Abstract

In this work, an amperometric biosensor for lactate determination based on a sonogel–carbon transducer has been developed and evaluated using the lactate oxidase enzyme coated with a multipolymer layer as a bioreceptor. The biosensor obtained had adequate sensitivity (4.16 × 10−8 A mM−1) and a wide linear working range (0.2–20 mM) that allowed for the determination of lactate at high concentrations without showing enzyme saturation phenomena. The selectivity of the biosensor was also verified using interferents commonly observed in physiological samples. Moreover, a microfluidic cell was designed and fabricated to allow the determination of lactate with the proposed biosensor in a continuous regime. In the end, the viability of the biosensor was tested with the proposed flow system using synthetic samples, obtaining excellent results.

1. Introduction

In recent years, there has been an increasing interest in lactate determination due to the fundamental role it plays in many areas. High lactate levels in the human body can occur because of various pathological diseases [1]. Due to this fact, lactate quantification could be essential to the diagnosis of these pathologies, the prognosis of patient survival and the evaluation of the success of the treatment. Therefore, there is a need for a reliable, real-time determination method in the biomedical field. In general, traditional methods of lactate detection and quantification are complex, and require long analysis times, specialized personnel and/or the use of expensive instrumentation. Therefore, their integration in the field of biomedicine is very challenging, making it necessary to develop faster, more efficiently, cheaper and easier-to-implement methodologies [2,3].

Biosensors, in particular those using an enzyme as a bioreceptor, can overcome these limitations and offer an advantageous alternative to conventional techniques. These devices combine the high sensitivity and specificity of biological components with physicochemical transducers to provide complex analytical measurements in simple and easy-to-use formats [4]. In addition, they offer the possibility of discrete or continuous measurements, providing fast and reliable results. For continuous determination, the use of microfluidic cells is recommended, where the sample volume required for analysis is much smaller than for batch measurements. One of the options for building microfluidic cells is to print them using additive technology [5,6].

In this work, handmade ceramic sonogel–carbon electrodes have been prepared and modified with several layers of Prussian Blue, lactate oxidase with gold nanoparticles, and protective polymers to obtain a lactate biosensor. This device has been tested in the determination of lactate in both the batch and continuous mode. The repeatability, reproducibility, stability of the signal and lifetime of the biosensor have been studied as well. Finally, the biosensor has been applied successfully in the monitoring of lactate in complex synthetic samples.

2. Materials and Methods

2.1. Preparation of Sonogel–Carbon Electrode

The sonogel–carbon (SNGC) electrodes were prepared as reported elsewhere [7]. Briefly, a reaction mixture was prepared from 100 μL of a 0.2 M hydrochloric acid solution and 500 μL of the methylmethoxysilane (MTMOS) precursor. The mixture was sonicated for 10 s, by using a high-power ultrasound probe at 40% of amplitude. Then, 500 mg of spectroscopic-grade graphite was added and homogeneously mixed into a paste. Afterwards, the fabrication of the electrodes was carried out by filling capillary tubes with the prepared material. The electrodes (geometric area: 1.04 × 10−2 cm2) were ready to be used after a gentle polishing of the surface with P1200 emery paper (Struers, Germany) and establishing electrical contact by inserting a copper wire.

Before being used, the working SNGC electrodes were electrochemically activated in 0.1 M H2SO4 aqueous solution by two polarization steps at −0.7 V for 10 s, and at +1.8 V for 10 s, respectively. This electrochemical procedure was repeated four times.

2.2. Synthesis of Gold Sononanoparticles

Gold sononanoparticles were synthesized following the method described previously [8]. In the first place, 1.25 mL of 1.5 mM KAuCl4 aqueous solution was placed in a cylindrical glass vessel and sonicated with a high-power ultrasound generator at 13% amplitude. After 1.5 min of sonication, 250 μL of 38.8 mM sodium citrate aqueous solution was added to the vessel. The color of the solution turns into dark red wine after 4 min, indicative of the formation of AuSNPs. The sample vessel was maintained during the 5.5 min of the process in a water bath at ambient temperature to prevent local heating produced by the sonication.

2.3. Fabrication of the Lactate Biosensor

The lactate biosensor was prepared using a layer-by-layer modification method. Firstly, a mediator layer of Prussian Blue (PB) was drop-casted into the sonogel–carbon electrode surface by mixing 2 μL of a 0.1 M KCl, 0.1 M FeCl3 and 0.01 M HCl solution and 2 μL of a 0.1 M KCl, 0.1 M K3Fe(CN)6 and 0.01 M HCl solution. The mixture was removed after 20 min. Then, the electrode was rinsed with 0.01 M HCl and Milli-Q grade water and subsequently annealed in the oven at 100 °C for 1 h.

Secondly, the enzyme layer was prepared by drop-casting 5.5 μL of a mixture containing 2.2 mg of lactate oxidase in 260 μL of AuSNPs solution. This layer was dried for 3 h. Afterwards, the diffusion membrane was prepared by assembling several polymeric layers. For the first one, 4 μL of a 1% w/v chitosan in 0.1 M acetic acid (pH 4.5) solution was drop-casted and dried for 2 h. Then, 1 μL of a solution of 10 mg/mL PVC in tetrahydrofuran was drop-casted twice and dried in a few minutes. Finally, 0.5 μL of 1% Nafion solution in ethanol (pH 7.5) was drop-casted and dried for 2 h. All the drying steps were performed at room temperature and in darkness.

2.4. Analytical Performance of the Biosensor in Batch Mode

The electrochemical performance of the prepared device was characterized in an electrochemical cell constituted by the lactate biosensor as a working electrode, an Ag/AgCl/KCl 3 M electrode as the reference electrode and a platinum electrode as the auxiliary electrode. The chronoamperometry technique was selected for the measurements applying 0.20 V, whereas 0.1 M K2HPO4 and 0.1 M KH2PO4 buffer solution (PBS) with pH 7.4 was used due to similarity with a physiological medium. Calibration of the biosensor in the presence of lactate was performed using concentrations ranging from 0.2 to 20 mM by adding adequate volumes from 1000 to 100 mM lactate stock solutions in PBS. Signal stability was recorded in buffer solution for 8 h and lifetime was recorded in 2 mM lactate solution after up to 21 days.

2.5. Analysis in Continuous Mode

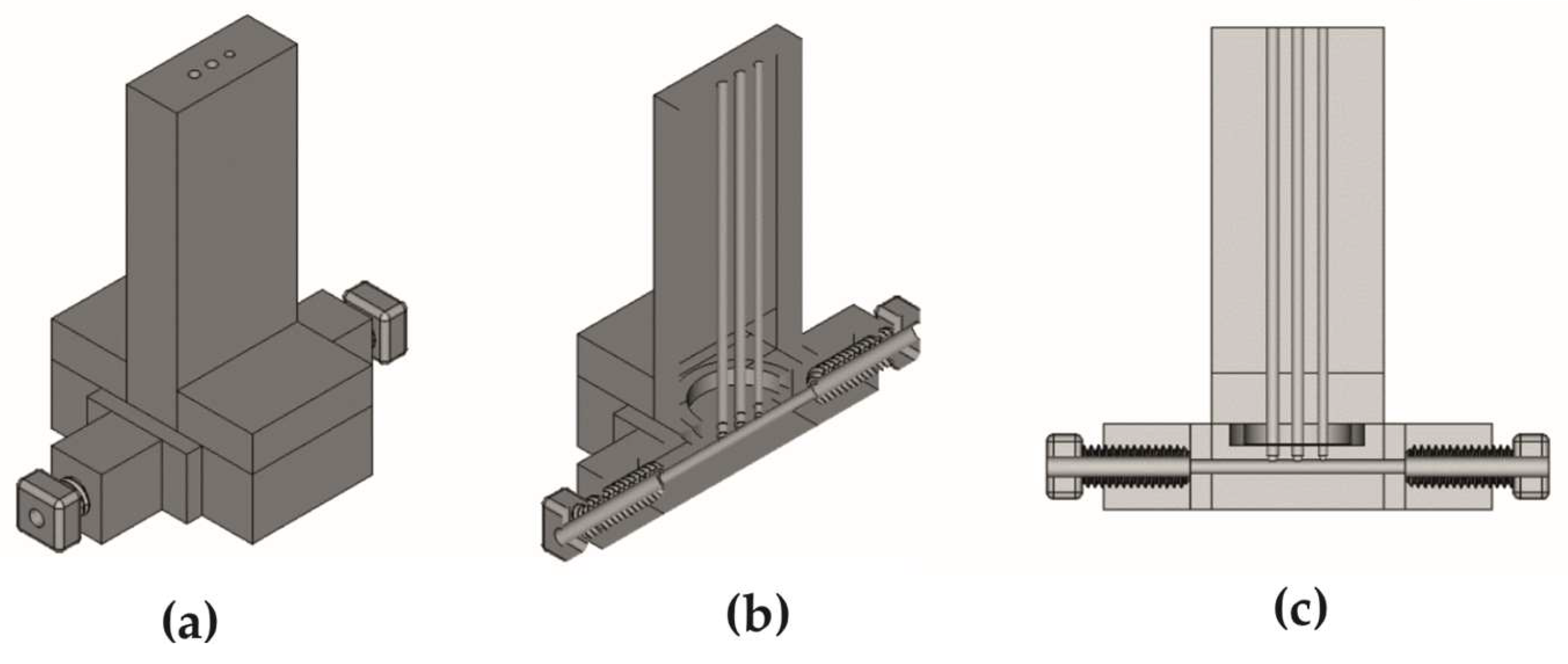

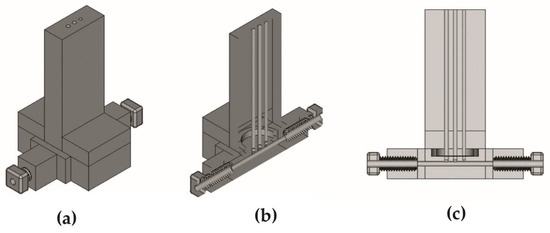

A 3D microfluidic cell was designed for the application of the lactate biosensor in continuous mode by using FreeCAD software. This cell was printed with a 3D printer Original Prusa MINI+ (Prusa, Czech Republic) using polyethylene terephthalate glycol (PTEG) as polymeric filament. The structure of the designed piece is shown in Figure 1.

Figure 1.

Microfluidic cell design images: (a) isometric view; (b) isometric view with cut in plane Y; (c) lateral view with cut in plane Y.

This electrochemical cell was constituted by the lactate biosensor as a working electrode, a bare SNG-C electrode as an auxiliary electrode and a silver rod with polyvinyl butyral and polyurethane protection as a reference electrode. The solution was pushed to the cell with a peristaltic pump working at 0.4 mL/min flow. A working potential of 0.02 V was used with the chronoamperometric technique, whereas the calibration of the biosensor in the presence of lactate was performed using stock solutions with concentrations ranging from 0.2 to 20 mM in PBS. Finally, synthetic samples were prepared by imitating an artificial interstitial fluid (105 mM NaCl, 26 mM NaHCO3, 4 mM KCl, 1.7 mM Na2HPO4, 1.2 mM CaCl2, 4.7 mM Glucose, 2.5 mM Urea and 0.1% Albumin) and adding adequate amount of 100 mM lactate stock solution to reach 2 and 4 mM of lactate.

3. Results and Discussion

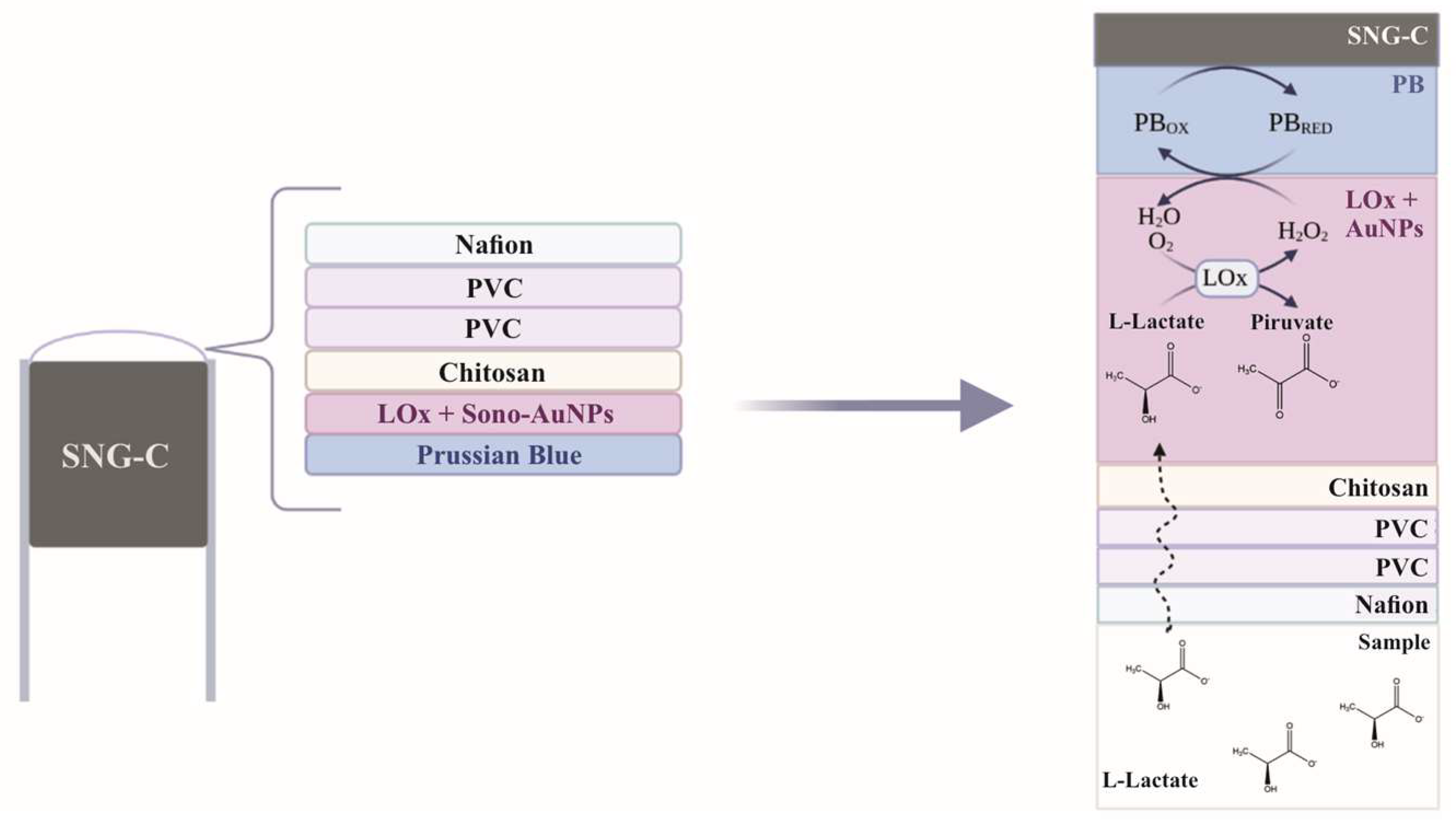

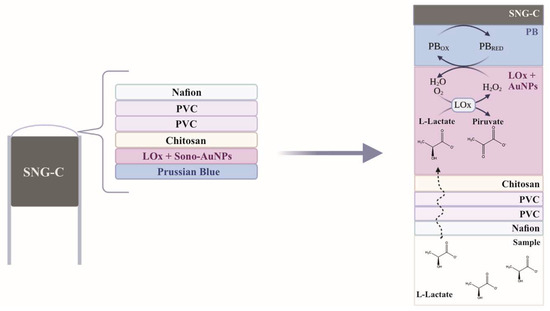

The layers disposition in the lactate biosensor developed and their theoretical performance is shown in Figure 2. Briefly, lactate in media diffuses through the semipermeable membrane composed of several layers of polymers. The amount of lactate is restrained by this diffusion membrane to avoid enzyme saturation phenomena of the biosensor and extend the working linear range until 20 mM. Lactate reduction to pyruvate is selectively promoted by the lactate oxidize enzyme in the next layer, boosted by the gold sononanoparticles while being protected by the chitosan layer. Finally, an excess of PB reduces all the H2O2 produced by the oxidation of lactate, whereas the amount of analyte can be estimated by the subsequent reduction in PB at a low working potential (0.02–0.2 V). The developed biosensor has been named SNGC-PB-LOxAuNPs-Chit-PVC-Naf.

Figure 2.

Scheme of the layers configurations in the lactate biosensor developed and the proposed electrochemical reaction mechanism.

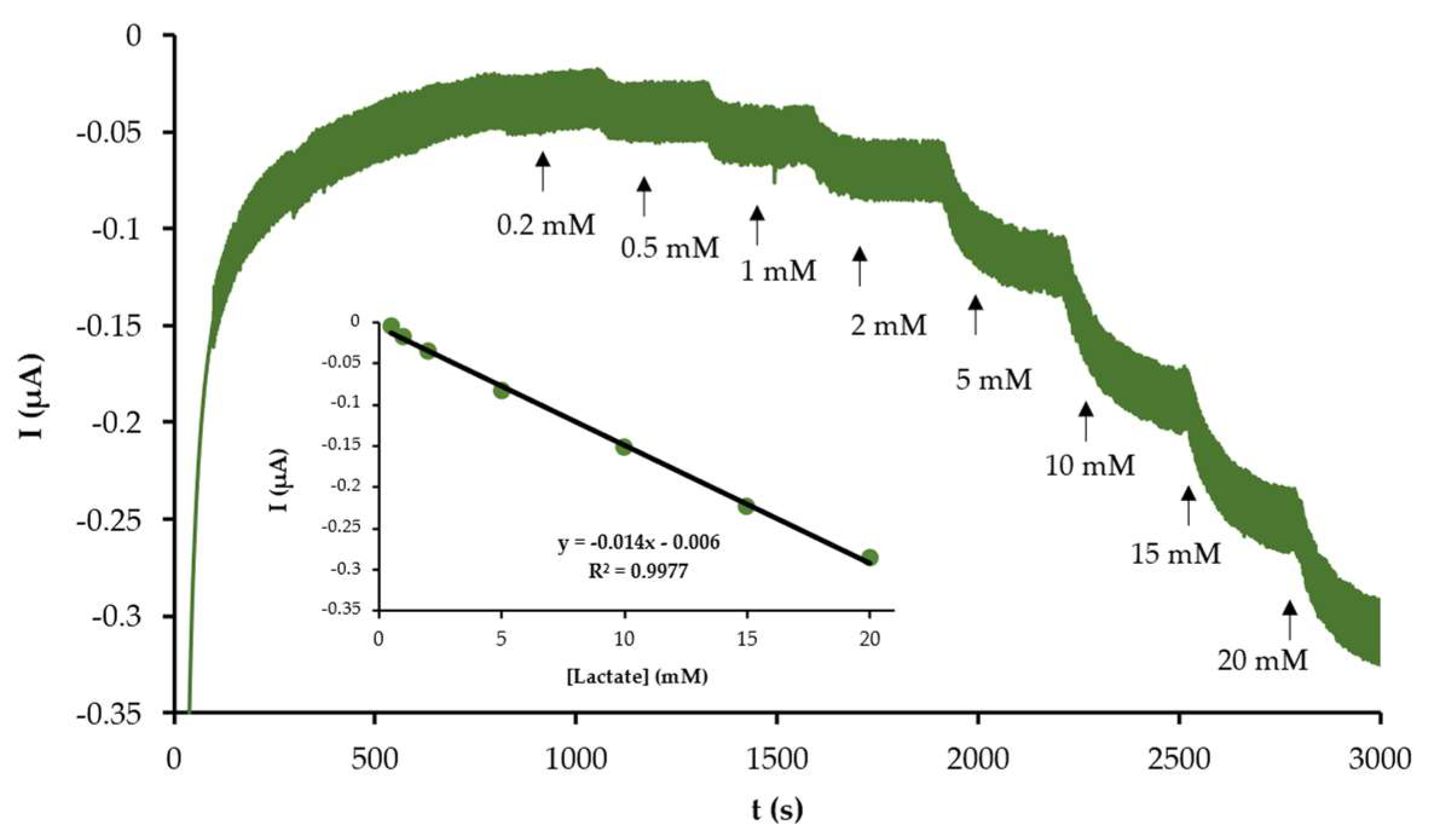

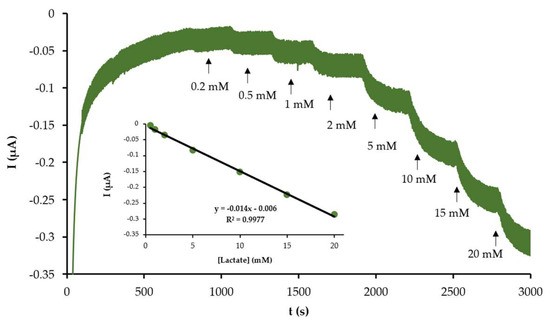

3.1. Assert the Electroanalytical Performance of the Biosensor

The biosensor electroanalytical performance was first tested in batch mode to verify their applicability. The calibration with lactate was carried out in the concentration range of 0.2–20 mM, a higher concentration found in human blood, as described in the experimental Section 2.4. The signal recorded with the developed device drops with each addition, as can be observed in Figure 3. As shown in the inset of this figure a great linear relationship was established between the current intensity fall and lactate concentration, with an excellent correlation coefficient (R2) of 0.9977. The sensitivity was calculated as the slope of the calibration curve. The average sensitivity of the developed biosensor was 4.16 × 10−8 A mM−1, whereas the limit of detection was 0.057 mM calculated as three times the standard deviation of the blank divided by the slope. Thus, this device can be applied to the determination of lactate in a wide linear range with great sensitivity.

Figure 3.

Chronoamperogram recorded with an SNGC-PB-LOxAuNPs-Chit-PVC-Naf biosensor in batch mode in presence of different concentrations of lactate: 0.2, 0.5, 1, 2, 5, 10, 15 and 20 mM. The inset displays the calibration plot obtained.

Furthermore, the repeatability and reproductivity of the developed device were also calculated by measuring a solution with 2 mM of lactate with three biosensors several times. Hence, the relative standard deviation (RSD) of the repeatability was 3.17%, whereas the RSD for reproductivity was 6.36%. The stability of the signal of the biosensor was also studied by recording it during 8 h and no significant change was observed. Finally, the lifetime of the device was tracked for 21 days while keeping it in PBS in darkness and cold. The signal was measured in 2 mM lactate solution and the obtained current intensity was almost invariable for 15 days, which suggests a degradation of the layers of the biosensors after more than two weeks. All these results suggest the robustness of this device in the determination of lactate.

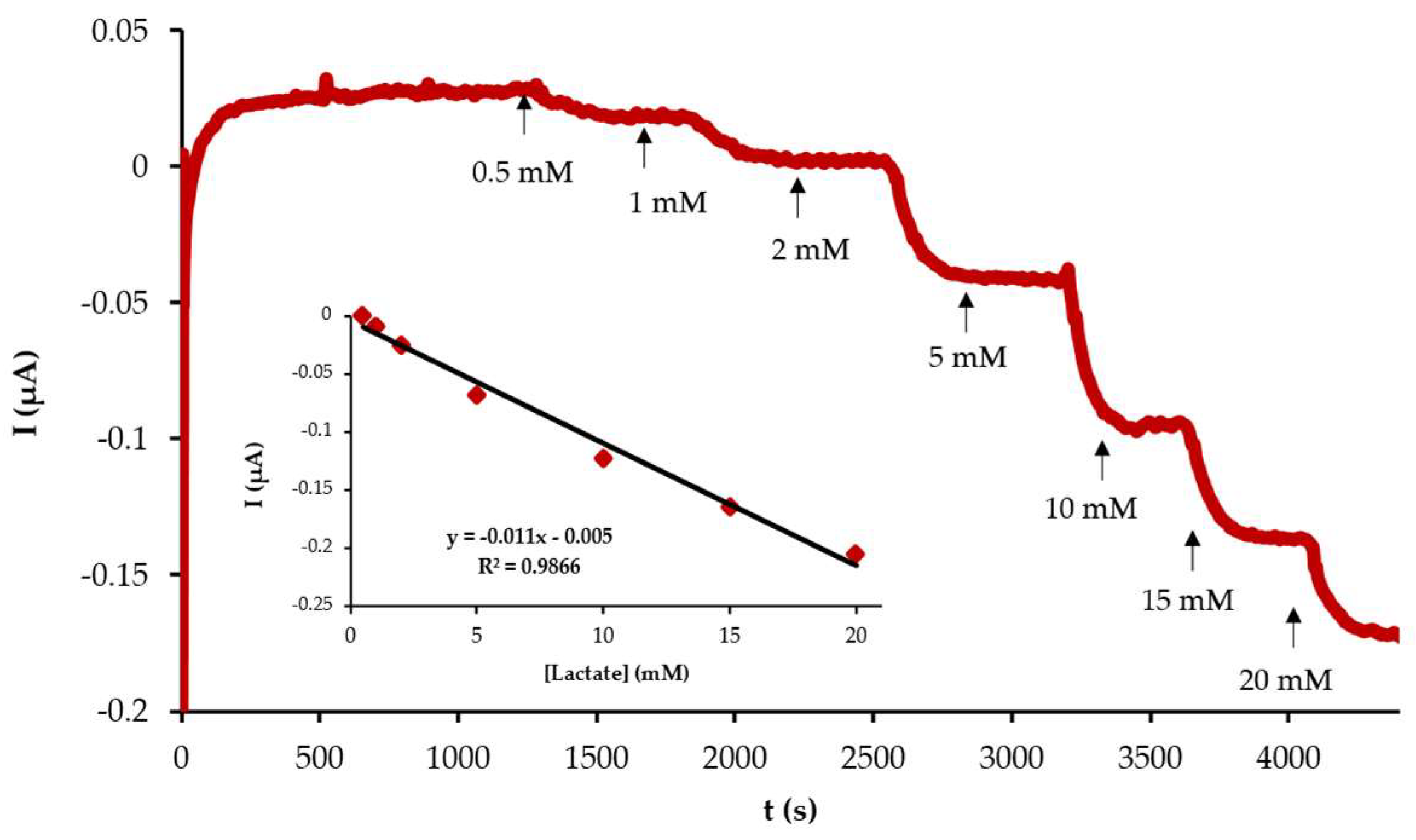

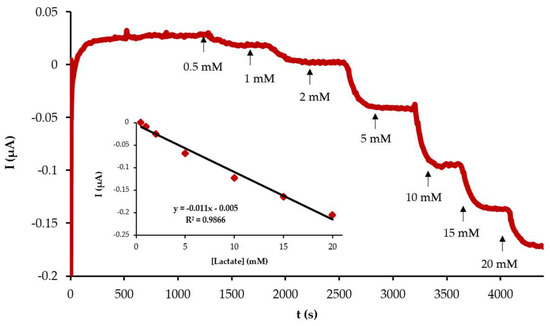

3.2. Applicability of the Biosensor in the Monitoring of Lactate

The next step was to test the biosensor in a continuous mode to determine its applicability in the monitoring of lactate in the human body. A microfluidic cell for the application of the biosensor in continuous mode was designed to be fabricated by 3D impression. The tailoring process aided in creating a specific cell to fulfil the requirements of the size of the electrodes as well as minimize the volume of the sample at the same time. The entry and exit of the cell had connected polytetrafluoroethylene tubes to flow the working solutions by using a peristaltic pump, as described in experimental Section 2.5. The signal with PBS was stable and the calibration with several stock solutions of lactate was carried out. The intensity of the signal falls with each stock solution, as can be observed in Figure 4. Moreover, the linear relationship was great as shown in the inset of the figure, with a correlation coefficient (R2) of 0.9866. As expected, the sensitivity calculated in this mode was lower than the one obtained in batch mode due to less exposure time between the biosensor and the working solution [9]. These results validate the use of the designed microfluidic cell and the use of the biosensor for continuous monitoring of lactate.

Figure 4.

Chronoamperogram recorded with an SNGC-PB-LOxAuNPs-Chit-PVC-Naf biosensor in a microfluidic cell in presence of different concentrations of lactate: 0.5, 1, 2, 5, 10, 15 and 20 mM. The inset displays the calibration plot obtained.

Finally, the developed device was applied in the continuous determination of lactate in synthetic samples. This sample simulates the matrix of a biological sample of interstitial fluid to study the applicability of the biosensor in this complex medium. Two samples with lactate concentrations of 2 and 4 mM were prepared and measured. The recovery factor for the samples, calculated as the lactate concentration determined divided by lactate concentration spiked, was 103 ± 2% for the 2 mM sample and 95 ± 5% for the 4 mM sample. These excellent results suggest a nearly negligible effect of the matrix in the lactate determination and potential applicability of the developed biosensor in the analysis of human biological real samples.

4. Conclusions

In this work, a new lactate biosensor has been prepared by a layer-by-layer modification of a handmade ceramic electrode with a redox mediator, an enzyme and nanoparticles amplifier, and several polymers as diffusion membranes. This configuration has been an appropriate design to reach high lactate concentration (20 mM) without enzyme saturation phenomena obtaining also great sensitivity and limit of detection values. Moreover, a cheap and versatile microfluidic cell has been prepared by 3D impression and the applicability of the biosensor in the continuous monitoring of lactate in complex samples has been proved. These excellent results give us hope to apply them in the successful monitoring of lactate in human bodies.

Author Contributions

Conceptualization, D.B.-M. and L.C.-A.; methodology, J.J.G.-G.; software, J.J.G.-G.; validation, J.M.P.-S. and D.B.-M.; formal analysis, L.B.-D.; investigation, A.S.-P. and L.B.-D.; resources, J.J.G.-G.; data curation, L.B.-D.; writing—original draft preparation, A.S.-P.; writing—review and editing, J.J.G.-G. and D.B.-M.; visualization, J.M.P.-S.; supervision, D.B.-M.; project administration, L.C.-A.; funding acquisition, J.M.P.-S. All authors have read and agreed to the published version of the manuscript.

Funding

Authors thank Agencia Estatal de Investigación (AEI), Ministerio de Ciencia e Innovación of Spain and FEDER funds (EU) for the ‘Multibioanalysis’ research project (Proyecto de Generación del Conocimiento, PID2021-122578NB-I00) financed by MCIN/AEI/10.13039/501100011033/FEDER, UE “ERDF A way of making Europe”. They also thank ‘Plan Propio 2022–2023′ from University of Cadiz for their funding through the “Acceso al uso de Servicios Centrales de Investigación. Financiación de Actividades” (Ref: SC2022–001) and the “Proyectos Noveles” para impulsar su Carrera Científica” (Ref: PR2022-025, SENSPOT) programs. Finally, authors acknowledge the funds provided by Junta de Andalucía and University of Cadiz through the program “Ayudas a los Grupos de Investigación adscritos a la Universidad de Cádiz”, Calls 2022 and 2023.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Rattu, G.; Khansili, N.; Maurya, V.K.; Krishna, P.M. Lactate detection sensors for food, clinical and biological applications: A review. Environ. Chem. Lett. 2021, 19, 1135–1152. [Google Scholar] [CrossRef]

- Nikolaus, N.; Strehlitz, B. Amperometric lactate biosensors and their application in (sports) medicine, for life quality and wellbeing. Microchim. Acta 2008, 160, 15–55. [Google Scholar] [CrossRef]

- Liu, M.; Yang, M.; Wang, M.; Wang, H.; Cheng, J. A Flexible Dual-Analyte Electrochemical Biosensor for Salivary Glucose and Lactate Detection. Biosensors 2022, 12, 210. [Google Scholar] [CrossRef] [PubMed]

- García-Guzmán, J.J.; Sierra-Padilla, A.; Palacios-Santander, J.M.; Fernández-Alba, J.J.; Macías, C.G.; Cubillana-Aguilera, L. What Is Left for Real-Life Lactate Monitoring? Current Advances in Electrochemical Lactate (Bio)Sensors for Agrifood and Biomedical Applications. Biosensors 2022, 12, 919. [Google Scholar] [CrossRef] [PubMed]

- Rathee, K.; Dhull, V.; Dhull, R.; Singh, S. Biosensors based on electrochemical lactate detection: A comprehensive review. Biochem. Biophys. Rep. 2016, 5, 35–54. [Google Scholar] [CrossRef] [PubMed]

- Alimi, O.A.; Meijboom, R. Current and future trends of additive manufacturing for chemistry applications: A review. J. Mater. Sci. 2021, 56, 16824–16850. [Google Scholar] [CrossRef] [PubMed]

- Cordero-rando, M.M.; De Cisneros, L.H.; Blanco, E.; Naranjo-Rodríguez, I. The Sonogel-Carbon Electrode As a Sol—Gel Graphite-Based Electrode. Anal. Chem. 2002, 74, 2423–2427. [Google Scholar] [CrossRef] [PubMed]

- Cubillana-Aguilera, L.M.; Franco-Romano, M.; Gil, M.L.A.; Naranjo-Rodríguez, I.; De Cisneros, J.L.H.-H.; Palacios-Santander, J.M. New, fast and green procedure for the synthesis of gold nanoparticles based on sonocatalysis. Ultrason. Sonochem. 2011, 18, 789–794. [Google Scholar] [CrossRef] [PubMed]

- Baronas, R.; Ivanauskas, F.; Kulys, J. Modelling dynamics of amperometric biosensors in batch and flow injection analysis. J. Math. Chem. 2002, 32, 225–237. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).