Development of a Chemical Sensor Based on Deep Eutectic Solvents and Its Application for Milk Analysis †

Abstract

:1. Introduction

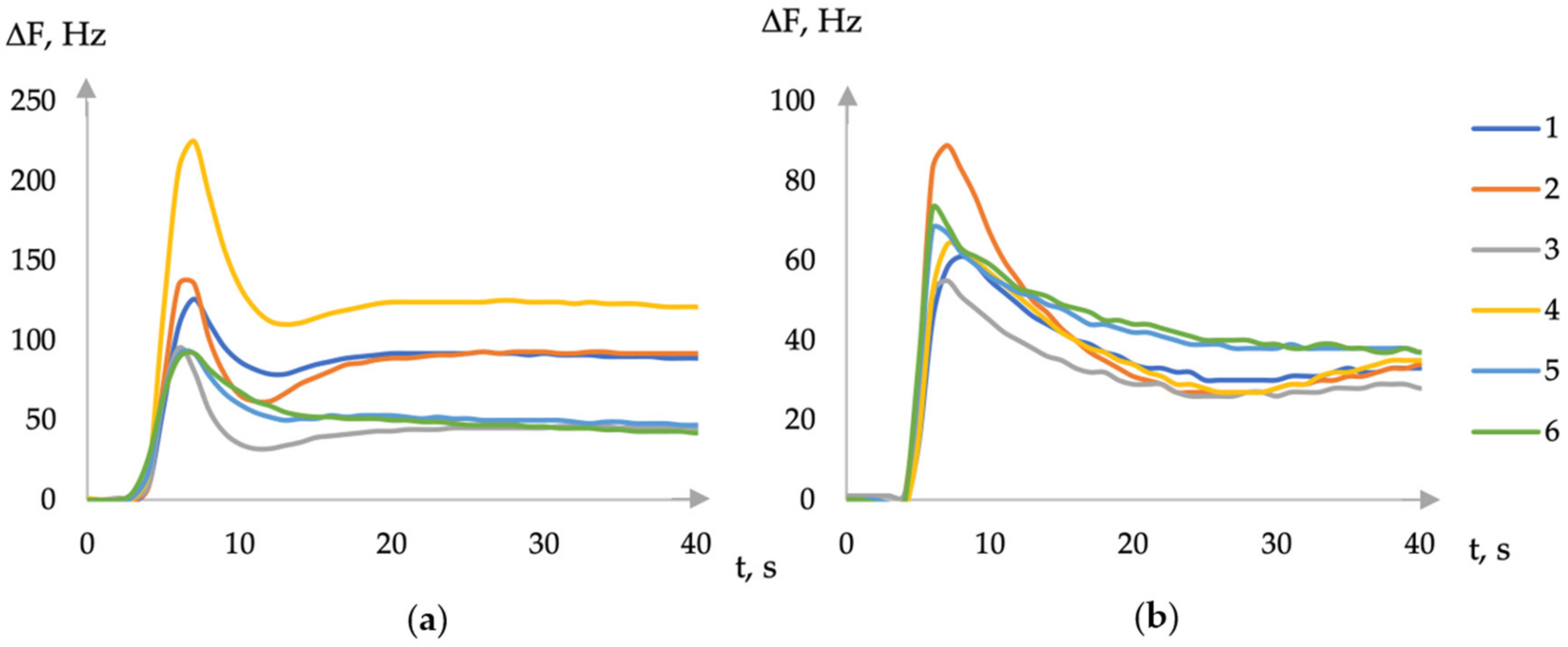

2. Materials and Methods

2.1. Preparation of Deep Eutectic Solvents

2.2. Formation and Analysis of Sensitive Layers of Sensors Based on a Deep Eutectic Solvent

2.3. Estimation of Volatile Compounds Sorption Features via Coating Based on a Deep Eutectic Solvent

2.4. Milk Analysis

2.4.1. Determination of Physical and Chemical Properties of the Milk

2.4.2. Determination of Microbiological Indicators

2.5. Data Processing

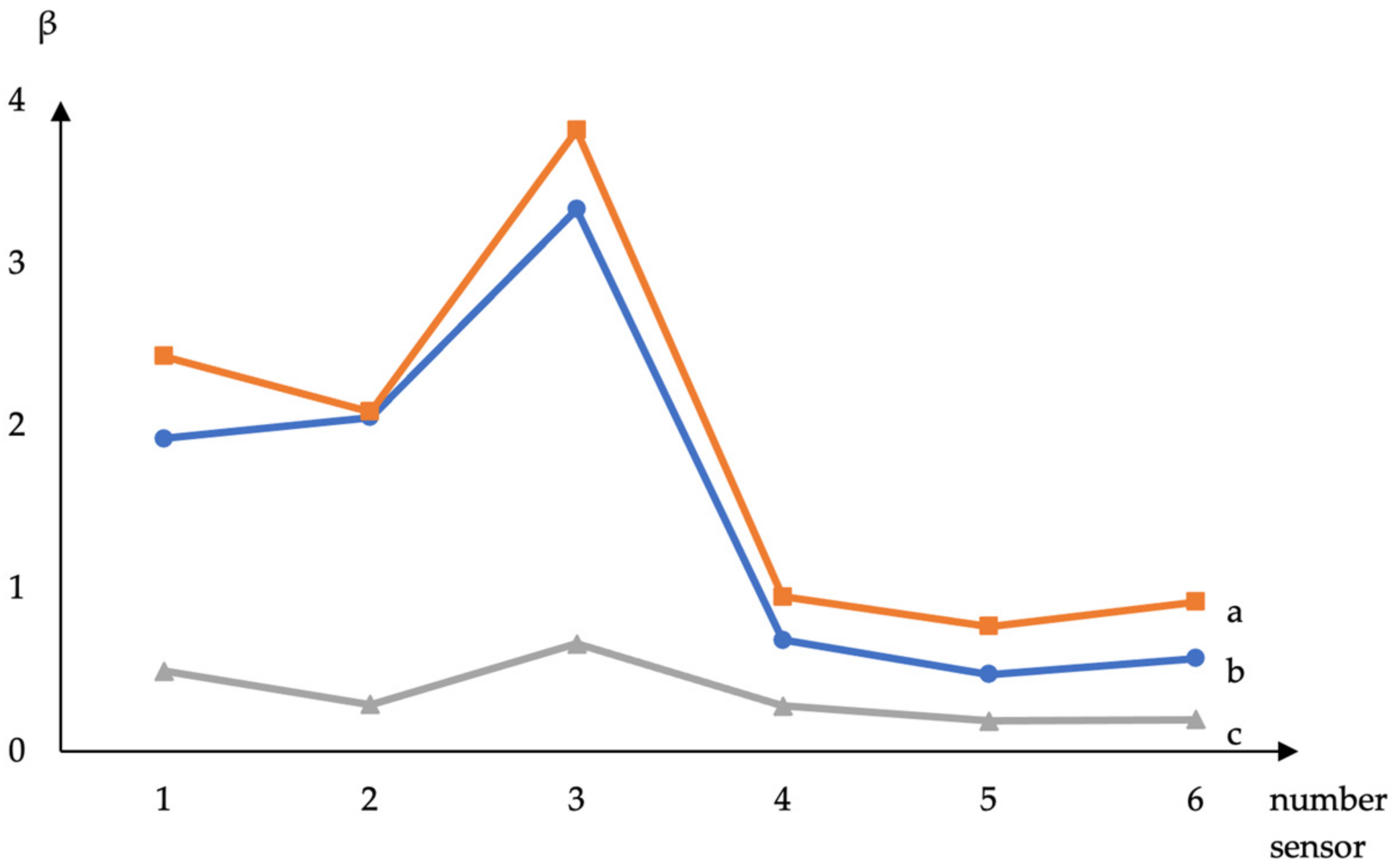

3. Results

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| No | Mass Fraction of Dry Solids, % | Mass Fraction of Fat, %, | Mass Fraction of Total Protein, % | Titratable Acidity, °Т | QMAFAnM *, CFU/mL | Quantity of Yeast CFU/mL | Quantity of Mold CFU/mL |

|---|---|---|---|---|---|---|---|

| 1 | 16.02 ± 0.12 | 7.5 ± 0.3 | 3.46 ± 0.15 | 19 ± 0.5 | 10,000,000 | 100,000 | 0 |

| 2 | 12.22 ± 0.13 | 3.8 ± 0.1 | 3.74 ± 0.10 | 20 ± 0.5 | 4,000,000 | 10,000 | 0 |

| 3 | 13.36 ± 0.08 | 4.8 ± 0.1 | 3.45 ± 0.10 | 19 ± 0.5 | 4,500,000 | 1000 | 10 |

| 4 | 15.15 ± 0.14 | 7.5 ± 0.5 | 3.26 ± 0.10 | 15 ± 0.5 | 340,000 | 0 | 0 |

| 5 | 11.63 ± 0.13 | 3.5 ± 0.1 | 3.01 ± 0.10 | 19 ± 0.5 | 2,400,000 | 1500 | 160 |

| 6 | 11.77 ± 0.11 | 3.1 ± 0.1 | 3.30 ± 0.15 | 19 ± 0.5 | 590,000 | 650 | 900 |

| 7 | 10.83 ± 0.09 | 3.9 ± 0.1 | 2.40 ± 0.10 | 15 ± 0.5 | 4,640,000 | 5680 | 0 |

| 8 | 12.31 ± 0.12 | 3.7 ± 0.1 | 3.10 ± 0.15 | 18 ± 0.5 | 98,000,000 | 8004 | 60 |

| 9 | 11.41 ± 0.06 | 3.2 ± 0.1 | 2.00 ± 0.05 | 15 ± 0.5 | 480,000 | 0 | 10 |

| 10 | 12.14 ± 0.10 | 4.1 ± 0.1 | 2.88 ± 0.10 | 16 ± 0.5 | 5,700,000 | 34,200 | 300 |

| 11 | 11.72 ± 0.07 | 3.4 ± 0.1 | 1.16 ± 0.10 | 15 ± 0.5 | 42,000,000 | 1800 | 0 |

| 12 | 10.92 ± 0.09 | 3.3 ± 0.1 | 1.35 ± 0.10 | 11 ± 0.5 | 2,000,000 | 2300 | 10 |

| 13 | 11.44 ± 0.11 | 3.6 ± 0.1 | 2.59 ± 0.15 | 17 ± 0.5 | 3,400,000 | 17,400 | 10 |

| 14 | 15.07 ± 0.15 | 6.5 ± 0.3 | 3.07 ± 0.10 | 16 ± 0.5 | 39,000,000 | 100,000 | 0 |

References

- Nazemi, H.; Joseph, A.; Park, J.; Emadi, A. Advanced Micro- and Nano-Gas Sensor Technology: A Review. Sensors 2019, 19, 1285. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.; Sikarwar, S.; Verma, A.; Yadav, B.C. The recent development of metal oxide heterostructures based gas sensor, their future opportunities and challenges: A review. Sens. Actuators A Phys. 2021, 332, 113127. [Google Scholar] [CrossRef]

- Kuchmenko, T.A.; Shuba, A.A.; Menzhulina, D.A.; Volkova, A.A.; Vecherkin, V.A.; Cornejo Tueros, J.V. On a Correlation between the Results of In-Hospital Analysis of Biosamples from Children Performed Using Standard Methods and an Array of Piezosensors. J. Anal. Chem. 2022, 77, 376–387. [Google Scholar] [CrossRef]

- Matindoust, S.; Farzi, G.; Nejad, M.B.; Shahrokhabadi, M.H. Polymer-based gas sensors to detect meat spoilage: A review. React. Funct. Polym. 2021, 165, 104962. [Google Scholar] [CrossRef]

- Yuan, H.; Li, N.; Fan, W.; Cai, H.; Zhao, D. Metal–organic Framework Based Gas Sensors. Adv. Sci. 2021, 9, 2104374. [Google Scholar] [CrossRef] [PubMed]

- Masuda, Y. Recent advances in SnO2 nanostructure based gas sensors. Sens. Actuators B Chem. 2022, 364, 131876. [Google Scholar] [CrossRef]

- Kuchmenko, T.A.; Menzhulina, D.A.; Murakhovskii, I.A. Using Highly Sensitive Piezo Sensors in an Open System for the Diagnostic Analysis of Skin Volatile Substances. J. Anal. Chem. 2023, 78, 1013–1028. [Google Scholar] [CrossRef]

- Norizan, M.N.; Moklis, M.H.; Demon, S.Z.N.; Halim, N.A.; Samsuri, A.; Mohamad, I.S.; Knight, V.F.; Abdullah, N. Carbon nanotubes: Functionalisation and their application in chemical sensors. RSC Adv. 2020, 10, 43704–43732. [Google Scholar] [CrossRef] [PubMed]

- Fauzi, F.; Rianjanu, A.; Santoso, I.; Triyana, K. Gas and humidity sensing with quartz crystal microbalance (QCM) coated with graphene-based materials—A mini review. Sens. Actuators A Phys. 2021, 330, 112837. [Google Scholar] [CrossRef]

- Shakeel, A.; Rizwan, K.; Farooq, U.; Iqbal, S.; Altaf, A.A. Advanced polymeric/inorganic nanohybrids: An integrated platform for gas sensing applications. Chemosphere 2022, 294, 133772. [Google Scholar] [CrossRef] [PubMed]

- Shuba, A.; Kuchmenko, T.; Umarkhanov, R. Piezoelectric Gas Sensors with Polycomposite Coatings in Biomedical Application. Sensors 2022, 22, 8529. [Google Scholar] [CrossRef] [PubMed]

- Shuba, A.; Kuchmenko, T.; Umarkhanov, R.; Bogdanova, E. Composite Coatings of Piezoelectric Quartz Sensors Based on Viscous Sorbents and Casein Micelles. In Proceedings of the XVII International Research Conference Proceedings, Istanbul, Türkiye, 24–25 April 2023. [Google Scholar]

- Kuchmenko, T.; Menzhulina, D.; Shuba, A. Noninvasive Detection of Bacterial Infection in Children Using Piezoelectric E-Nose. Sensors 2022, 22, 8496. [Google Scholar] [CrossRef] [PubMed]

- GOST R 54668-2011; Milk and Milk Products. Methods for Determination of Moisture and Dry Substance mass Fraction. Standartinform: Moscow, Russia. Available online: https://internet-law.ru/gosts/gost/52063/ (accessed on 7 August 2023). (In Russian)

- GOST 5867-90; Milk and Dairy Products. Methods of Determination of Fat. Standartinform: Moscow, Russia. Available online: https://internet-law.ru/gosts/gost/2476/ (accessed on 7 August 2023). (In Russian)

- GOST 25179-2014; Milk and Milk Products. Method for Determination of Protein. Standartinform: Moscow, Russia. Available online: https://internet-law.ru/gosts/gost/58007/ (accessed on 7 August 2023). (In Russian)

- GOST R 54758-2011; Milk and Milk Products. Methods for Determination of Density. Standartinform: Moscow, Russia. Available online: https://internet-law.ru/gosts/gost/52080/ (accessed on 7 August 2023). (In Russian)

- GOST R 54669-2011; Milk and Milk Products. Methods for Determination of Acidity. Standartinform: Moscow, Russia. Available online: https://internet-law.ru/gosts/gost/52065/ (accessed on 7 August 2023). (In Russian)

- GOST 8218-89; Milk Method of Purity Determination. Standartinform: Moscow, Russia. Available online: https://internet-law.ru/gosts/gost/38652/ (accessed on 7 August 2023). (In Russian)

- GOST 32901-2014; Milk and Milk Products. Methods of Microbiological Analysis. Standartinform: Moscow, Russia. Available online: https://docs.cntd.ru/document/1200115745 (accessed on 7 August 2023). (In Russian)

- GOST 33566–2015; Milk and Dairy Products. Determination of Yeasts and Molds. Standartinform: Moscow, Russia. Available online: https://internet-law.ru/gosts/gost/61246/ (accessed on 7 August 2023). (In Russian)

- Doerffel, K. Statistics in Analytical Chemistry, 5th ed.; Dt. Verlag für Grundstoffindustrie, Cop.: Leipzig, Germany, 1990; 256p. [Google Scholar]

| Covering | Acetic Acid | Butyric Acid | Ethanol | Butanol | Butanol-2 | Acetaldehyde | Film Masses | Baseline Drift *, kHz |

|---|---|---|---|---|---|---|---|---|

| choline + erythritol | 11.96 | 17.59 | 0.54 | 0.57 | 0.13 | 2.20 | 8.81 | 4.22 |

| choline + xylitol | 12.21 | 9.56 | 0.45 | 0.39 | 0.11 | 2.13 | 8.58 | 1.415 |

| choline + sorbitol | 11.25 | 10.13 | 0.46 | 0.34 | 0.08 | 1.93 | 15.47 | 0.644 |

| choline + erythritol + ASO | 6.54 | 23.84 | 0.50 | 1.17 | 0.14 | 2.06 | 5.29 | 0.213 |

| choline + xylitol + ASO | 4.63 | 32.20 | 0.52 | 2.75 | 0.19 | 1.65 | 4.56 | 0.563 |

| choline + sorbitol + ASO | 4.94 | 24.93 | 0.43 | 1.49 | 0.15 | 1.69 | 5.71 | 0.544 |

| Sensors Parameter | Titratable Acidity, °Т | Sensor Parameter | Quantity of Mold CFU/mL | Sensor Parameter | Quantity of Yeast CFU/mL |

|---|---|---|---|---|---|

| ΔFmax, choline+sorbitol | 0.609 | ΔF80s, choline+sorbitol | 0.643 | ΔFmax, choline+erythritol+ASO | 0.830 |

| βcholine+sorbitol | 0.679 | βcholine+erythritol+ASO | 0.868 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shuba, A.; Anokhina, E.; Umarkhanov, R.; Bogdanova, E. Development of a Chemical Sensor Based on Deep Eutectic Solvents and Its Application for Milk Analysis. Eng. Proc. 2023, 48, 34. https://doi.org/10.3390/CSAC2023-14889

Shuba A, Anokhina E, Umarkhanov R, Bogdanova E. Development of a Chemical Sensor Based on Deep Eutectic Solvents and Its Application for Milk Analysis. Engineering Proceedings. 2023; 48(1):34. https://doi.org/10.3390/CSAC2023-14889

Chicago/Turabian StyleShuba, Anastasiia, Ekaterina Anokhina, Ruslan Umarkhanov, and Ekaterina Bogdanova. 2023. "Development of a Chemical Sensor Based on Deep Eutectic Solvents and Its Application for Milk Analysis" Engineering Proceedings 48, no. 1: 34. https://doi.org/10.3390/CSAC2023-14889

APA StyleShuba, A., Anokhina, E., Umarkhanov, R., & Bogdanova, E. (2023). Development of a Chemical Sensor Based on Deep Eutectic Solvents and Its Application for Milk Analysis. Engineering Proceedings, 48(1), 34. https://doi.org/10.3390/CSAC2023-14889