Abstract

A rapid screening method to identify suitable candidate inks for printed electronics applications is necessary. Herein, we investigate the in-plane thermoelectric properties of PEDOT:PSS for energy harvesting applications on human skin using silver nanoparticle inkjet-printed test structures. The in-plane electrical and thermal conductivity are measured. The Seebeck coefficient, ZT figure of merit, and power factor are consequently determined. PEDOT:PSS films resulted in low-efficiency thermoelectric properties at 293 K to 313 K and demonstrated a correlation between film thickness and in-plane thermoelectric properties. This study demonstrates that the test structures enable generalisable characterisation of thin-film inkjet-printable materials for thermoelectric purposes.

1. Introduction

Ultra-low-grade waste heat and low-grade waste heat sources have gained much interest because of their potential in the heating sector, forming approximately 60% of the lost primary energy [1]. Waste heat recovery (WHR) technologies promise major prospects and opportunities in improving heat energy utilisation [2]. Solid-state devices like thermoelectric generators (TEGs) can enhance energy recovery methods by harvesting energy from heat sources with low temperature gradients relative to the environmental temperature [3]. TEGs are advantageous in that they have no moving parts, produce no vibrations and are relatively environmentally friendly [4], and they can be used on human skin for energy harvesting applications. The efficiency of thermoelectric (TE) energy conversion in TEGs is governed by the dimensionless figure of merit [5],

where is the electrical conductivity, S is the Seebeck coefficient, k is thermal conductivity and T is the average temperature. Highly efficient TEGs comprise materials with high S and , and low k values. The TE performance of the TEG is characterised by the material power factor,

and the TE improvement thereof leads to a high ZT value. Test structures were developed for the in-plane TE characterisation of PEDOT:PSS thin films for research and development of flexible TEG applications.

2. Materials and Methods

Sample Preparation

The test structures were formed with silver nanoparticle (AgNP) ink (Harima NPS-JL). The AgNP ink was initially prepared by mixing a 3 mL sample with the Corning variable-speed LSE vortex mixer for 30 min. A Fujifilm Dimatix 10 pL drop volume cartridge was filled with 1.5 mL of the prepared ink and thereafter inkjet-printed on a flexible polyimide (PI) substrate (Polyphonic XF-613). The PI was pre-treated with isopropanol alcohol and air-dried before inkjet printing. The inkjet printer settings used for the Dimatix DMP-2850 are indicated in Table 1. The chosen waveform, jetting voltage settings and drop spacing provided effective drops on the Dimatix drop watcher. The inkjet printer platen temperature was set to 50 °C to control ink spreading on the PI substrate. The resultant test structures were cured at 353 K for 12 h and thereafter tested for electrical continuity. PEDOT:PSS ink (1.3 wt % dispersion in water, conductive grade) was purchased from Sigma Aldrich and prepared similar to the AgNP ink, with a vortex mixer for 30 min. The PEDOT:PSS thin films were formed by direct ink deposition onto the flexible test structure samples and further cured at 353 K for 30 min. The various thin-film sample thicknesses ranged from 10 µm to 25 µm.

Table 1.

Dimatix DMP-2850 single-nozzle printing parameters.

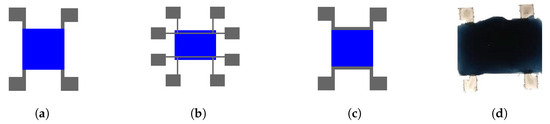

TE characterisation of AgNP test structures (grey) in Figure 1 was used for in-plane characterisation of the PEDOT:PSS thin films (blue). The probe pads for all test structures were kept to 2.5 mm2. Figure 1a shows the van der Pauw resistivity four-point probe measurements [6]. Figure 1b shows a resistive heater–sensor structure for measuring the thermal conductivity and Figure 1c is used to determine the Seebeck coefficient of the thin film.

Figure 1.

Characterisation of test structures: (a) Electrical conductivity. (b) Thermal conductivity. (c) Seebeck coefficient. (d) Microscopic image of PEDOT:PSS thin film on four-point probe test structure.

3. Results

3.1. Sample Profile Characterisation

The samples were analysed to determine the film’s dimensional profile with the Olympus DSX1000 microscope (Olympus Corporation, Tokyo, Japan) including the DSX10-XLOB40X objective (Olympus Corporation, Tokyo, Japan) in dark field (DF) mode. Figure 1d shows a microscopic image of the four-point probe test structure with the directly deposited PEDOT:PPS thin film. The mean surface area measured from the 2D profiles of five PEDOT:PSS samples is 130 µm2 and the mean height is 20 µm.

3.2. Measurement Results

The measured results are summarised in Table 2. The four-point probe test structure in Figure 1a was used to measure the PEDOT:PSS film surface resistance and thereafter, the dimensional characteristics and surface resistance results were used to determine the mean sheet resistance and electrical conductivity (). The test structure in Figure 1b was used to measure thermal conductivity by applying 1 VDC across one end of the AgNP heating electrodes, and the current and temperature gradients between the heater and sensor electrodes were monitored over time. By using the Joules heating effect [7], the mean in-plane thermal conductivity was determined. The Seebeck coefficient was determined by subjecting the opposing AgNP electrodes in Figure 1c to a temperature gradient of 22 K and measuring the subsequent thermal voltage across the PEDOT:PSS film [8]. The ZT value and PF were thus calculated from the measured TE results.

Table 2.

Mean thermoelectric characteristics.

4. Discussion

The results of this study demonstrate that the PEDOT:PSS thin films can be rapidly characterised for research and development of flexible TEG applications on human skin. The PEDOT:PSS ink characterised here resulted in low efficiency as the in-plane electrical conductivity and Seebeck coefficient are low compared to enhanced PEDOT:PSS inks [9]. This led to a low power factor performance and subsequently a low ZT figure of merit. Thermal conductivity remained intrinsically low as only the in-plane thermal conductivity was considered in this study. Electrical conductivity and thermal conductivity were inversely proportional to film thickness while the Seebeck coefficient remained relatively constant with the increase in film thickness. The electrical conductivity can be further improved with the addition of a suitable solvent to the PEDOT:PSS ink [10], and thereafter characterised using the proposed method. The measurement accuracy can be improved by inkjet printing the PEDOT:PSS thin films with nanometer thicknesses. This is better suited for monitoring thin-film thermal energy transfer, charge carrier transport and thus thermal properties [11]. Further investigation is required to produce methods for the inclusion of cross-plane characterisation of thin films. The proposed test structures are valid for lab environment production and demonstrate manufacturing readiness level 4 (MRL-4) compliance. Full-rate production implementation requires large-scale printing methods [12] for a production-relevant environment and may require additional measurement technique research. To reach MRL-5, print quality and management strategies of the test structures [13] must be considered. This study demonstrates that conductive inkjet-printable polymers like PEDOT:PSS can be deposited on flexible substrates such as thin films and characterised using the proposed AgNP test structures for rapid research and development ink screening for low-temperature flexible printed electronic applications.

Author Contributions

Conceptualisation, P.M. and T.-H.J.; methodology, P.M.; investigation, P.M.; resources, T.-H.J.; writing—original draft preparation, P.M.; writing—review and editing, P.M. and T.-H.J.; visualisation, P.M.; supervision, T.-H.J.; project administration, T.-H.J.; funding acquisition, T.-H.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the South African Department of Science and Innovation Nano and Micro Manufacturing Facility grant.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Additional data can be obtained from the authors.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the research or in the decision to publish the results.

References

- Oh, J.; Han, U.; Jung, Y.; Kang, Y.T.; Lee, H. Advancing waste heat potential assessment for net-zero emissions: A review of demand-based thermal energy systems. Renew. Sustain. Energy Rev. 2024, 202, 114693. [Google Scholar] [CrossRef]

- Saghafifar, M.; Omar, A.; Mohammadi, K.; Alashkar, A.; Gadalla, M. A review of unconventional bottoming cycles for waste heat recovery: Part I—Analysis, design, and optimization. Renew. Sustain. Energy Rev. 2019, 198, 110905. [Google Scholar] [CrossRef]

- Liu, Y.; Riba, J.-R.; Moreno-Eguilaz, M.; Sanllehí, J. Application of Thermoelectric Generators for Low–Temperature–Gradient Energy Harvesting. Appl. Sci. 2023, 13, 2603. [Google Scholar] [CrossRef]

- Hewawasam, L.; Jayasena, A.; Afnan, M.; Ranasinghe, R.; Wijewardane, M. Waste heat recovery from thermo-electric generators (TEGs). Energy Rep. 2020, 6, 474–479. [Google Scholar] [CrossRef]

- Zhang, Q.; Yang, C.-L.; Wang, M.-S.; Ma, X.-G. Evaluate dimensionless figure of merit for thermoelectric materials based on the intrinsic carrier concentration and bipolar effect. Mater. Today Commun. 2022, 31, 103760. [Google Scholar] [CrossRef]

- Nikolov, G.T.; Gieva, E.E.; Nikolova, B.M.; Ruskova, I.N. Virtual System for Sheet Resistance Measurement of Inkjet Printed Conductive Layers. In Proceedings of the 2019 X National Conference with International Participation (ELECTRONICA), Sofia, Bulgaria, 16–17 May 2019; IEEE: Sofia, Bulgaria, 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Whulanza, Y.; Ammarsyah, R.; Yatim, A. Characterization of Silver Resistive Electrode as Heating Module for Portable Thermocycler Device. In Proceedings of the 2021 IEEE International Biomedical Instrumentation and Technology Conference (IBITeC), Yogyakarta, Indonesia, 20–21 October 2021; IEEE: Yogyakarta, Indonesia, 2021; pp. 40–45. [Google Scholar] [CrossRef]

- Linseis, V.; Völklein, F.; Reith, H.; Woias, P.; Nielsch, K. Platform for in-plane ZT measurement and Hall coefficient determination of thin films in a temperature range from 120 K up to 450 K. J. Mater. Res. 2016, 31, 3196–3204. [Google Scholar] [CrossRef]

- Fan, Z.; Ouyang, J. Thermoelectric Properties of PEDOT:PSS. Adv. Electron. Mater. 2019, 5, 1800769. [Google Scholar] [CrossRef]

- Galliani, M.; Ferrari, L.M.; Bouet, G.; Eglin, D.; Ismailova, E. Tailoring inkjet-printed PEDOT:PSS composition toward green, wearable device fabrication. APL Bioeng. 2023, 7, 016101. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Riba, J.-R.; Moreno-Eguilaz, M.; Sanllehí, J. A short account of thermoelectric film characterization techniques. Mater. Today Phys. 2023, 36, 101173. [Google Scholar] [CrossRef]

- Lee, M.; Parajuli, S.; Moon, H.; Song, R.; Lee, S.; Shrestha, S.; Park, J.; Yang, H.; Jung, Y.; Cho, G.; et al. Characterization of silver nanoparticle inks toward stable roll-to-roll gravure printing. Flex. Print. Electron. 2022, 7, 014003. [Google Scholar] [CrossRef]

- Zhang, J.; Ahmadi, M.; Fargas, G.; Perinka, N.; Reguera, J.; Lanceros-Méndez, S.; Llanes, L.; Jiménez-Piqué, E. Silver Nanoparticles for Conductive Inks: From Synthesis and Ink Formulation to Their Use in Printing Technologies. Metals 2022, 12, 234. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).