Research on Road Performance of Solid-Waste-Based-Gelling-Agent-Stabilized Sub-Base †

Abstract

:1. Introduction

2. Raw Materials

2.1. Earth and Rock Materials and Solid-Waste-Based Cementitious Agents

2.2. Cement-Stabilized Aggregates

3. Tests and Results

3.1. Compaction Tests

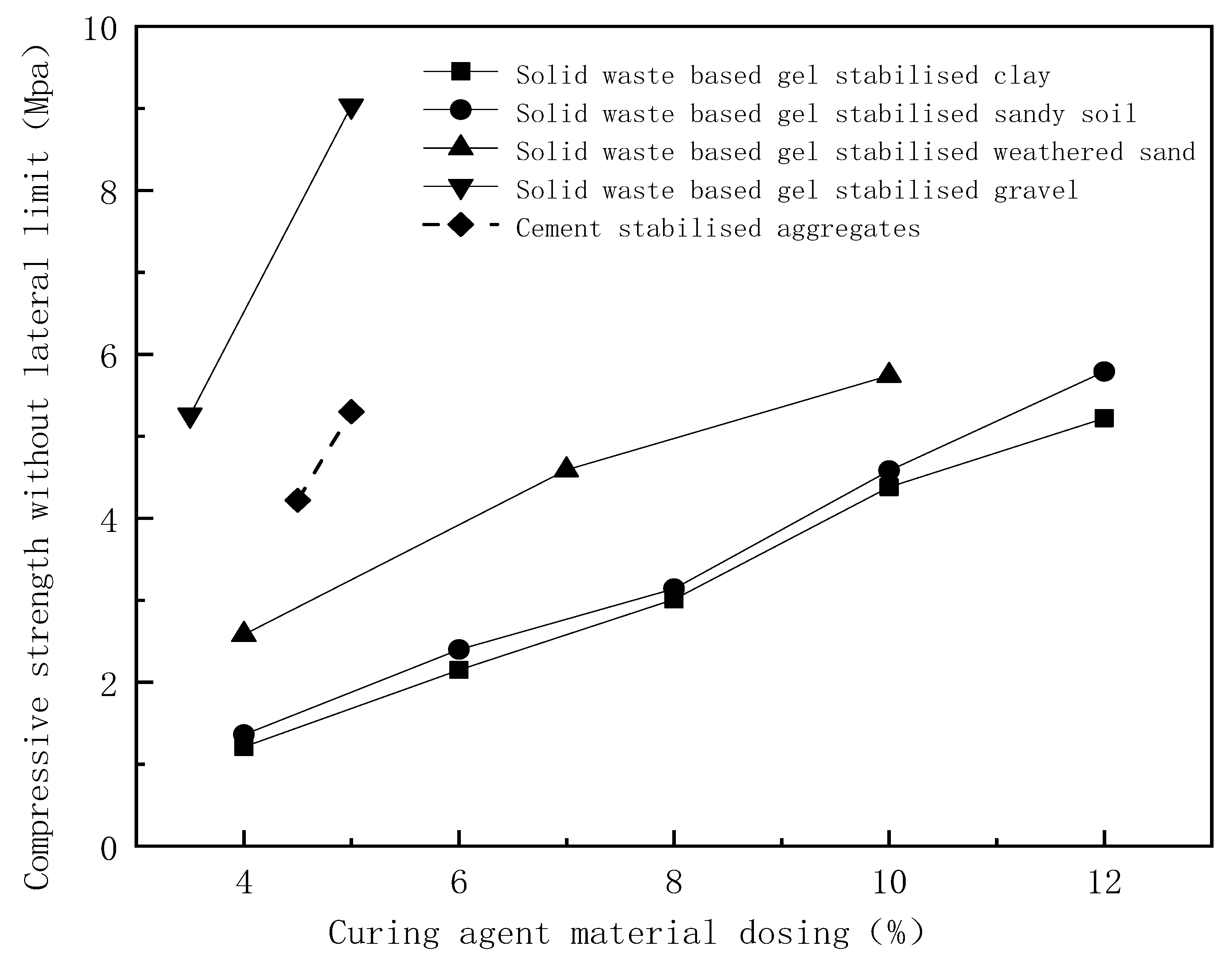

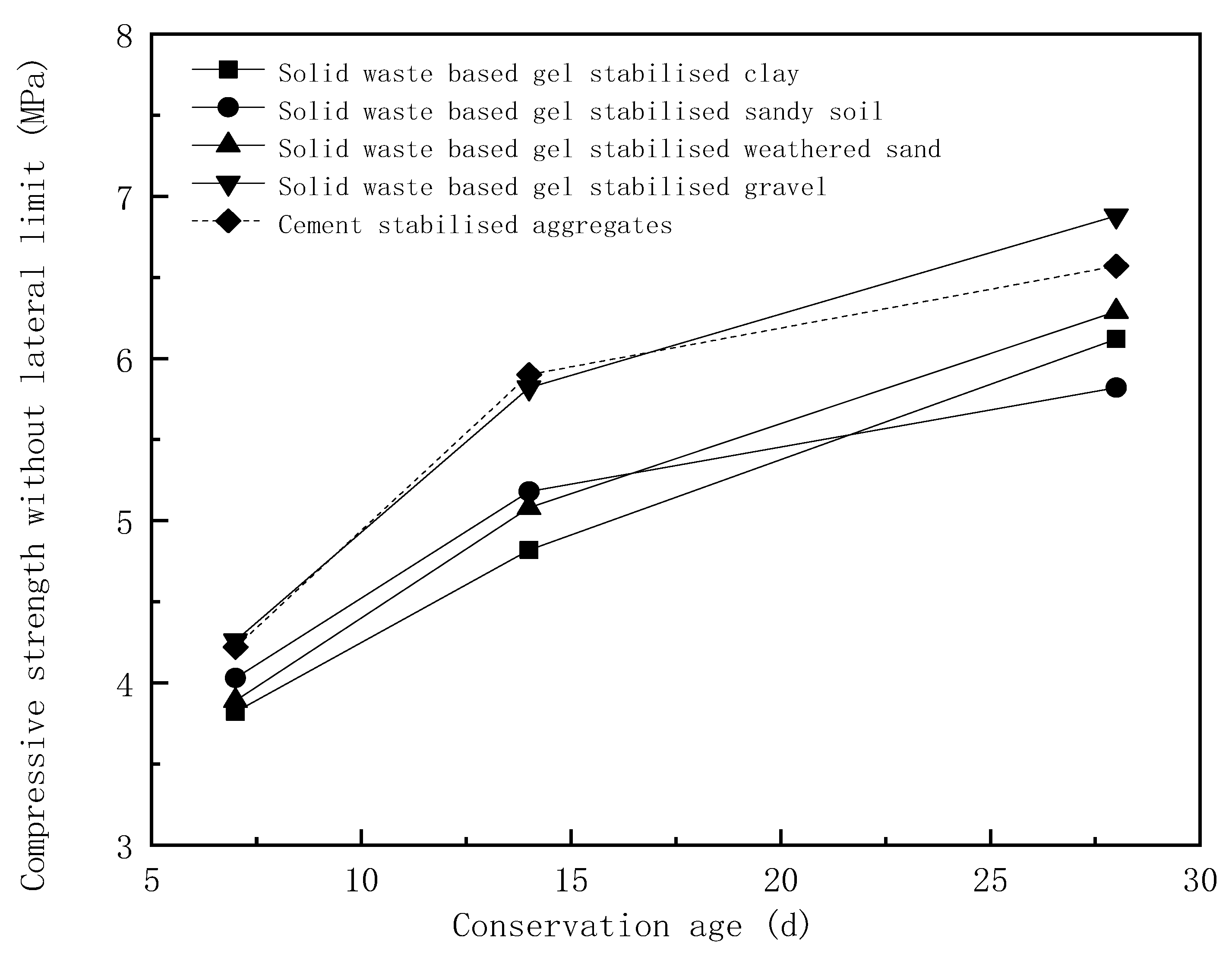

3.2. Lateral Limitless Compressive Strength Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, K.; Wang, H.; Li, S. Hydrochloric acid leaching of red mud for aluminium recovery. Nonferrous Met. 2012, 7, 16–18. (In Chinese) [Google Scholar]

- Chen, D. Recovery of titanium dioxide from red mud. Ind. Environ. 1994, 3, 42–45. (In Chinese) [Google Scholar]

- Agatzini-Leonardou, S.; Oustadakis, P.; Tsakiridis, P.; Markopoulos, C. Titanium leaching from red mud by diluted sulfuric acid at atmospheric pressure. J. Hazard. Mater. 2008, 157, 579–586. (In Chinese) [Google Scholar] [CrossRef] [PubMed]

- Zhang, J. Preliminary study on the recovery of titanium dioxide from red mud. China Resour. Compr. Util. 2003, 1, 28–30. (In Chinese) [Google Scholar]

- Niu, W. Technical points of highway coal gangue filling roadbed. Heilongjiang Sci. Technol. Inf. 2013, 14, 241. (In Chinese) [Google Scholar]

- Jan, X. Application of coal gangue backfill for highway roadbed. TranspoWorld 2013, 291, 187–188. (In Chinese) [Google Scholar]

- Cui, H.; Zhu, C.; Yang, S.; Hu, S. Study on the strength characteristics of new improved soil containing red mud curing agent for cold zone road base. J. Hebei Inst. Archit. Civ. Eng. 2021, 39, 18–26. (In Chinese) [Google Scholar]

- Xiao, Z.; Dai, A.; Zhang, Q.; Sui, N. Research on the construction technology of cold regenerated base layer of asphalt pavement. J. Highw. Transp. Res. Dev. (Appl. Technol. Ed.) 2020, 16, 91–92+96. (In Chinese) [Google Scholar]

- Liu, J.; Wei, B.; Yang, S. Experimental study on the unconfined compressive strength of saline soils modified with soil condensate. J. Hebei Inst. Archit. Civ. Eng. 2021, 39, 29–33. (In Chinese) [Google Scholar]

- Liu, J.; Zhang, G.; Zhang, N. Experimental study on salt swelling characteristics of saline soils improved by curing agents under freeze-thaw cycles. J. Hebei Inst. Archit. Civ. Eng. 2020, 38, 60–63. (In Chinese) [Google Scholar]

- Yue, G.; Xie, R.; Guo, W.; Peng, L.; Tang, Y.; Yu, P.; Mo, L. Preparation and properties of polycarboxylate superplasticizer for solid waste-based cementitious materials. New Build. Mater. 2022, 49, 120–123+128. (In Chinese) [Google Scholar]

| Indicators | Fineness (%) | Density (kg/m2) | Specific Surface Area (m2/kg) | ||

|---|---|---|---|---|---|

| Type | |||||

| Solid-waste-based gelling | 4.6 | 2870 | 681 | ||

| Water consumption at standard consistency (%) | Coagulation time (min) | Sand flow rate (mm) | |||

| 30.4 | Initial condensation | 198 | 182 | ||

| Final condensation | 269 | ||||

| Flexural strength at different ages (MPa) | Compressive strength at different ages (MPa) | ||||

| 3 d | 4.3 | 3 d | 21.1 | ||

| 28 d | 10.6 | 28 d | 57.7 | ||

| Maximum Dry Density (g/cm3) | Optimum Moisture Content (%) | Plastic Limit (%) | Liquid Limit (%) | Plasticity Index | |

|---|---|---|---|---|---|

| Clay | 1.98 | 11.7 | 14.8 | 28.2 | 13.4 |

| Sandy soil | 1.88 | 9.9 | 12.0 | 21.8 | 9.8 |

| Weathered sand | 2.11 | 6.9 | - | - |

| Aperture (mm) | 10 | 5 | 2 | 1 | 0.5 | 0.25 | 0.075 |

|---|---|---|---|---|---|---|---|

| Pass rate (%) | 100 | 93.6 | 62.7 | 44.9 | 22.6 | 11.3 | 2.5 |

| Aggregate Sizes (mm) | Proportion (%) |

|---|---|

| 20–30 | 17 |

| 10–20 | 38 |

| 5–10 | 18 |

| 0–5 | 27 |

| Sieve Hole Size (mm) | 31.5 | 26.5 | 19 | 9.5 | 4.75 | 2.36 | 0.6 | 0.075 |

|---|---|---|---|---|---|---|---|---|

| Pass rate (%) | 100 | - | 74.2 | 45.3 | 27.8 | 19.2 | 8.4 | 3.8 |

| Indicators | Fineness (%) | Density (kg/m2) | Specific Surface Area (m2/kg) | Water Consumption at Standard Consistency (%) | ||

|---|---|---|---|---|---|---|

| Type | ||||||

| P.C-32. 5 | 1.5 | 3000 | 387.6 | 29.0 | ||

| Coagulation time (min) | Flexural strength at different ages(MPa) | Compressive strength at different ages (MPa) | ||||

| Initial condensation | 260 | 3 d | 3.39 | 3 d | 11.52 | |

| Final condensation | 310 | 28 d | 8.05 | 28 d | 49.32 | |

| Curing Materials | Types of Soil | Curing Material Dosing (%) | Optimum Moisture Content (%) | Maximum Dry Density (g/cm3) |

|---|---|---|---|---|

| Solid-waste-based gelling agents | Clay | 4 | 11.9 | 1.99 |

| 6 | 12.1 | 2.01 | ||

| 8 | 11.8 | 2.04 | ||

| 10 | 12.4 | 2.05 | ||

| 12 | 12.0 | 2.08 | ||

| Sandy soil | 4 | 9.8 | 1.91 | |

| 6 | 10.0 | 1.92 | ||

| 8 | 9.7 | 1.95 | ||

| 10 | 9.9 | 1.95 | ||

| 12 | 10.1 | 1.97 | ||

| Weathered sand | 4 | 6.9 | 2.12 | |

| 7 | 6.8 | 2.13 | ||

| 10 | 6.9 | 2.15 | ||

| Gravel | 6 | 4.9 | 2.35 | |

| Cement | Gravel | 5 | 5.0 | 2.33 |

| Curing Materials | Types of Soil | Curing Material Dosing (%) | 7 d Unconfined Compressive Strength Average Value (MPa) | Representative Value for 7 d Unconfined Compressive Strength (MPa) |

|---|---|---|---|---|

| Solid-waste-based gelling agents | Clay | 4 | 1.58 | 1.21 |

| 6 | 2.49 | 2.15 | ||

| 8 | 3.38 | 3.01 | ||

| 10 | 4.72 | 4.38 | ||

| 12 | 5.59 | 5.22 | ||

| Sandy soil | 4 | 1.73 | 1.36 | |

| 6 | 2.77 | 2.40 | ||

| 8 | 3.51 | 3.14 | ||

| 10 | 4.95 | 4.58 | ||

| 12 | 6.16 | 5.79 | ||

| Weathered sand | 4 | 2.95 | 2.58 | |

| 7 | 4.97 | 4.59 | ||

| 10 | 6.21 | 5.74 | ||

| Gravel | 6 | 5.72 | 5.26 | |

| Cement | Gravel | 5 | 9.86 | 9.03 |

| Types of Mixed Materials | Optimum Dosing of Gel Material (%) | |

|---|---|---|

| Solid-waste-based-gelling-agent-stabilized clay | Grassroots | 10 |

| Substrate | 8 | |

| Solid-waste-based-gelling-agent-stabilized sandy soil | Grassroots | 10 |

| Substrate | 8 | |

| Solid-waste-based gelling agent to stabilize weathered sand | Grassroots | 7 |

| Substrate | 5 | |

| Solid-waste-based-gelling-agent-stabilized gravel | Grassroots | 5.5 |

| Cement-stabilized aggregates | Grassroots | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, T.; Qi, Y. Research on Road Performance of Solid-Waste-Based-Gelling-Agent-Stabilized Sub-Base. Eng. Proc. 2023, 38, 55. https://doi.org/10.3390/engproc2023038055

Guo T, Qi Y. Research on Road Performance of Solid-Waste-Based-Gelling-Agent-Stabilized Sub-Base. Engineering Proceedings. 2023; 38(1):55. https://doi.org/10.3390/engproc2023038055

Chicago/Turabian StyleGuo, Tao, and Yueqiang Qi. 2023. "Research on Road Performance of Solid-Waste-Based-Gelling-Agent-Stabilized Sub-Base" Engineering Proceedings 38, no. 1: 55. https://doi.org/10.3390/engproc2023038055

APA StyleGuo, T., & Qi, Y. (2023). Research on Road Performance of Solid-Waste-Based-Gelling-Agent-Stabilized Sub-Base. Engineering Proceedings, 38(1), 55. https://doi.org/10.3390/engproc2023038055