Inkjet-Printed Flexible Temperature Sensor Based on Silver Nanoparticles Ink †

Abstract

:1. Introduction

2. Materials and Methods

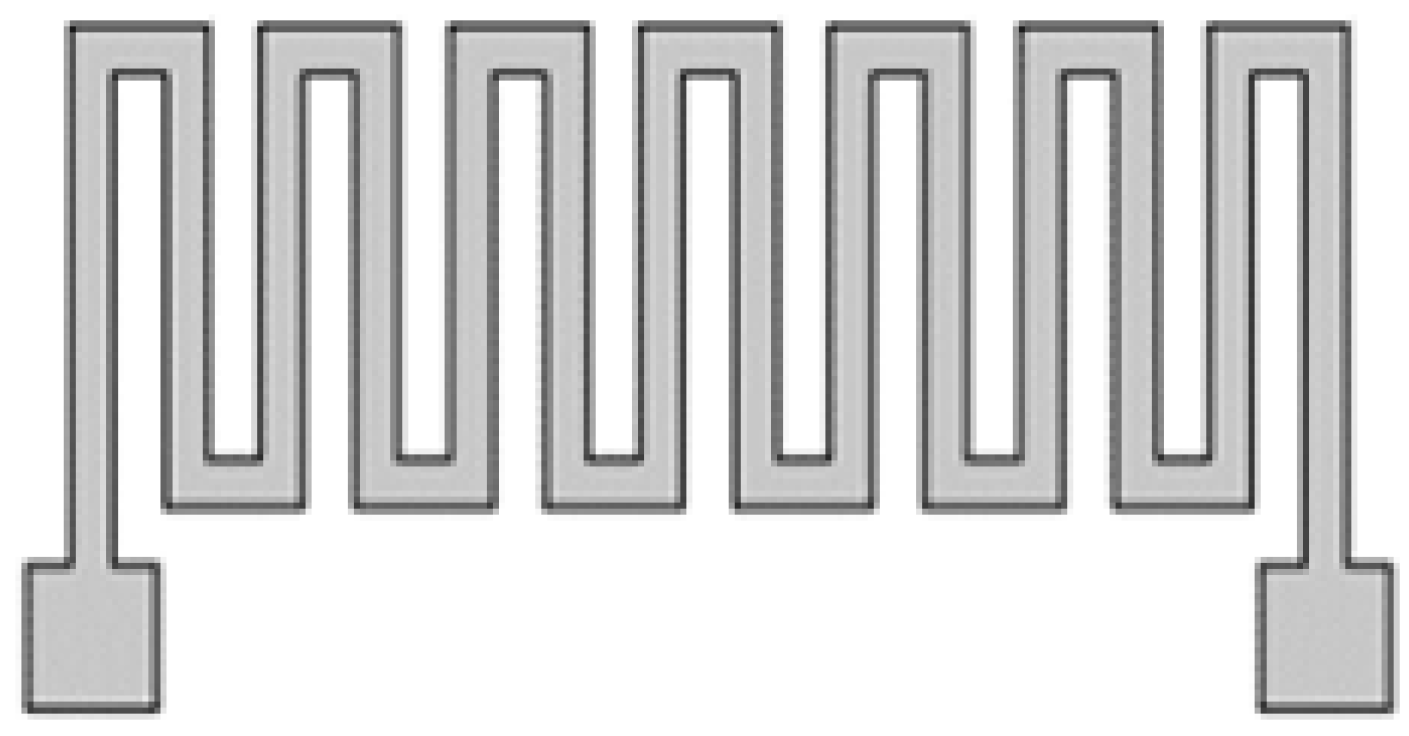

2.1. Temperature Sensor Design

2.2. Flexible Substrate and Ink Preparation

2.3. Inkjet Printing

2.4. Sensor Characterization

3. Results and Discussion

3.1. Geometrical Characterization

3.2. Electrical Characterazation

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Barmpakos, D.; Segkos, A.; Tsamis, C.; Kaltsas, G. A Disposable Inkjet-Printed Humidity and Temperature Sensor Fabricated on Paper. Proceedings 2018, 2, 977. [Google Scholar]

- Ali, S.; Khan, S.; Bermak, A. Inkjet-Printed Human Body Temperature Sensor for Wearable Electronics. IEEE Access 2019, 7, 163981–163987. [Google Scholar] [CrossRef]

- Dankoco, M.D.; Tesfay, G.Y.; Benevent, E.; Bendahan, M. Temperature sensor realized by inkjet printing process on flexible substrate. Mater. Sci. Eng. B 2016, 205, 1–5. [Google Scholar] [CrossRef]

- Cui, W.; Lu, W.; Zhang, Y.; Lin, G.; Wei, T.; Jiang, L. Gold nanoparticle ink suitable for electric-conductive pattern fabrication using in ink-jet printing technology. Colloids Surf. A Physicochem. Eng. Asp. 2010, 358, 35–41. [Google Scholar] [CrossRef]

- Lim, S.; Joyce, M.; Fleming, P.D.; Aijazi, A.T.; Atashbar, M. Inkjet Printing and Sintering of Nano-Copper Ink. J. Imaging Sci. Technol. 2013, 57, 1–7. [Google Scholar] [CrossRef]

- Saha, T.K.; Knaus, T.N.; Khosla, A. Investigation of Printing Properties on Paper Substrate. J. Electrochem. Soc. 2018, 165, B3163. [Google Scholar] [CrossRef]

- Öhlund, T.; Schuppert, A.; Andres, B.; Forsberg, S.; Andersson, H.; Schmidt, W.; Nilsson, H.-E.; Zhang, R.; Olin, H. Assisted sintering of silver nanoparticle inkjet ink on paper with active coatings. RSC Adv. 2015, 5, 64841–64849. [Google Scholar] [CrossRef]

- Wignes, F.L.; Glascoe, C.; Makar, G.; Karacolak, T.; Sekhar, P. A paper based 2-element antenna for WLAN MIMO applications fabricated using inkjet technology. Microw. Opt. Technol. Lett. 2017, 59, 2785–2790. [Google Scholar] [CrossRef]

- Hassan, A.; Ali, S.; Hassan, G.; Bae, J.; Lee, C.H. Inkjet-printed antenna on thin PET substrate for dual band Wi-Fi communications. Microsyst. Technol. 2016, 23, 3701–3709. [Google Scholar] [CrossRef]

- Huang, Q.; Shen, W.; Fang, X.; Chen, G.; Guo, J.; Xu, W.; Tan, R.; Song, W. Highly flexible and transparent film heaters based on polyimide films embedded with silver nanowires. RSC Adv. 2015, 5, 45836–45842. [Google Scholar] [CrossRef]

| Properties | JS-B25HV | In-House AgNPs Ink |

|---|---|---|

| Silver content (wt. %) | 25 | 10 |

| Viscosity (cP) | 8–10 | 6.5 |

| Surface tension(dyne/cm) | 30–32 | 57–66 |

| Particle size (nm) | 60–80 | 30–60 |

| Printer Parameter | Value |

|---|---|

| Substrate Thickness (um) | 200 |

| Tickle Control (kHz) | 5 kHz |

| Plate Temperature (°C) | 40 |

| Cartridge Temperature (°C) | 30 |

| Jetting Voltage (v) | 22 |

| Meniscus Setpoint (inches H2O) | 3.5 |

| Cartridge Print Height (mm) | 0.5 |

| Number of jets to use | 1 |

| Printer Parameter | Value |

|---|---|

| Substrate Thickness (um) | 200 |

| Tickle Control (kHz) | 5 kHz |

| Plate Temperature (°C) | 40 |

| Cartridge Temperature (°C) | 30 |

| Jetting Voltage (v) | 15 |

| Meniscus Setpoint (inches H2O) | 4 |

| Cartridge Print Height(mm) | 0.5 |

| Number of jets to use | 1 |

| Parameter | Design | JS-B25HV | In-house Ink |

|---|---|---|---|

| Finger width (mm) | 0.5 | 0.5 ± 0.04 | 0.5 ± 0.03 |

| Gap between fingers (mm) | 0.4 | 0.4 ± 0.04 | 0.4 ± 0.03 |

| Experiment | Temperature Coefficient of Resistance(c−1) | Sensitivity (Ω/°C) |

|---|---|---|

| 1 | 12.3626 × 10−4 | 0.0514 |

| 2 | 11.6026 × 10−4 | 0.0457 |

| 3 | 13.4704 × 10−4 | 0.0543 |

| 4 | 9.9668 × 10−4 | 0.1071 |

| 5 | 10.0343 × 10−4 | 0.1086 |

| 6 | 7.3363 × 10−4 | 0.0786 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liew, Q.J.; Aziz, A.S.A.; Lee, H.W.; Lee, M.W.; Hawari, H.F.; Md Khir, M.H. Inkjet-Printed Flexible Temperature Sensor Based on Silver Nanoparticles Ink. Eng. Proc. 2020, 2, 3. https://doi.org/10.3390/ecsa-7-08216

Liew QJ, Aziz ASA, Lee HW, Lee MW, Hawari HF, Md Khir MH. Inkjet-Printed Flexible Temperature Sensor Based on Silver Nanoparticles Ink. Engineering Proceedings. 2020; 2(1):3. https://doi.org/10.3390/ecsa-7-08216

Chicago/Turabian StyleLiew, Qiao Jun, Aiman Sajidah Abd Aziz, Hing Wah Lee, Mai Woon Lee, Huzein Fahmi Hawari, and Mohd Haris Md Khir. 2020. "Inkjet-Printed Flexible Temperature Sensor Based on Silver Nanoparticles Ink" Engineering Proceedings 2, no. 1: 3. https://doi.org/10.3390/ecsa-7-08216

APA StyleLiew, Q. J., Aziz, A. S. A., Lee, H. W., Lee, M. W., Hawari, H. F., & Md Khir, M. H. (2020). Inkjet-Printed Flexible Temperature Sensor Based on Silver Nanoparticles Ink. Engineering Proceedings, 2(1), 3. https://doi.org/10.3390/ecsa-7-08216