Development and Characterization of Biomass Pellets Using Yard Waste †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Yard Waste Collection

2.2. Palletization Process

2.2.1. Shredding of Collected Waste

2.2.2. Moisture Content

2.2.3. Sample Preparation

2.2.4. Palletization

2.3. Analysis of Pellets

2.3.1. Volatile Matter Determination

2.3.2. Ash Content Determination

2.3.3. Fixed Carbon Determination

2.3.4. Calorific Value Determination

2.3.5. Calculation of Carbon Contents

2.3.6. Calculation for Hydrogen Content Measurement

2.3.7. Determination of Nitrogen

2.3.8. Flue Gases Determination

2.3.9. Determination of Yard Waste Pellet Durability

2.3.10. Bulk Density

3. Results and Discussions

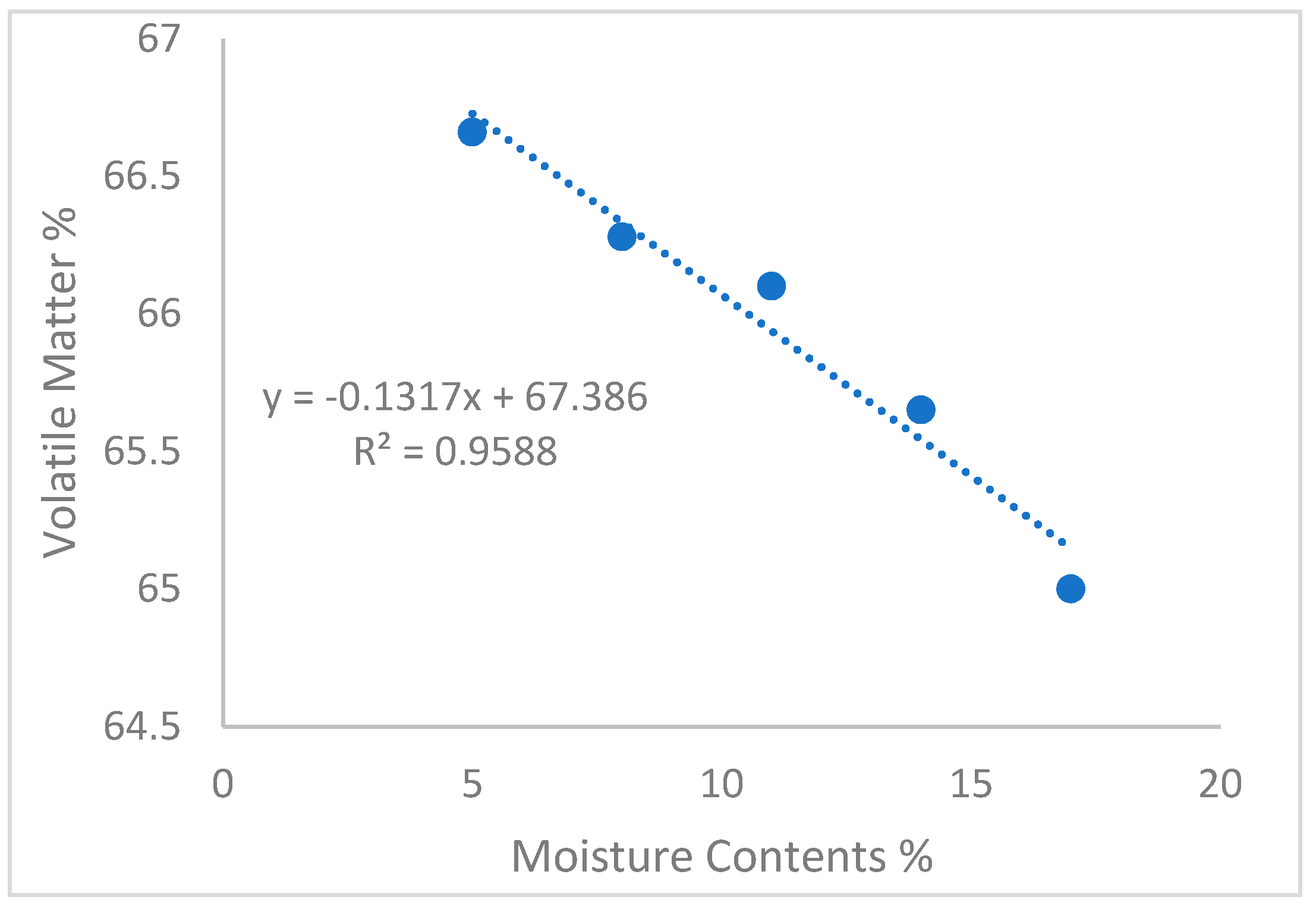

3.1. Effect of Moisture Content on Volatile Matter

3.2. Effect of Moisture Content on Ash Contents

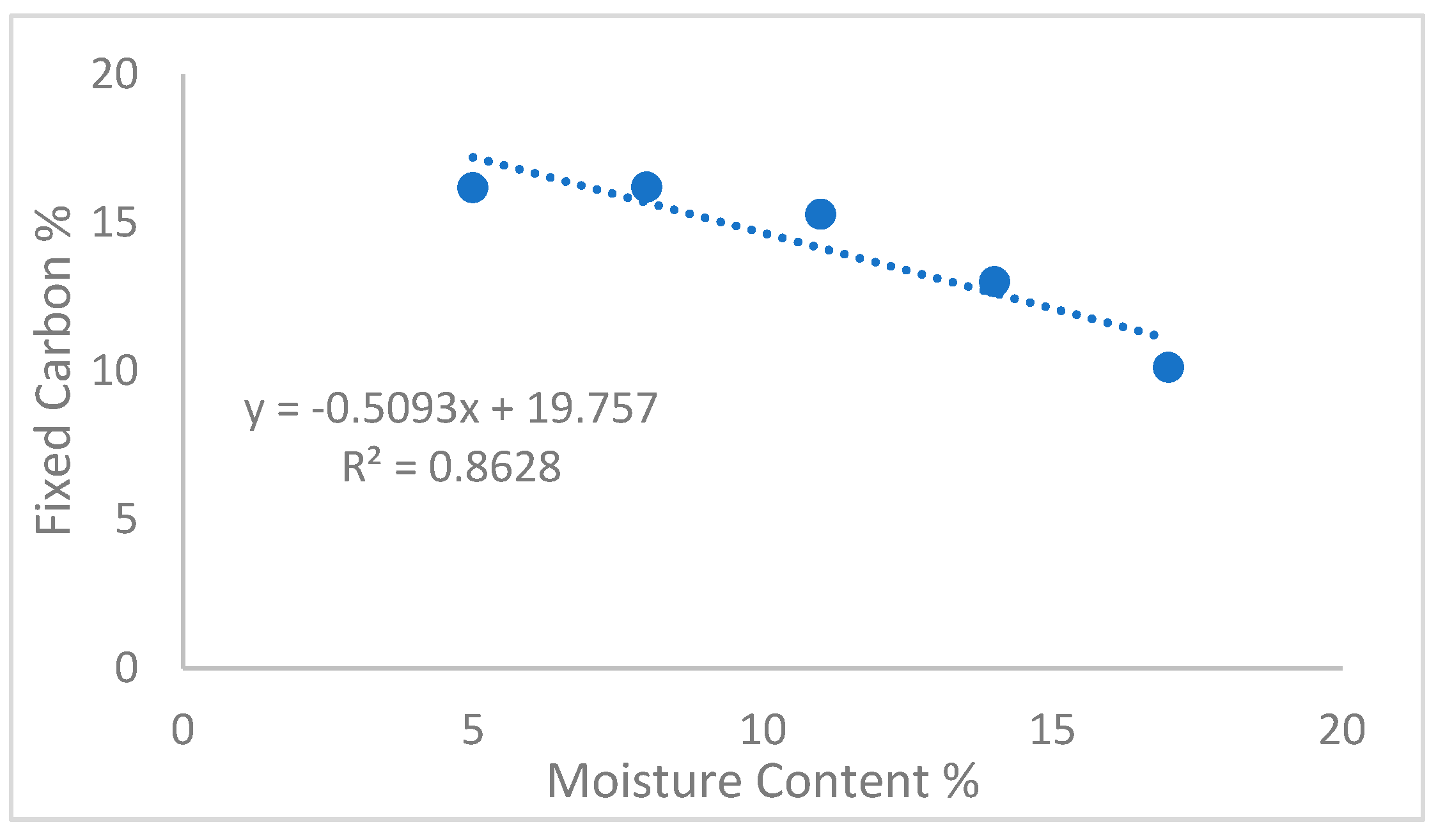

3.3. Effect of Moisture Content on Fixed Carbon

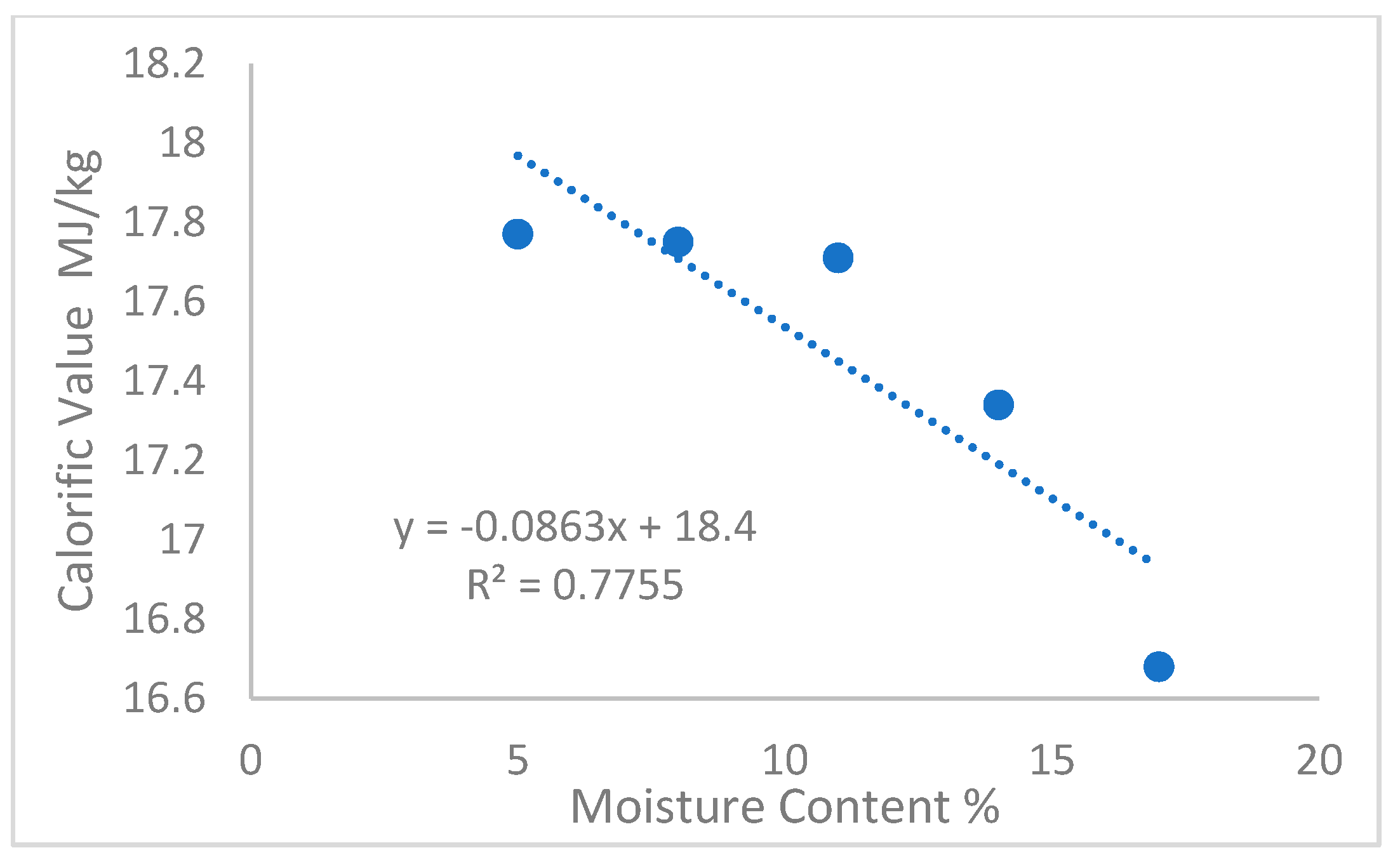

3.4. Effect of Moisture Content on Calorific Value

3.5. Effect of Moisture Content on Density

3.6. Effect of Moisture Content on Durability

3.7. Ultimate Analysis

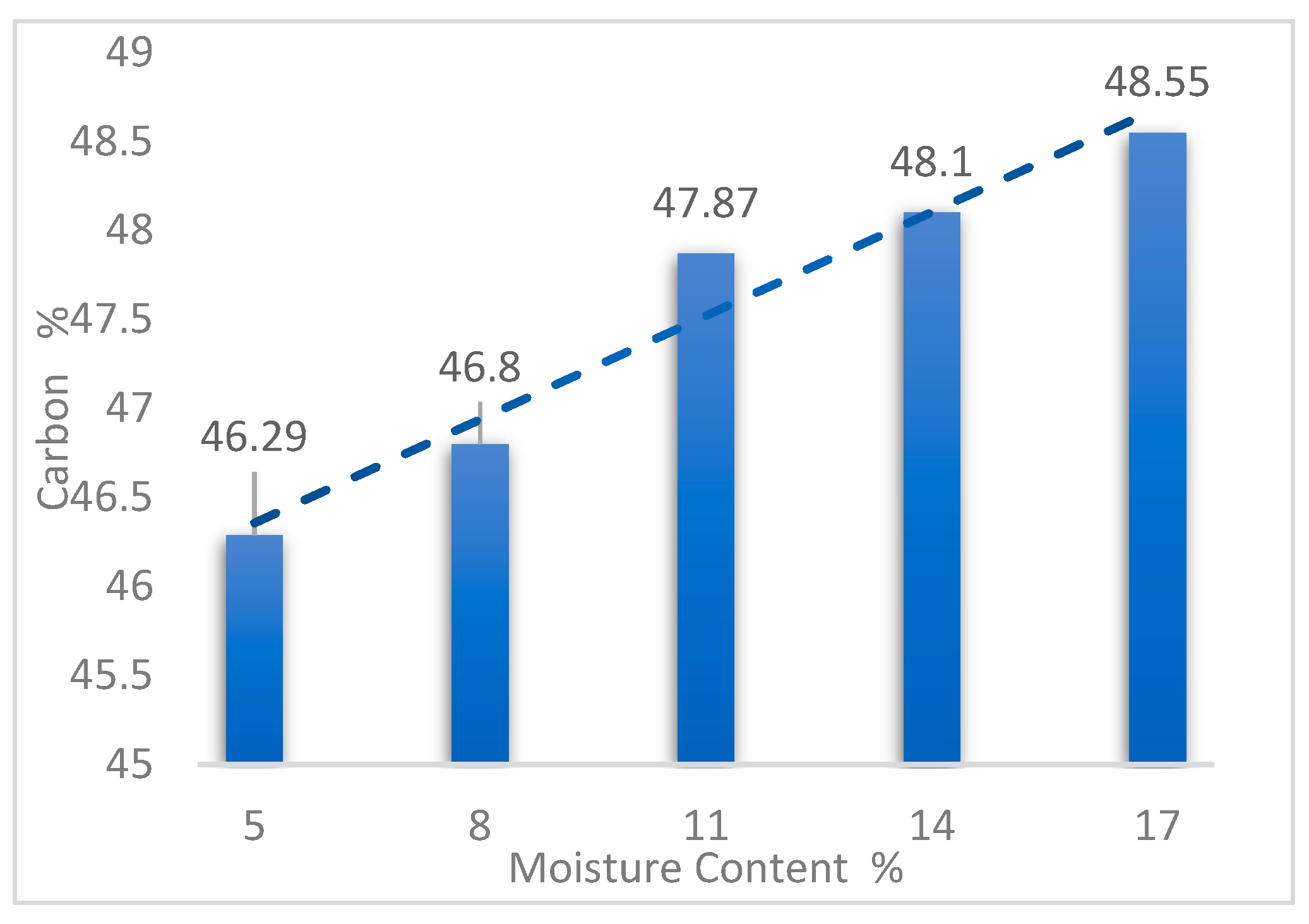

3.7.1. Contents of Carbon

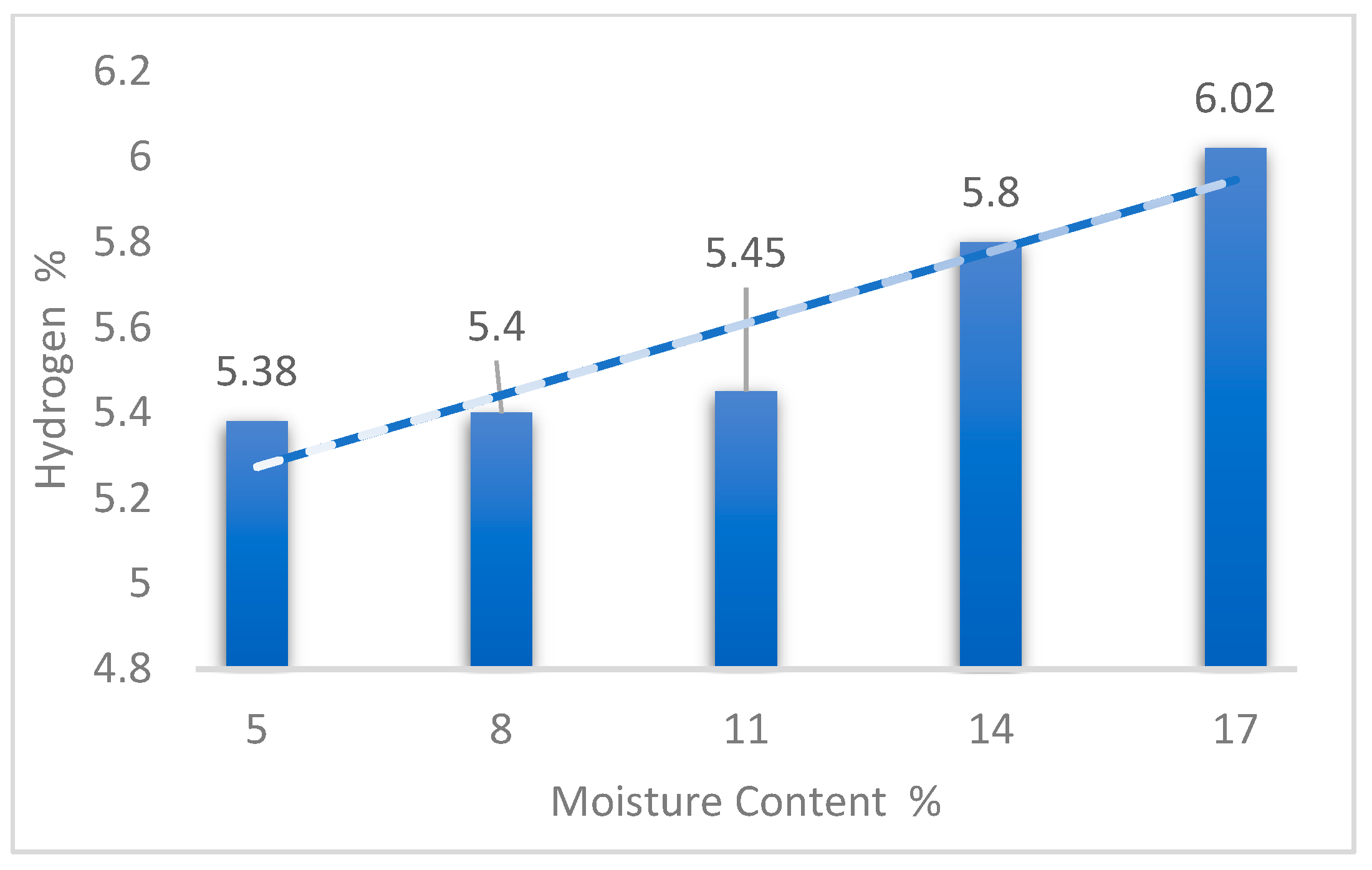

3.7.2. Hydrogen Contents

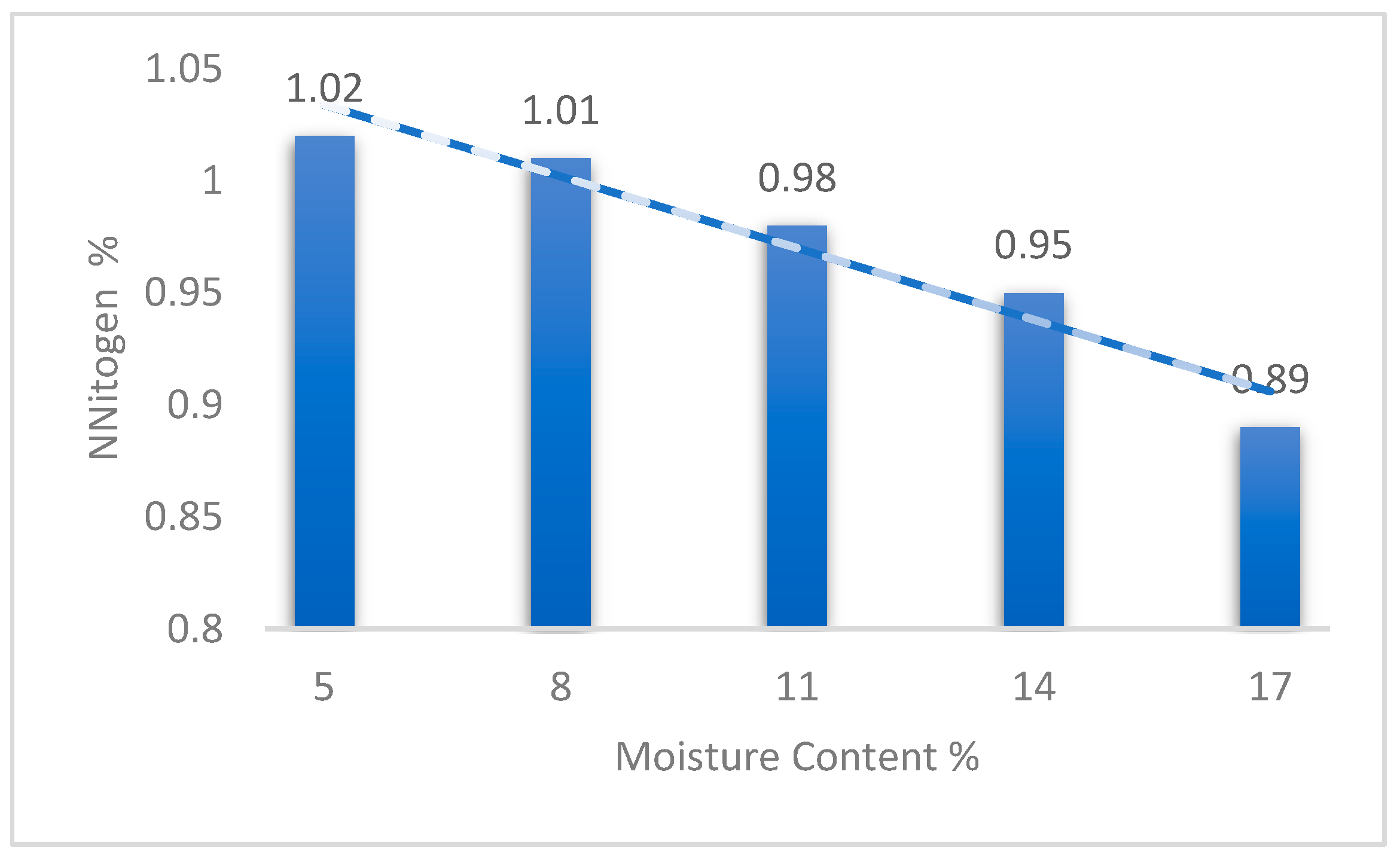

3.7.3. Nitrogen Contents

3.8. Exhaust Gas Analysis

3.8.1. Emissions of Carbon Dioxide

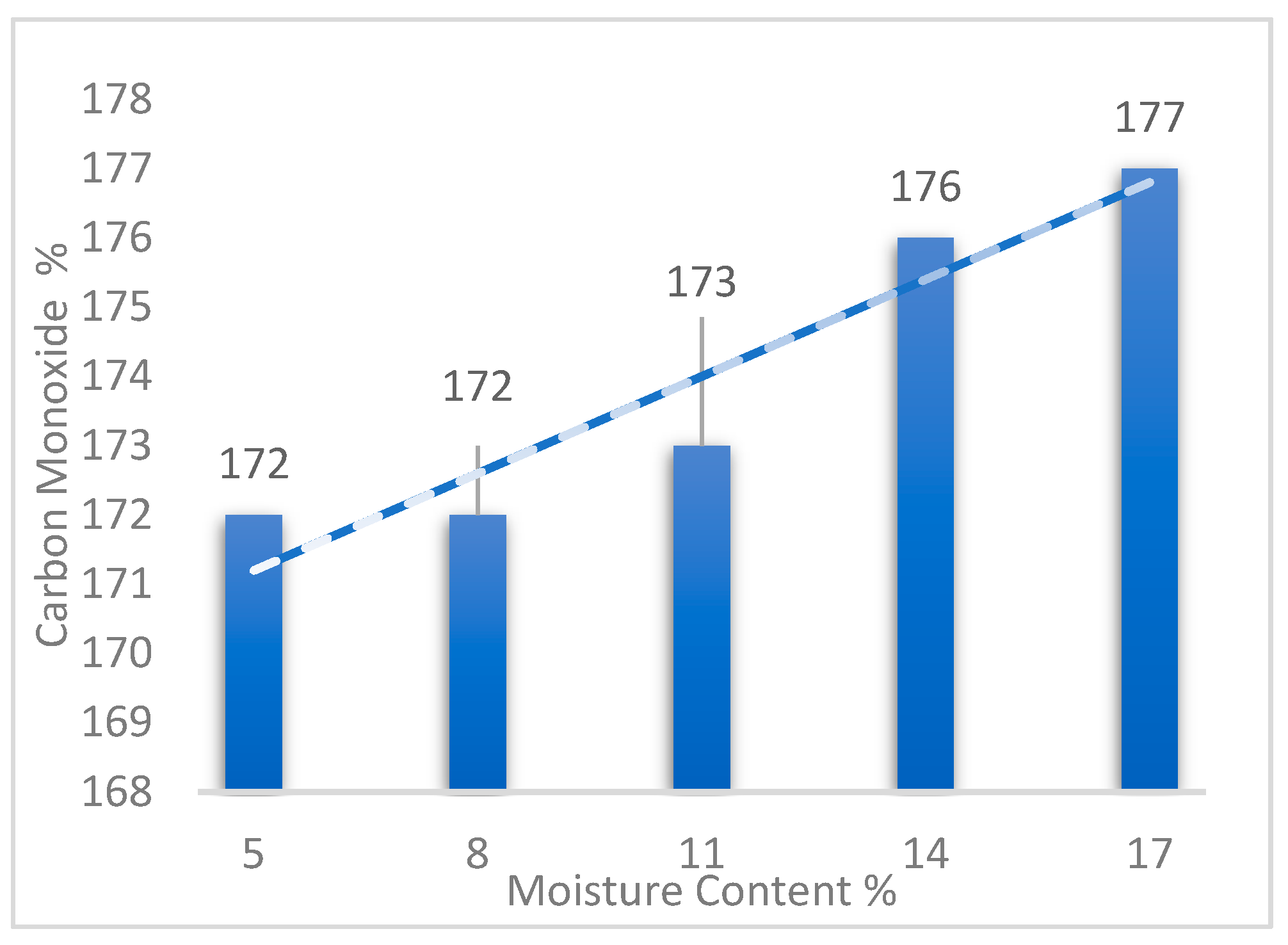

3.8.2. Emissions of Carbon Monoxide

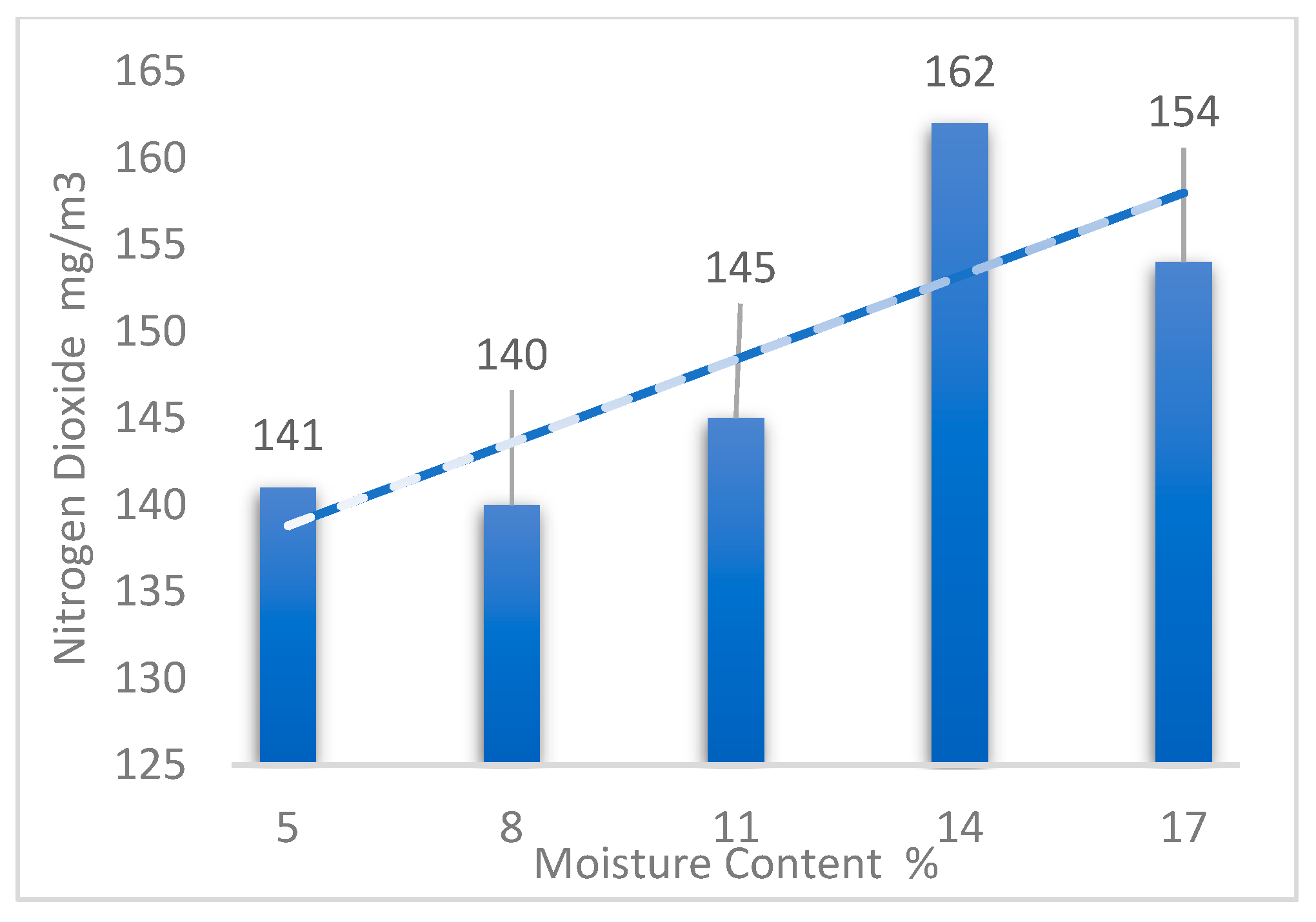

3.8.3. Emission of Nitrogen Oxide

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- SECTOR ASSESSMENT (SUMMARY): ENERGY. Available online: https://www.adb.org/sites/default/files/linked-documents/47015-001-ssa.pdf (accessed on 20 September 2016).

- State Bank of Pakistan. State Bank of Pakistan Third Quarterly Report 2020–21; State Bank of Pakistan: Karachi, Pakistan, 2020; Available online: https://www.sbp.org.pk/reports/quarterly/fy21/Third/Chap-1.pdf (accessed on 15 July 2021).

- Pakistan Economic Survey; Ministry of Finance, Government of Pakistan: Islamabad, Pakistan, 2021. Available online: https://www.finance.gov.pk/survey/chapter_22/Economic%20Survey%202021-22.pdf (accessed on 31 January 2022).

- Year Book 2020–2021. Government of Pakistan Ministry of Energy (Power Division) Islamabad. Available online: https://power.gov.pk/SiteImage/Publication/YearBook2020-21.pdf (accessed on 30 June 2022).

- Planning Commission of Pakistan. Pakistan Vision 2025; Planning Commission of Pakistan, 2018. Available online: https://www.pc.gov.pk/uploads/vision2025/Vision-2025-Executive-Summary.pdf (accessed on 15 June 2023).

- International Monetary Fund. IMF Executive Board Approves US$6 Billion 39-Month EFF Arrangement for Pakistan; International Monetary Fund, 2019. Available online: https://www.imf.org/en/News/Articles/2019/07/03/pr19264-pakistan-imf-executive-board-approves-39-month-eff-arrangement (accessed on 3 July 2019).

- Pakistan Energy Commission. Pakistan Energy Outlook Report; Pakistan Energy Commission: Islamabad, Pakistan, 2020. Available online: https://www.pc.gov.pk/uploads/report/IEP_Outlook_Final.pdf (accessed on 1 March 2022).

- Climate Risk Country Profile: Pakistan (2021): The World Bank Group and the Asian Development Bank. Available online: https://climateknowledgeportal.worldbank.org/sites/default/files/2021-05/15078-WB_Pakistan%20Country%20Profile-WEB.pdf (accessed on 1 February 2021).

- China-Pakistan Economic Corridor (CPEC) and the Emerging Maritime Security Environment. Islamabad, Pakistan. 2018. Available online: https://issi.org.pk/wp-content/uploads/2018/08/IP_Farooq_Rashid_No_37_2018.pdf (accessed on 15 August 2018).

- Ministry of Energy (Power Division). Pakistan Energy Efficiency and Conservation Act; Ministry of Energy (Power Division): Islamabad, Pakistan, 2019. Available online: https://power.gov.pk/ (accessed on 1 February 2020).

- Petroleum, B. BP Statistical Review of World Energy 2015. Available online: https://www.bp.com/content/dam/bp/business-sites/en/global/corporate/pdfs/energy-economics/statistical-review/bp-statistical-review-of-world-energy-2015-full-report.pdf (accessed on 28 June 2016).

- Park, C.; Fujimori, S.; Hasegawa, T.; Takakura, J.; Takahashi, K.; Hijioka, Y. Avoided economic impacts of energy demand changes by 1.5 and 2 °C climate stabilization. Environ. Res. Lett. 2018, 13, 045010. [Google Scholar] [CrossRef]

- Canuel, E. Sustainable development, natural resource extraction, and the Arctic: The road ahead. Alaska L. Rev. 2016, 33, 31. [Google Scholar]

- Saidur, R.; Abdelaziz, E.; Demirbas, A.; Hossain, M.; Mekhilef, S. A review on biomass as a fuel for boilers. Renew. Sustain. Energy Rev. 2011, 15, 2262–2289. [Google Scholar] [CrossRef]

- Xiao, Z.; Yuan, X.; Jiang, L.; Chen, X.; Li, H.; Zeng, G.; Leng, L.; Wang, H.; Huang, H. Energy recovery and secondary pollutant emission from the combustion of co-pelletized fuel from municipal sewage sludge and wood sawdust. Energy 2015, 91, 441–450. [Google Scholar] [CrossRef]

- Larsson, S.H.; Thyrel, M.; Geladi, P.; Lestander, T.A. High quality biofuel pellet production from pre-compacted low density raw materials. Bioresour. Technol. 2008, 99, 7176–7182. [Google Scholar] [CrossRef] [PubMed]

- Adapa, P.; Tabil, L.; Schoenau, G. Grinding performance and physical properties of non-treated and steam-exploded barley, canola, oat, and wheat straw. Biomass Bioenergy 2011, 35, 549–561. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Wright, C.T.; Hess, J.R.; Kenney, K.L. A review of biomass densification systems to develop uniform feedstock commodities for bioenergy application. Biofuels Bioprod. Biorefin. 2011, 5, 683–707. [Google Scholar] [CrossRef]

- Agar, D.A.; Rudolfsson, M.; Kalén, G.; Campargue, M.; Perez, D.D.S.; Larsson, S.H. A systematic study of ring-die pellet production from forest and agricultural biomass. Fuel Process. Technol. 2018, 180, 47–55. [Google Scholar] [CrossRef]

- Chen, W.-H.; Peng, J.; Bi, X.T. A state-of-the-art review of biomass torrefaction, densification and applications. Renew. Sustain. Energy Rev. 2015, 44, 847–866. [Google Scholar] [CrossRef]

- Singh, R.; Krishna, B.B.; Mishra, G.; Kumar, J.; Bhaskar, T. Strategies for selection of thermo-chemical processes for the valorization of biomass. Renew. Energy 2016, 98, 226–237. [Google Scholar] [CrossRef]

- REN21, R. Global Status Report, REN21 Secretariat, Paris, France. In Tech. Rep. 2017, pp. 91–93. Available online: https://www.ren21.net/wp-content/uploads/2019/05/GSR2017_Full-Report_English.pdf (accessed on 13 March 2017).

- Dafnomilis, I.; Hoefnagels, R.; Pratama, Y.W.; Schott, D.L.; Lodewijks, G.; Junginger, M. Review of solid and liquid biofuel demand and supply in Northwest Europe towards 2030—A comparison of national and regional projections. Renew. Sustain. Energy Rev. 2017, 78, 31–45. [Google Scholar] [CrossRef]

- Guo, M.; Song, W.; Buhain, J. Bioenergy and biofuels: History, status, and perspective. Renew. Sustain. Energy Rev. 2015, 42, 712–725. [Google Scholar] [CrossRef]

- Chauhan, A.; Saini, R. Renewable energy based off-grid rural electrification in Uttarakhand state of India: Technology options, modelling method, barriers and recommendations. Renew. Sustain. Energy Rev. 2015, 51, 662–681. [Google Scholar] [CrossRef]

- Pradhan, P.; Arora, A.; Mahajani, S.M. Pilot scale evaluation of fuel pellets production from garden waste biomass. Energy Sustain. Dev. 2018, 43, 1–14. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zafar, U.; Sarwar, A.; Safdar, M.; Sabir, R.M.; Majeed, M.D.; Raza, A. Development and Characterization of Biomass Pellets Using Yard Waste. Eng. Proc. 2023, 56, 323. https://doi.org/10.3390/ASEC2023-16603

Zafar U, Sarwar A, Safdar M, Sabir RM, Majeed MD, Raza A. Development and Characterization of Biomass Pellets Using Yard Waste. Engineering Proceedings. 2023; 56(1):323. https://doi.org/10.3390/ASEC2023-16603

Chicago/Turabian StyleZafar, Usman, Abid Sarwar, Muhammad Safdar, Rehan Mehmood Sabir, Muhammad Danish Majeed, and Aamir Raza. 2023. "Development and Characterization of Biomass Pellets Using Yard Waste" Engineering Proceedings 56, no. 1: 323. https://doi.org/10.3390/ASEC2023-16603

APA StyleZafar, U., Sarwar, A., Safdar, M., Sabir, R. M., Majeed, M. D., & Raza, A. (2023). Development and Characterization of Biomass Pellets Using Yard Waste. Engineering Proceedings, 56(1), 323. https://doi.org/10.3390/ASEC2023-16603