Abstract

Construction planning and scheduling, including task sequences, constraints, and interdependencies, is poorly structured within digital models such as BIM and Digital Twin and lacks effective integration with planning documents to support scheduling analysis, logic-based reasoning, and automation. To address this gap, this paper develops an AI-enabled framework organized into three core dimensions: (1) enriching BIM and integrating reality data with activity, spatial, and resource attributes; (2) formalizing planning logic using a planning ontology to represent execution relationships; and (3) applying AI techniques to extract planning knowledge, validate constraints, and generate automated schedules. The framework supports logic-based planning, progress tracking, and coordination across construction processes.

1. Introduction

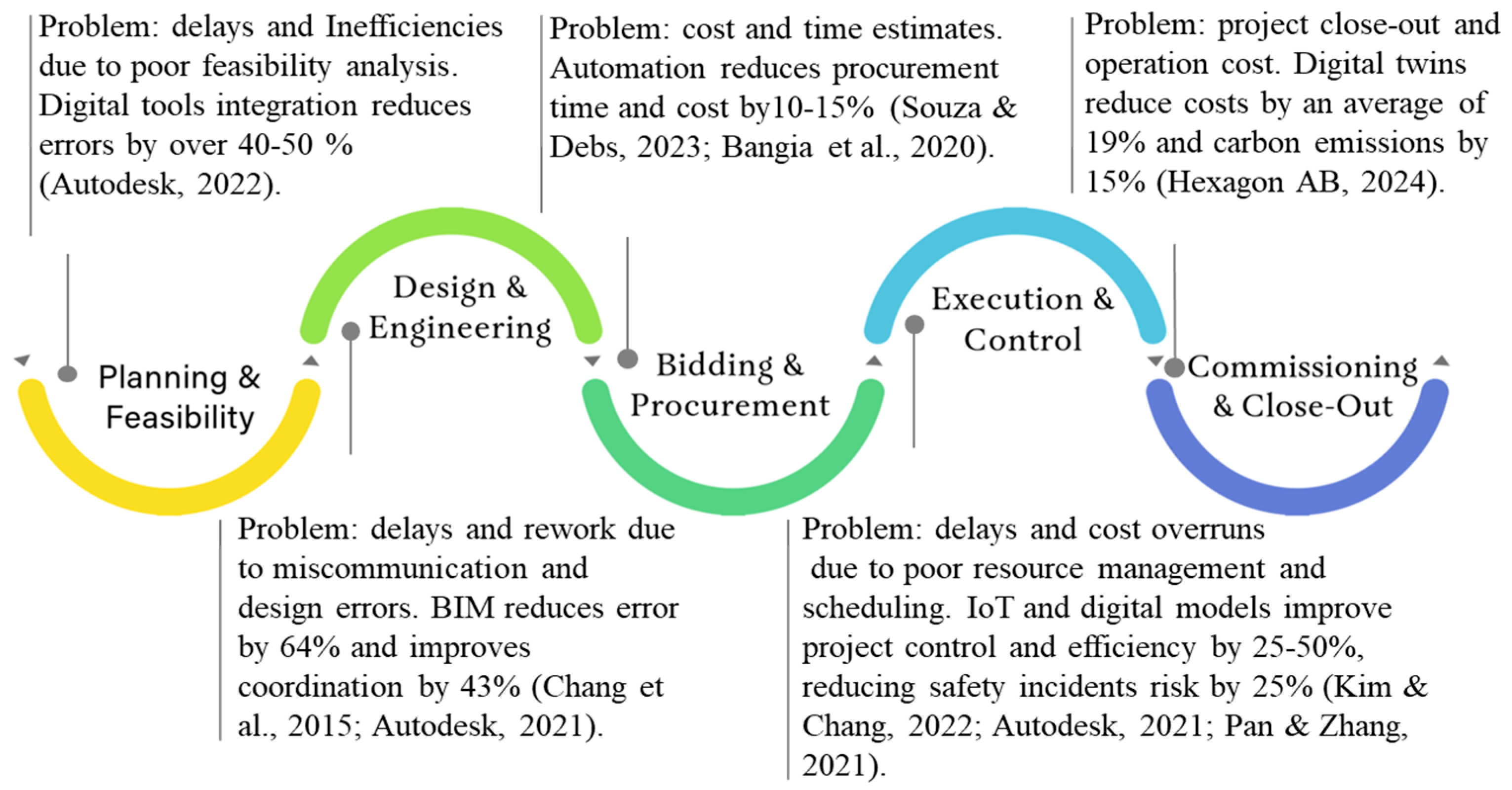

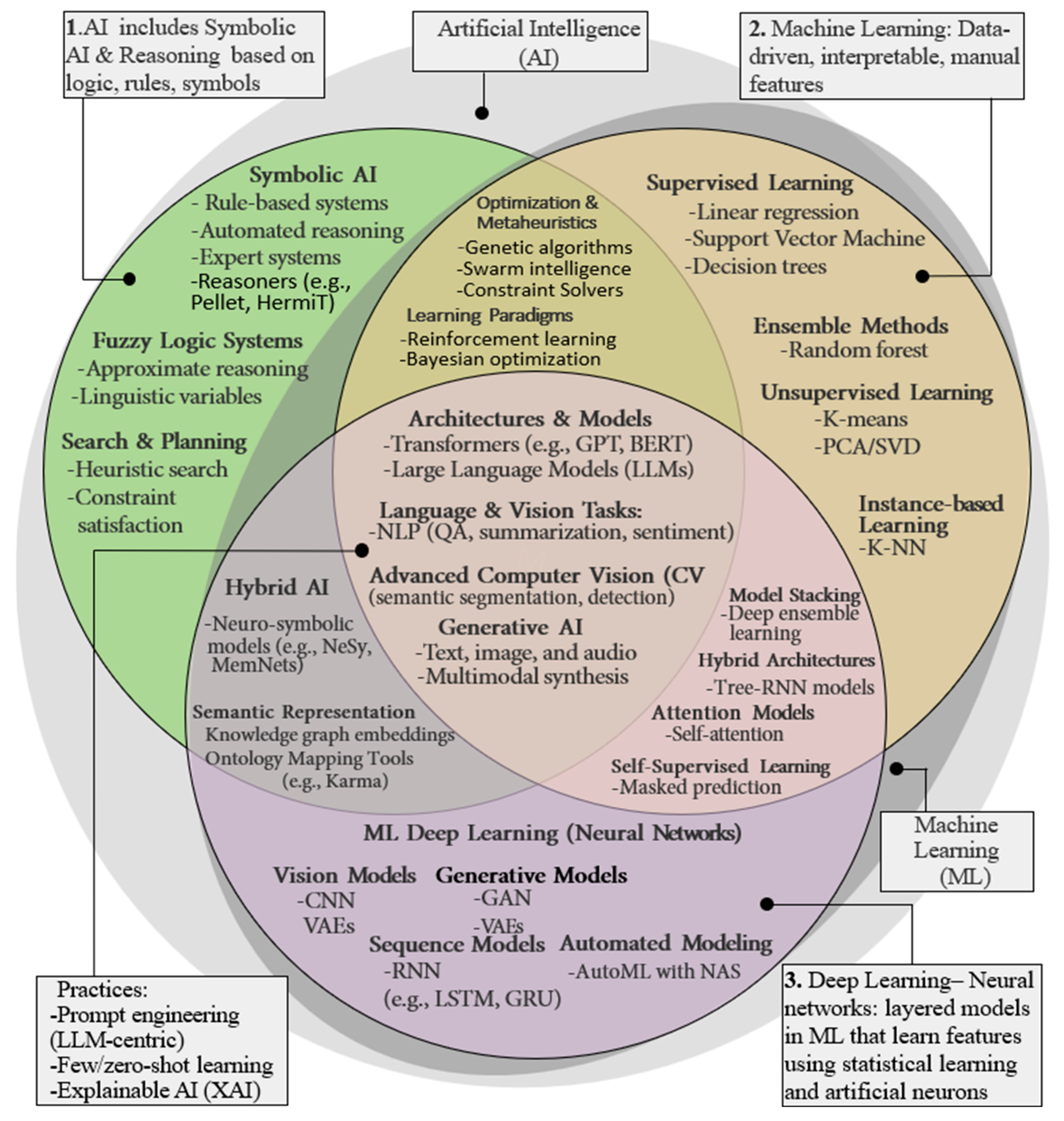

The construction industry is undergoing a steady transformation in efforts to enhance efficiency in project management and reduce time and cost overruns [1,2]. Traditional workflows often suffer from unreliable task-level predictive planning, contributing to coordination problems and delays [3,4]. However, digital technologies such as Building Information Modeling (BIM), the Internet of Things (IoT), and Digital Twins (DT) are enabling more integrated and data-supported project delivery; these tools have advanced design coordination and performance tracking across specific construction phases [5,6]. As illustrated in Figure 1, digital technologies contribute across multiple project stages, from design to execution, by helping to reduce design clashes, improved coordination, and enhanced decision-making [7,8]. For example, BIM has been shown to minimize coordination errors, DT implementations support operational energy optimization, and IoT-integrated systems enable proactive site safety monitoring [8,9,10]. Despite these advances, the application of BIM and DT is often limited in supporting structured modeling of planning and execution of construction processes. Current systems face limitations in effectively representing workflows, task interdependencies, and time-based logic in a structured digital format. As a result, essential planning and execution knowledge, such as process flows, activity sequencing, resource coordination, and site constraints, remains external to digital models and is often dispersed across schedules, specifications, and reports [11,12].

Figure 1.

Inefficiencies and the Impact of Digital Technologies Across Project Phases. (References: Souza & Debs, 2023 [5]; Autodesk, 2022 [13]; Bangia et al., 2020 [14]; Hexagon AB, 2024 [15]; Chang et al., 2015 [16]; Autodesk, 2021 [17]; Kim & Chang, 2022 [18]; Autodesk, 2021 [19]; Pan & Zhang, 2021 [20]).

This gap is particularly evident in the separation between BIM platforms and dedicated planning tools like Primavera P6 or Microsoft Project, which are typically used in isolation and require manual data translation. Although interoperability standards such as Industry Foundation Classes (IFC) and schema elements like IfcTask and IfcWorkSchedule exist, their practical implementation remains limited and requires manual input [21]: Table 1 presents BIM and digital tool interoperability standards in construction.

Table 1.

Current BIM standards interoperability purpose and limitations.

Present-day digital models effectively represent geometry and asset-related data but often lack structured representation of construction logic, activity sequences, resource dependencies, and planning constraints. This results in critical planning knowledge, task relationships, temporal flows, and procedural rules being isolated from the central project model. Overcoming this fragmentation requires more than visual coordination or manual sequencing. It requires enriched BIM models that embed links between physical components, spatial structure, available resources, and execution logic. Ontology-based modeling provides a formal way to represent such domain knowledge, enabling systems to reason about interdependencies and constraints [22,23]. When combined with AI methods like multimodal extraction and ML, information extracted from unstructured and visual project data (e.g., documents, drawings, images) can be linked to BIM and used to support scheduling, constraint validation, risk analysis, and enhanced monitoring.

This paper proposes an AI-driven semantic framework integrating enriched BIM and real-time data, construction process ontology, and Digital Twin (DT) data into a structured system. The framework uses AI techniques for extracting planning knowledge from construction documents and ML for learning temporal and semantic relationships, to support automated scheduling, constraint validation, and improved planning and monitoring. While still an emerging research direction, such an approach shows promise in bridging the divide between digital representation and real-world planning and execution in construction projects.

2. Methodology

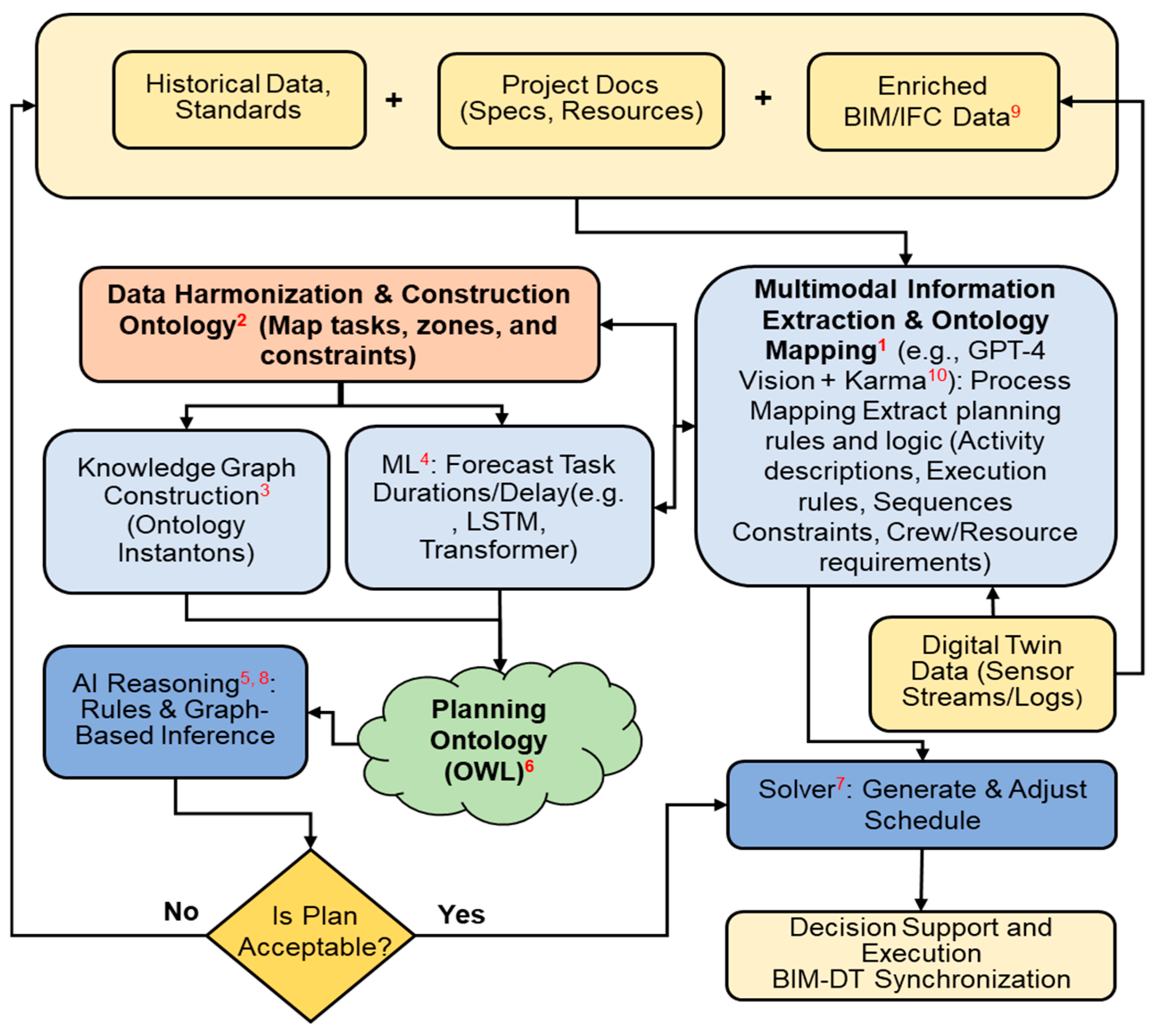

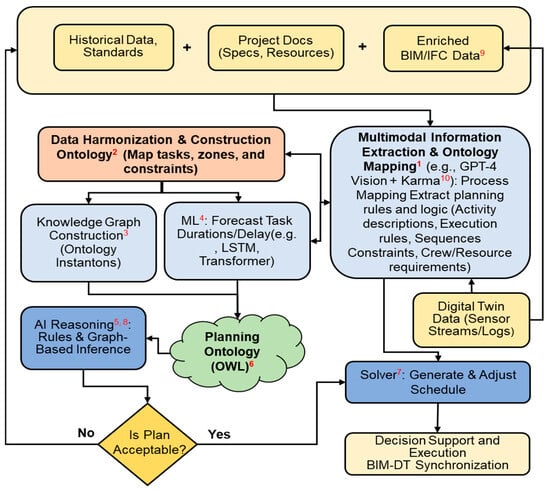

This study develops a structured methodology for an AI-driven framework that integrates enriched BIM data, Digital Twin (DT) technologies, and construction planning knowledge. As shown in Figure 2, the framework is organized into four interdependent components: (1) enriching BIM and construction data through spatial and resource attributes; (2) harmonizing and formalizing this data into a construction scheduling ontology; (3) applying AI techniques, such as multimodal AI for extracting execution logic (e.g., combining text and image interpretation and ML for temporal forecasting and optimization; and (4) enabling schedule generation, planning and control decision-making, and BIM-DT synchronization through ontology-based integration. The ontology serves as the conceptual backbone of the system, with core classes (e.g., Activity, Resource, Constraint) defined in OWL to support reasoning, and validated using SHACL for structure and SWRL for rule enforcement. AI modules use Python 3.11 tools such as PyTorch v2.2, OR-Tools v9.9, and HuggingFace v4.40, and work with structured data from BIM models, planning documents, and sensor inputs. The framework integrates into real-world project workflows by connecting BIM authoring tools (e.g., Revit/Dynamo 2025), document repositories, and Digital Twin and reality capture data to the semantic processing workflow illustrated in Figure 2. Construction data is parsed, aligned with the ontology, and continuously updated through progress tracking, enabling AI-assisted schedule generation, validation, and control.

Figure 2.

AI-Driven Framework and Workflow for Semantic Integration in Automated, Logic-Based Construction Planning and Monitoring (The number has been explained below).

- Multimodal AI extracts construction data from drawings, images, and documents.

- Ontology mapping aligns extracted data with structured domain models.

- Knowledge graphs represent linked entities and planning relationships.

- ML (e.g., LSTM, Transformer) predicts task durations and potential delays.

- Ontology Reasoners validate planning logic, enforce constraints, and infer relationships.

- OWL ontology defines core planning classes, roles, and dependencies.

- Solvers (e.g., OR-Tools) generate and optimize construction schedules.

- Rule Engines evaluate plan feasibility using constraints, resource logic, and goals.

- IfcOpenShell parses .ifc (e.g., JSON, CSV, XML), Dynamo. rvt models to (e.g., CSV).

- Karma maps data (e.g., CSV, JSON) to ontology classes for semantic modeling and RDF output.

2.1. Enriched BIM Data

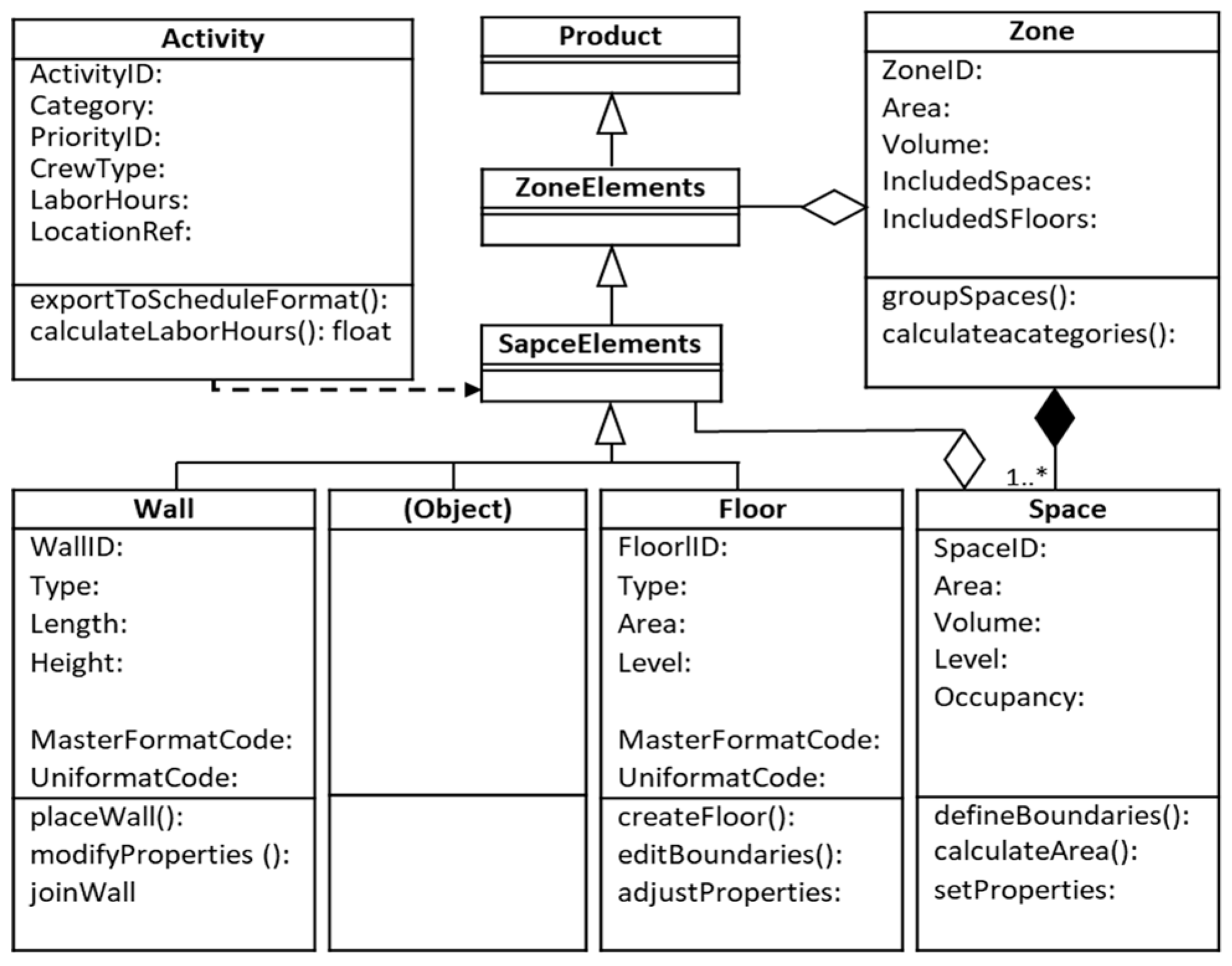

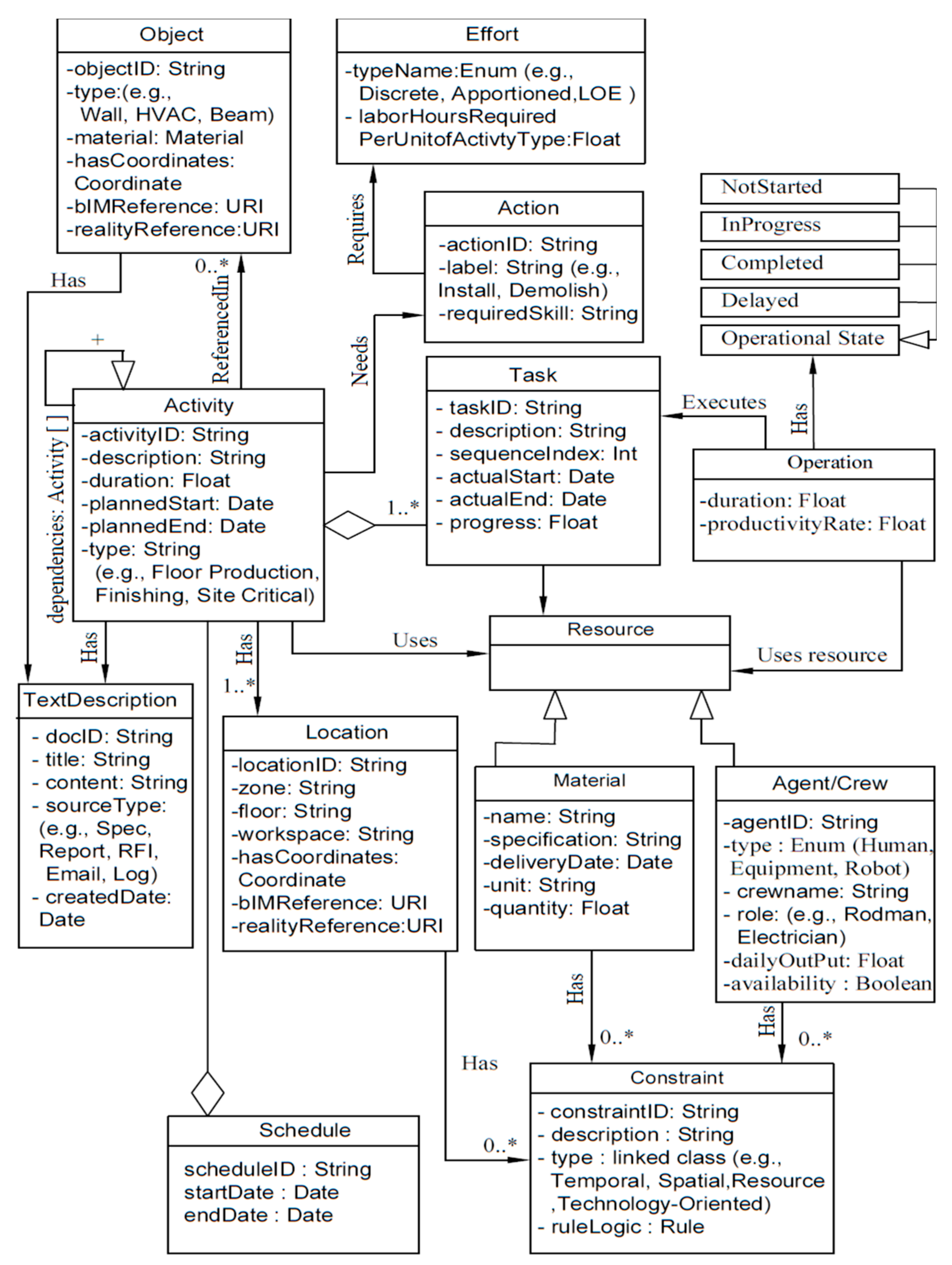

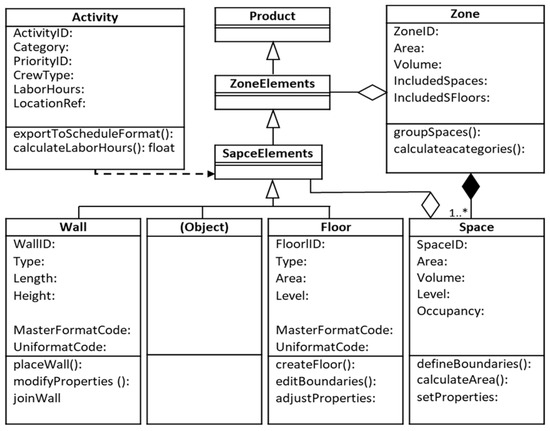

The first step in the methodology involves enriching BIM data with construction planning information. This helps to address the common fragmentation where essential scheduling knowledge, such as task dependencies, spatial zones, resource needs, and site constraints, is often isolated in external tools or documents. The framework embeds scheduling semantics directly into the BIM schema. As illustrated in Figure 3, the Unified Modeling Language (UML) diagram shows how physical components and spatial hierarchies (e.g., buildings, floors, zones) are structured and linked to construction tasks, resources, and material specifications. This transforms BIM from a geometric model into a semantically enriched representation that supports both spatial and process planning, enabling not only the “what” and “where” but also the “when” and “how” of construction activities. The enriched schema introduces new classes and attributes that connect building elements, work areas, resource estimates, and execution logic. Each BIM object is linked to corresponding scheduled activities and enhanced with metadata for planning and monitoring purposes. Following the Enhanced Planning Method proposed by [24], the model categorizes and locates tasks within spatial zones to facilitate AI-driven scheduling and improve planning.

Figure 3.

UML diagram of BIM elements and their spatial structure. X.. * Indicates a multiplicity range, where X is a non-negative integer (e.g., 0, 1, 2, etc.), and (Object) is a placeholder for any additional object type in the model.

Key enriched attributes include: Activity identifiers and hierarchy: Each task has a unique ID and category (e.g., floor production, finishing) and is mapped to its corresponding work area. Spatial location: Tasks are associated with specific BIM zones (e.g., floors or rooms), enabling location-based scheduling. Resource and effort attributes: Tasks include estimating required labor, equipment, materials, and crew effort, facilitating sequencing, and combinatorial optimization. This approach builds on IFC-based BIM standards by integrating scheduling logic directly into the BIM environment. Using the methodology proposed by [24], the framework links tasks to building elements, resources, and spatial zones by classifying activities according to type and location. The result is a unified, semantically rich BIM model that forms the basis for AI-driven scheduling and monitoring.

2.2. Digital Twin Data in Construction

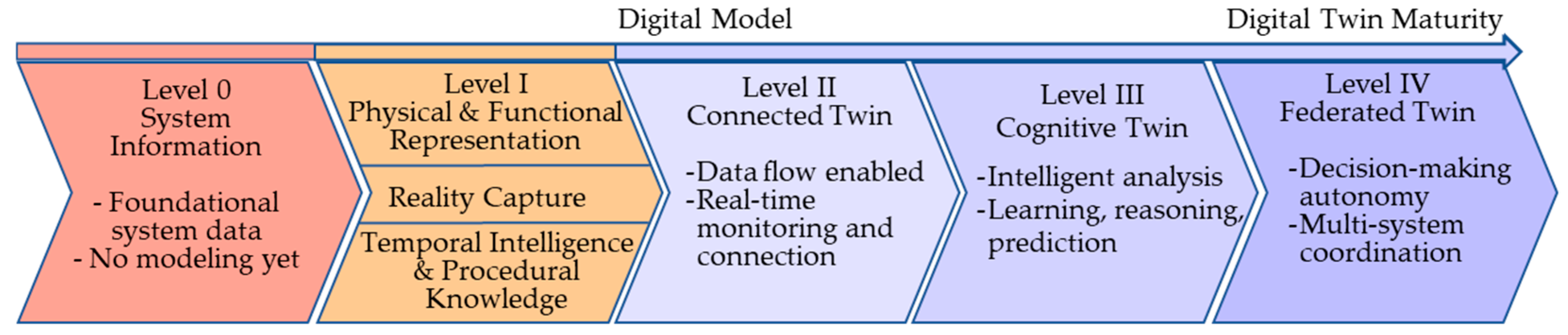

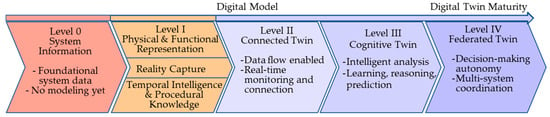

Integrating DT data enables real-time synchronization between construction plans and field progress. A DT is a live digital representation of the construction environment, continuously updated through IoT sensors and site data [6,12,17]. As illustrated in Figure 4, the digital twin maturity model outlines how capabilities progress from basic digital representations to advanced, intelligent systems.

Figure 4.

The maturity model of the digital twin. Table 2 presents the corresponding functional maturity levels, illustrating how the digital twin maturity model guides the framework’s integration strategy by aligning DT functionality with planning automation needs.

Table 2.

Digital Twin Model Functional Maturity Forward Approach.

Table 2.

Digital Twin Model Functional Maturity Forward Approach.

| Digital Model Maturity in the Built Environment | Functional Capability | |||

|---|---|---|---|---|

| Two-Way Communication | Lifecycle Integration | Intelligence/Learning | Human- Machine Interaction | |

| Level 0: System Information | No | No | No | No |

| Level 1: Physical & Functional Representation | Limited | Design Phase | No | Basic |

| Level IA: Enriched Physical & Functional Representation | Yes | Design and Construction | No | Interactive |

| Level II: Connected Twin | Yes | +Operational Phase | No | Interactive |

| Level III: Cognitive Twin | Yes | Full Lifecycle | Assistive | Assistive |

| Level IV: Federated Twin | Yes | Full Lifecycle | Autonomous | Minimal |

DT data enhances the scheduling ontology by updating object states and triggering rule-based actions such as rescheduling tasks or identifying resource issues based on real-time progress. Sensor data mapped to ontology and BIM elements ensures changes are semantically interpreted and computationally actionable. This supports the development of the framework into a responsive, closed-loop system that supports proactive monitoring, real-time reasoning, and adaptive scheduling.

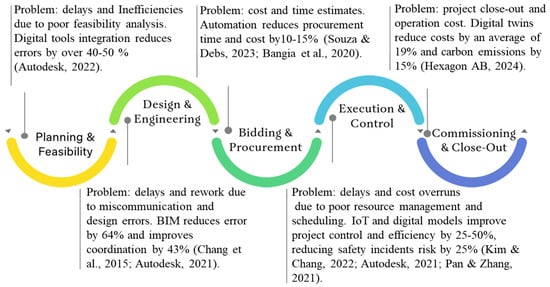

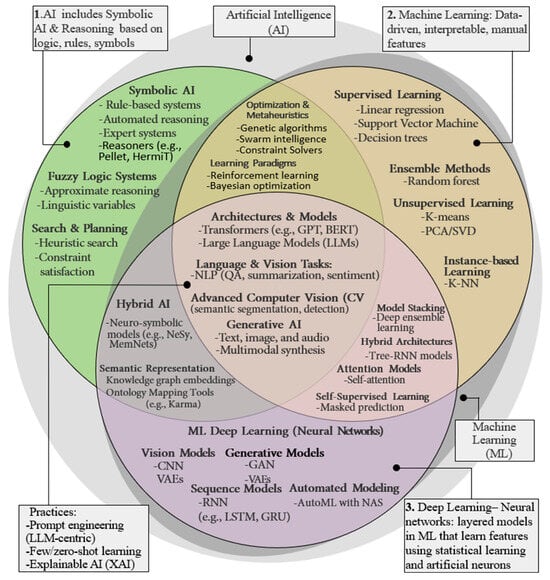

2.3. AI in Construction Planning

AI enables specific automation, optimization, and intelligent support within the proposed framework. Figure 5 presents a contextual categorization of AI techniques and commonly used AI techniques [25,26,27]. The proposed framework applies selected AI methods to support logic-based reasoning, knowledge extraction, automated scheduling, monitoring, and semantically integrated BIM and Digital Twin data for planning. The AI functionality is embedded across the core components of the framework, as shown in Figure 2. It supports data flow from BIM, digital twin, and project documents to automated schedules and reasoning about project planning and execution.

Figure 5.

Classification of common AI techniques and contextual classification.

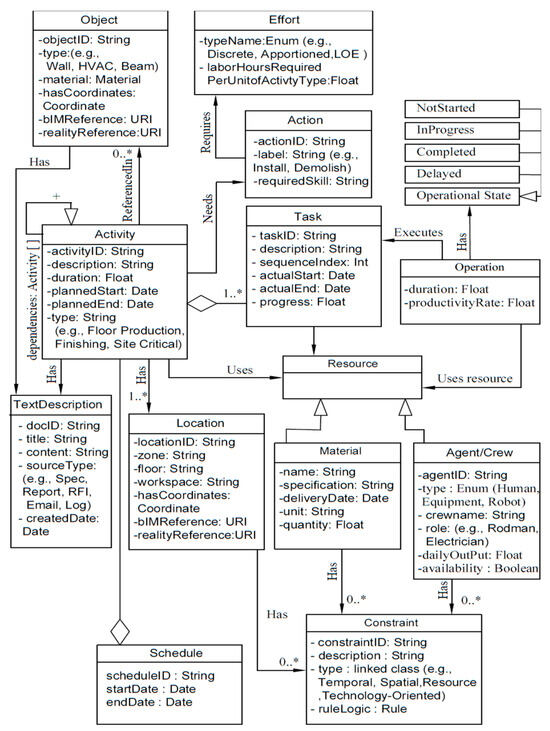

2.3.1. Multimodal Information Extraction & Ontology Mapping

This module extracts planning knowledge from various heterogeneous sources, including construction documents, technical drawings, images, and diagrams. Using GPT-4 Vision and AI semantic representation tools (Figure 5), the system helps interpret textual and visual inputs to identify critical planning elements such as activity descriptions, execution procedures, sequencing logic, spatial and temporal constraints, and resource or crew requirements. Recent advancements in large language models (LLMs) enable generative structuring and schema mapping to support this process [26,28]. These elements are then aligned with ontology models to produce structured representations in formats such as RDF, including semantic assertions to capture complex relationships, conditional logic, and contextual attributes (Figure 6). This semantically enriched data is harmonized into the construction scheduling ontology (Figure 2), enabling downstream tasks such as automated schedule generation, constraint validation, rule-based reasoning, advanced semantic querying, and progress tracking.

Figure 6.

UML representation of Construction schedule and process ontology. X.. * Indicates a multiplicity range where X is a non-negative integer (e.g., 0, 1, 2, etc.).

2.3.2. Machine Learning (ML)

ML techniques are applied after the scheduling logic, such as task dependencies, work scope, resources, and constraints, has been extracted and structured through multimodal information extraction and semantic modeling. Once these foundational elements are established, ML models can analyze historical data, real-time DT inputs, and structured ontology-based relationships to estimate activity durations, predict delays, and identify patterns across project timelines. Recurrent models like LSTM and GRU are suitable for modeling time-dependent construction behaviors [25]. Training data for ML models may include structured records from past construction projects or data logged through DT-enabled monitoring systems, depending on availability and project phase. The outputs inform sequence optimization and proactive decision-making within the schedule generation module.

2.3.3. Rule-Based and Graph-Based Reasoning

Rule-based reasoning validates the logic of generated plans by enforcing domain constraints encoded in the ontology (Section 2.4), such as precedence, spatial allocation, and resource constraints. In parallel, graph-based reasoning using logic traversal over ontology structures evaluates plan feasibility, identifies inconsistencies, and supports knowledge inference across interconnected scheduling entities. These reasoning processes interact with the harmonized knowledge base of enriched BIM and DT data. The harmonized ontology not only defines the semantic structure of the framework but also operates as a dynamic knowledge graph. This knowledge graph comprises instantiated entities (e.g., construction activities, resources, constraints, spatial zones) and their interrelationships derived from BIM, DT, and multimodal AI-extracted data. As a result, AI models can traverse and reason over this graph to infer logical consequences, detect conflicts, and support constraint-aware planning. The graph-based structure enables semantic querying, traceability, and advanced analytics, forming the computational foundation for rule-based and learning-based decision support throughout the planning and monitoring lifecycle. These AI techniques form a coherent decision-making layer that activates after the BIM and DT data and structured construction information have been semantically harmonized and instantiated within the scheduling ontology. AI facilitates data extraction, learning-based prediction, and logic reasoning modules, making planning automation responsive, traceable, and integrated across the digital–physical project environment.

2.4. Construction Scheduling Ontology

Ontologies provide a formal and machine-interpretable structure for representing domain knowledge, enabling automated reasoning across heterogeneous data sources [22,23]. In construction, scheduling ontologies have emerged as essential tools for capturing activity logic, sequencing constraints, resource relationships, and project-specific knowledge to support AI-enhanced planning and monitoring [29,30]. The construction scheduling ontology developed in this study serves as the unifying semantic structure of the framework, integrating information from BIM, Digital Twin (DT), planning documents, and AI models into a unified knowledge representation. In this context, the ontology functions as a domain-specific knowledge graph, where activities, constraints, resources, and spatial zones are semantically linked to enable intelligent reasoning and dynamic planning. As shown in Figure 6, the ontology defines core classes, such as Activity, Resource, Location, Constraint, and OperationalState, and their semantic relationships to support automated schedule generation and dynamic reasoning. This structure links construction activities to spatial work zones, resources, procedures, and logical dependencies.

Each ontology instance is instantiated using harmonized data streams from enriched BIM models (Section 2.1), DT inputs (Section 2.2), and extracted knowledge from project documents (via multimodal extraction and ontology mapping; Section 2.3). Relationships like occursAt, usesResource, hasPredecessor, or subjectToConstraint formalize the execution logic between components. These are encoded as OWL 2 axioms, enabling validation using Description Logic (DL) reasoners. Where needed, domain-specific rules can be defined using SWRL or validated through SHACL constraints.

To ensure interoperability, ontology elements reference source identifiers from the BIM and DT systems. This enables traceability; for example, when a delay is detected in the DT model, the linked activity within the ontology can trigger a re-evaluation of downstream dependencies via reasoning logic. The ontology also supports SPARQL querying, allowing agents or stakeholders to issue targeted information requests (e.g., “Which critical tasks in Zone B depend on concrete curing conditions?”), thereby enhancing proactive monitoring and control.

As represented in Figure 2, this ontology integrates all framework components into a coherent semantic model, acting as a shared reasoning layer across BIM, scheduling logic, and Digital Twin data. It translates construction logic into a structured schema, facilitating automation, consistency, and real-time coordination across all planning stages.

3. Results

This work developed an AI-driven framework that enhances construction planning and monitoring. It combines data that are typically scattered across project documents, including design models, schedules, procedures, and site logs and updates. The framework organizes this information into a structured environment where planning logic, resources, constraints, and real-time project data are connected to support execution and control.

The framework includes four core components: (1) an enriched BIM model with task resources, spatial information, and attributes; (2) a construction-specific ontology that links information across domains; (3) an AI logic layer that interprets, validates, and forecasts planning outcomes; and (4) synchronization with Digital Twin and reality data inputs that keep the execution plan updated based on real-time site conditions. AI enables the system to support the extraction of planning logic from documents and drawings using multimodal methods, identify conflicts or missing conditions, and anticipate delays. In a simplified case study of a two-story educational building, the 2nd-floor construction sequence consisting of five tasks: A1018 (Formwork Removal), A1042 (Wall Framing), A2067 (Electrical Rough-In), A3089 (Drywall), and A4093 (Stucco and Painting) was scheduled using both traditional and ontology-based methods. The proposed framework extracted logic from project documents and BIM (via GPT-4 and Revit Dynamo), modeled dependencies in OWL, validated constraints using SHACL and SWRL (e.g., A3089 blocked by inspections of A2067 and A1042), and handled a 2-day logistical delay using OR-Tools. It generated a logic-consistent, 19-day schedule. Traditional methods, which rely on manual inputs, may overlook constraints such as inspections or logistical delays unless explicitly stated and incorporated in the planning, reducing schedule accuracy.

The system enables AI-assisted schedule generation, adjustment, and validation based on planning logic and real-time updates. Planners and managers provide inputs through BIM tools, document repositories, or ontology editors. AI tools generate structured outputs such as task logic, updated schedules, or delay forecasts using Python-based libraries, and present them as linked BIM documents or query able reports. Natural language assistants can also help users interpret results. Processing runs in the background, keeping the interface decision-focused and straightforward.

4. Discussion

This study addresses a core limitation in construction: fragmented information and disconnected sources of project planning and control. While BIM improves design coordination, critical planning data schedules, procedures, resources, constraints, and progress remain scattered across documents, models, and systems. This limits efficiency, automation, and the ability to respond to changes. The proposed framework integrates this information into a structured environment. The system enables continuous reasoning about task status, constraints, and dependencies by connecting enriched BIM data, logic extracted through multimodal AI and ontology mapping, and real-time inputs within a planning ontology. Planning becomes a continuously adaptive process, rather than a static deliverable. As shown in Table 3, the framework improves over conventional approaches by supporting semantic and AI integration, real-time feedback, and reasoning. It supports automating logic-based planning and monitoring.

Table 3.

Comparison of traditional vs. AI-driven semantic planning methods.

5. Conclusions

This paper presented a framework integrating BIM, Digital Twin data, and planning knowledge to support logic-based scheduling, real-time progress tracking, and AI-assisted planning and automation. It connects fragmented data and execution logic through an ontology, enhancing schedule feasibility analysis, automated planning, constraint checking, and control. Potential barriers to adoption include the limited use of semantic tools in practice, technical skill gaps, and integration challenges. These can be addressed through industry collaboration, simplified tools for practical use, and further studies. Future work will focus on these studies and on extending the ontology and framework for broader use, as well as validating it across diverse case studies and industry conditions.

Author Contributions

Conceptualization, Q.A.; methodology, writing—original draft preparation, review and editing, Q.A., M.H. and A.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Aljohani, A.; Ahiaga-Dagbui, D.; Moore, D. Construction projects cost overrun: What does the literature tell us? Int. J. Innov. Manag. Technol. 2017, 8, 137. [Google Scholar] [CrossRef]

- Opoku, D.G.J.; Perera, S.; Osei-Kyei, R.; Rashidi, M. Digital twin application in the construction industry: A literature review. J. Build. Eng. 2021, 40, 102726. [Google Scholar] [CrossRef]

- Ballard, G.; Tommelein, I. 2020 Current Process Benchmark for the Last Planner (R) System of Project Planning and Control; University of California: Berkeley, CA, USA, 2021. [Google Scholar] [CrossRef]

- Soman, R.K.; Molina-Solana, M. Automating look-ahead schedule generation for construction using linked-data based constraint checking and reinforcement learning. Autom. Constr. 2022, 134, 104069. [Google Scholar] [CrossRef]

- Souza, A.S.C.D.; Debs, L. Identifying emerging technologies and skills required for construction 4.0. Buildings 2023, 13, 2535. [Google Scholar] [CrossRef]

- Tang, S.; Shelden, D.R.; Eastman, C.M.; Pishdad-Bozorgi, P.; Gao, X. A review of building information modeling (BIM) and the internet of things (IoT) devices integration: Present status and future trends. Autom. Constr. 2019, 101, 127–139. [Google Scholar] [CrossRef]

- Azhar, S. Building information modeling (BIM): Trends, benefits, risks, and challenges for the AEC industry. Leadersh. Manag. Eng. 2011, 11, 241–252. [Google Scholar] [CrossRef]

- Abdelbary, M.; Edkins, A.; Dorra, E.M. Reducing CRR in fast-track projects through BIM. J. Inf. Technol. Constr. 2020, 25, 140–160. [Google Scholar] [CrossRef]

- Cespedes-Cubides, A.S.; Jradi, M. A review of building digital twins to improve energy efficiency in the building operational stage. Energy Inform. 2024, 7, 11. [Google Scholar] [CrossRef]

- Chung, W.W.S.; Tariq, S.; Mohandes, S.R.; Zayed, T. IoT-based application for construction site safety monitoring. Int. J. Constr. Manag. 2023, 23, 58–74. [Google Scholar] [CrossRef]

- Han, K.K.; Golparvar-Fard, M. Potential of big visual data and building information modeling for construction performance analytics: An exploratory study. Autom. Constr. 2017, 73, 184–198. [Google Scholar] [CrossRef]

- Amer, F.; Koh, H.Y.; Golparvar-Fard, M. Automated methods and systems for construction planning and scheduling: Critical review of three decades of research. J. Constr. Eng. Manag. 2021, 147, 03121002. [Google Scholar] [CrossRef]

- Autodesk. Industry-Wide BIM Adoption Is Accelerating Digital Transformation. Autodesk. 2022. Available online: https://damassets.autodesk.net/content/dam/autodesk/www/industry/aec/bim/aec-bim-study-smart-market… (accessed on 11 March 2025).

- Bangia, M.; Cruz, G.; Huber, I.; Landauer, P.; Sunku, V. Sales Automation: The Key to Boosting Revenue and Reducing Costs. McKinsey & Company. 13 May 2020. Available online: https://www.mckinsey.com/capabilities/growth-marketing-and-sales/our-insights/sales-automation-the-key-to-boosting-revenue-and-reducing-costs (accessed on 11 March 2025).

- Hexagon, A.B. The Digital Twin Industry Report; Calameo: Paris, France, 2024; Available online: https://www.calameo.com/read/001915796155d0c494c32?authid=L8cWi6laffjB (accessed on 5 March 2025).

- Chang, S.; Son, J.; Jeong, W.; Yi, J.S. BIM-integrated simulation of construction operations for lean production management. In Proceedings of the Modular and Offsite Construction (MOC) Summit Proceedings, Edmonton, AB, Canada, 19–21 May 2015; pp. 288–294. [Google Scholar]

- Autodesk. Digital Transformation: The Future of Connected Construction. Autodesk Construction Cloud. 2020. Available online: https://constructioncloud.autodesk.com/rs/572-JSV-775/images/Autodesk-IDC-Digital%20Transformation_The-Future-of-Connected-Construction.pdf (accessed on 12 March 2025).

- Kim, S.; Chang, S. Construction project level-based environmental, social, and governance (C-ESG): A review. EPiC Ser. Built Environ. 2022, 3, 236–244. [Google Scholar]

- Autodesk. Keeping Pace with the Modern Construction Industry. Autodesk. 2021. Available online: https://damassets.autodesk.net/content/dam/autodesk/www/pdfs/adk-dodgereport-construction-whitepaper-fnl.pdf (accessed on 10 March 2025).

- Pan, Y.; Zhang, L. Roles of artificial intelligence in construction engineering and management: A critical review and future trends. Autom. Constr. 2021, 122, 103517. [Google Scholar] [CrossRef]

- Schlehen, J.; Borrmann, A. Advanced process representation for semi-automated linking between construction schedules and IFC files. In Proceedings of the LDAC 2024—Linked Data in Architecture and Construction, Bochum, Germany, 13–14 June 2024. [Google Scholar]

- El-Gohary, N.M.; El-Diraby, T.E. Domain ontology for processes in infrastructure and construction. J. Constr. Eng. Manag. 2010, 136, 730–744. [Google Scholar] [CrossRef]

- Getuli, V. Ontologies for Knowledge Modeling in Construction Planning: Theory and Application; Firenze University Press: Florence, Italy, 2020. [Google Scholar] [CrossRef]

- Amarkhil, Q.; Elwakil, E. Enhanced planning and scheduling in building construction projects: An innovative approach to overcome scheduling challenges. Int. J. Constr. Manag. 2024, 24, 1719–1729. [Google Scholar] [CrossRef]

- Sarker, I.H. AI-based modeling: Techniques, applications and research issues towards automation, intelligent and smart systems. SN Comput. Sci. 2022, 3, 158. [Google Scholar] [CrossRef] [PubMed]

- Hagos, D.H.; Battle, R.; Rawat, D.B. A systematic review of large language models and foundation models in artificial intelligence. Appl. Sci. 2024, 14, 843. [Google Scholar] [CrossRef]

- Ressi, D.; Ferrando, A.; Reforgiato Recupero, D.; Fenu, G. AI-enhanced blockchain technology: A comprehensive survey. Future Gener. Comput. Syst. 2024, 146, 133–150. [Google Scholar] [CrossRef]

- Singh, A.K.; Pal, A.; Kumar, P.; Lin, J.J.; Hsieh, S.H. Prospects of integrating BIM and NLP for automatic construction schedule management. In Proceedings of the ISARC 2023: International Symposium on Automation and Robotics in Construction, Chennai, India, 5–7 July 2023; Volume 40, pp. 238–245. [Google Scholar]

- Amarkhil, Q.; Alroomi, A. Ontology-based framework for AI-driven scheduling and monitoring with BIM and reality data integration. In Proceedings of the ISEC 2025/ASEA SEC 7 Conference, Sydney, Australia, 17–21 November 2025. [Google Scholar]

- Zhao, X.; Zhang, Y.; Wang, C. How BIM training affects individual learning: A perspective of experiential learning theory. Autom. Constr. 2019, 104, 286–296. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).