Abstract

This study examines the durability of stretchable conductive tracks on knitted fabrics. Two knitted fabrics with three designs of conductive tracks are tested to assess the fabric strain release and resistance change after a 50% elongation. The optimised design, made with all needle back jacquard knitting with sinusoidal conductive tracks, exhibits a 4% increase in fabric length and a 0.23 Ω (38.9%) increase in resistance. This e-textile is used to fabricate a sleeve with integrated functional electrical stimulation (FES) for stroke rehabilitation. The optimised electrode pattern, designed for stroke arm/hand rehabilitation, was achieved through co-design with stroke survivors and healthcare professionals. The prototype was tested on stroke survivors to assess stimulation comfort and ease of use. Tests have confirmed that the electrode sleeve (e-sleeve) is comfortable to wear and that stroke survivors are able to don and doff the e-sleeve using a single hand, facilitating independent home use.

1. Introduction

In the UK, stroke incurs an annual cost of GBP 26 billion to the National Health Service and society [1], with around 100,000 new cases yearly [2]. One of the clinically approved and commonly used effective methods for stroke rehabilitation is functional electrical stimulation (FES). FES works by emitting controlled electrical impulses through electrodes placed on the skin. It mimics the body’s natural signals, promoting muscle contractions; aids the prevention of muscle atrophy; improves muscle strength; and facilitates functional movements. For stroke patients, who often struggle to open their hands independently, FES can contract the forearm muscle, enabling them to open their affected hand. Existing FES products are often challenging for stroke survivors to set up without assistance from caregivers or healthcare professionals, limiting their use. Our previous research identified user needs in stroke rehabilitation and received positive feedback on the use of wearable e-textile FES [3]. This study aims to address the need for a durable FES solution, empowering stroke survivors in their recovery and improving independence. Challenges lie in the precise placement of the electrodes on the target forearm muscles and the independent use of the FES sleeve via single-handed operation.

Knitting is a well-established technique in the textile industry to realise stretchable, high-elasticity fabrics; therefore, knitted fabrics are often chosen to realise stretchable e-textiles. Lamination of conductive tracks on a knitted fabric to achieve FES stimulation has been achieved in previous work [4]. However, the previous prototype is not durable, and the conductive tracks frequently break. This paper evaluates the performance of three conductive track shapes (straight, sine wave, and horseshoe) on two knitted fabrics (tubular jacquard and all needle back jacquard) and discusses how to achieve the best durability.

The bespoke prototypes have been designed for three stroke survivors. The electrode positions were defined in a testing session by a physiotherapist experienced in FES for stroke rehabilitation. Their forearm dimensions and electrode placement were measured, allowing for estimation of the e-sleeve’s dimensions and electrode positions, and documented under ethics approval ID: University of Southampton ERGO 70296. The prototypes are designed according to user feedback on the requirements of a partially open and Velcro-based closure structure.

2. Knitted Fabrics and Tensile Property

The fabrics have been designed to have stretchability and to provide support. The fabrics include two types of yarn; one is Elastomeric [5], consisting of 81% nylon and 19% Lycra; the other is Fluid yarn [6], composed of 91% viscose, 7% nylon, and 2% elastane. Both fabrics are knitted at 18 gauge with a double-bed knitting machine (SHIMA SEIKI SES122-FF).

2.1. Fabric Structure

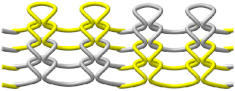

This study chose tubular jacquard and all needle back jacquard fabrics due to their capacity to employ all front and back needles, offering a relatively flat interface to the lamination of conductive transfer materials. Moreover, these fabrics not only demonstrate appropriate stretchability and breathability but also retain their shape to hold the sleeve designs around the arm.

The structure views of both jacquard fabrics are listed in Table 1. The top view indicates the yarn trace where the yarn is knitted line by line, gradually forming a layered structure. The front appearance of both jacquards is designed to be the same 2 × 2 stitch color repeat square. The reverse side view indicates the interface structure where the conductive tracks will be laminated.

Table 1.

The structure views of tubular jacquard and all needle back jacquard.

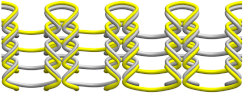

2.2. Fabrics Tensile Test

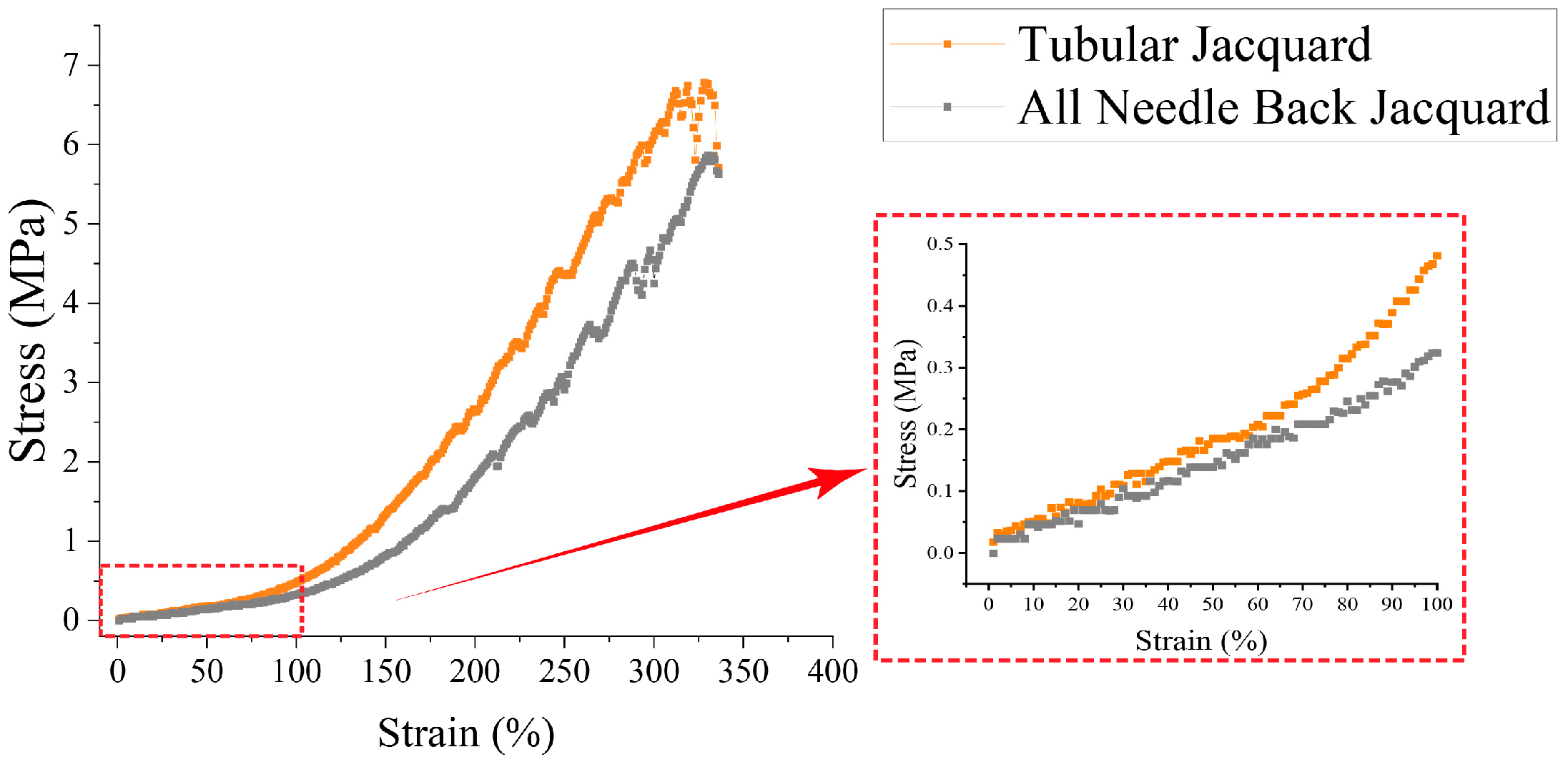

As shown in Figure 1, the stress and strain plot of the tubular jacquard fabric are represented by the yellow dots, and the all needle back jacquard is in grey.

Figure 1.

The stress and strain plot of tubular jacquard and all needle back jacquard.

Both knitted fabrics break at around 350% strain. They display a linear plot for strains below 50%, indicating a spring-like structure capable of bouncing back after stretching. However, the tubular jacquard fabric requires a higher stress to achieve the same strain than the all needle back jacquard fabric. This indicates that the tubular knit is more tightly constructed.

3. Stretchability Test

3.1. Sample Preparation and Test Set-Up

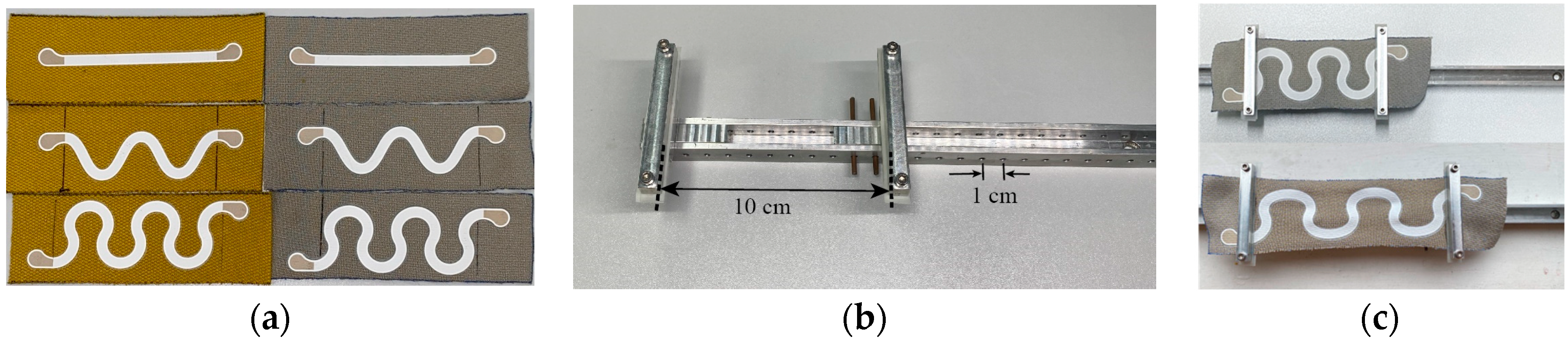

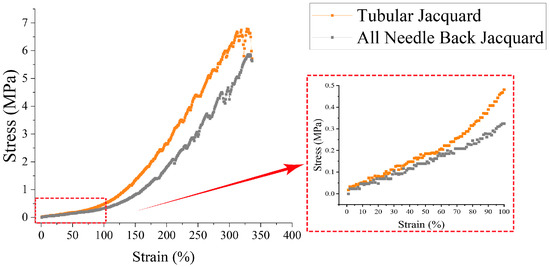

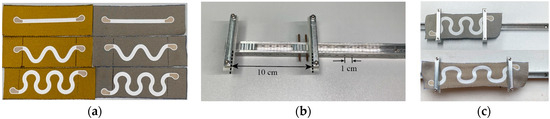

As shown in Figure 2a, three shapes of conductive tracks are investigated in this research: a straight line, a sine wave, and a horseshoe shape. The tracks were provided by Conductive Transfers Ltd. The tracks are laminated to both fabrics at 165 °C for 12 s under 6 bar pressure. After peeling off the support sheet, the insulated conductive materials have adhered to the fabrics.

Figure 2.

(a) Laminated conductive track on tubular fabrics (yellow) and all needle back fabrics (grey). (b) The stretch apparatus which consists of two clamps and a groove. There are holes in the groove and the base of the clamps. The clamps can be fixed by two posts pushed through to holes in the groove. (c) The test set-up where the fabric with a horseshoe track was clamped with a 10 cm stretchable length and stretched by 50% to 15 cm.

For the stretchability test, in accordance with the ASTM D3107 test standard, conductive tracks of 10 cm length are printed on fabric of area 6 cm × 17 cm. The stretch test is achieved by clamping the sample on an apparatus, which is shown in Figure 2b.

The fabrics are held initially at 10 cm then stretched to 15 cm and held in that position for 30 min, as shown in Figure 2c. The recorded measurements include the length recovery after 30 min of stretching, the initial resistance, stretched resistance, and also the recovery resistance after 24 h.

3.2. Result

3.2.1. Length Recovery

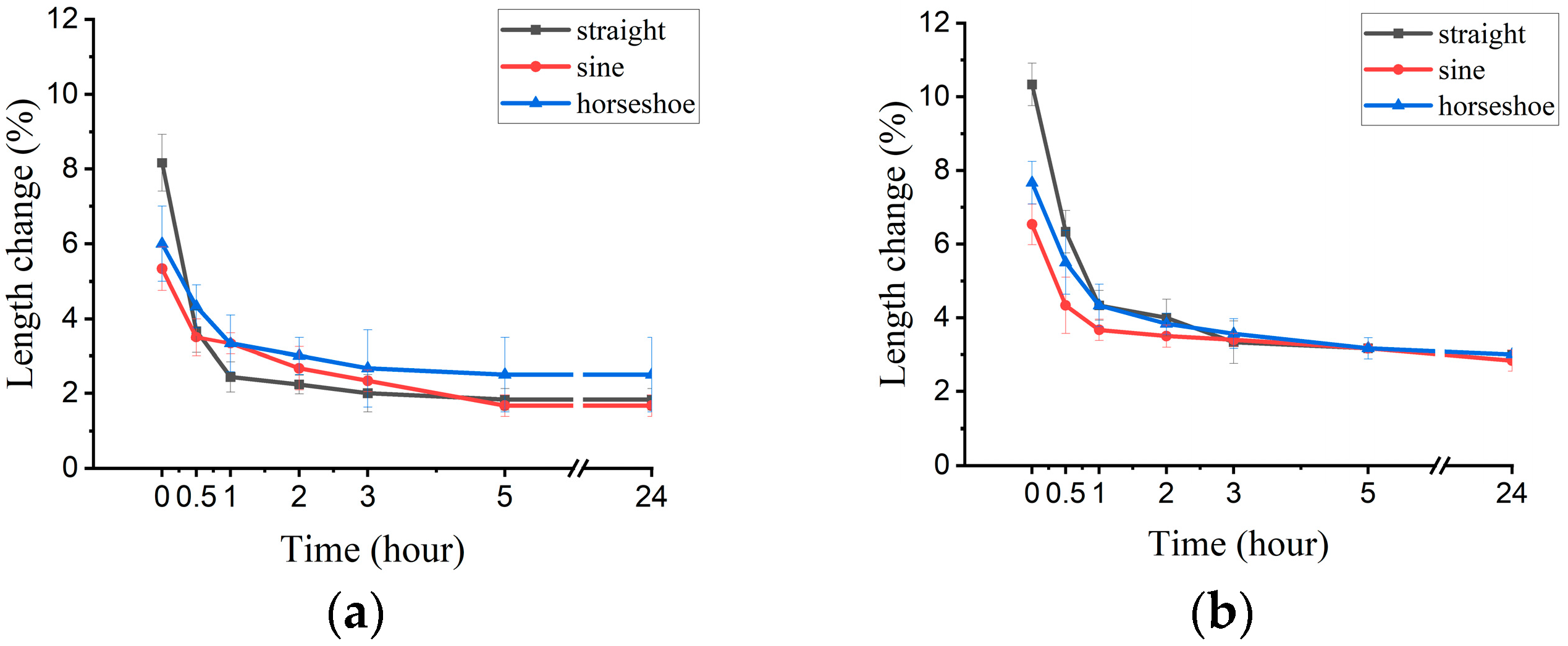

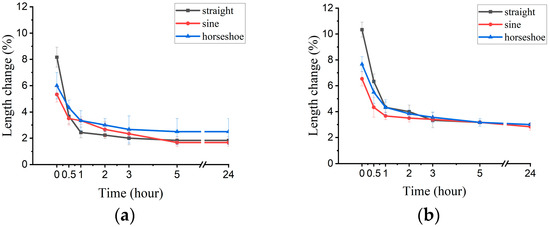

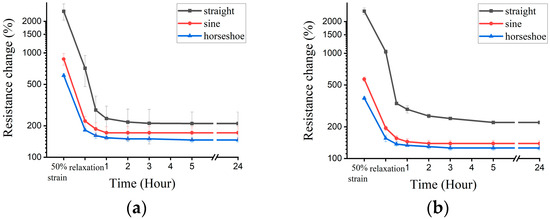

The strain releases of all three track shapes on tubular and all needle back jacquard fabrics are shown in Figure 3. The tubular jacquard fabric had greater and faster elastic recovery than the all needle back jacquard fabric for all track shapes. For the three different shapes, the straight line shape shows the most fabric growth after release but decreases the most during recovery. The horseshoe shape shows the opposite behaviour; it has lower fabric growth than the straight line but recovers less, showing a slightly higher increase after stretching. The sine wave shape demonstrates the lowest fabric change after strain release and exhibits the lowest fabric growth after 24 h.

Figure 3.

(a) Tubular jacquard fabric strain release. The sine wave conductive track achieves the lowest length increase (2%). (b) All needle back jacquard fabric strain release. An increase of about 3% length appears on all three shapes of the conductive track.

3.2.2. Resistance Change

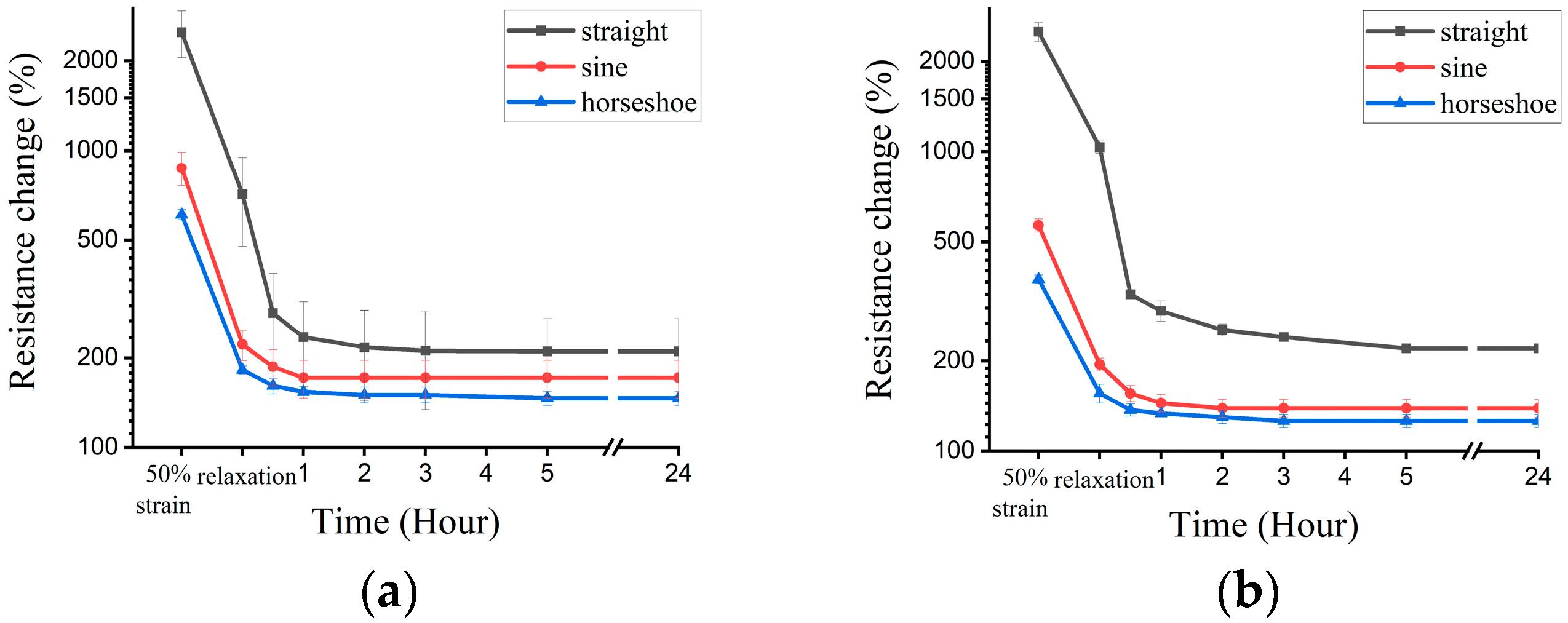

The resistance change shown in Figure 4 demonstrates that the tubular jacquard fabric has less resistance change than the all needle back jacquard fabric for a straight line track. However, for the sine wave- and horseshoe-shaped tracks, all needle back jacquard fabrics have a lower resistance change.

Figure 4.

(a) Tubular jacquard fabric resistance change with 50% strain and during recovery. (b) All needle back jacquard fabric resistance change with 50% strain and during recovery.

This shows that the resistance change is higher for the straight line than for the sine wave, which is, in turn, higher than the horseshoe shape. However, considering that the horseshoe shape requires 66% more material and occupies a larger area than the sine wave, the benefits of the horseshoe shape in terms of resistance change do not justify the cost and the additional change of the textile property as more areas are covered by printed tracks. Therefore, the sine wave is chosen to be the optimal shape.

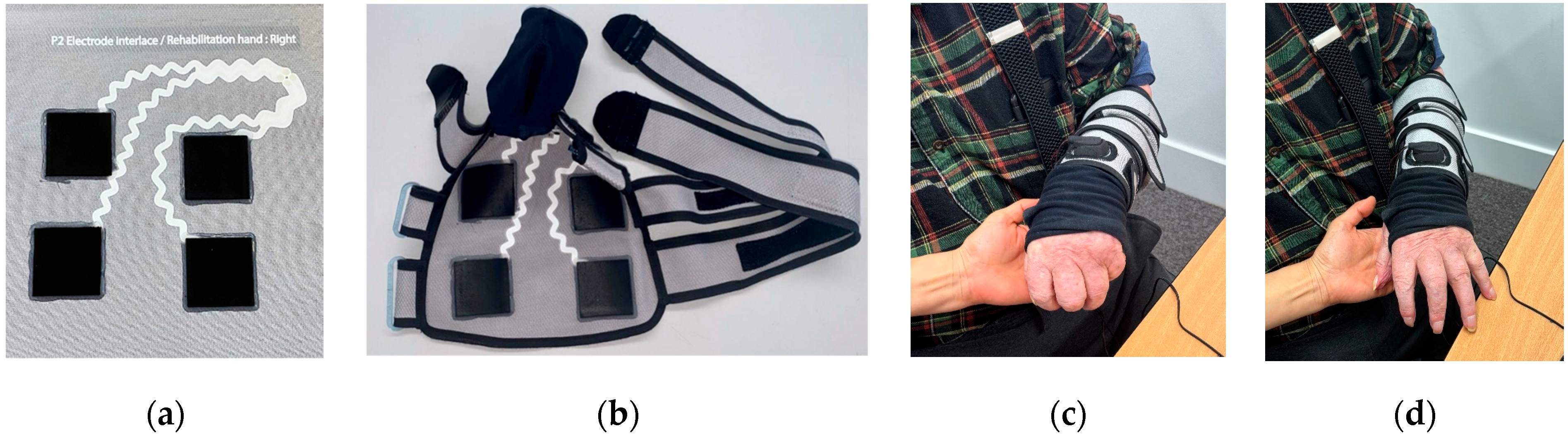

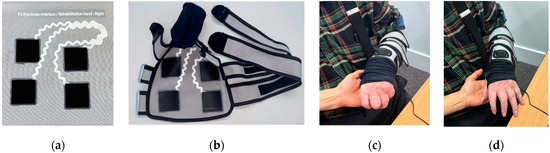

4. E-Sleeve Design and Usability Test

Figure 5a shows the layout of the printed carbon electrode (black) and sine wave track (white). The alignment of the electrodes to the forehand muscle is achieved by using a pre-arranged pattern and a thumb hole on the sleeve, which resulted in the desired muscle activation during user testing. The open wrap sleeve design and Velcro closure of the sleeve, as shown in Figure 5b, allowed participants to don and doff the e-sleeve independently using only one hand. Figure 5c,d show that one of the stroke survivor participants achieved an open hand gesture in FES stimulation while using the e-sleeve.

Figure 5.

(a) Sine wave track with pads and wearable carbon electrode on all needle back fabrics; (b) an e-sleeve with open and Velcro closure structure; (c) a stroke hand at relaxation mode; (d) the stroke hand achieved open gesture with FES stimulation.

5. Conclusions

This study investigated the stretchability of conductive tracks on knitted fabrics, particularly focusing on tubular jacquard fabric and all needle back jacquard fabric. Findings indicate that tubular jacquard fabric with laminated tracks exhibits better strain recovery, whereas shaped tracks on all needle back jacquard fabric maintain lower resistance changes. Among track designs, the sinusoidal track was found to be the most cost-effective, offering lower material costs and efficient resistance recovery. Additionally, electrode alignment was achieved via a pre-arranged pattern and thumb hole on the e-sleeve, enabling optimal muscle activation during user testing. The e-sleeve’s design, incorporating an open structure with Velcro closure, facilitated independent donning and doffing by participants, enhancing its practical applicability.

Author Contributions

Conceptualization, K.Y. and P.B.; methodology, K.Y.; fabrication, S.S., O.K., M.L. and G.L.-T.; investigation, M.L. and G.L.-T.; data curation, M.L.; writing—original draft preparation, M.L.; writing—review and editing, J.T.; visualization, G.L.-T. and O.K.; supervision, K.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Innovate UK, project number 10045467, under the project title “Reliable and Accessible Electronic Textile for Stroke Rehabilitation”.

Institutional Review Board Statement

The study was approved by the Faculty of Arts and Humanities Ethics Committee at the University of Southampton on 21/02/2022 with a submission ID of ERGO 70296.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data supporting this study’s results are available within the article.

Acknowledgments

The authors would like to thank the stroke survivors at Different Strokes Southampton for attending the prototype testing sessions. The authors would like to thank Cotronics Manufacturing Ltd. for providing the connector used in this study.

Conflicts of Interest

The authors declare no conflicts of interest. The conductive tracks were fabricated by Conductive Transfers Limited, an engagement that was solely for acquiring the necessary materials without influencing the research process or its outcomes. Additionally, the fabrication of the fabric, along with the test results and data acquisition, were conducted at the University of Southampton.

References

- Patel, A.; Berdunov, V.; Quayyum, Z.; King, D.; Knapp, M.; Wittenberg, R. Estimated societal costs of stroke in the UK based on a discrete event simulation. Age Ageing 2020, 49, 270–276. [Google Scholar] [CrossRef] [PubMed]

- Stroke Statistics. Available online: https://www.stroke.org.uk/what-is-stroke/stroke-statistics (accessed on 6 September 2023).

- Liu, M.; Ward, T.; Keim, O.; Yin, Y.; Tudor, M.; Yang, K. Smart Textile with Integrated Functional Electrical Stimulation and Movement Sensor for Hand Exercise. In Proceedings of the Annual Conference of the International Functional Electrical Stimulation Society (IFESS): RehabWeek 2022, Rotterdam, The Netherlands, 25–29 July 2022. [Google Scholar] [CrossRef]

- Liu, M.; Ward, T.; Keim, O.; Yin, Y.; Taylor, P.; Tudor, J.; Yang, K. Design and Test of E-Textiles for Stroke Rehabilitation. Eng. Proc. 2023, 30, 16. [Google Scholar] [CrossRef]

- Elastomeric. Available online: https://www.yeoman-yarns.co.uk/product/elastomeric/ (accessed on 15 January 2024).

- Fluid. Available online: https://www.yeoman-yarns.co.uk/product/fluid/ (accessed on 15 January 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).