily assembled, the entire downscaled mechanized process area would be ideally limited to 1 square meter at a height of less than 50 cm.

2. Material Properties

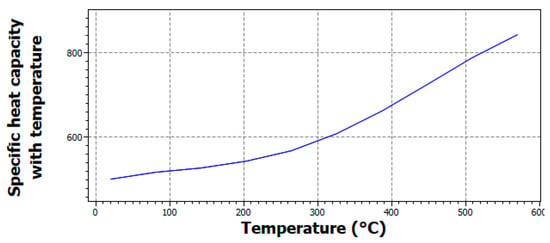

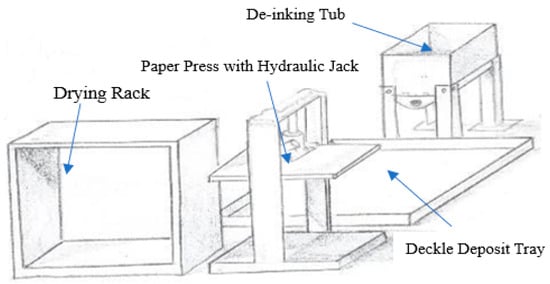

Material properties is important for any design and fabrication and for that Granta software (Figure 1) assist to select right materials for the right application. This is where this paper focuses on the design of small-scale paper recycling and how products can be achieved [8,9]. Required materials, including old paper scraps, water, a blender or food processor, a de-inking tub, a deckle, a mesh screen, a sponge or felt pad, a hydraulic car jack converted into a presser, plywood or wooden boards, heavy-duty plastic sheets or wax paper, a drying rack, clothespins or clips, a bucket or basin, and towels are gathered (Figure 2).

Figure 1.

Specific heat capacity with temperature.

Figure 2.

Small-scale model of the Paper Recycling Process showing the drying rack, de-inking tub, presser, and slurry tray.

Pressure Applied in Compressing Paper in One Cycle

This was calculated using an applied force of 50 KN.

Pressure (P) is defined as force (F) per unit area (A), and it is measured in pascals (Pa).

For 21 cm × 30 cm (standard A4 size),

Now, the pressure applied in one press is as follows: = 793,651.59 Pa.

The pressure applied during the compression of paper in a single cycle, calculated using an applied force of 50 kN, is approximately 793,651.59 pascals (Pa). This pressure, as defined by the formula P = F/A, where P is pressure, F is force, and A is the area, reflects the force distributed over a standard A4 paper size of 21 cm × 30 cm (0.21 m × 0.3 m). However, when evaluated from the perspective of efficiency in a single compression cycle, the system demonstrates a low level of efficiency and is not ergonomic. It is essential to acknowledge that this system was primarily designed for understanding and adjusting critical parameters in paper recycling rather than for large-scale practical applications. In the pursuit of sustainability and increased efficiency in large-scale paper recycling production, further refinements and optimizations in both the mechanical aspects and process design would be necessary to ensure that the pressure applied translates into a more effective and environmentally friendly recycling process.

3. Conclusions

The growth of the paper recycling sector is one possible remedy that might have significant long-term effects on the country. PNG may anticipate other vital events by expanding the above-described small-scale model. First, the industry may create jobs in the production, processing, and collecting sectors, which will help reduce unemployment and promote economic expansion. Furthermore, PNG may improve its financial independence and trade balance by decreasing its reliance on imported paper and exploring global markets for recycled goods. Crucially, this adjustment can alleviate strain on the nation’s priceless rainforests and biodiversity, supporting efforts to mitigate and preserve climate change.

Moreover, PNG may advance its objectives to mitigate climate change and adopt the circular economy by cutting greenhouse gas emissions and landfill garbage. Developing downstream processing skills, such as creating various paper products and investing in sustainable technology, is crucial to maximizing the advantages. Papua New Guinea can develop a resilient sector that guarantees both economic prosperity and environmental well-being by committing to addressing climate change and promoting economic growth in line with its 2050 vision.

Author Contributions

Conceptualization, D.W. and M.W.; methodology, A.M.; validation, A.M. and J.W. formal analysis, A.M. investigation, D.W.; resources, M.W.; data curation, D.W.; writing—original draft preparation, M.W.; writing—review and editing, A.M. and J.W.; visualization, A.M.; supervision, A.M.; project administration, A.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data are provided in the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- United Nations. The 2030 Agenda for Sustainable Development; United Nations: New York, NY, USA, 2015. [Google Scholar]

- Yin, R. An alternative approach to forest investment assessment. Can. J. For. Res. 1997, 27, 2072–2078. [Google Scholar] [CrossRef]

- Esa, H.; Tapaninen, U. Economics of a Nordic Paper Mill: Case Study. Ind. Manag. Data Syst. 2010, 110, 5–23. [Google Scholar] [CrossRef]

- Ekbage, D. Process Modelling in Pulp and Paper Manufacture; Karlstads University: Karlstad, Sweden, 2020. [Google Scholar]

- Steven Keller, D. Paper Drying in the Manufacturing Process; Miami University: Oxford, OH, USA, 2018. [Google Scholar]

- Mohamed, A.; Ben, J.; Muduli, K. Implementation of Autonomous Maintenance and Its Effect on MTBF, MTTR, and Reliability of a Critical Machine in a Beer Processing Plant. In Applications of Computational Methods in Manufacturing and Product Design: Select Proceedings of IPDIMS 2020; Springer Nature: Singapore, 2022; pp. 511–521. [Google Scholar]

- Mohamed, A.; Muduli, K. Corrosion Performance in Grain Structure of C22 in Acidic Environment. In Advances in Industrial Production ICEM; Springer: Singapore, 2022; pp. 469–476. [Google Scholar]

- Mohamed, A. First Year Engineering, Hands-on, Team Design Project Course; Reflections of a Ph. D. Student Teaching Assistant. Educ. Pract. Innov. 2015, 2, 1–8. [Google Scholar]

- Oyekola, P.; Mohamed, A. Automated Vision Application in Industrial Defect Identification. In Recent Trends in Product Design and Intelligent Manufacturing Systems; Deepak, B., Bahubalendruni, M.R., Parhi, D., Biswal, B.B., Eds.; Springer: Singapore, 2023. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).