Investigation of Elastic Properties of Sc Doped AlN: A First principles and Experimental Approach †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Computational Method

2.2. Experiments

3. Results and Discussion

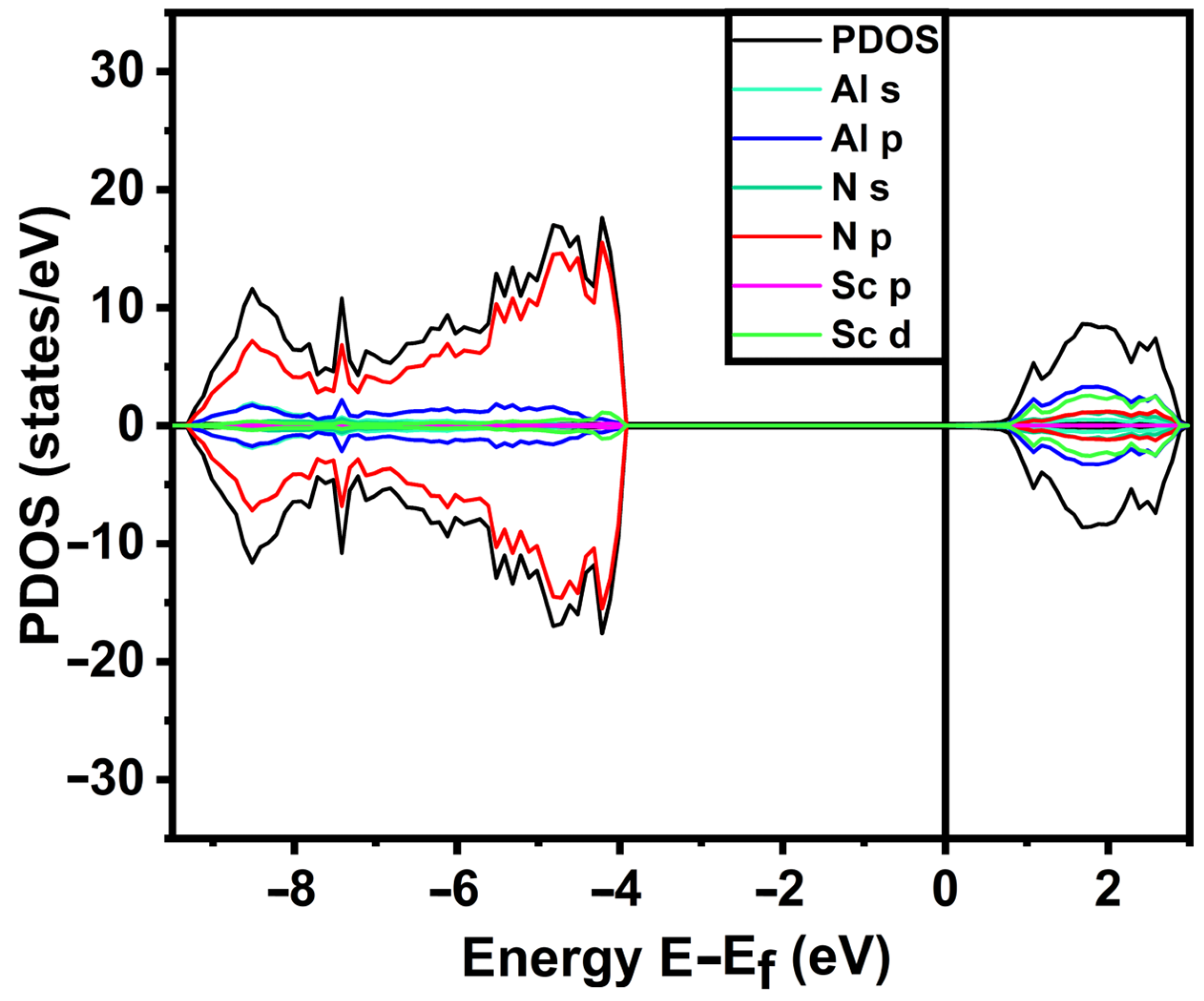

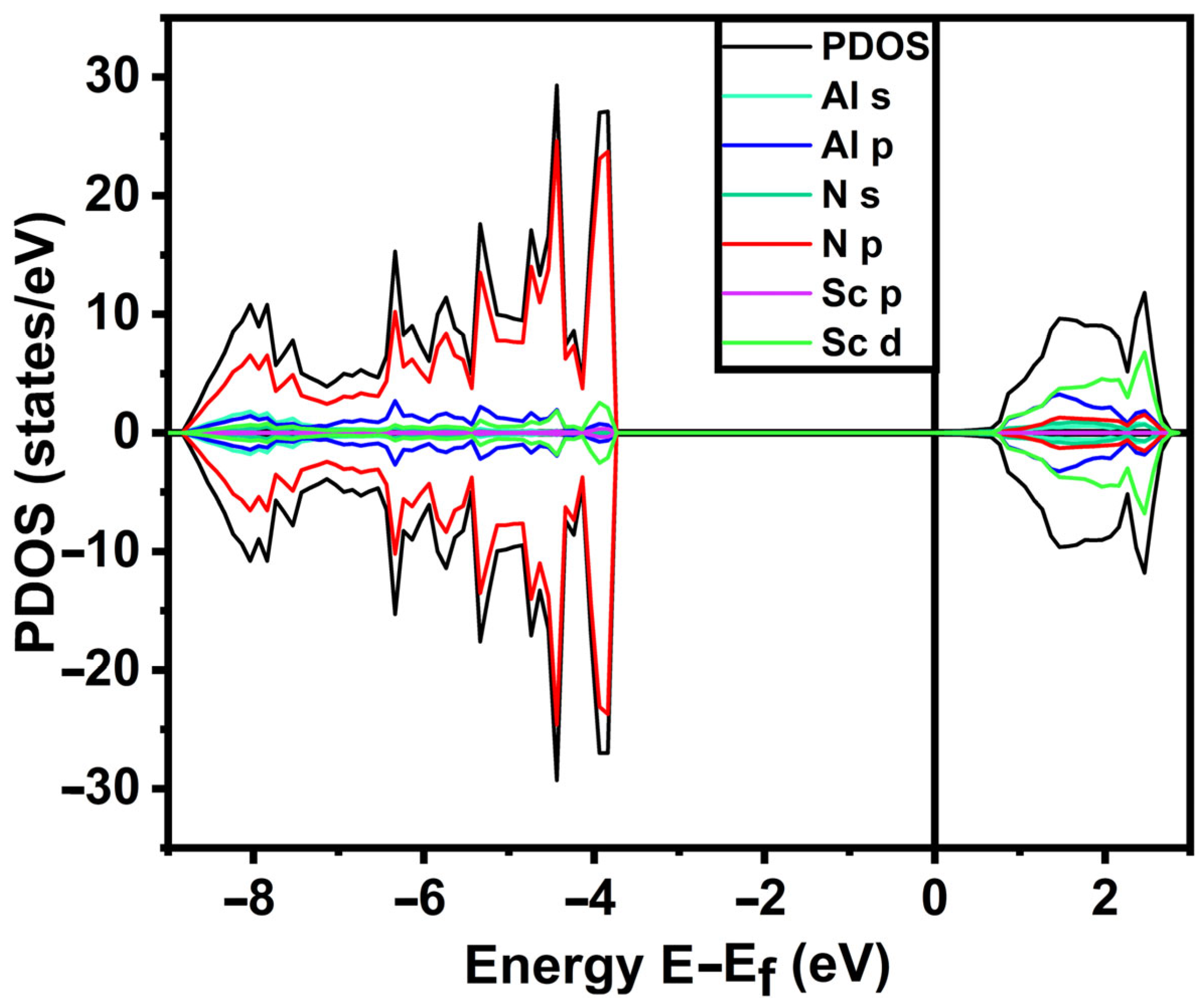

3.1. Computations

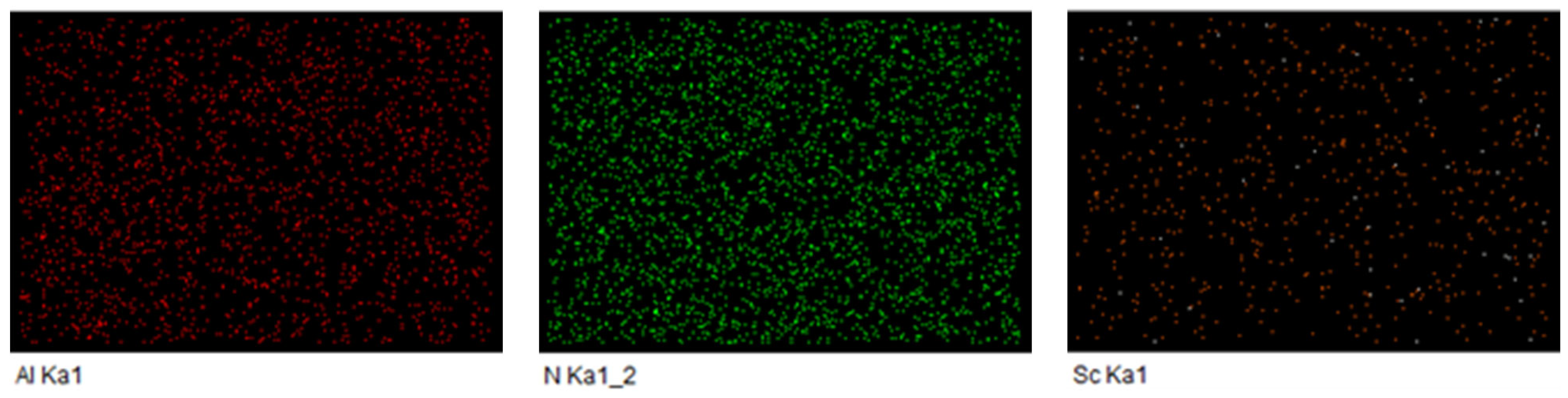

3.2. Experiments

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jia, Y.; Seshia, A.A. Five Topologies of Cantilever-Based MEMS Piezoelectric Vibration Energy Harvesters: A Numerical and Experimental Comparison. Microsyst. Technol. 2016, 22, 2841–2852. [Google Scholar] [CrossRef]

- Ke, G.; Tao, Y.; He, Z.; Guo, H.; Chen, Y.; DiBattista, J.; Chan, E.; Yang, Y. Influence of Sputtering Atmosphere on Crystal Quality and Electrical Properties of Zirconium Aluminum Nitride Thin Film. Surf. Coatings Technol. 2016, 290, 87–93. [Google Scholar] [CrossRef]

- Xiao, S.; Suzuki, R.; Miyake, H.; Harada, S.; Ujihara, T. Improvement Mechanism of Sputtered AlN Films by High-Temperature Annealing. J. Cryst. Growth 2018, 502, 41–44. [Google Scholar] [CrossRef]

- Liu, H.; Zhong, J.; Lee, C.; Lee, S.-W.; Lin, L. A Comprehensive Review on Piezoelectric Energy Harvesting Technology: Materials, Mechanisms, and Applications. Appl. Phys. Rev. 2018, 5, 041306. [Google Scholar] [CrossRef]

- Nguyen, H.H.; Van Minh, L.; Oguchi, H.; Kuwano, H. Development of Highly Efficient Micro Energy Harvesters with MgHf-Codoped AlN Piezoelectric Films. Proc. IEEE Int. Conf. Micro Electro Mech. Syst. 2018, 222–225. [Google Scholar] [CrossRef]

- Du, S.; Jia, Y.; Zhao, C.; Amaratunga, G.A.J.; Seshia, A.A. A Nail-Size Piezoelectric Energy Harvesting System Integrating a MEMS Transducer and a CMOS SSHI Circuit. IEEE Sens. J. 2020, 20, 277–285. [Google Scholar] [CrossRef]

- Pinto, R.M.R.; Gund, V.; Dias, R.A.; Nagaraja, K.K.; Vinayakumar, K.B. CMOS-Integrated Aluminum Nitride MEMS: A Review. J. Microelectromechanical. Syst. 2022, 31, 500–523. [Google Scholar] [CrossRef]

- Pinto, R.M.R.; Gund, V.; Calaza, C.; Nagaraja, K.K.; Vinayakumar, K.B. Piezoelectric Aluminum Nitride Thin-Films: A Review of Wet and Dry Etching Techniques. Microelectron. Eng. 2022, 257, 111753. [Google Scholar] [CrossRef]

- Xu, R.; Kim, S.-G. Figures of Merits of Piezoelectric Materials in Energy. In Proceedings of the PowerMEMS 2012, Atlanta, GA, USA, 2–5 December 2012; pp. 464–467. [Google Scholar]

- Akiyama, M.; Kamohara, T.; Kano, K.; Teshigahara, A.; Takeuchi, Y.; Kawahara, N. Enhancement of Piezoelectric Response in Scandium Aluminum Nitride Alloy Thin Films Prepared by Dual Reactive Cosputtering. Adv. Mater. 2009, 21, 593–596. [Google Scholar] [CrossRef] [PubMed]

- Hirata, K.; Yamada, H.; Uehara, M.; Anggraini, S.A.; Akiyama, M. First-Principles Study of Piezoelectric Properties and Bonding Analysis in (Mg, X, Al)N Solid Solutions (X = Nb, Ti, Zr, Hf). ACS Omega 2019, 4, 15081–15086. [Google Scholar] [CrossRef] [PubMed]

- Tasnádi, F.; Alling, B.; Höglund, C.; Wingqvist, G.; Birch, J.; Hultman, L.; Abrikosov, I.A. Origin of the Anomalous Piezoelectric Response in Wurtzite ScxAl1-XN Alloys. Phys. Rev. Lett. 2010, 104, 137601. [Google Scholar] [CrossRef] [PubMed]

- Giannozzi, P.; Andreussi, O.; Brumme, T.; Bunau, O.; Buongiorno Nardelli, M.; Calandra, M.; Car, R.; Cavazzoni, C.; Ceresoli, D.; Cococcioni, M.; et al. Advanced Capabilities for Materials Modelling with Quantum ESPRESSO. J. Phys. Condens. Matter 2017, 29, 465901. [Google Scholar] [CrossRef] [PubMed]

- Giannozzi, P.; Baseggio, O.; Bonfà, P.; Brunato, D.; Car, R.; Carnimeo, I.; Cavazzoni, C.; de Gironcoli, S.; Delugas, P.; Ferrari Ruffino, F.; et al. Quantum ESPRESSO toward the Exascale. J. Chem. Phys. 2020, 152, 154105. [Google Scholar] [CrossRef] [PubMed]

- Giannozzi, P.; Baroni, S.; Bonini, N.; Calandra, M.; Car, R.; Cavazzoni, C.; Ceresoli, D.; Chiarotti, G.L.; Cococcioni, M.; Dabo, I.; et al. QUANTUM ESPRESSO: A Modular and Open-Source Software Project for Quantum Simulations of Materials. J. Phys. Condens. Matter 2009, 21, 395502. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y. Development and Characterization of Piezoelectric AlScN-Based Alloys for Electroacoustic Applications; University of Freiburg: Freiburg im Breisgau, Germany, 2019. [Google Scholar]

- Manna, S. Design and Discovery of New Piezoelectric Materials Using Density Functional Theory; Colorado School of Mines: Golden, CO, USA, 2018. [Google Scholar]

- Wu, D.; Chen, Y.; Manna, S.; Talley, K.; Zakutayev, A.; Brennecka, G.L.; Ciobanu, C.V.; Constantine, P.; Packard, C.E. Characterization of Elastic Modulus Across the (Al1–xScx)N System Using DFT and Substrate-Effect-Corrected Nanoindentation. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2018, 65, 2167–2175. [Google Scholar] [CrossRef] [PubMed]

- Ambacher, O.; Christian, B.; Feil, N.; Urban, D.F.; Elsässer, C.; Prescher, M.; Kirste, L. Wurtzite ScAlN, InAlN, and GaAlN Crystals, a Comparison of Structural, Elastic, Dielectric, and Piezoelectric Properties. J. Appl. Phys. 2021, 130, 045102. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Targets | Aluminum (99.999%), Scandium (99.9%) |

| Base pressure | 1 × 10−6 mbar |

| Sputtering Pressure | 6.6 × 10−3 mbar |

| Sputtering temperature | 300 °C |

| Argon | 15 sccm (99.999%) |

| Nitrogen | 5 sccm (99.999%) |

| Sputtering power | Al-175 W, Sc-50 W & 60 W |

| Composition Al1−xScxN | c-Axis (Å) | c/a | C11 GPa | C12 GPa | C13 GPa | C33 GPa | C44 GPa |

|---|---|---|---|---|---|---|---|

| AlN (x = 0) | 5.062 (4.98) | 1.6118 (1.60) | 374.2 (376.0) | 123.5 (129.0) | 92.0 (98.0) | 357.7 (353.0) | 110.7 (113.0) |

| AlScN (x = 0.6) | 5.083 | 1.6115 | 368.7 | 141.7 | 114.5 | 345.1 | 103.2 |

| AlScN (x = 0.25) | 5.142 | 1.6138 | 352.4 | 203.4 | 176.2 | 332.1 | 83.8 |

| Composition Al1-xScxN | Bulk Modulus GPa | Young’s Modulus GPa | Shear Modulus GPa | Poisson’s Ratio |

|---|---|---|---|---|

| AlN (x = 0) | 191.2 (195.0) | 303.0 (306.0) | 122.5 (122.2) | 0.236 (0.24) |

| AlScN (x = 0.6) | 184.1 | 282.5 | 111.4 | 0.267 |

| AlScN (x = 0.25) | 178.2 | 217.1 | 80.5 | 0.348 |

| Sample | Power (W) | 2 Theta (°) | FWHM (°) | c-Axis (Å) | Crystallite Size (nm) | Micro Strain (10−3) |

|---|---|---|---|---|---|---|

| AlN | Al-175 | 36.06 | 0.34 | 0.497 | 24.27 ± 1.45 | 4.61 ± 0.28 |

| AlScN 1 | Al-175 Sc-50 | 35.59 | 0.40 | 0.504 | 20.82 ± 1.25 | 5.44 ± 0.33 |

| AlScN 2 | Al-175 Sc-60 | 35.63 | 0.27 | 0.503 | 30.91 ± 1.85 | 3.66 ± 0.22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rudresh, J.; Srihari, N.V.; Kowshik, S.; Sandeep; Nagaraja, K.K. Investigation of Elastic Properties of Sc Doped AlN: A First principles and Experimental Approach. Eng. Proc. 2023, 59, 86. https://doi.org/10.3390/engproc2023059086

Rudresh J, Srihari NV, Kowshik S, Sandeep, Nagaraja KK. Investigation of Elastic Properties of Sc Doped AlN: A First principles and Experimental Approach. Engineering Proceedings. 2023; 59(1):86. https://doi.org/10.3390/engproc2023059086

Chicago/Turabian StyleRudresh, Jyothilakshmi, N. V. Srihari, Suhas Kowshik, Sandeep, and K. K. Nagaraja. 2023. "Investigation of Elastic Properties of Sc Doped AlN: A First principles and Experimental Approach" Engineering Proceedings 59, no. 1: 86. https://doi.org/10.3390/engproc2023059086

APA StyleRudresh, J., Srihari, N. V., Kowshik, S., Sandeep, & Nagaraja, K. K. (2023). Investigation of Elastic Properties of Sc Doped AlN: A First principles and Experimental Approach. Engineering Proceedings, 59(1), 86. https://doi.org/10.3390/engproc2023059086