Highly Sensitive Hydrogen Sensor Based on Palladium-Coated Tapered Optical Fiber at Room Temperature †

Abstract

:1. Introduction

2. Experiments

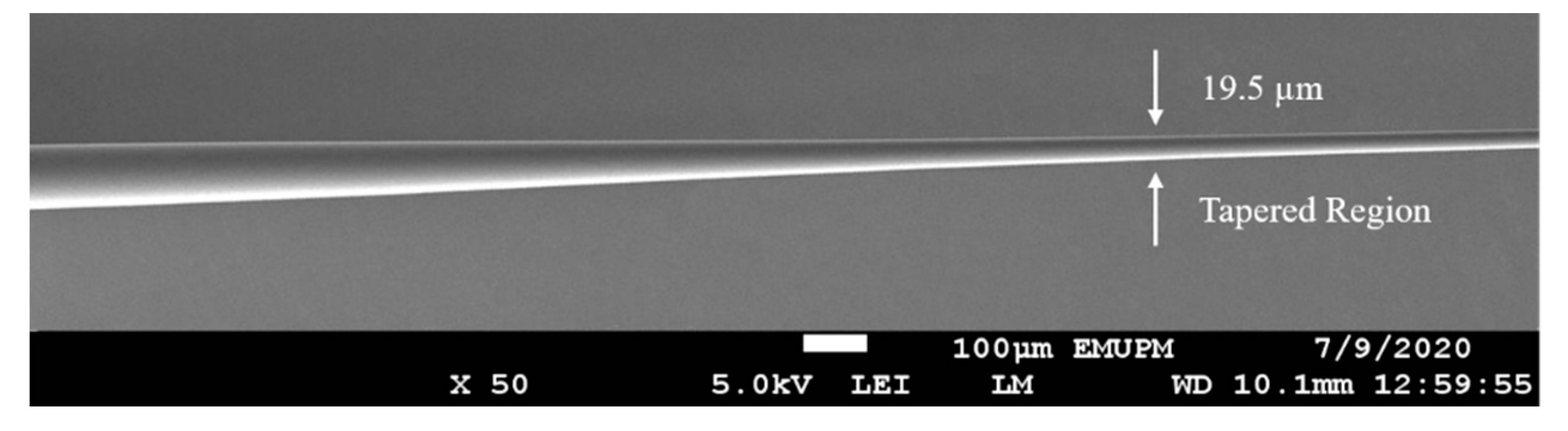

2.1. Fabrication of Tapered Optical Fiber

2.2. Palladium Functionalization of the Tapered Optical Fiber

2.3. Material Characterization

3. Results and Discussion

4. The Sensing Mechanism for Tapered Pd NPs Coated Optical Fibers

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Parra, D.; Valverde, L.; Pino, F.J.; Patel, M.K. A review on the role, cost and value of hydrogen energy systems for deep decarbonisation. Renew. Sustain. Energy Rev. 2019, 101, 279–294. [Google Scholar] [CrossRef]

- Fisser, M.; Badcock, R.A.; Teal, P.D.; Hunze, A. Optimizing the sensitivity of palladium based hydrogen sensors. Sens. Actuators B Chem. 2018, 259, 10–19. [Google Scholar] [CrossRef]

- Pospíšilová, M.; Kuncová, G.; Trögl, J. Fiber-optic chemical sensors and fiber-optic bio-sensors. Sensors 2015, 15, 25208–25259. [Google Scholar] [CrossRef] [PubMed]

- Rajan, G. Optical Fiber Sensors: Advanced Techniques and Applications; CRC Press: Boca Raton, FL, USA, 2015; ISBN 1482228297. [Google Scholar]

- Chen, A.; Ostrom, C. Palladium-based nanomaterials: Synthesis and electrochemical applications. Chem. Rev. 2015, 115, 11999–12044. [Google Scholar] [CrossRef] [PubMed]

- Dai, J.; Yang, M.; Yu, X.; Lu, H. Optical hydrogen sensor based on etched fiber Bragg grating sputtered with Pd/Ag composite film. Opt. Fiber Technol. 2013, 19, 26–30. [Google Scholar] [CrossRef]

- Kazemi, A.A.; Goswami, K.; Mendoza, E.; Kempen, L. Plastic optical fiber hydrogen detection sensor systems for harsh environment in aerospace application. Proc. SPIE 2012. [Google Scholar] [CrossRef]

- Kim, Y.H.; Kim, M.J.; Rho, B.S.; Park, M.-S.; Jang, J.-H.; Lee, B.H. Ultra sensitive fiber-optic hydrogen sensor based on high order cladding mode. IEEE Sens. J. 2010, 11, 1423–1426. [Google Scholar] [CrossRef]

- Coelho, L.; De Almeida, J.; Santos, J.L.; Viegas, D. Fiber optic hydrogen sensor based on an etched Bragg grating coated with palladium. Appl. Opt. 2015, 54, 10342–10348. [Google Scholar] [CrossRef] [PubMed]

- Dai, J.; Yang, M.; Chen, Y.; Cao, K.; Liao, H.; Zhang, P. Side-polished fiber Bragg grating hydrogen sensor with WO 3-Pd composite film as sensing materials. Opt. Express 2011, 19, 6141–6148. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Wang, J.; Wang, F.; Su, W.; Yang, L.; Lv, J.; Fu, G.; Li, X.; Liu, Q.; Sun, T. Surface plasmon resonance (SPR) infrared sensor based on D-shape photonic crystal fibers with ITO coatings. Opt. Commun. 2020, 464, 125496. [Google Scholar] [CrossRef]

- Girei, S.H.; Shabaneh, A.A.; Ngee-Lim, H.; Hamidon, M.N.; Mahdi, M.A.; Yaacob, M.H. Tapered optical fiber coated with graphene based nanomaterials for measurement of ethanol concentrations in water. Opt. Rev. 2015, 22, 385–392. [Google Scholar] [CrossRef]

- Coelho, L.; de Almeida, J.M.M.M.; Santos, J.L.; Viegas, D. Fiber optic hydrogen sensor based on an etched Bragg grating coated with palladium. Appl. Opt. 2015, 54, 10342. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Xu, C.; Gao, G.; Li, X. Facile synthesis of well-dispersed Pd–graphene nanohybrids and their catalytic properties in 4-nitrophenol reduction. Rsc Adv. 2014, 4, 13644–13651. [Google Scholar] [CrossRef]

- Arasu, P.T.; Noor, A.S.M.; Khalaf, A.L.; Yaacob, M.H. Highly sensitive plastic optical fiber with palladium sensing layer for detection of hydrogen gas. In Proceedings of the 2016 IEEE Region 10 Symposium (TENSYMP), Bali, Indonesia, 9–11 May 2016; pp. 390–393. [Google Scholar] [CrossRef]

- González-Sierra, N.E.; Gómez-Pavón, L.d.C.; Pérez-Sánchez, G.F.; Luis-Ramos, A.; Zaca-Morán, P.; Muñoz-Pacheco, J.M.; Chávez-Ramírez, F. Tapered optical fiber functionalized with palladium nanoparticles by drop casting and laser radiation for H2 and volatile organic compounds sensing purposes. Sensors 2017, 17, 2039. [Google Scholar] [CrossRef]

- Basu, S.; Basu, P.K. Nanocrystalline metal oxides for methane sensors: Role of noble metals. J. Sens. 2009, 2009. [Google Scholar] [CrossRef]

- Renganathan, B.; Sastikumar, D.; Srinivasan, R.; Ganesan, A.R. Nanocrystalline samarium oxide coated fiber optic gas sensor. Mater. Sci. Eng. B 2014, 186, 122–127. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alkhabet, M.M.; Girei, S.H.; Paiman, S.; Arsad, N.; Mahdi, M.A.; Yaacob, M.H. Highly Sensitive Hydrogen Sensor Based on Palladium-Coated Tapered Optical Fiber at Room Temperature. Eng. Proc. 2020, 2, 8. https://doi.org/10.3390/ecsa-7-08186

Alkhabet MM, Girei SH, Paiman S, Arsad N, Mahdi MA, Yaacob MH. Highly Sensitive Hydrogen Sensor Based on Palladium-Coated Tapered Optical Fiber at Room Temperature. Engineering Proceedings. 2020; 2(1):8. https://doi.org/10.3390/ecsa-7-08186

Chicago/Turabian StyleAlkhabet, Mohammed Majeed, Saad Hayatu Girei, Suriati Paiman, Norhana Arsad, Mohd Adzir Mahdi, and Mohd Hanif Yaacob. 2020. "Highly Sensitive Hydrogen Sensor Based on Palladium-Coated Tapered Optical Fiber at Room Temperature" Engineering Proceedings 2, no. 1: 8. https://doi.org/10.3390/ecsa-7-08186

APA StyleAlkhabet, M. M., Girei, S. H., Paiman, S., Arsad, N., Mahdi, M. A., & Yaacob, M. H. (2020). Highly Sensitive Hydrogen Sensor Based on Palladium-Coated Tapered Optical Fiber at Room Temperature. Engineering Proceedings, 2(1), 8. https://doi.org/10.3390/ecsa-7-08186