Abstract

The aim of this work was the synthesis of functional hydrogel materials obtained via photopolymerization. The resulting systems were characterized in terms of chemical structure using Fourier transform infrared spectroscopy. Subsequently, their sorption capacity and surface morphology were determined along with roughness analysis. The resulting materials have been modified with fluorescein dye and can be used in many branches of industry and medicine, for example, in innovative diagnostic systems.

1. Introduction

The properties of hydrogel, like any material, depend on the stimuli acting on it. Known also as superabsorbents due to their high reversible absorption of water capacity, these materials do not react in contact with it [1,2]. Hydrogels can be formed from a variety of substances, such as poly(ethylene glycol), poly(N-vinylpyrrolidone), poly(vinyl alcohol), methacrylic acid, acrylic acid, poly(aspartic acid), maleic anhydride or polysaccharides. Their resistance to external factors depends on what substances their material is made of [3]. One of the most popular ways of delivering the drug is orally in the form of hydrogel. In the digestive tract, there are various environments, both acidic and alkaline. Due to their free swelling ability in an acidic medium such as gastric juice, it is possible for hydrogels to release drugs, e.g., for the treatment of gastric ulcers. These are hydrogels based on N-vinylpyrrolidone, aryl acid, chitosan or polyethylene glycol diacetate, among others. With the increase in pH, the swelling rate increases, greatly increasing above pH = 7. The intestines have an alkaline environment, where the process occurs faster [4,5]. Temperature is also a factor that can affect the swelling coefficient; the higher the ambient temperature, the slower the hydrogel material swells [6]. At low temperatures, some hydrogels are liquid; the structure of the hydrogel is preserved at the temperature of the human body. Some hydrogels are crosslinked by freezing. The high incubation temperature reduces the swelling rate of the material [7,8]. A sample not stored in water releases water from its structure via evaporation. Hydrogels are being tested for use as artificial muscles. This application is made possible via the shrinking and stretching of the difference in the concentration of hydrogen ions in the liquid surrounding the material [9,10]. Based on many studies, it has been proven that the ions contained in the surrounding liquid have a major influence on the sorption capacity of hydrogels and the density of the polymer network. Studies show a high absorption capacity of distilled water, which does not contain added elements, while the smallest capacity is found in SBF liquid, where elements such as Na+, K+, Mg2+, Ca2+, Cl−, HCO3−, HPO42− or SO42− are present [11,12]. Light plays an important role because some polymers are crosslinked under UV conditions. This makes it possible to restore bonds in degraded materials, e.g., those degraded via the oxidation and reduction of disulfide bridges [13]. Figure 1 presents examples of applications of smart hydrogel materials.

Figure 1.

Uses of multisensitive hydrogel polymer systems.

Hydrogels are environmentally sensitive materials, but their application is very wide. They are used in many sectors of industry, and sensitivity to the external environment is often an advantage when used, e.g., in artificial muscles or medicines. In the present work, hydrogel systems exhibiting sorption capabilities in simulated bodily fluids were obtained. The aim of this study was to determine the influence of the amount of crosslinking agent on the properties of polymer systems.

2. Materials and Methods

2.1. Materials

The main reagents, such as poly(vinyl alcohol) (PVA, crystalline powder, 87–89% hydrolyzed, Mw 13,000–23,000), poly(ethylene glycol) (PEG, powder, average mol wt. 6000), diacrylate poly(ethylene glycol) (crosslinking agent, PEGDA, average molecular weight Mn = 700 g/mol) and 2-hydroxy-2-methylpropiophenone (photoinitiator, 97%, d = 1.077 g/mL), and fluorescein (for fluorescence, free acid) were purchased from Sigma-Aldrich (Saint Louis, MO, USA). All purchased reagents had a “clean for analysis” purity grade.

2.2. Synthesis of Hydrogel Materials

Hydrogel materials were obtained via photopolymerization. Appropriate amounts of the polymeric components PVA and PVP were first mixed. Fluorescein and a variable amount of crosslinking agent were then added. After thorough mixing, a photoinitiator was added to the reaction mixture, and the whole was placed in polymerization form. The process was carried out at room temperature using EMITA VP-60 lamina with a power of 180 W and a wavelength of λ = 320. The polymerization time for each material was 5 min. After synthesis, the materials were thoroughly dried to a solid mass and then subjected to physicochemical characterization using infrared spectroscopy and sorption analysis. In addition, their surface morphology and basic parameters determining roughness were determined. The composition of the hydrogel materials is presented in Table 1.

Table 1.

Composition of the hydrogel materials.

2.3. FT-IR Infrared Spectroscopy Analysis

The infrared spectroscopy analysis was performed using the Thermo Scientific Nicolet iS5 spectrophotometer equipped with an ATR attachment. Spectra were recorded in the range of 3600–500 cm−1 (32 scans, resolution 4.0 cm−1). The measurement was carried out at room temperature.

2.4. Analysis of Soprtion Capacity

The sorption capacity of the polymeric materials was carried out by determining the swelling coefficient. For each material, a sample, 1 cm in diameter, was prepared and carefully weighed. The samples were then placed in distilled water, Ringer liquid and PBS phosphate buffer (each in 50 mL of the corresponding liquid). After 24 h and 48 h, the sample was weighed again, and the swelling coefficient was determined according to the following formula (Equation (1)):

where the following definitions apply:

α = (mt − m0)/m0,

- α—swelling ratio, g/g;

- mt—mass of swollen sample after time “t”, g;

- m0—mass of dry sample (before the study), g.

2.5. Microscopic Observations and Roughness Profile

Then, the surface morphology of the obtained materials and basic roughness parameters were determined using an advanced VKX-7000 Keyence digital microscope (KEYENCE, Mechelen, Belgia). Observations were conducted for all received materials at room temperature.

3. Result and Discussion

3.1. FT-IR Infrared Spectroscopy Analysis

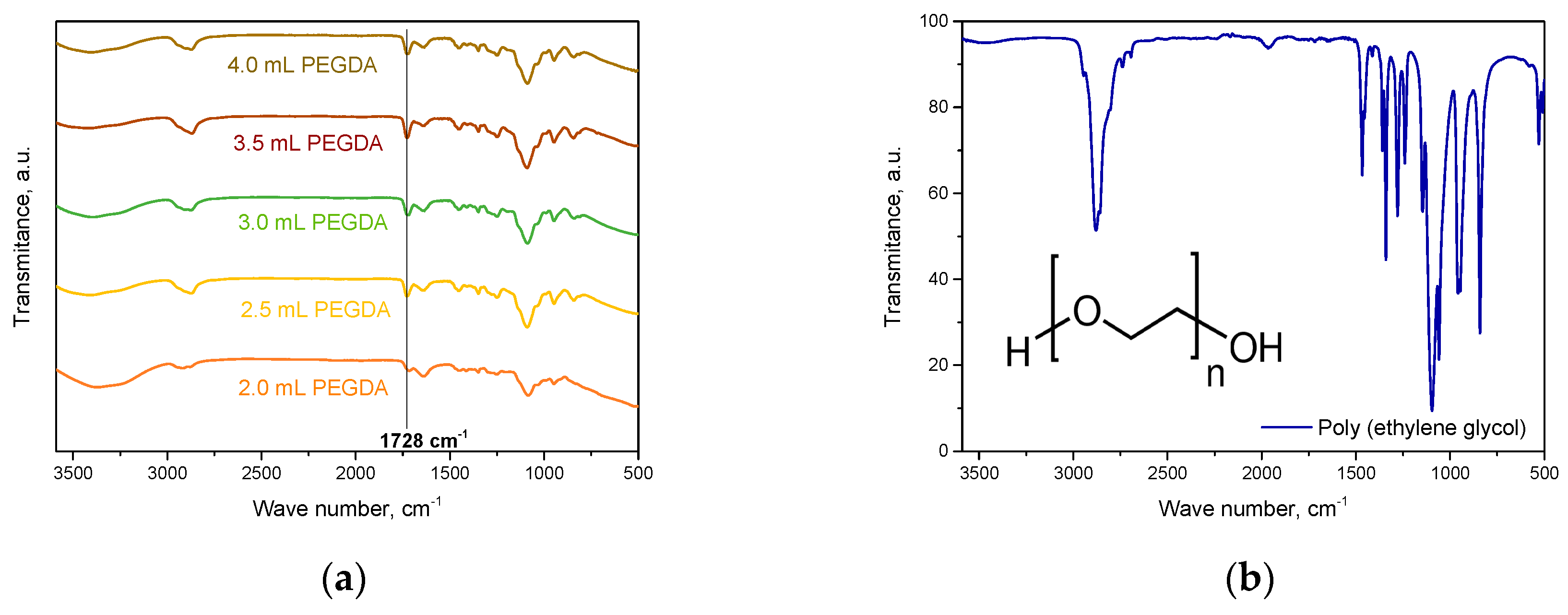

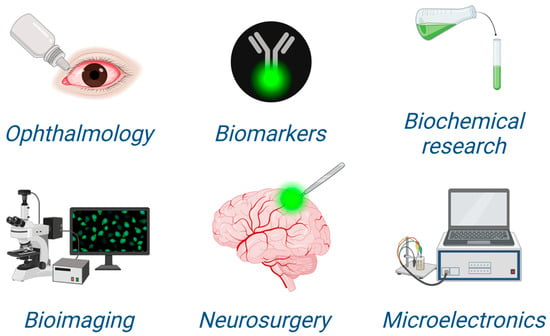

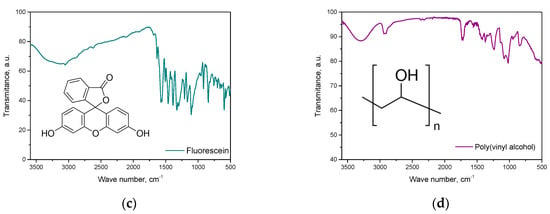

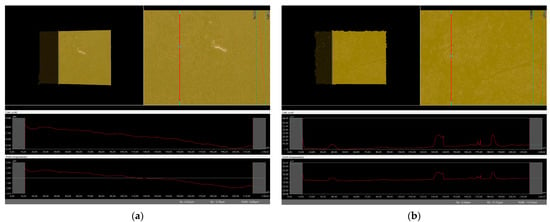

Spectroscopic analysis was performed in order to determine the chemical structure of the resulting hydrogels. Spectroscopic spectra are presented in Figure 2.

Figure 2.

FT-IR spectra of hydrogel materials (a), poli(ethylene glycol) (b), fluorescein (c) and poly(vinyl alcohol) (d).

On the basis of the performed spectroscopic analysis, the absorption bands characteristic of functional groups of polymer components and fluorescein were identified. No large differences were noted for samples obtained with different crosslinking agent contents. However, particular attention should be paid to the absorption band at a wavelength of about 1728 cm−1, which is derived from the tensile vibrations of the C=O group also present in the crosslinking agent. With the increase in PEGDA, we observed an immeasurable increase in the intensity of this band. The results obtained are consistent with the results presented by other researchers [14,15]

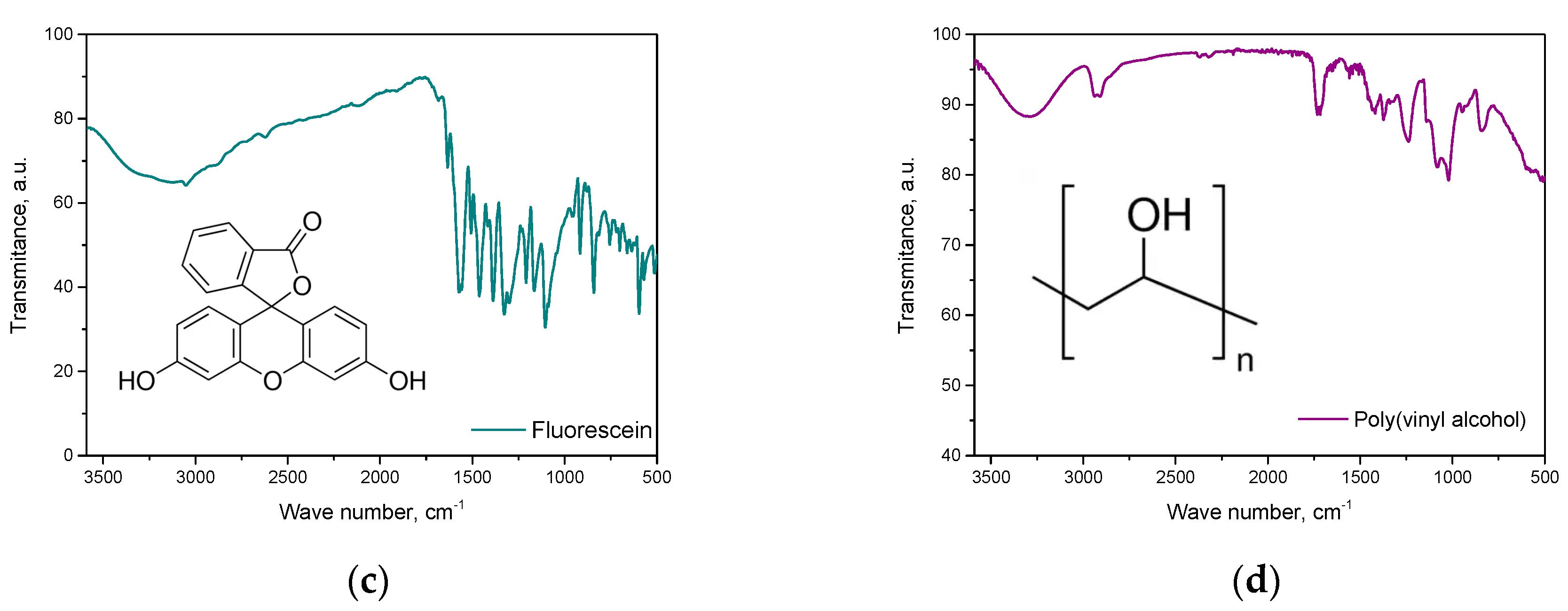

3.2. Analysis of Soprtion Capacity

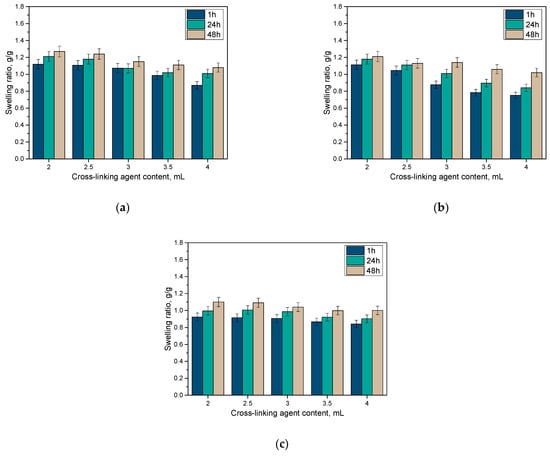

The results of the sorption capacity analysis in the form of swelling coefficients are presented in Figure 3.

Figure 3.

Results of sorption capacity analysis in distilled water (a), Ringer solution (b) and PBS buffer (c); (n—number of repetitions; n = 3).

All analyzed materials showed sorption properties. As the amount of crosslinking agent increased, decreasing values of the swelling factor were observed. The amount of crosslinking agent is one of the key parameters influencing the crosslinking process of hydrogel materials and their structure. In line with the amount of crosslinker, the crosslinking density of the material increases, and the amount of free space for the penetrating fluid decreases. The type of incubation medium is also important. The highest values of swelling coefficients were recorded for distilled water. In the case of Ringer fluid and PBS, these factors were much lower. The presence of additional ions in these fluids may influence the formation of additional bonds and interactions, which increases the polymer density of the matrix and limits its sorption capacity. This is not the case for distilled water without additional ions.

3.3. Microscopic Observations and Roughness Profile

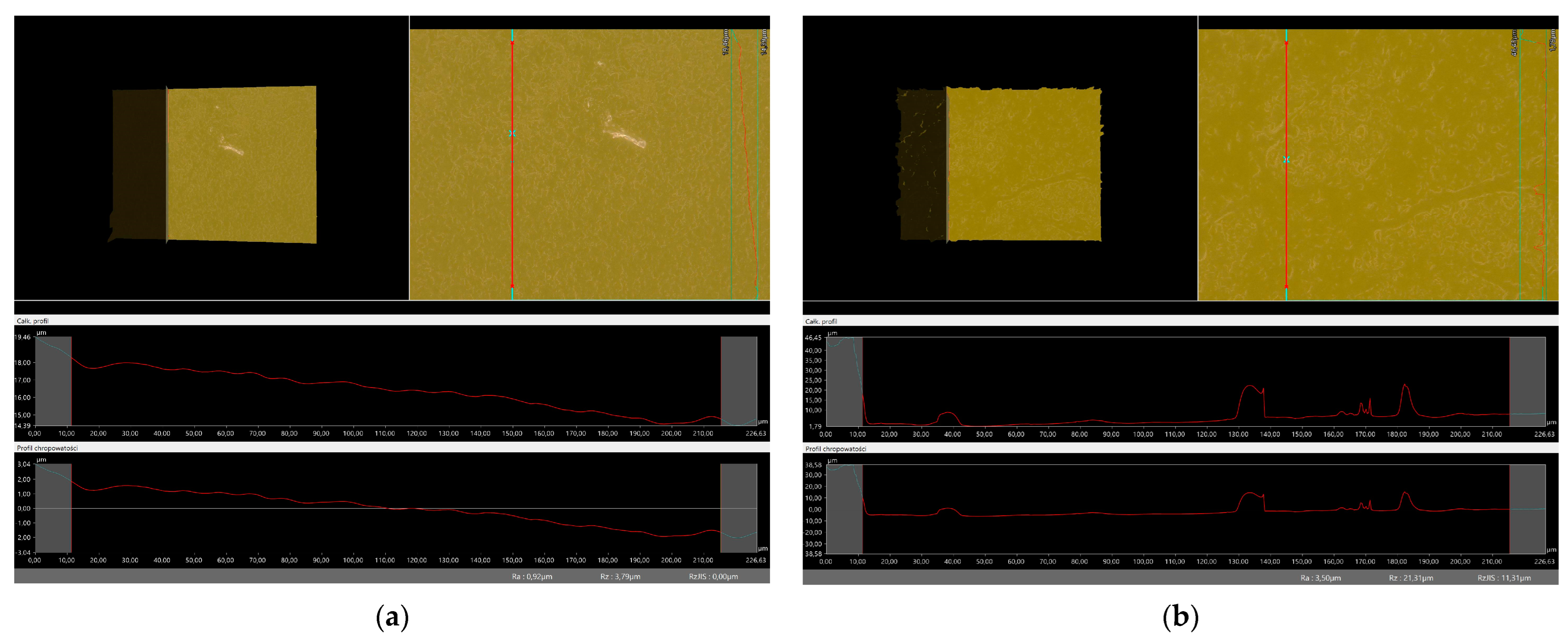

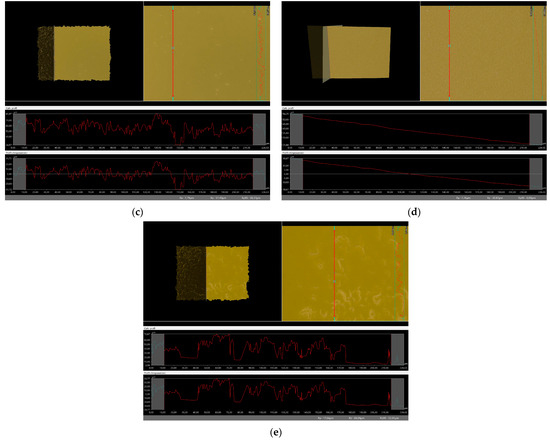

In Figure 4 and Table 2, the subsequent results of the microscopic observations and the roughness parameters of the obtained hydrogel materials are presented.

Figure 4.

Digital microscope images and roughness profile of hydrogel materials with different amount of PEGDA: 2.0 (a); 2.5 (b); 3.0 (c); 3.5 (d); 4.0 (e).

Table 2.

Parameters of roughness of hydrogel materials.

Based on the analysis, it was confirmed that with an increase in the amount of crosslinking agent, the surface roughness of the obtained materials increases. The crosslinking agent is directly related to the crosslinking process of these materials, and its greater quantity changes their internal and surface structure. The relationship between the increasing amount of crosslinking agent and the increasing roughness of these materials has been determined, which may translate into the possibility of synthesizing hydrogels with controlled and desired properties and morphologies.

4. Conclusions

- The chosen photopolymerization method allows us to obtain hydrogel materials modified with fluorescent dye;

- As the amount of crosslinking agent increases, hydrogel materials exhibit reduced sorption properties as a result of the increasing crosslinking density of the polymer matrix;

- The amount of crosslinking agent also significantly affects the surface morphology and roughness of the resulting materials; with the increase in PEGDA, an increase in the value of the roughness parameters was noted;

- Determination of the correlation between the amount of crosslinking agent and the properties of hydrogel materials allows us to obtain materials with the properties desired for their subsequent use.

Author Contributions

Conceptualization, B.T., M.B. and M.K; methodology, B.T., M.B. and K.S.; software, B.T. and M.B.; validation, B.T. and M.B.; formal analysis, M.B., K.S., K.R., M.I., J.P., A.W. and D.W.; investigation, M.B., K.S., K.R., M.I., J.P., A.W. and D.W; resources B.T.; data curation, B.T. writing—original draft preparation, B.T., M.B., K.S. and K.G.; visualization, K.S.; supervision, B.T. and M.K.; project administration, B.T.; funding acquisition, B.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research was carried out within the SMART-MAT Functional Materials Science Club of the Faculty of Materials Engineering and Physics of the Cracow University of Technology and as part of the project entitled, “SmartGels”, financed by the FutureLab organization operating at CUT.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data sharing is not applicable for this article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Caló, E.; Khutoryanskiy, V.V. Biomedical Applications of Hydrogels: A Review of Patents and Commercial Products. Eur. Polym. J. 2015, 65, 252–267. [Google Scholar] [CrossRef]

- Majcher, M.J.; Hoare, T. Applications of Hydrogels BT—Functional Biopolymers. In Functional Biopolymers; Jafar Mazumder, M.A., Sheardown, H., Al-Ahmed, A., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 453–490. ISBN 978-3-319-95990-0. [Google Scholar]

- Cao, H.; Duan, L.; Zhang, Y.; Cao, J.; Zhang, K. Current Hydrogel Advances in Physicochemical and Biological Response-Driven Biomedical Application Diversity. Signal Transduct. Target. Ther. 2021, 6, 426. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Blevins, W.E.; Park, H.; Park, K. Gastric Retention Properties of Superporous Hydrogel Composites. J. Control. Release 2000, 64, 39–51. [Google Scholar] [CrossRef] [PubMed]

- Şen, M.; Uzun, C.; Güven, O. Controlled Release of Terbinafine Hydrochloride from PH Sensitive Poly(Acrylamide/Maleic Acid) Hydrogels. Int. J. Pharm. 2000, 203, 149–157. [Google Scholar] [CrossRef] [PubMed]

- Roy, N.; Saha, N. PVP-Based Hydrogels: Synthesis, Properties and Applications. In Hydrogels: Synthesis, Characterization and Applications; Nova Science Publishers: New York, NY, USA, 2012; pp. 227–252. [Google Scholar]

- Chamkouri, H. A Review of Hydrogels, Their Properties and Applications in Medicine. Am. J. Biomed. Sci. Res. 2021, 11, 485–493. [Google Scholar] [CrossRef]

- Zhang, K.; Feng, W.; Jin, C. Protocol Efficiently Measuring the Swelling Rate of Hydrogels. MethodsX 2020, 7, 100779. [Google Scholar] [CrossRef] [PubMed]

- Cui, Y.; Li, D.; Gong, C.; Chang, C. Bioinspired Shape Memory Hydrogel Artificial Muscles Driven by Solvents. ACS Nano 2021, 15, 13712–13720. [Google Scholar] [CrossRef] [PubMed]

- Park, N.; Kim, J. Hydrogel-Based Artificial Muscles: Overview and Recent Progress. Adv. Intell. Syst. 2020, 2, 1900135. [Google Scholar] [CrossRef]

- Sannino, A.; Demitri, C.; Madaghiele, M. Biodegradable Cellulose-Based Hydrogels: Design and Applications. Materials 2009, 2, 353–373. [Google Scholar] [CrossRef]

- Salgado-Delgado, A.; Hernández-Cocoletzi, H.; Rubio-Rosas, E.; Escobedo Morales, A.; Chigo, E.; Olarte, A.; Salgado-Delgado, R.; Castaño, V. Simulated Body Fluid Nucleation of Poly(Vinyl Alcohol)/Nanohydroxyapatite Hydrogels. Polimery 2019, 64, 487–492. [Google Scholar] [CrossRef]

- Li, L.; Scheiger, J.M.; Levkin, P.A. Design and Applications of Photoresponsive Hydrogels. Adv. Mater. 2019, 31, 1807333. [Google Scholar] [CrossRef] [PubMed]

- Imani, M.; Sharifi, S.; Ziaee, F. Monitoring of Polyethylene Glycol-Diacrylate-Based Hydrogel Formation by Real Time NMR Spectroscopy. Iran. Polym. J. 2007, 16, 13–20. [Google Scholar]

- Roy, P.; Swami, V.; Kumar, D.; Rajagopal, C. Removal of Toxic Metals Using Superabsorbent Polyelectrolytic Hydrogels. J. Appl. Polym. Sci. 2011, 122, 2415–2423. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).