Abstract

An armor-piercing fin-stabilized discarding sabot is used with a spare shell for 30 mm chain artillery. Due to the limited firepower of the bomb, the limited domestic shooting range, and the high public awareness of environmental protection, it is not easy to test the intrusion force. Therefore, an armor-piercing fin-stabilized discarding sabot is simulated and analyzed to optimize the design of tungsten composition to save research and development costs and improve ammunition performance. The key work of this research includes three parts: pre-work, armor-piercing fin-stabilized discarding sabot drawing, and numerical simulation analysis. Establishing a basic reference data system for ammunition specifications is currently being developed through finite element simulation analysis including the establishment of an armor-piercing fin-stabilized discarding sabot model and performing optimization design evaluation analysis.

1. Introduction

At present, the production accuracy of 30 mm wing stable shelling armor-piercing tracers is stable [1,2,3]. In order to make the tracer suitable for use in various countries, it is necessary to improve the bullet’s appearance to improve the speed and accuracy of the bullet [4,5]. The cost of mold production is relatively high, considering factors such as saving the defense budget and saving costs. The focus of this research is to establish a 30 mm wing-stabilized shelling armor-piercing tracer and different steel plate thickness models through finite element simulation analysis. Finite element analysis is used to set the density and impact speed of each tungsten rod, and the optimized mathematical calculation module is used. This research conducts analysis and uses materials and processes to construct physical bullets for comparative analysis, and through the big data database, to verify the reliability of the mathematical parameter calculation module of this research, and to implement the database construction and function integration.

2. Numerical Analysis

2.1. 30 mm Armor-Piercing Fin-Stabilized Discarding Sabot Geometry

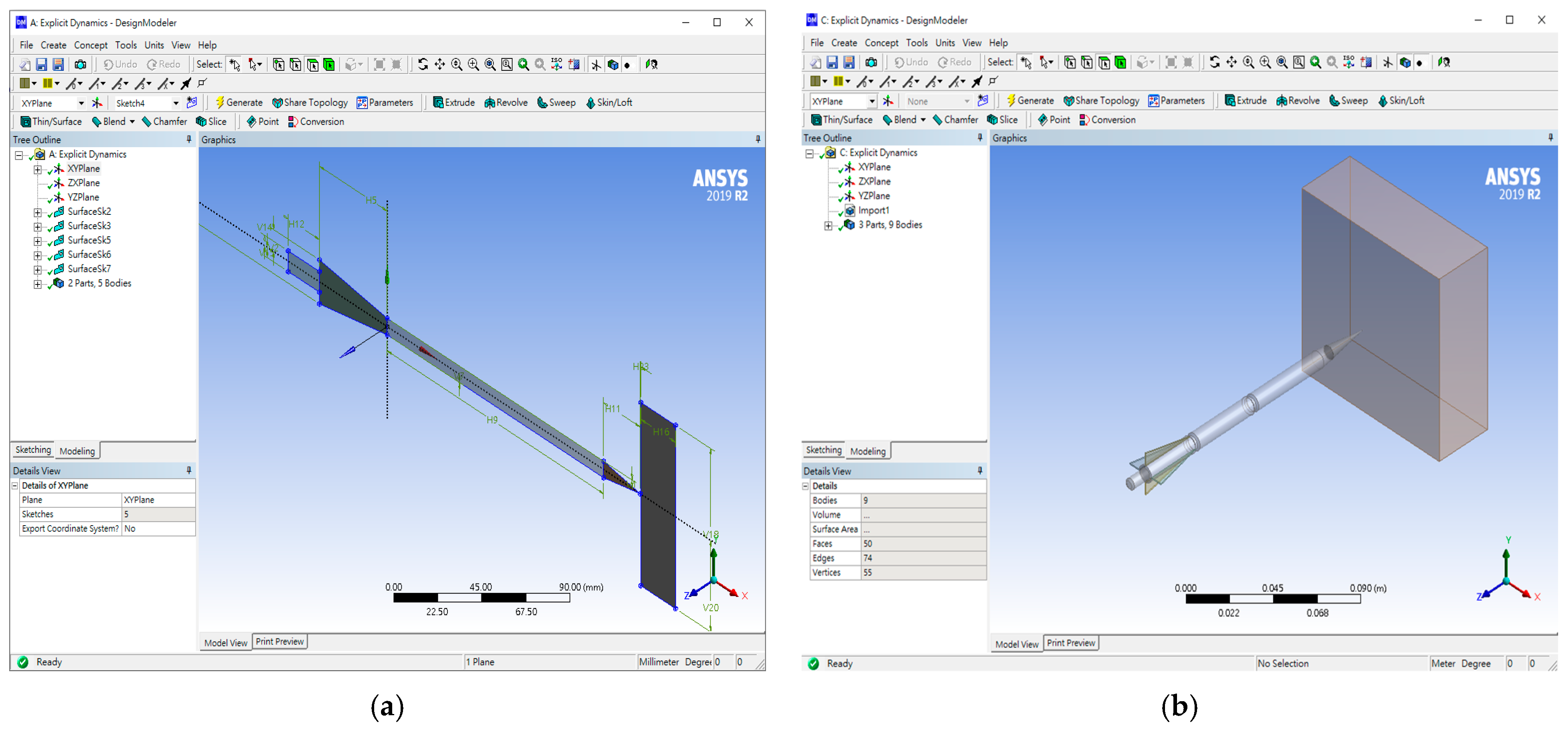

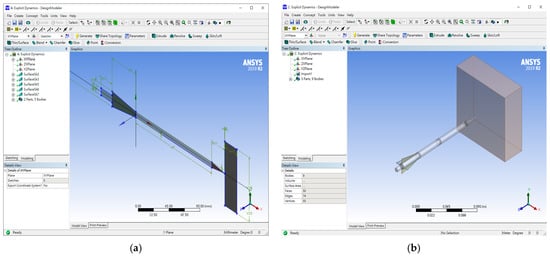

Using the ANSYS Workbench finite element analysis software graphics design tool, and according to the size of the 30 mm wing-stabilized shell-piercing tracer projectile, the 2D and 3D drawing files of this type of projectile were constructed, as shown in Figure 1.

Figure 1.

Build model: (a) 2D model and (b) 1D model.

2.2. Reference Armor Firing Rate

According to the US military technical manual MIL-STD-367 and MIL-STD-662F specifications as shown in Table 1, the shooting muzzle velocity is 1430 m/s, the simulated vertical target position is 1000 m away from the muzzle, and the impact velocity is 1306 m/s.

Table 1.

Distance and impact speed comparison table.

2.3. Two-Dimensional and Three-Dimensional Models for Simulation Analysis

According to the 30 mm wing stable shelling armor-piercing tracer material to select tungsten alloy material from the built-in database of ANSYS in Table 2, it is confirmed that the material properties are consistent with this analysis, and the 2D and 3D image files are imported to use the ANSYS Explicit Dynamics module for mesh analysis. The number of nodes is 21,198 and the number of grids is 20,422. The analysis and calculation module function confirm that the grid has converged and set the boundary condition parameters for the armor-piercing tracer and steel plate.

Table 2.

Tungsten rod material parameters.

3. Results and Discussion

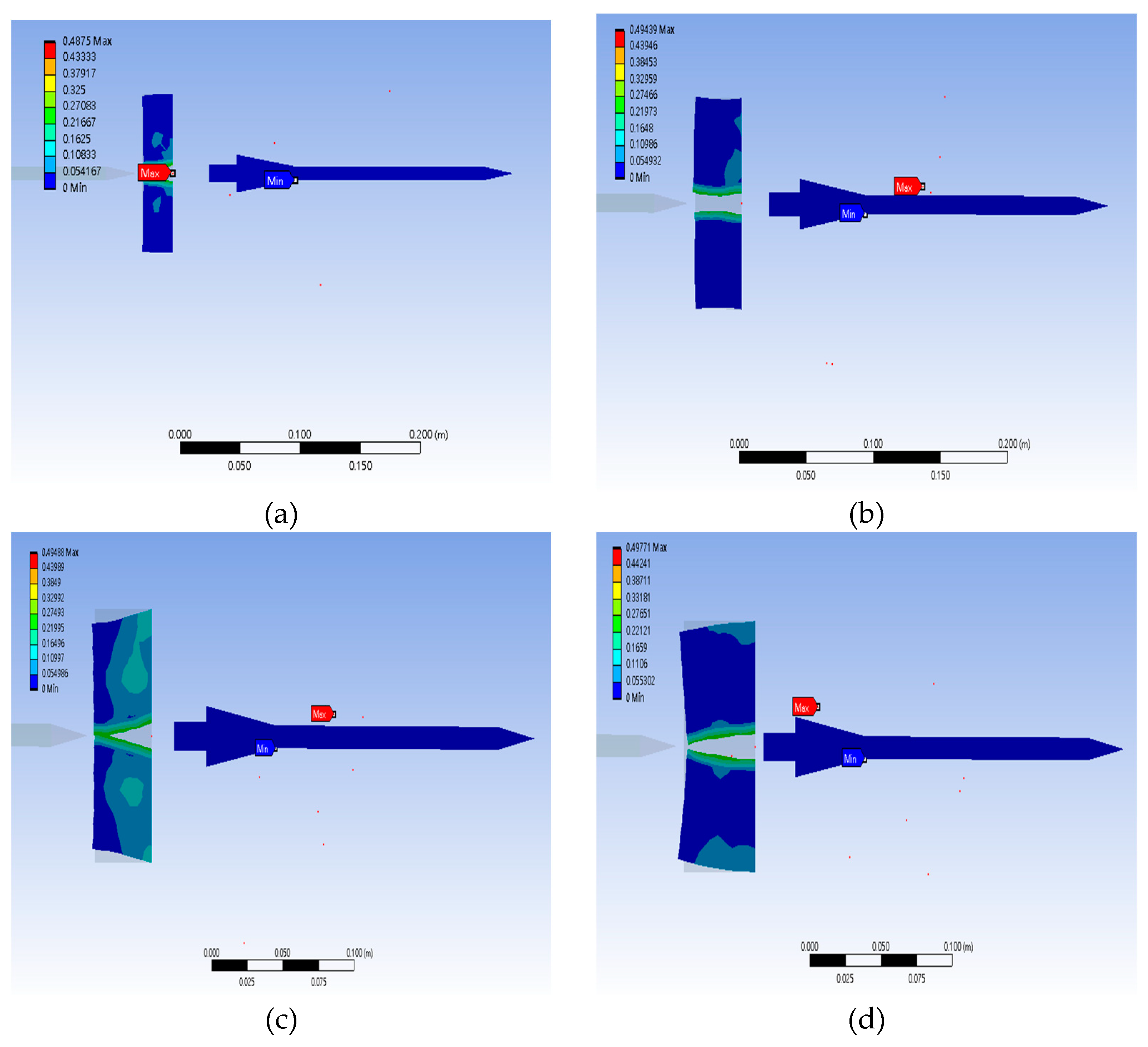

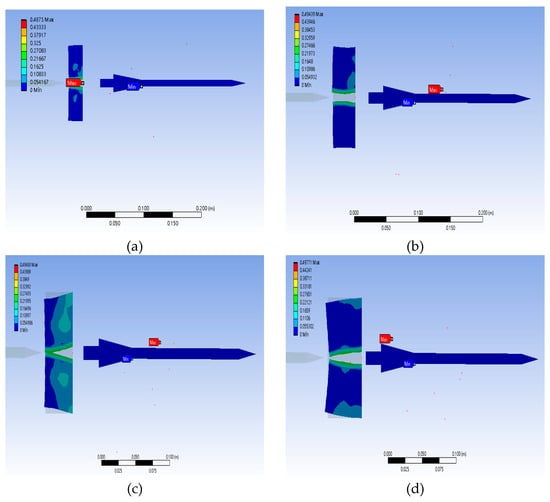

Through ANSYS finite element analysis, the armor-piercing tracer and the steel plate are set to be 1000 m away from the muzzle, and the thickness of the steel plate is set to 25, 35, 40, and 50 mm, and various mechanical analyses are performed through the post-processing module function. The strain data obtained from tracer bullets and steel plates of various thicknesses are shown in Figure 2.

Figure 2.

Steel plate thickness and strain analysis. (a) Thickness: 25 mm; (b) thickness: 35 mm; (c) thickness: 40 mm; (d) thickness: 50 mm.

If the density of the armor-piercing projectile does not change, by changing the boundary condition setting of the impact speed from 1000 to 1300 m/s, the armor-piercing projectile is affected by the speed, and the penetration depth continues to increase. This causes certain damage to various types of tank armor. The effect is shown in Table 3.

Table 3.

Comparison table of relationship between impact speed and penetrable depth.

The penetration depth of the steel plate is analyzed and observed after changing the density of the armor-piercing tracer, and the density is adjusted from 17.5 to 17.79 g/cm3, 18 and 18.5 g/cm3 through ANSYS finite element analysis. When the density of the tungsten rod increases, the penetration depth increases, and the results are shown in Table 4.

Table 4.

Penetration depth with tungsten rod density.

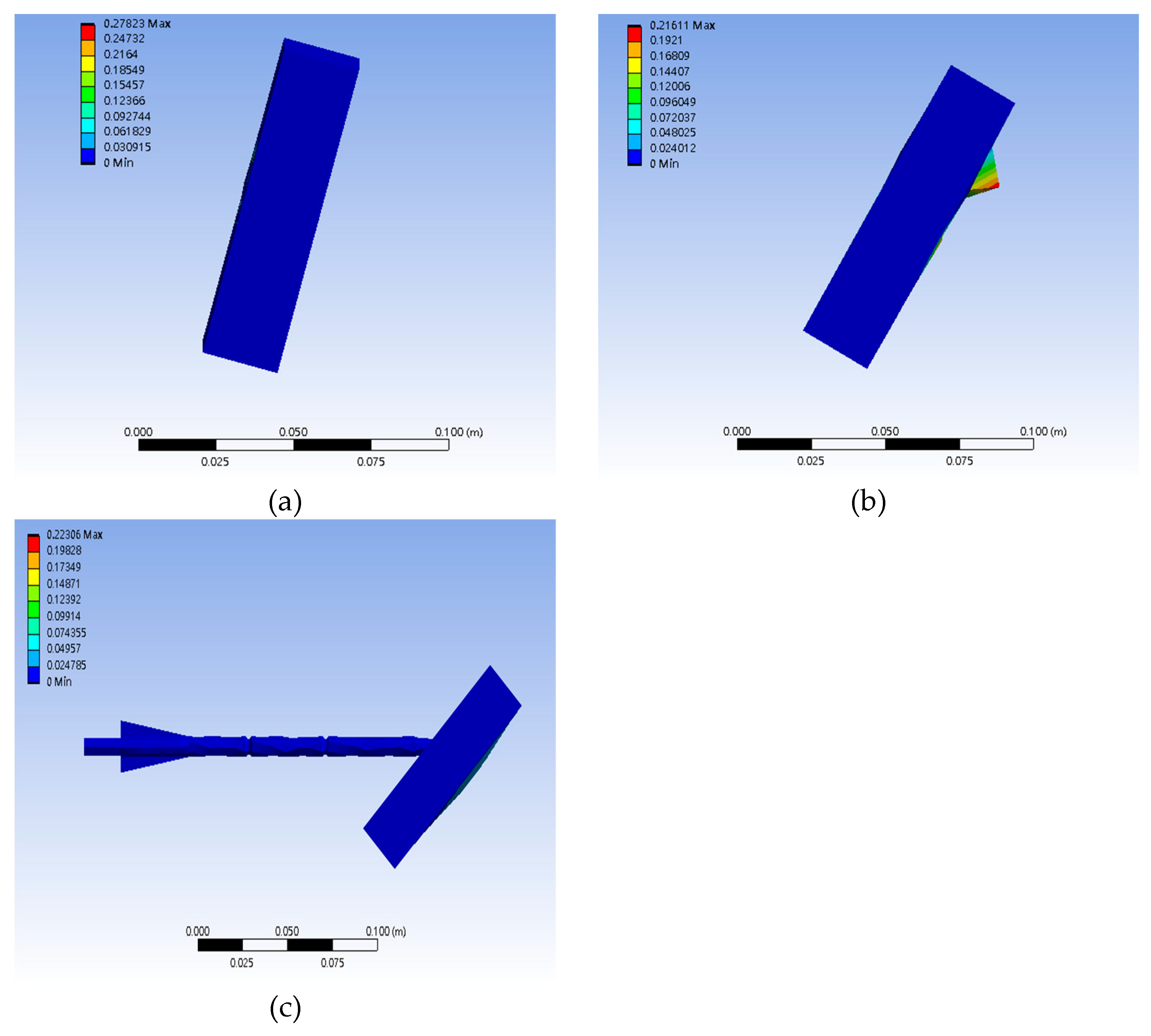

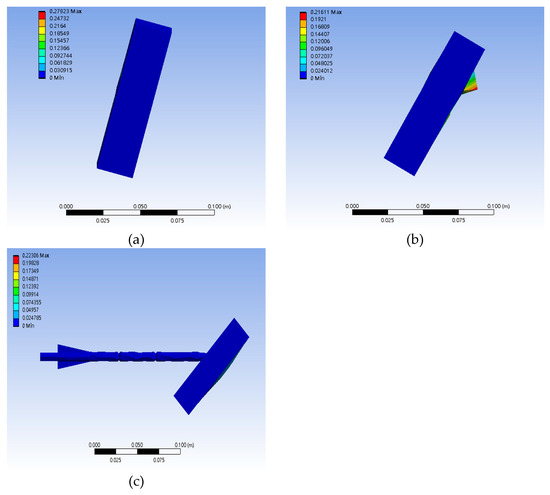

Taking a 25 mm-thick steel plate as an example, the influence of the incident angle is discussed. The inclination angle is defined as the angle α, the impact velocity of the armor-piercing projectile is set to 1306 m/s, and the inclination angle of the steel plate is set to 75, 60 and 45 degrees. As shown in Figure 3, when the angle of the steel plate is 45°, the armor-piercing projectile cannot penetrate completely through the steel plate; this angle is the extreme design angle.

Figure 3.

Effect of inclination angle. (a) Inclination: 75°; (b) inclination: 60°; (c) inclination: 45°.

4. Conclusions

In this study, an armor-piercing tracer with a 30 mm stabilized wing is developed. The software ANSYS Workbench is used for analysis. The density of the tungsten rod, the impact velocity, and the angle position of the steel plate designed for the armor-piercing tracer are analyzed by the Explicit Dynamics module. The test has led to the following conclusions.

- Through numerical simulation analysis, we calculated the penetration depth of the steel plate at different impact speeds. The greater the impact speed, the greater the depth of the steel plate that can be penetrated.

- The analysis of changing the density of the tungsten rod shows that the density of the tungsten rod increases, and the increased thickness of the armor-piercing tracer that can penetrate the steel plate increases.

- By changing the design and installation angle of the steel plate under the stable firing muzzle velocity, the armor-piercing tracer cannot penetrate the steel plate and only causes a certain degree of damage around the surface of the steel plate when it is placed at an inclination of 45°. The steel plate can be penetrated only by firing at the same range of shooting points. The analysis and research data can be used for evaluation and reference by the developers of the subsequent design of armored vehicles.

Author Contributions

Conceptualization, Y.-S.W. and C.-H.H.; methodology, Y.-S.W.; software, Y.-S.W.; validation, Y.-S.W. and C.-H.H.; formal analysis, Y.-S.W.; investigation, Y.-S.W.; resources, C.-H.H.; data curation, Y.-S.W.; writing—original draft preparation, Y.-S.W.; writing—review and editing, C.-H.H.; visualization, Y.-S.W.; supervision, C.-H.H.; project administration, C.-H.H. and Y.-S.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- MIL-STD-367 Armor Test Data Reporting. 1986. Available online: http://everyspec.com/MIL-STD/MIL-STD-0300-0499/MIL-STD-367_29115/ (accessed on 17 May 2019).

- MIL-STD-662F Department of Defense Test Method Standard v50 Ballistic Test for Armor. 1997. Available online: http://everyspec.com/MIL-STD/MIL-STD-0500-0699/MIL-STD-662F_6718/ (accessed on 21 May 2019).

- MIL-A-12560H (MR) w/INT. Amendment 4 Armor Plate, Steel, Wrought, Homogeneous (for Use in Combat-Vehicles and for Ammunition Testing). 2007. Available online: http://everyspec.com/MIL-SPECS/MIL-SPECS-MIL-A/MIL-A-12560H_AMENDMENT-3_10355/ (accessed on 21 May 2019).

- Kuo, H.-T. Simulations for the Dynamics of Sabot Discard and the Projectile Trajectory. Master’s Thesis, Chung Yuan Christian University, Taoyuan, Taiwan, 2004. [Google Scholar]

- Fu, S.-M. Study of Aerodynamic Characteristics of a Tail Fin-Stablized Projectile; Chung Cheng Institute of Technology, National Defense University Department of Mechanical and Aerospace Engineering: Taoyuan, Taiwan, 2013. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).