Rapid Route to Lab-on-Chip (LOC) Prototype Fabrication with Limited Resources †

Abstract

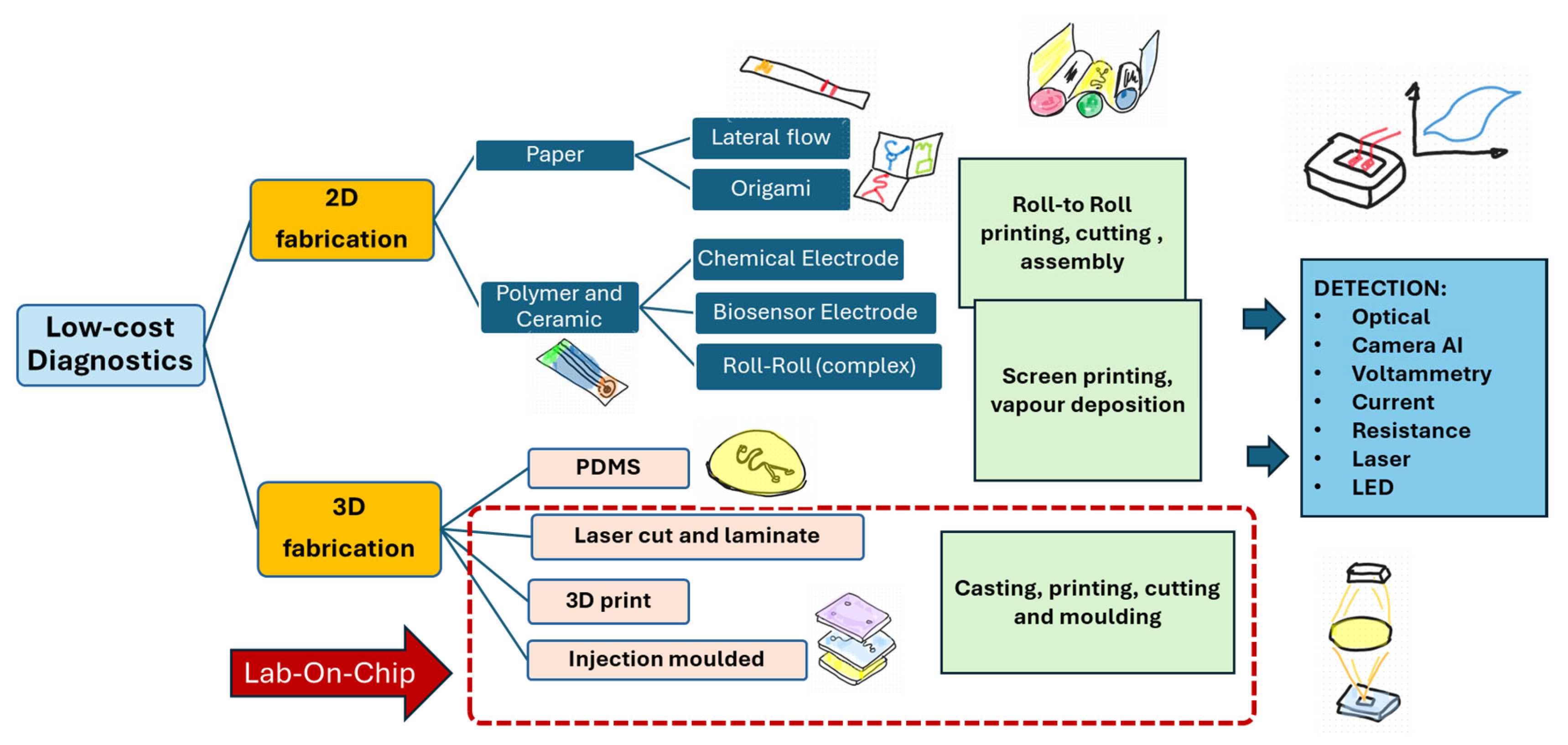

1. Introduction

1.1. Laser Cut and Laminated LOC

1.2. Injection Molded LOC

1.3. LOC Device Sealing

2. Materials and Methods

2.1. Laser Cutting and Lamination

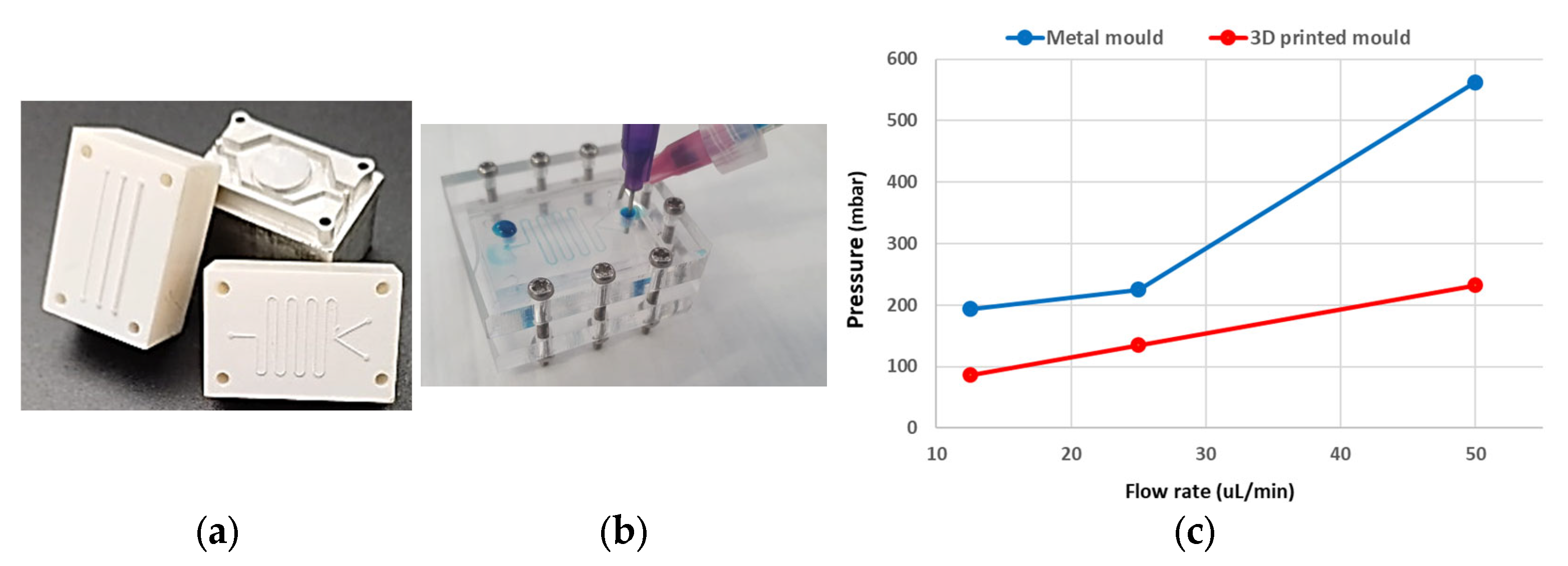

2.2. Injection Molding

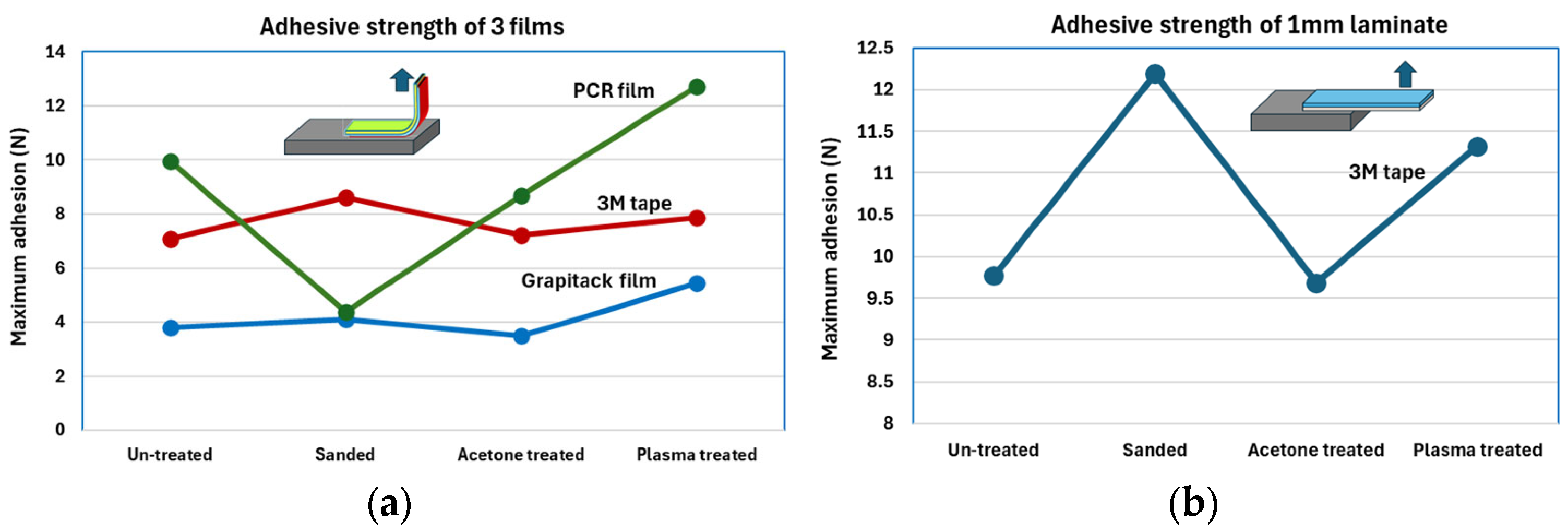

2.3. Adhesion Testing

3. Results

3.1. Lamination Test

3.2. Laser Cut and Laminated Magnetic Micro-Bead Separator

3.3. Injection Molding

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Land, K.J.; Boeras, D.I.; Chen, X.-S.; Ramsay, A.R.; Peeling, R.W. REASSURED diagnostics to inform disease control strategies, strengthen health systems and improve patient outcomes. Nat. Microbiol. 2019, 4, 46–54. [Google Scholar] [CrossRef] [PubMed]

- Omidfar, K.; Riahi, F.; Kashanian, S. Lateral Flow Assay: A Summary of Recent Progress for Improving Assay Performance. Biosensors 2023, 13, 837. [Google Scholar] [CrossRef] [PubMed]

- Wartmann, D.; Rothbauer, M.; Kuten Pella, O.; Barresi, C.; Visus, C.; Felzmann, T.; Peter, E. Automated, Miniaturized, and Integrated Quality Control-on-Chip (QC-on-a-Chip) for Cell-Based Cancer Therapy Applications. Front. Mater. 2015, 2, 60. [Google Scholar] [CrossRef]

- Formlabs. Available online: https://formlabs.com/blog/injection-molding-cost/ (accessed on 26 July 2024).

- Romoli, L.; Tantussi, G.; Dini, G. Experimental approach to the laser machining of PMMA substrates for the fabrication of microfluidic devices. Opt. Lasers Eng. 2011, 49, 419–427. [Google Scholar] [CrossRef]

- Kistrup, K.; Poulsen, C.E.; Hansen, M.; Wolff, A. Ultrasonic welding for fast bonding of self-aligned structures in lab-on-a-chip systems. Lab Chip. 2015, 15, 1998–2001. [Google Scholar] [CrossRef] [PubMed]

- Yablokov, M.; Kechek’yan, A.; Bazhenov, S.; Gil’man, A.; Piskarev, M.; Kuznetsov, A. Adhesive properties of plasma-modified polytetrafluoroethylene films. High Energy Chem. 2009, 43, 512–515. [Google Scholar] [CrossRef]

- Burlaga, B.; Kroma, A.; Poszwa, P.; Kłosowiak, R.; Popielarski, P.; Strek, T. Heat Transfer Analysis of 3D Printed Wax Injection Mold Used in Investment Casting. Materials 2022, 15, 6545. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scriba, M.; Kakaza, M.; Maesela, E.; Mandiwana, V. Rapid Route to Lab-on-Chip (LOC) Prototype Fabrication with Limited Resources. Eng. Proc. 2025, 109, 4. https://doi.org/10.3390/engproc2025109004

Scriba M, Kakaza M, Maesela E, Mandiwana V. Rapid Route to Lab-on-Chip (LOC) Prototype Fabrication with Limited Resources. Engineering Proceedings. 2025; 109(1):4. https://doi.org/10.3390/engproc2025109004

Chicago/Turabian StyleScriba, Manfred, Masibulele Kakaza, Eldas Maesela, and Vusani Mandiwana. 2025. "Rapid Route to Lab-on-Chip (LOC) Prototype Fabrication with Limited Resources" Engineering Proceedings 109, no. 1: 4. https://doi.org/10.3390/engproc2025109004

APA StyleScriba, M., Kakaza, M., Maesela, E., & Mandiwana, V. (2025). Rapid Route to Lab-on-Chip (LOC) Prototype Fabrication with Limited Resources. Engineering Proceedings, 109(1), 4. https://doi.org/10.3390/engproc2025109004