1. Introduction

This research focuses on developing and applying a precision robotic arm (PRR), specifically designed to improve the chocolate packaging process by reducing human errors and accelerating cycle times. The main objective is to increase productivity by freeing up human resources for higher-value tasks.

The uniqueness of this study lies in its ability to transform the way chocolate packaging is carried out, resulting in more efficient production and a more uniform distribution of chocolates in plastic trays, thus improving the quality of the final product.

However, it is important to note that this project faces significant challenges that require meticulous attention to both control and maintenance by specialized personnel. The creation of the PRR robotic arm involves considerable demands in terms of financial investment and technical resources, as well as in-depth engineering knowledge. Furthermore, adapting the PRR to the specific needs of different chocolate production lines can be a complex process. Finally, the ongoing costs associated with the maintenance and operation of the PRR, which require qualified personnel, are key aspects to consider in this engineering project.

2. Estate of Art

Automatic food packaging plays a fundamental role in the food industry, as it contributes significantly to improving efficiency and precision, and reducing possible errors. This is achieved by eliminating repetitive tasks typically performed by human workers, which, in the long term, can slow down the process and lead to errors. As delineated in the study by Smith and Jones (2018) [

1], the integration of automation into food packaging processes has demonstrated its efficacy in boosting productivity, curtailing cycle times, and safeguarding the final product’s quality. This is facilitated through the adept deployment of robotic systems that are proficient in swift and precise grasping and placing tasks.

The landscape of robotic arm technologies has witnessed manifold strides and innovations, each tailored to adapt these capabilities to the realm of food packaging. H. Lee’s work (2017) [

2], for instance, introduces a robotic arm with a PRR configuration, offering heightened dexterity and accuracy in food manipulation.

This project builds upon previous efforts by addressing the inherent challenges in automated packaging and leveraging a PRR robotic arm. However, its distinctiveness emerges from the incorporation of a universal vacuum gripper (UVG) bolstered by a mini-pump and balloon, as evidenced in the investigation conducted by Tong Chen (2020) [

3]. This pioneering approach facilitates the secure and efficient manipulation of chocolates during the packaging process, adeptly adapting to diverse product shapes and dimensions.

The selection of NEMA 17 motors for this project is rooted in their extensive applicability and well-established advantages within the domain of robotics [

4]. NEMA 17 motors, renowned for their compact form factor, superior precision, and suitable torque output for effective robotic arm motion, bear a nominal current capacity of up to 2.5 A, furnishing the requisite force for seamless and accurate joint and gripper movements. Additionally, these motors boast a standard resolution of 200 steps per revolution, which ensures an acceptable degree of positional accuracy when controlling robotic arm components [

5,

6].

3. Methodology

The decision to opt for the UVG was underpinned by its capacity to ensure the secure handling of chocolates, thus averting any potential damage during the manipulation process [

7]. Moreover, its straightforward design and user-friendly nature facilitated a seamless integration into our robotic system. This choice harmonizes seamlessly with our overarching aim of attaining impeccable, high-caliber packaging, thereby safeguarding the chocolates’ integrity and fostering a gratifying consumer experience [

8].

To avoid deformations in the PLA parts that make up a large part of the robot, it is essential to keep it at a temperature below 50 °C [

9], especially if it is exposed to the sun and high temperatures for long periods [

10].

The programming defines how the robot operates, including its ability to pick and place chocolates accurately and reliably. The code ensures smooth task execution with the help of the user interface, which provides a user-friendly means to operate the robot manually or set up automated tasks, making it accessible to a wide range of users. To carry out the pick & place task for the chocolates, we selected the trajectory that required the fewest possible movements and accomplished the task in the shortest amount of time [

11].

The primary parameter taken into consideration during programming was the activation and deactivation time of the vacuum gripper when picking up and releasing the chocolate. After several tests, it was determined that the optimal time for ensuring good synchronization between movements was 5 s. A time shorter than this did not guarantee a proper grip of the chocolate by the gripper.

3.1. Mechanical Design

The connection system entailed steel rods and an endless screw for the prismatic link (Link 1). This configuration facilitated seamless linear movement, which is pivotal for the precise functioning of the robotic arm during grasping and displacement.

Using the CAD design software SolidWorks, a 3D model of the assembly of the robotic arm was created. The CAE simulation software Ansys Workbench was used for obtaining a generative design. The components of the robot that can respond to the movements required by the robot were obtained. Next, we present a summary regarding the design of the gears that allowed the force transmission and movement execution relative to the load weight. This information is crucial when selecting the appropriate motors for the robotic arm design, as can see in the

Table 1.

3.2. Gripper

The chocolate used in the project had a spherical, irregular shape. Its approximate diameter varied between 3 and 4 cm, which gave it a compact and round appearance.

The determination of the grip force was also a significant challenge. A balance had to be found between the pressure exerted by the gripper’s fingers to hold the chocolate without damaging it. Excessive force could have deformed or broken the chocolate, and insufficient force did not ensure a secure and reliable grip.

Finally, the inclusion of force sensors to measure the pressure applied to the chocolate added complexity to the claw design. These sensors had to be precisely integrated into the gripper’s fingers to obtain accurate grip force measurements. The addition of sensors also required additional considerations in terms of wiring and calibration.

The vacuum grip system consisted of using the vacuum principle to achieve a safe and stable grip on the chocolate. The clamp used a bell with a line of silicone or other material that conformed to the chocolate, as can be seen in the blue highlighted area in

Figure 1, creating a tight seal around it. By generating a vacuum in the space between the bell and the chocolate, a gripping force was achieved that held the chocolate in place without the need to apply excessive pressure. The goal was to achieve a gripping system that was more efficient in terms of time and design compared to the three-fingered claw as can be seen in

Table 2.

This system allowed faster handling, and by not applying direct mechanical force to the chocolate, the risk of damaging it during the gripping process was minimized, as can be seen in

Figure 2.

The UVG (universal vacuum gripper) was identified as a superior method to the second gripper, as it was highly effective in gripping delicate objects. It was specifically adapted and optimized for Ferrero Rocher chocolates. The system consists of three main components: a 3D-printed bell, a globe, and fine-grained material.

Table 2 summarizes the different types of grippers that were considered throughout the project.

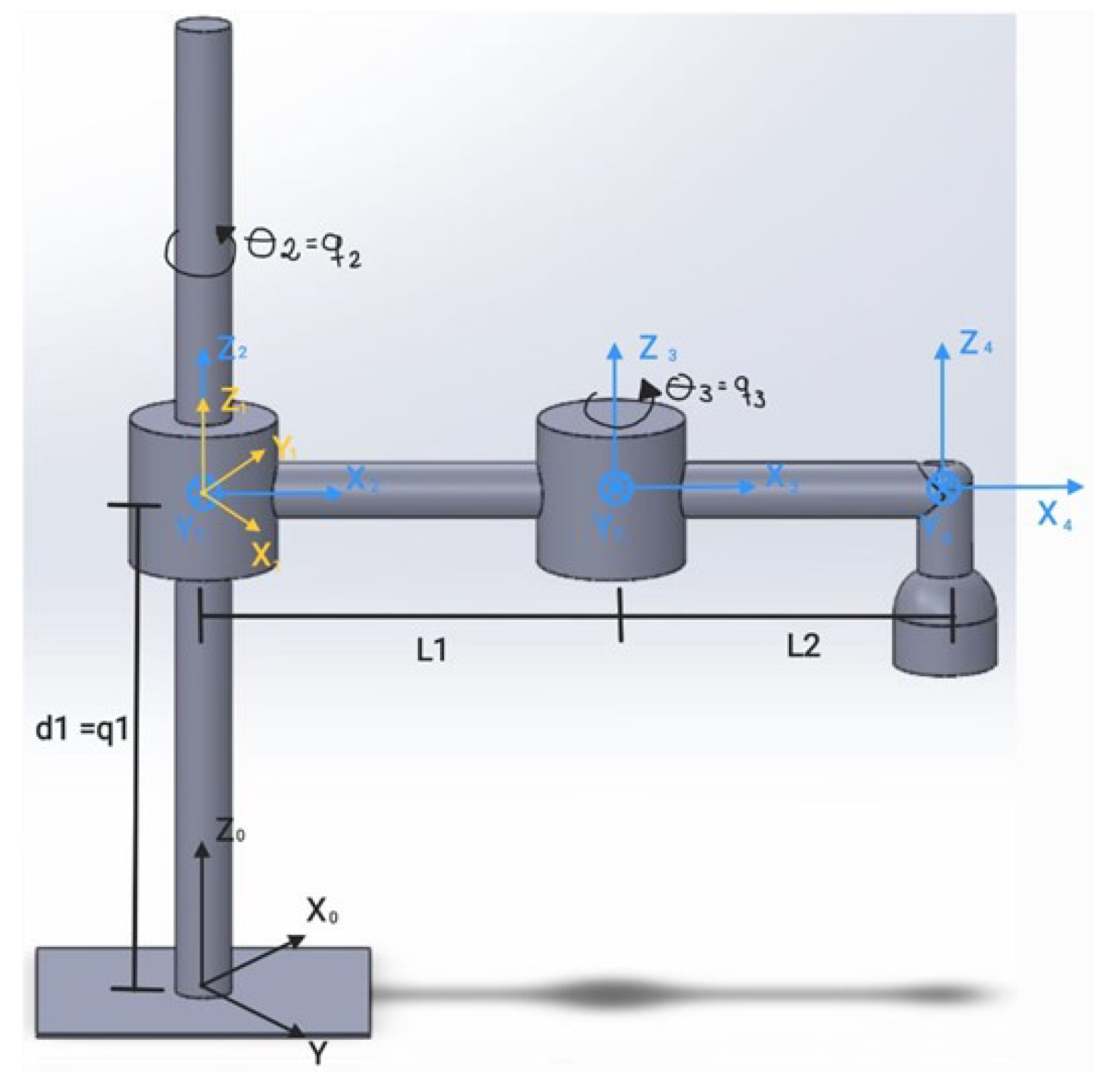

3.3. Denavit–Hartenberg

This section presents the Denavit–Hartenberg parameter table, which is a key tool in the analysis and kinematic modeling of the robotic arm. These parameters, such as link lengths, offset angles, and center distances, allow one to accurately describe the geometry and relationship of motion between the links of the arm. Accurately determining these parameters is essential to achieve precise and efficient control of the gripper positions and orientations during packaging tasks. In

Figure 3, you can see how the frames are placed for DHP calculation.

The Denavit–Hartenberg parameter (DHP) for our PRR robot is presented in

Table 3, along with the homogeneous transformation matrix obtained in MATLAB 2020.

From the table obtained in MATLAB 2020, the equations were obtained based on the parameters to be analyzed in the movements of the robotic arm.

3.4. Jacobian Matrix

Using a 2 × 2 Jacobian matrix, we target crucial aspects of packaging. As we prioritize precise chocolate placement over angular orientation, streamlining the Jacobian matrix accelerates the velocity calculations. Through MATLAB programming, we ensure effective robotic control, ensuring seamless and accurate handling of chocolate during packaging. This concept is illustrated in the following matrix:

3.5. Electronic Connections

The NEMA motors used in our project have a maximum current rating of 2.5 A, but they typically operate within a range of 1 to 1.5 A. By employing the Shield V3 and meticulous fine-tuning of the current limits, we ensure the effective and precise operation of our robotic arm.

4. Results

This text discusses the use of coffee as a fine-grained solid and the advantages and disadvantages of using a mini pump DC5 V/12 V −55 kPa vacuum pump air compressor for its application.

Table 4 summarizes the test results, evaluating them from 1 to 5 (with 5 being the best property).

Table 5 shows the type of grain of each material.

To ensure consistent and accurate positioning, a trajectory training mechanism was devised. This mechanism empowered the robotic arm to accurately follow predefined paths, facilitating the precise placement of chocolates within the blister. The paths can be seen in

Figure 4. This training process leveraged machine learning techniques to bolster the arm’s accuracy and efficiency in adhering to the designated trajectories.

Within the framework of this project’s development, an exploration of various robotic arm configurations was conducted. This included devising a methodology to instruct the robotic arm along predetermined trajectories, as well as creating a mechanism for executing an automated cycle to position six chocolates within a blister packaging, as can be seen in the

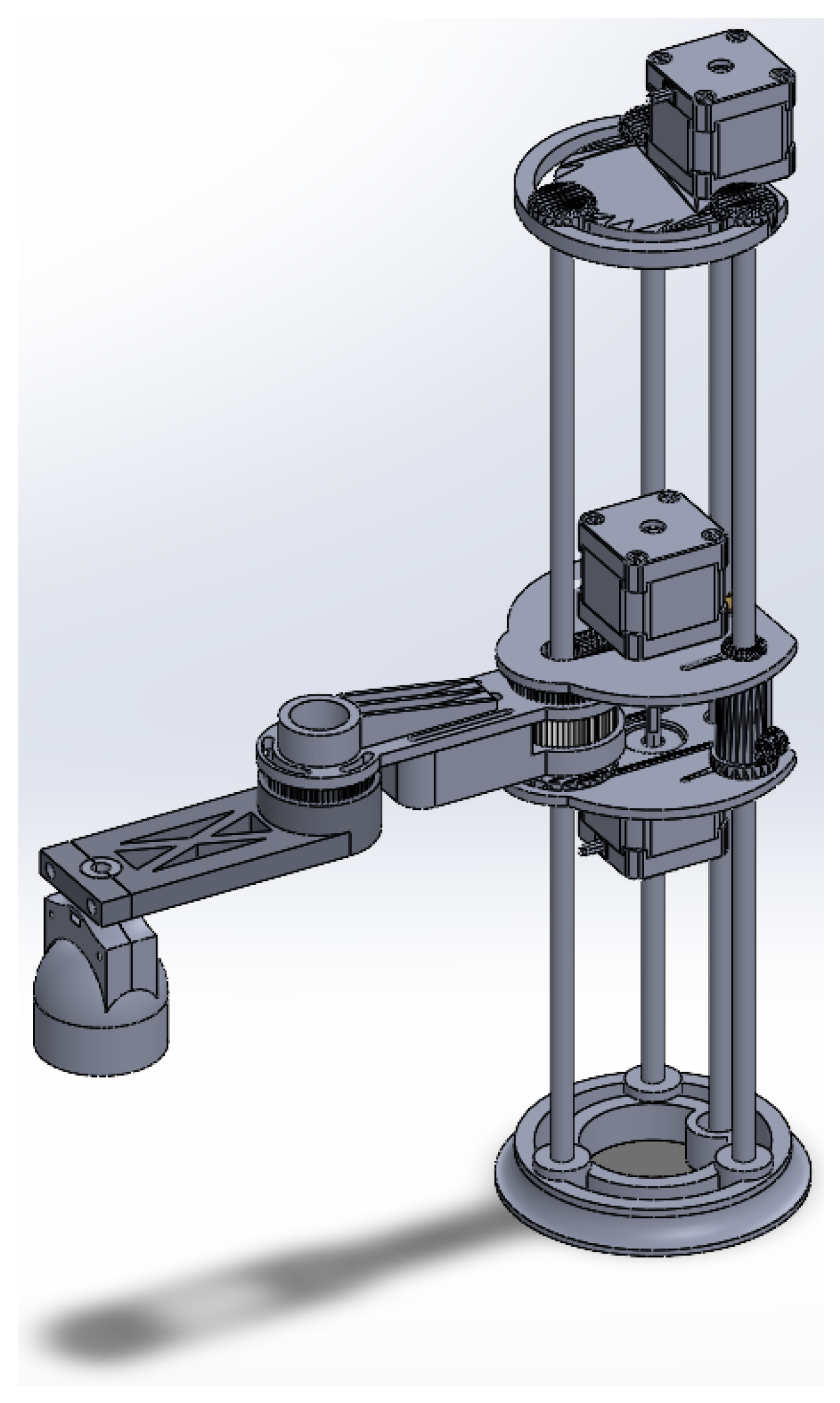

Figure 5. Notably, there is potential to refine the system through the implementation of algorithms aimed at automatically detecting the chocolate placements. Nonetheless, it is important to recognize that, in the context of an online production chain, the spatial arrangements of products consistently adhere to standardized layouts. Thus, this present endeavor is a valuable contribution to contemporary chocolate enterprises, aligning seamlessly with the established sequence of operations within their production processes. The final prototype can see in the

Figure 5.

The project’s development centered on the creation of a robotic arm system. This involved initially identifying and establishing ideal arm positions to ensure the precise placement of chocolates in blister packaging. These positions were determined through a comprehensive approach that integrated mathematical calculations, simulations, and physical experimentations, all aimed at achieving the exact alignment of the chocolates through the interface made in python 3.11 shown in

Figure 6.

5. Conclusions

The chocolate packaging process, using the final prototype of our PRR robotic arm with the universal vacuum gripper (UVG) shown in

Figure 7, has proven to be successful and efficient. Throughout the tests and measurements, an average time of 5 min and 20 s was achieved to complete the packaging process.

A total of 64 different configurations were employed to achieve precise positioning of the chocolates on the plastic trays. These settings were determined by programming and controlling the robotic arm, ensuring that each chocolate was placed correctly.

We are confident that this approach has the potential to improve efficiency and quality in the food packaging industry. The conclusions obtained in this report support the implementation of robotic technologies in the automation of similar processes, suggesting the potential for even greater speed and precision in the future.

Author Contributions

This work presents a low-cost alternative to conventional grippers for the manipulation of delicate objects. For the development, the contribution was: Investigation and Methodology: E.A.; Software and validation: G.C.; Data curation, resources and visualization: M.G. and for writting—review and editing: A.Q. All authors have read and agreed to the published version of the manuscript.

Funding

This work did not have any type of financing.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflict of interests.

References

- Smith, C.; Jones, D. Automation in food packaging: Benefits and impacts. Food Autom. J. 2018, 12, 45–58. [Google Scholar]

- Lee, H.; Kim, J.; Park, S. Development of a PRR robotic arm for food handling. In Robotics and Automation in Food Industry Conference Proceedings; Frontiers: Lausanne, Switzerland, 2021; pp. 112–117. [Google Scholar]

- Chen, T. Universal Vacuum Gripper (UVG) for efficient food packaging. IEEE Trans. Robot. 2020, 25, 78–85. [Google Scholar]

- Brown, A.; Johnson, M. Performance Analysis of NEMA 17 Stepper Motors in Robotic Arm Systems. In Proceedings of the International Conference on Robotics and Automation Proceedings, Virtually, 1 June 2020; pp. 112–117. [Google Scholar]

- Smith, C.; Jones, D. A Comparative Study of NEMA 17 Motors for Robotic Applications. J. Robot. Autom. 2019, 25, 45–58. [Google Scholar]

- Chen, L.; Wang, J. Design and Control of a Robotic Arm Using NEMA 17 Motors. Robot. Autom. Mag. 2018, 15, 78–85. [Google Scholar]

- Kumar, B. Vacuum Cup Grippers for Material Handling in Industry Researchgate. ReserchGate, Jun-2017. Available online: https://www.researchgate.net/publication/317823110_Vacuum_Cup_Grippers_for_Material_Handling_In_Industry (accessed on 15 February 2017).

- Universal Robots. SMC Vacuum Gripper Unit. Available online: https://www.smcworld.com/newproducts/ (accessed on 13 May 2023).

- IMPRESORAS3D.COM. Guía de Uso: Filamento PLA para Impresora 3D. Available online: https://www.impresoras3d.com/filamento-pla-consejos-caracteristicas-y-mucho-mas/ (accessed on 15 May 2023).

- Tandfonline.com. Measuring the Deliquescence Point of Crystalline Sucrose as a Function of Temperature Using a New Automatic Isotherm Generator. Available online: https://www.tandfonline.com/doi/full/10.1080/10942910903474393 (accessed on 15 May 2023).

- Human Focus. How to Prevent Human Error in Workplace. Available online: https://humanfocus.co.uk/blog/human-error-and-workplace-safety/ (accessed on 15 May 2023).

- Sciencedirect.com. Instant Coffee. Available online: https://www.sciencedirect.com/topics/agricultural-and-biological-sciences/instant-coffee (accessed on 15 May 2023).

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).