Enhancing Power Efficiency in 4IR Solar Plants through AI-Powered Energy Optimization †

Abstract

:1. Introduction

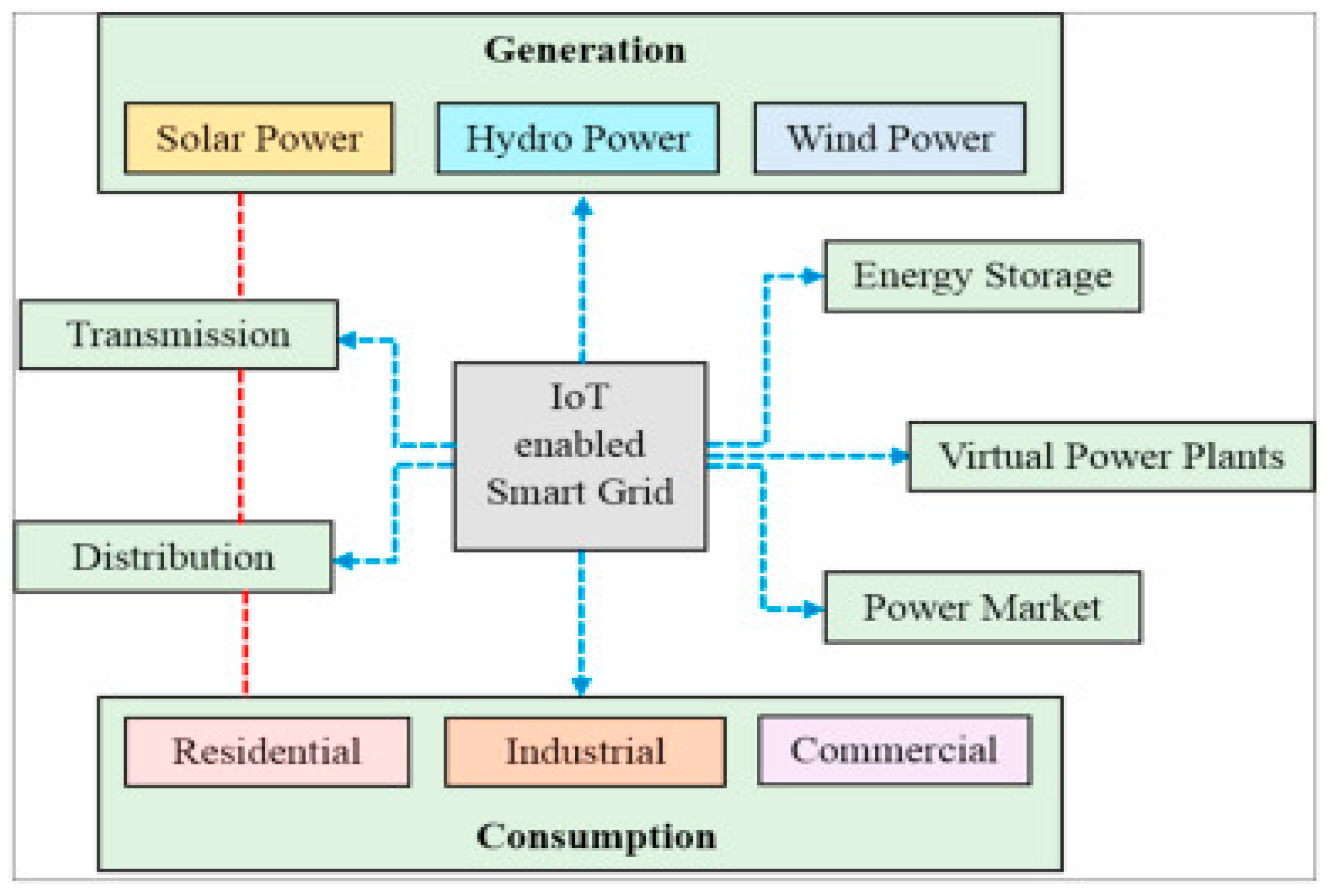

- Intelligent Grid: Solar energy provides a more reliable, efficient and intelligent power grid since the solar panels are placed on the rooftop or in areas not affected by weather conditions.

- Uninterrupted Power Supply: Solar energy provides an uninterrupted power supply as it uses decentralized location to assist in energy distribution.

- Consumer Engagement: Solar energy attracts the attention of customers and helps them to engage with industry companies as part of the digital transformation process.

2. Materials and Methods

- Reinforcement Learning: Reinforcement learning algorithms use iterative trial and error to find a solution to a problem. The goal of the algorithm is to identify an optimal behavior or solution to a problem with the highest reward. This makes it a useful tool for finding the most efficient energy source.

- Neural Networks: Neural networks are used to analyze large amounts of data and find patterns and relationships within the data. This allows for the system to better identify the most efficient energy source and determine the best way to adapt it.

- Evolutionary Algorithms: Evolutionary algorithms use biological and evolutionary principles to search and find the best solution. These algorithms are used to identify the most efficient energy source and adapt it.

- Swarm Optimization: Swarm optimization algorithms use collective intelligence to find the best solution to a problem. This makes them particularly useful for efficient energy source identification and adaptation.

3. Proposed Model

- First, the system collects data from the machines, such as miscellaneous operating parameters like temperature, pressure, humidity, and electrical current consumption.

- This data is then analyzed using artificial intelligence algorithms to identify patterns in the machines’ energy usage and identify opportunities for improvement.

- Based on the analysis, the system creates an optimized operational profile for the machines with recommendations for improvements.

- This energy-saving profile is then implemented into the machines’ settings, resulting in reduced energy usage and improved efficiency.

- The system also monitors the results of the optimized parameters, ensuring their effectiveness is maintained.

- Intelligent Mobile Solar Tracking System: This system can automate and optimize the solar tracking process, allowing solar plants to adjust their solar panels according to the course of the sun for maximum power efficiency. This can be customized to different solar plant sizes, making it flexible for any installation or scale. The University of Queensland implemented the system and saw an increased power output of up to 25%.

- SolarPanelHub: It is a web-based monitoring and control system designed to help solar plant owners track, monitor and optimize power plants. It can be customized to various industry sectors, such as agriculture, transport, energy, water supply, and lighting. The system has also been implemented by several solar companies and has resulted in an increased efficiency of up to 30%.

- Halotech Solar Performance System: It is an intelligent solar power system designed to enhance solar plant performance in a multitude of industries. The system uses advanced machine learning algorithms and sensors to accurately monitor and optimize solar panel output. By using the system, solar plants have seen an increased energy output of up to 40%.

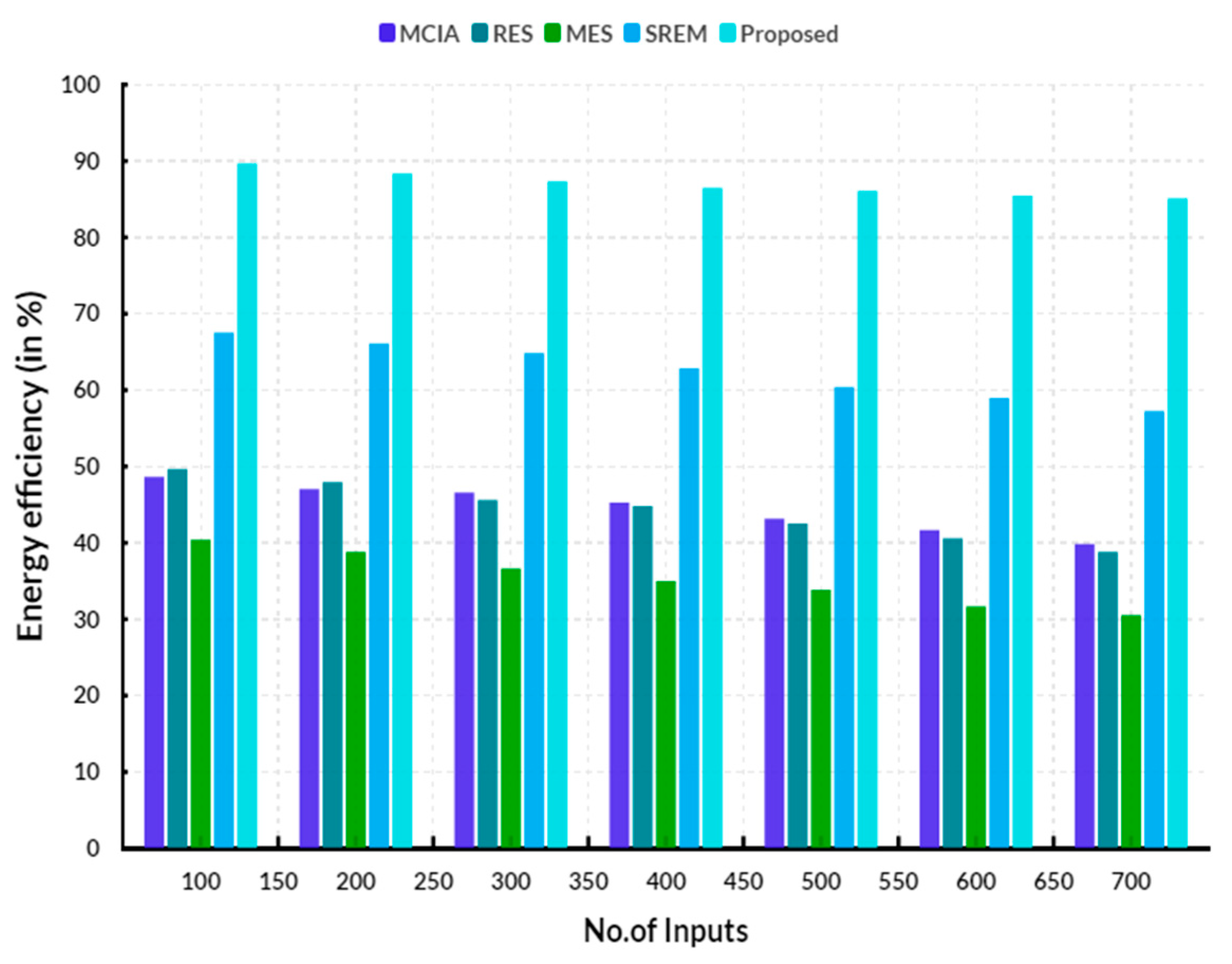

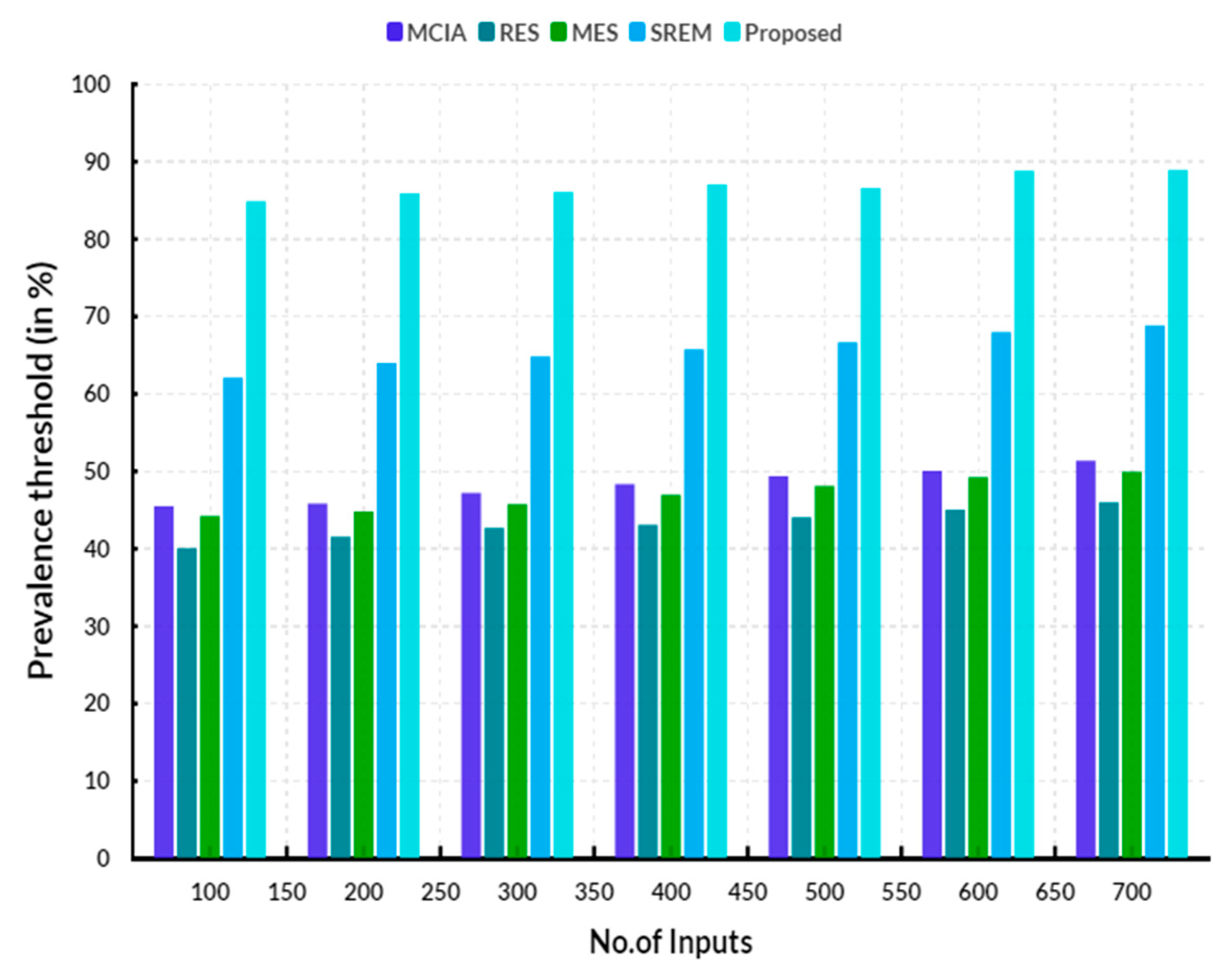

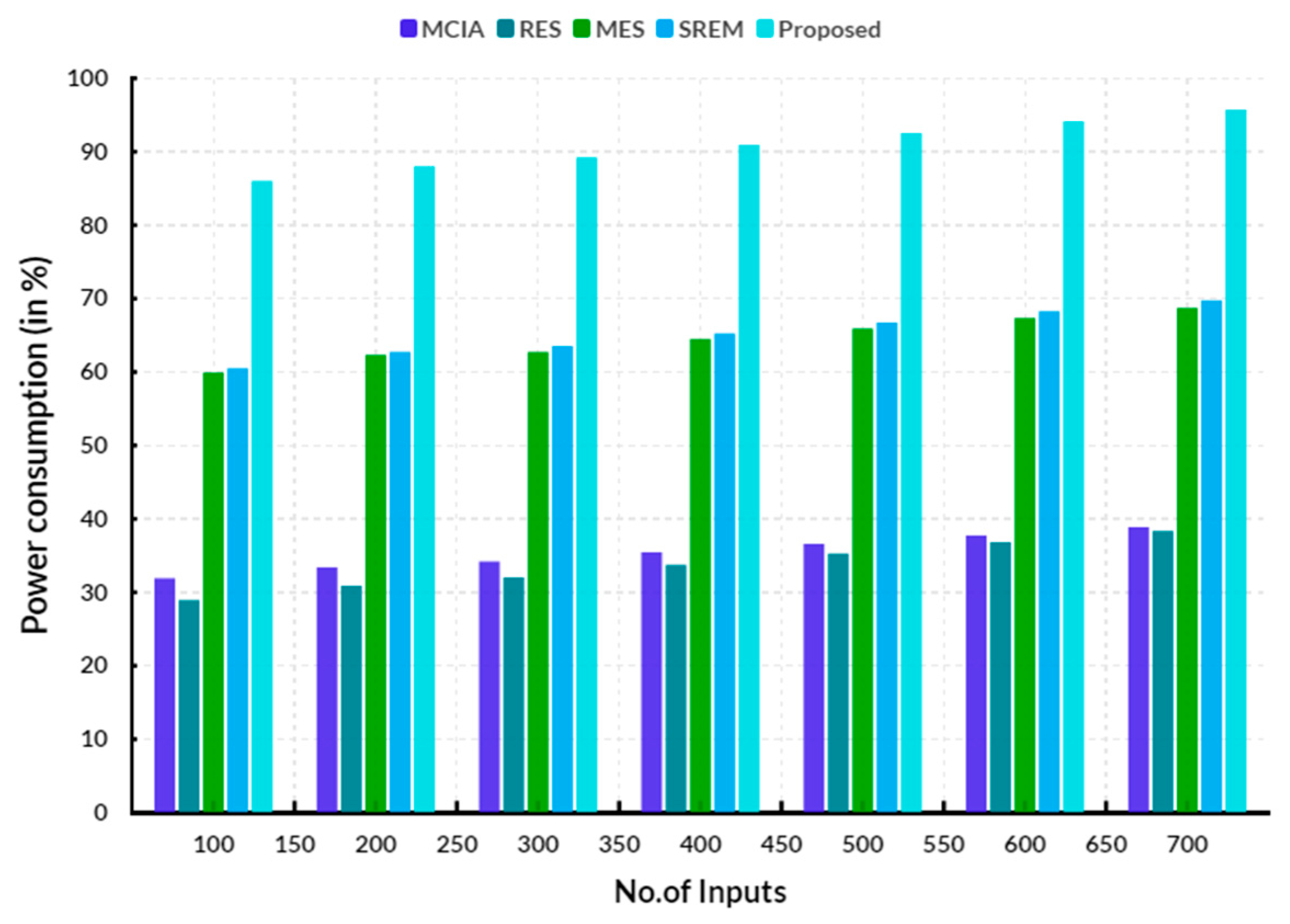

4. Results and Discussion

- AI systems can suffer from poor generalization and a lack of domain knowledge, which means their optimized solutions, may not be optimal in environments different from the ones they have been trained on.

- AI systems rely on datasets to learn from and optimize their solutions. If these datasets contain biases or are incomplete, the AI system may generate flawed predictions or optimization scenarios.

- AI systems may not have the capability to change their approach or strategy when faced with dynamic changes in the environment, which could cause them to falter.

- AI systems may not be able to accurately model the long-term effects of their optimizations, meaning that short-term gains could be greatly outweighed by negative long-term impacts.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ahmad, T.; Zhu, H.; Zhang, D.; Tariq, R.; Bassam, A.; Ullah, F.; Alshamrani, S.S. Energetics Systems and artificial intelligence: Applications of industry 4.0. Energy Rep. 2022, 8, 334–361. [Google Scholar] [CrossRef]

- Mastrocinque, E.; Ramírez, F.J.; Honrubia-Escribano, A.; Pham, D.T. Industry 4.0 enabling sustainable supply chain development in the renewable energy sector: A multi-criteria intelligent approach. Technol. Forecast. Soc. Change 2022, 182, 121813. [Google Scholar] [CrossRef]

- Mithas, S.; Chen, Z.L.; Saldanha, T.J.; De Oliveira Silveira, A. How will artificial intelligence and Industry 4.0 emerging technologies transform operations management? Prod. Oper. Manag. 2022, 31, 4475–4487. [Google Scholar] [CrossRef]

- Cheah, C.G.; Chia, W.Y.; Lai, S.F.; Chew, K.W.; Chia, S.R.; Show, P.L. Innovation designs of industry 4.0 based solid waste management: Machinery and digital circular economy. Environ. Res. 2022, 213, 113619. [Google Scholar] [CrossRef] [PubMed]

- Proposedramirsis, G.; Kantaros, A.; Al-Darraji, I.; Piromalis, D.; Apostolopoulos, C.; Pavlopoulou, A.; Khan, F.Q. A modern approach towards an industry 4.0 model: From driving technologies to management. J. Sens. 2022, 2022, 5023011. [Google Scholar]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R.; Gonzalez, E.S. Understanding the adoption of Industry 4.0 technologies in improving environmental sustainability. Sustain. Oper. Comput. 2022, 3, 203–217. [Google Scholar] [CrossRef]

- Soori, M.; Arezoo, B.; Dastres, R. Internet of things for smart factories in industry 4.0, a review. Internet Things Cyber-Phys. Syst. 2023, 3, 192–204. [Google Scholar] [CrossRef]

- Rajawat, A.S.; Mohammed, O.; Shaw, R.N.; Ghosh, A. Renewable energy system for industrial internet of things model using fusion-AI. In Applications of AI and IOT in Renewable Energy; Academic Press: Cambridge, MA, USA, 2022; pp. 107–128. [Google Scholar]

- Raja Santhi, A.; Muthuswamy, P. Industry 5.0 or industry 4.0 S? Introduction to industry 4.0 and a peek into the prospective industry 5.0 technologies. Int. J. Interact. Des. Manuf. (IJIDeM) 2023, 17, 947–979. [Google Scholar] [CrossRef]

- Yilmaz, A.; Dora, M.; Hezarkhani, B.; Kumar, M. Lean and industry 4.0: Mapping determinants and barriers from a social, environmental, and operational perspective. Technol. Forecast. Soc. Change 2022, 175, 121320. [Google Scholar] [CrossRef]

- Liu, L.; Song, W.; Liu, Y. Leveraging digital capabilities toward a circular economy: Reinforcing sustainable supply chain management with Industry 4.0 technologies. Comput. Ind. Eng. 2023, 178, 109113. [Google Scholar] [CrossRef]

- Kurniawan, T.A.; Meidiana, C.; Othman, M.H.D.; Goh, H.H.; Chew, K.W. Strengthening waste recycling industry in Malang (Indonesia): Lessons from waste management in the era of Industry 4.0. J. Clean. Prod. 2023, 382, 135296. [Google Scholar] [CrossRef]

- Liu, Z.; Sun, Y.; Xing, C.; Liu, J.; He, Y.; Zhou, Y.; Zhang, G. Artificial intelligence powered large-scale renewable integrations in multi-energy systems for carbon neutrality transition: Challenges and future perspectives. Energy AI 2022, 10, 100195. [Google Scholar] [CrossRef]

- Jamwal, A.; Agrawal, R.; Sharma, M. Deep learning for manufacturing sustainability: Models, applications in Industry 4.0 and implications. Int. J. Inf. Manag. Data Insights 2022, 2, 100107. [Google Scholar] [CrossRef]

- Raja Santhi, A.; Muthuswamy, P. Pandemic, War, Natural Calamities, and Sustainability: Industry 4.0 Technologies to Overcome Traditional and Contemporary Supply Chain Challenges. Logistics 2022, 6, 81. [Google Scholar] [CrossRef]

- Aravindaraj, K.; Chinna, P.R. A systematic literature review of integration of industry 4.0 and warehouse management to achieve Sustainable Development Goals (SDGs). Clean. Logist. Supply Chain 2022, 5, 100072. [Google Scholar] [CrossRef]

- Bedi, P.; Goyal, S.B.; Rajawat, A.S.; Shaw, R.N.; Ghosh, A. Application of AI/IoT for smart renewable energy management in smart cities. In AI and IoT for Smart City Applications; Piuri, V., Shaw, R.N., Ghosh, A., Islam, R., Eds.; Springer: Singapore, 2002; Volume 1002, pp. 115–138. [Google Scholar]

- Sharma, V.; Tripathi, A.K. A systematic review of meta-heuristic algorithms in IoT based application. Array 2022, 14, 100164. [Google Scholar] [CrossRef]

- Yang, J.; Ni, J.; Li, Y.; Wen, J.; Chen, D. The intelligent path planning system of agricultural robot via reinforcement learning. Sensors 2022, 22, 4316. [Google Scholar] [CrossRef] [PubMed]

- Mitra, A.; Bera, B.; Das, A.K.; Jamal, S.S.; You, I. Impact on blockchain-based AI/ML-enabled big data analytics for Cognitive Internet of Things environment. Comput. Commun. 2023, 197, 173–185. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boobalan, S.; Lakshmi, T.K.; Ghate, S.N.; Haqqani, M.H.; Jaiswal, S. Enhancing Power Efficiency in 4IR Solar Plants through AI-Powered Energy Optimization. Eng. Proc. 2023, 59, 87. https://doi.org/10.3390/engproc2023059087

Boobalan S, Lakshmi TK, Ghate SN, Haqqani MH, Jaiswal S. Enhancing Power Efficiency in 4IR Solar Plants through AI-Powered Energy Optimization. Engineering Proceedings. 2023; 59(1):87. https://doi.org/10.3390/engproc2023059087

Chicago/Turabian StyleBoobalan, S., TR. Kalai Lakshmi, Shubhangi N. Ghate, Mohammed Hameeduddin Haqqani, and Sushma Jaiswal. 2023. "Enhancing Power Efficiency in 4IR Solar Plants through AI-Powered Energy Optimization" Engineering Proceedings 59, no. 1: 87. https://doi.org/10.3390/engproc2023059087

APA StyleBoobalan, S., Lakshmi, T. K., Ghate, S. N., Haqqani, M. H., & Jaiswal, S. (2023). Enhancing Power Efficiency in 4IR Solar Plants through AI-Powered Energy Optimization. Engineering Proceedings, 59(1), 87. https://doi.org/10.3390/engproc2023059087