1. Introduction

The application of composite materials in the civil engineering sector has been growing due to their advantages, such as their freedom of design, high specific strength and stiffness compared to traditionally used materials, and good chemical resistance to most civil environments [

1]. However, published studies mainly address the advantages obtained with these materials, to the detriment of their structural response. An example of this is the impact response, to which they are very sensitive to the loading mode because the residual mechanical properties are significantly affected.

In this context, it is possible to find some studies (numerical and experimental) that analyse the influence of several parameters such as the energy and geometry of the impactor and the stacking sequence [

2,

3,

4,

5,

6,

7,

8,

9]. On the other hand, in terms of residual strength, they focus essentially on compression after impact (CAI) [

7,

10,

11,

12,

13], and few address the tensile loading mode [

14,

15,

16,

17]. Therefore, recognizing this gap, this study aims at comprehensively understanding and augmenting the available literature on the post-impact tensile mechanical response of woven glass fibre-reinforced polymer composite structures, also referred to as Tension After Impact (TAI). Understanding how the residual strength of composite materials is affected by impact events will enable architects and engineers to make informed decisions when selecting materials and designing structures that can withstand unforeseen incidents. Ultimately, this work aims to elevate the standards of building construction by integrating the crucial aspect of post-impact tensile strength into the design process, ensuring robustness and resilience in the face of real-world challenges.

2. Experimental Procedure

Composite laminate plates were fabricated using a bi-directional E-glass fabric (EC9 68 × 2) in conjunction with epoxy resin (SR1500) and a hardener (SD2503) (both provided by Sicomin, Chateauneuf les Martigues, France). The woven fabric layers were stacked to fabricate 10 ply laminate woven fabric reinforced composites. To ensure optimal impregnation, resin film infusion (RFI) was employed. After this stage, the composite plates were positioned within a vacuum bag for 12 h at room temperature, employing a maximum pressure of 0.5 mbar. This step served the dual purpose of eliminating any trapped air bubbles and maintaining a consistent fibre volume fraction and uniform thickness. Subsequently, the plates underwent an 8 h curing process at 60 °C.

The specimens were cut to dimensions of 250 mm (length) × 25 mm (width) using a diamond saw. A total of 25 specimens were prepared, with 5 serving as control specimens (0 impacts) and 5 specimens for each impact count (1, 2, 3, and 5). The average thickness of the specimens was 1.86 ± 0.048 mm. It is important to note that aluminium end tabs were bonded to the specimens for the tensile tests, as shown in

Figure 1a. To determine the fibre weight ratio, a burnout test was conducted in accordance with ASTM D3171-15 [

18]. The results revealed a fibre weight ratio of 63.9%, which corresponded to a fibre volume fraction of about 47%.

Table 1 provides a summary of the experimental tests carried out in this study.

The low-velocity impact (LVI) tests were conducted utilizing the IMATEK-IM10 drop weight testing machine (IMATEK, Old Knebworth, UK), shown in

Figure 1b. A 10 mm diameter impactor with a mass of 2.823 kg was employed. The drop height was defined so that the impact energy was 4 J. It is important to note that this energy level induced visible damage in a single impact, yet it did not lead to complete puncture of the specimens, thus allowing for a thorough assessment of the post-impact mechanical response. Further details about the drop weight testing machine can be found in [

19].

Following each impact, a visual inspection of the specimens was conducted. Leveraging the material’s translucency, photos were taken with intense backlighting to facilitate the identification and delineation of the damaged area.

The static tensile strengths of the control specimens (zero impacts) and the impacted specimens were obtained using the universal testing machine Shimadzu AG-100 (Shimadzu Europa GmbH, Duisburg, Germany), represented in

Figure 1c, with a 3 mm/min displacement rate. All the experimental tests were carried out at standard room temperature.

3. Results and Discussion

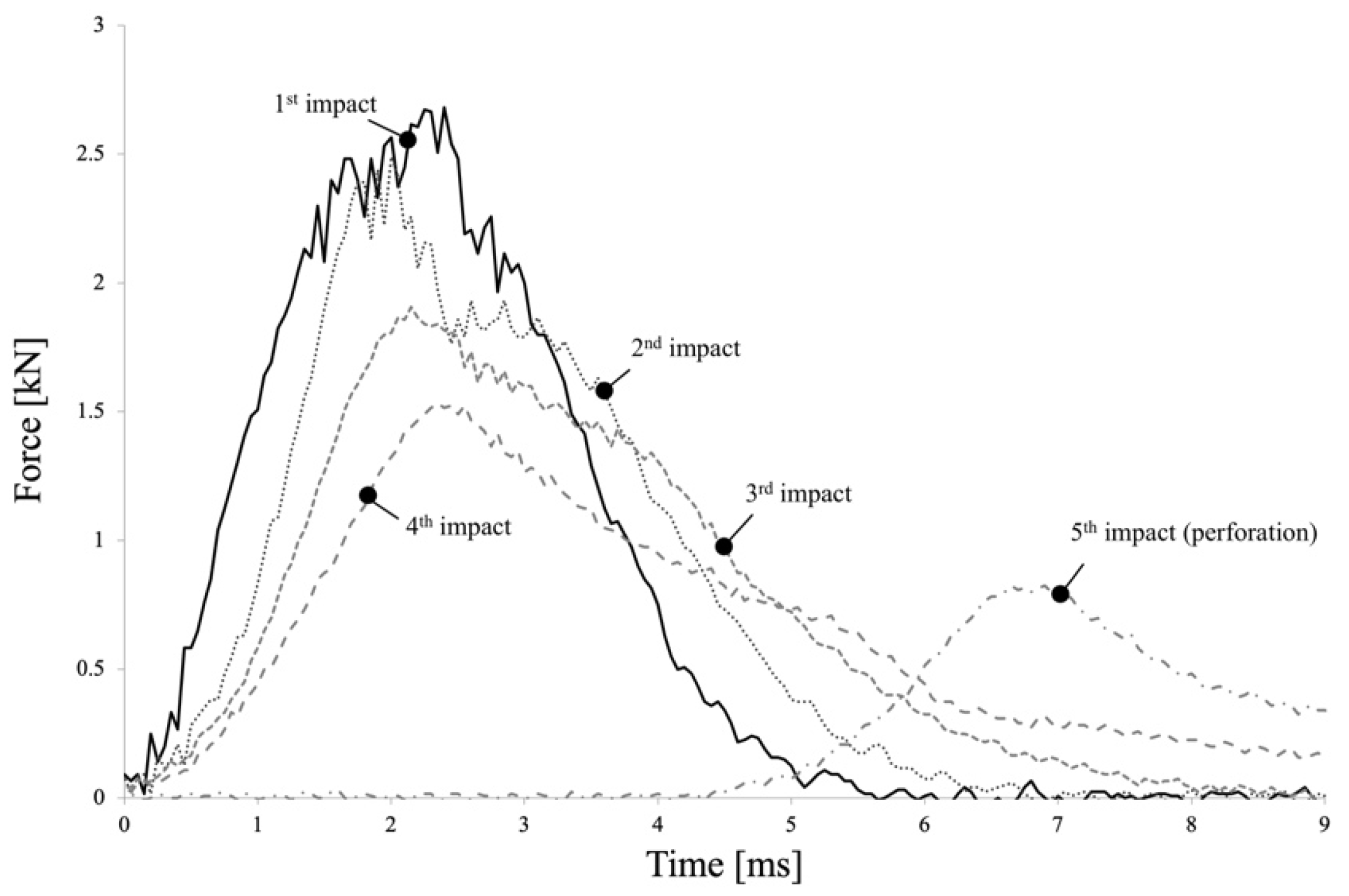

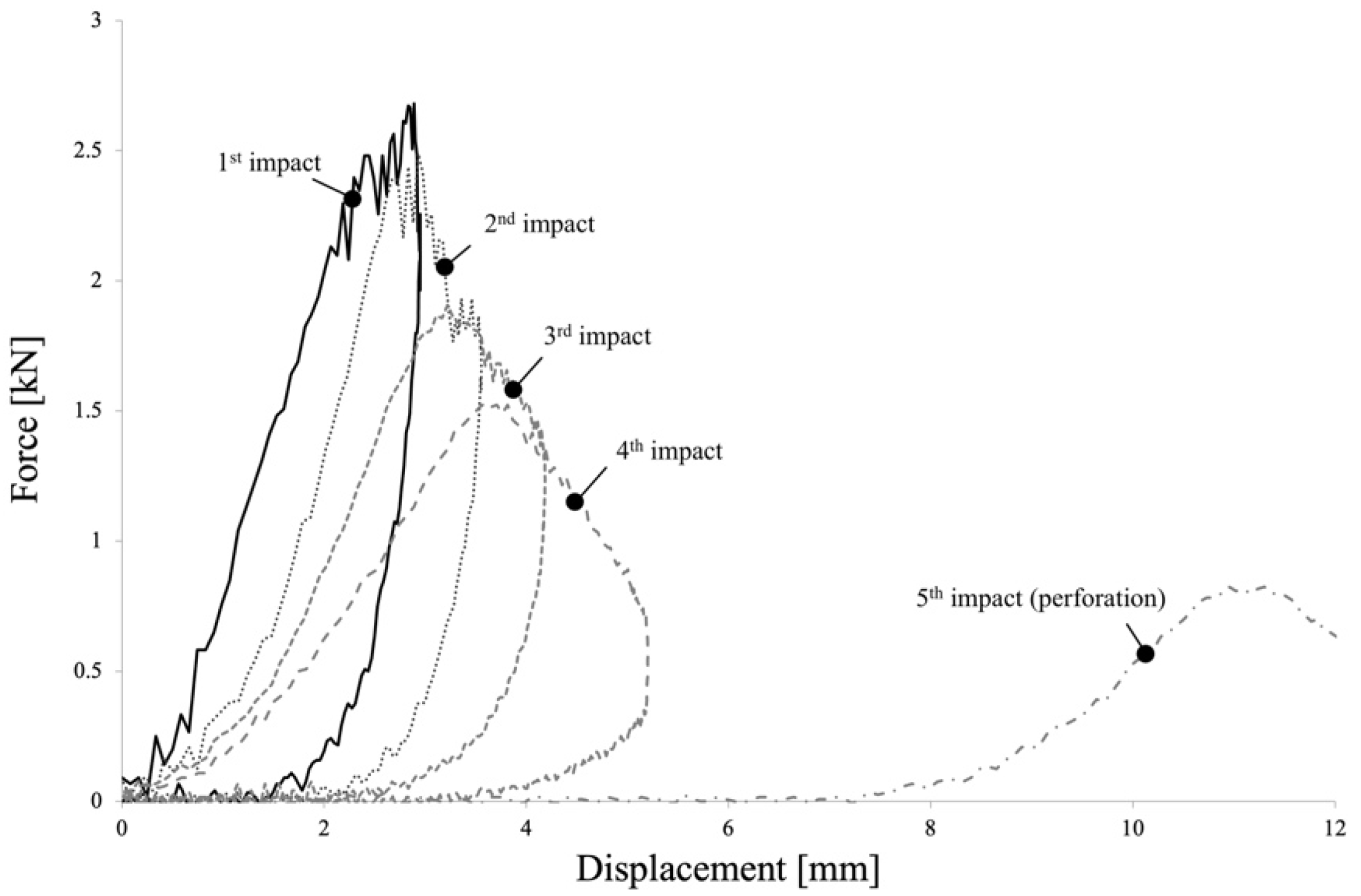

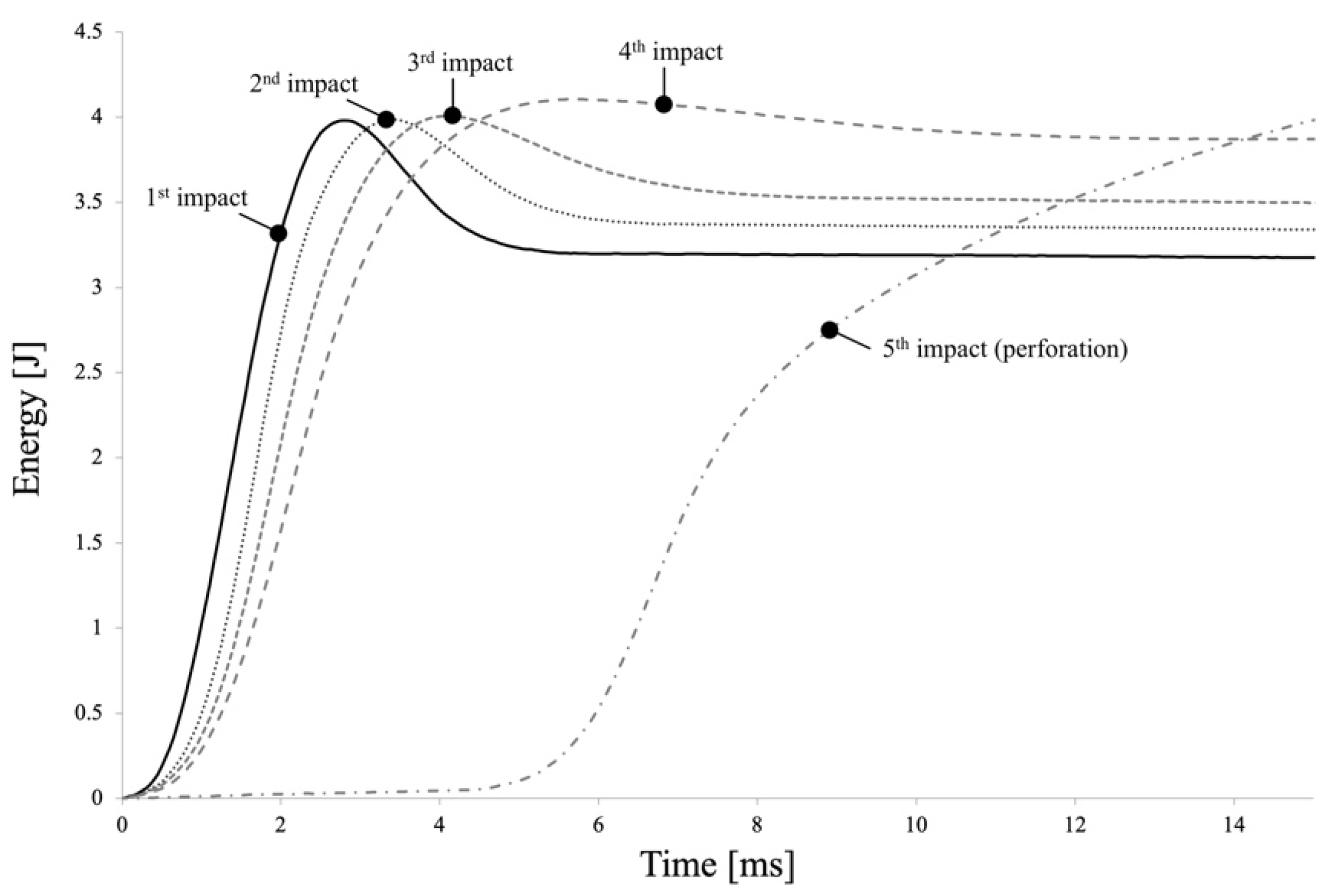

Representative force–time, force–displacement, and energy–time impact response curves for the [0,90]

10 woven fabric composite laminates are shown in

Figure 2,

Figure 3 and

Figure 4, respectively. It can be observed in

Figure 1 that the impact force initially rises over time until it reaches a peak value, after which it gradually decreases due to the impactor’s rebound until returning to zero. At this instant, the impactor loses contact with the sample.

This consistent profile is observed across all impacts. It is noteworthy that the maximum force diminishes after each impact. For example, in comparison to the first impact, the maximum force decreases by approximately 7.6% at the 2nd impact, 30% at the 3rd impact, 42.6% at the 4th impact, and 68.4% at the 5th impact. Examining the maximum displacement depicted in

Figure 3, it shows an increase of around 20.7% after the 2nd impact, and, from that point onwards, it approximately doubles its value with each subsequent impact. It is possible to appreciate in the energy–time curves represented in

Figure 4 that the absorbed energy up until the 4th impact is not sufficiently high to cause puncture of the specimens. The impactor strikes the specimen, rebounds, and does not penetrate fully. However, at the 5th impact, full perforation occurs, resulting in the complete absorption of all impact energy. Moreover, it can be observed that the absorbed impact energy steadily increases after each impact. For example, compared to the 1st impact, the absorbed energy is 7.9% higher at the 2nd impact, and it further increases by 12% and 20.9% at the 3rd and 4th impacts, respectively. Finally, the contact time also extends with each subsequent impact. For example, the contact time increases by approximately 16% from the 1st to the 2nd impact, whereas it rises by about 44.8% and 124.2% at the 3rd and 4th impacts, respectively.

Figure 5 provides a visual representation of representative damaged areas resulting from impacts 1 to 4. As the specimens are already completely perforated at the 5th impact, their corresponding damaged areas were not included in the analysis. Upon the 1st impact, damage in the form of delamination is observed around the impact point, exhibiting a circular shape. This delamination area becomes more pronounced with the 2nd impact. While the damaged area seemingly remains unchanged at the 3rd impact, the failure of fibres becomes evident, resulting in partial puncture that becomes clearly visible by the 4th impact.

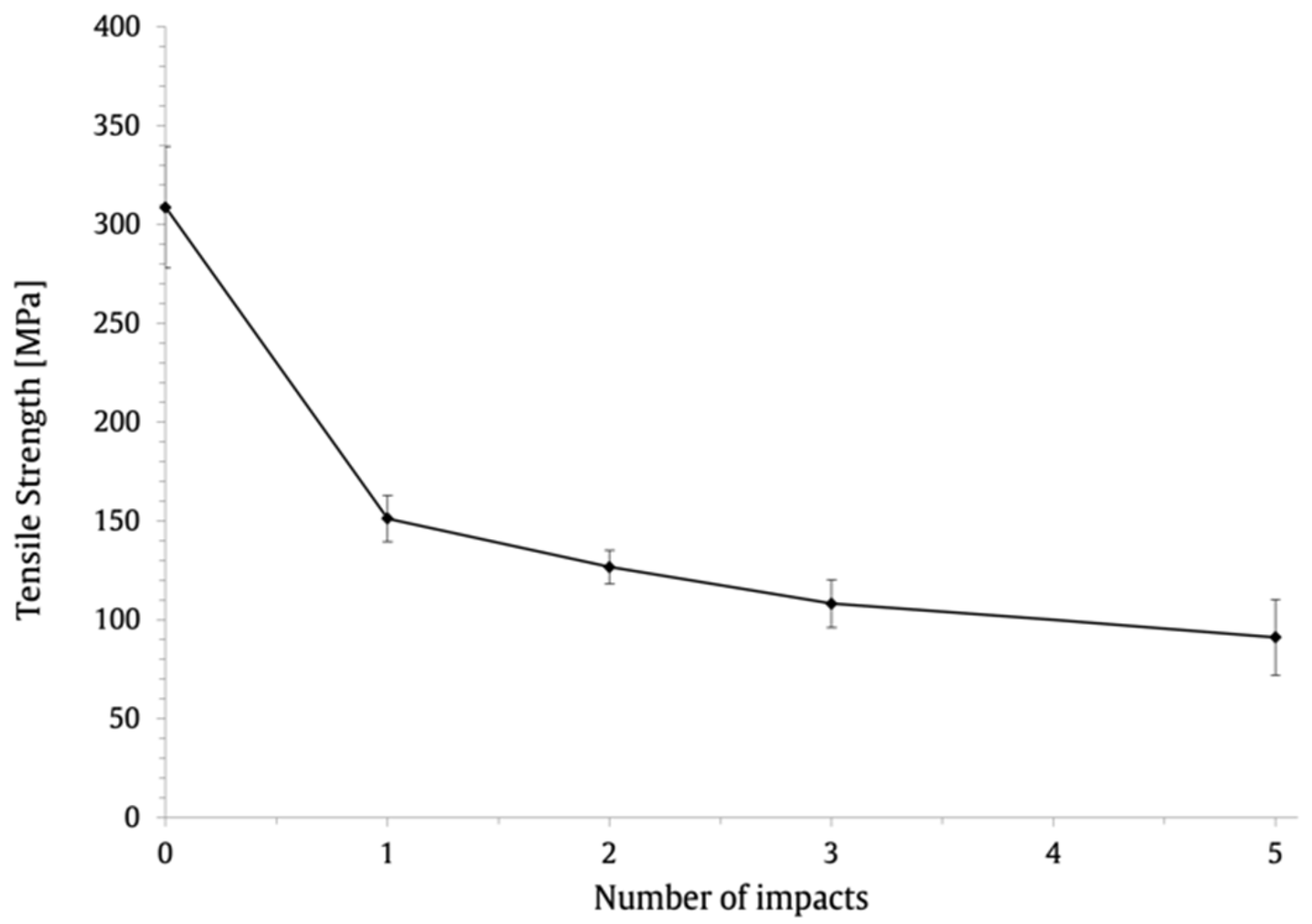

To assess the residual tensile strength of the multi-impacted specimens, static tensile tests were conducted. The residual tensile strength, for both the impacted specimens and the control ones, is shown in

Figure 6.

The results emphasize the strong influence of the number of impacts on the residual tensile strength, particularly following the 1st impact. A clear distinction can be observed between two distinct stages: the initial stage between the control specimens and the 1st impact, and the subsequent stage encompassing impacts 2 to 5. It is evident that the tensile strength experiences a substantial decrease from 308.7 N to 151.2 N during the initial stage, corresponding to a reduction of approximately 51%. During the second stage, encompassing impacts 2 to 5, the rate of decrease in tensile strength diminishes to approximately 39.7%. These results indicate that, in static terms, the effect of the introduced damage becomes less pronounced as the number of impacts increases. However, it is important to note that the overall tensile strength continues to be impacted by the cumulative damage inflicted by multiple impacts.

Finally, to gain further insights into the effect of damage on the residual tensile strength, representative static stress–strain curves for both the control and multi-impacted specimens are presented in

Figure 7. It can be observed that a substantial loss of stiffness occurs in the multi-impacted specimens, and, as expected, increasing the number of impacts leads to a reduction in the specimen’s stiffness.

4. Conclusions

In this experimental study, the effects of repeated low-velocity impacts on the residual tensile strength of woven fabric reinforced composite laminates was investigated. The comprehensive analysis involved evaluating the force and energy histories, as well as various parameters, including maximum impact force and displacement, absorbed energy, contact time, static tensile behaviour, and damage evolution.

It was observed that the maximum impact force decreases with the number of impacts, but the reduction is only substantial starting at the 3rd impact. The maximum displacement increases about 20.7% after the 2nd impact, and it approximately doubles its value with each subsequent impact. Additionally, it was seen that the absorbed impact energy steadily increases after each impact, and, at the 5th impact, when full perforation occurs, the impact energy is completely absorbed. Finally, it was found that the contact time also extends with each subsequent impact.

The findings revealed a significant decrease in the residual tensile strength after the 1st impact, amounting to a reduction of approximately 51%. This highlights the immediate and substantial impact of the initial damage on the tensile strength of the specimens. Furthermore, the findings indicate that the subsequent impacts, leading up to full perforation, had a relatively diminished effect on the residual tensile strength. From the 2nd to the 5th impact, it was observed a decrease of approximately 39.7% in the tensile strength. This implies that, in terms of static behaviour, the effectiveness of the damage inflicted by subsequent impacts becomes less pronounced.

The progression of damage throughout the multiple impacts was also analysed. The observed decrease in tensile strength corresponds to the evolving damage mechanisms and the interaction between the impacted areas.

These results underscore the importance of considering the cumulative effects of multiple low-velocity impacts on the residual tensile strength of composite laminates. The findings have significant implications for building design and construction, emphasizing the need to account for potential damage and degradation in structures subjected to repeated impacts.

Author Contributions

Conceptualization, C.A.C.P.C. and L.M.F.; methodology, C.A.C.P.C. and L.M.F.; formal analysis, C.A.C.P.C., L.M.F. and P.N.B.R.; investigation, C.A.C.P.C., L.M.F. and P.N.B.R.; resources L.M.F. and C.A.C.P.C.; writing—original draft preparation, L.M.F., C.A.C.P.C. and P.N.B.R.; writing—review and editing, L.M.F., C.A.C.P.C. and P.N.B.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

This research was sponsored by national funds through FCT-Fundação para a Ciência e a Tecnologia, under the projects UIDB/00285/2020 and LA/P/0112/2020.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhao, J.; Li, G.; Wang, Z.; Zhao, X.-L. Fatigue Behavior of Concrete Beams Reinforced with Glass- and Carbon-Fiber Reinforced Polymer (GFRP/CFRP) Bars after Exposure to Elevated Temperatures. Compos. Struct. 2019, 229, 111427. [Google Scholar] [CrossRef]

- Ferreira, L.; Coelho, C.; Reis, P. Impact Response of Semi-Cylindrical Composite Laminate Shells Under Repeated Low-Velocity Impacts. In Proceedings of the 2022 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 21 February 2022; pp. 1–5. [Google Scholar]

- Reis, P.N.B.; Sousa, P.; Ferreira, L.M.; Coelho, C.A.C.P. Multi-Impact Response of Semicylindrical Composite Laminated Shells with Different Thicknesses. Compos. Struct. 2023, 310, 116771. [Google Scholar] [CrossRef]

- Ferreira, L.M.; Coelho, C.A.C.P.; Reis, P.N.B. Numerical Simulations of the Low-Velocity Impact Response of Semicylindrical Woven Composite Shells. Materials 2023, 16, 3442. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, L.M.; Coelho, C.A.C.P.; Reis, P.N.B. Effect of Cohesive Properties on Low-Velocity Impact Simulations of Woven Composite Shells. Appl. Sci. 2023, 13, 6948. [Google Scholar] [CrossRef]

- Ferreira, L.M.; Coelho, C.A.C.P.; Reis, P.N.B. Numerical Predictions of Intralaminar and Interlaminar Damage in Thin Com-posite Shells Subjected to Impact Loads. Thin-Walled Struct. 2023, 192, 111148. [Google Scholar] [CrossRef]

- Andrew, J.J.; Arumugam, V.; Saravanakumar, K.; Dhakal, H.N.; Santulli, C. Compression after Impact Strength of Repaired GFRP Composite Laminates under Repeated Impact Loading. Compos. Struct. 2015, 133, 911–920. [Google Scholar] [CrossRef]

- Balcı, O.; Çoban, O.; Bora, M.Ö.; Akagündüz, E.; Yalçin, E.B. Experimental Investigation of Single and Repeated Impacts for Repaired Honeycomb Sandwich Structures. Mater. Sci. Eng. A 2017, 682, 23–30. [Google Scholar] [CrossRef]

- David-West, O.; Nash, D.; Banks, W. An Experimental Study of Damage Accumulation in Balanced CFRP Laminates Due to Repeated Impact. Compos. Struct. 2008, 83, 247–258. [Google Scholar] [CrossRef]

- Davies, G.; Olsson, R. Impact on Composite Structures. Aeronaut. J. 2004, 108, 541–563. [Google Scholar] [CrossRef]

- Liv, Y.; Guillamet, G.; Costa, J.; González, E.V.; Marín, L.; Mayugo, J.A. Experimental Study into Compression after Impact Strength of Laminates with Conventional and Nonconventional Ply Orientations. Compos. B Eng. 2017, 126, 133–142. [Google Scholar] [CrossRef]

- Sasikumar, A.; García-Rodríguez, S.M.; Arbeláez, J.J.; Trias, D.; Costa, J. On How Unsymmetrical Laminate Designs with Tailored Ply Clusters Affect Compression after Impact Strength Compared to Symmetric Baseline. Compos. Struct. 2020, 238, 111958. [Google Scholar] [CrossRef]

- Sinclar, R.; Robinson, P.; Iannucci, L. Directed Compression Tests on FALCOM Biaxial Cross-Ply Material; FALCOM/WP3/ICL/TR01; Imperial College London: London, UK, 2005. [Google Scholar]

- Ferreira, L.M.; Coelho, C.A.C.P.; Reis, P.N.B. Residual Tensile Strength of Multi-Impacted Woven Glass Fibre-Reinforced Polymer Composites. In Proceedings of the 20th International Conference on Experimental Mechanics, Porto, Portugal, 2–7 July 2023; INEGI/FEUP (Faculty of Engineering of University of Porto): Porto, Portugal, 2023; pp. 269–270. [Google Scholar]

- Hoseinlaghab, S.; Farahani, M.; Safarabadi, M.; Nikkhah, M. Tension-after-Impact Analysis and Damage Mechanism Evaluation in Laminated Composites Using AE Monitoring. Mech. Syst. Signal Process. 2023, 186, 109844. [Google Scholar] [CrossRef]

- Malhotra, A.; Guild, F.J. Impact Damage to Composite Laminates: Effect of Impact Location. Appl. Compos. Mater. 2014, 21, 165–177. [Google Scholar] [CrossRef]

- Feng, W.; Xu, F.; Xie, W.; Wang, A.; Ma, C. Impact and Tension-after-Impact Behaviors of Scarf-Repaired Composite Laminates: An Experimental and Numerical Approach. Mech. Adv. Mater. Struct. 2023, 30, 1260–1273. [Google Scholar] [CrossRef]

- D30 Committee. Test Methods for Constituent Content of Composite Materials; ASTM International: West Conshohocken, PA, USA.

- Ferreira, L.M.; Aranda, M.T.; Muñoz-Reja, M.; Coelho, C.; Távara, L. Ageing Effect on the Low-Velocity Impact Response of 3D Printed Continuous Fibre Reinforced Composites. Compos. Part B Eng. 2023, 267, 111031. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).