Rapid, Low-Cost Production of Multilayer Molds for PDMS Lab-on-Chip Devices †

Abstract

1. Introduction

2. Materials and Methods

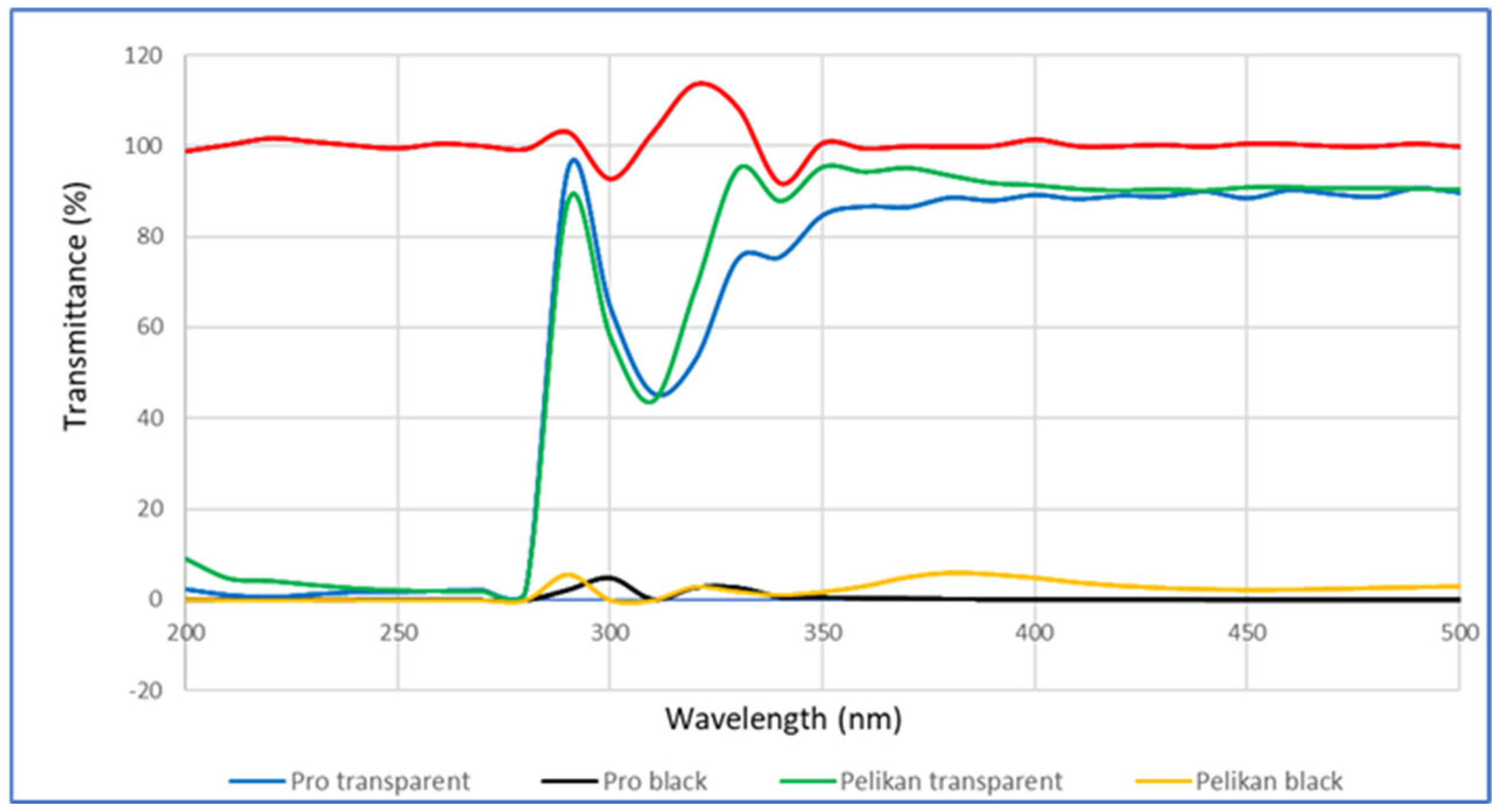

2.1. Mask Production

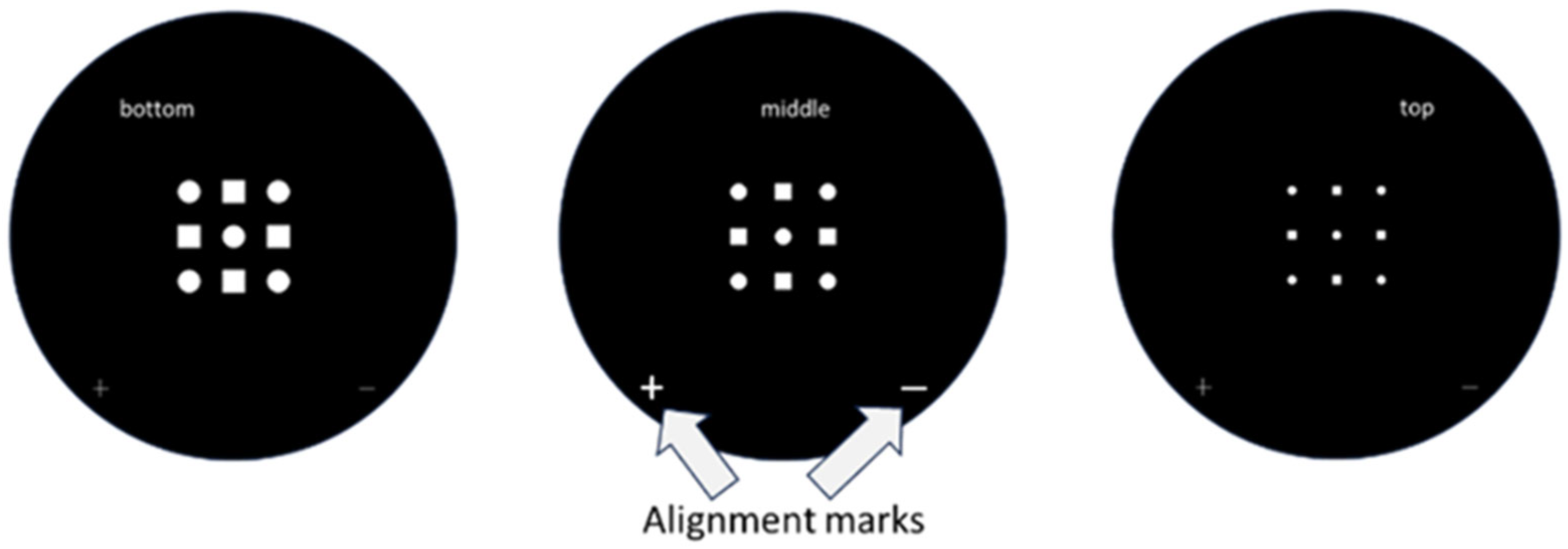

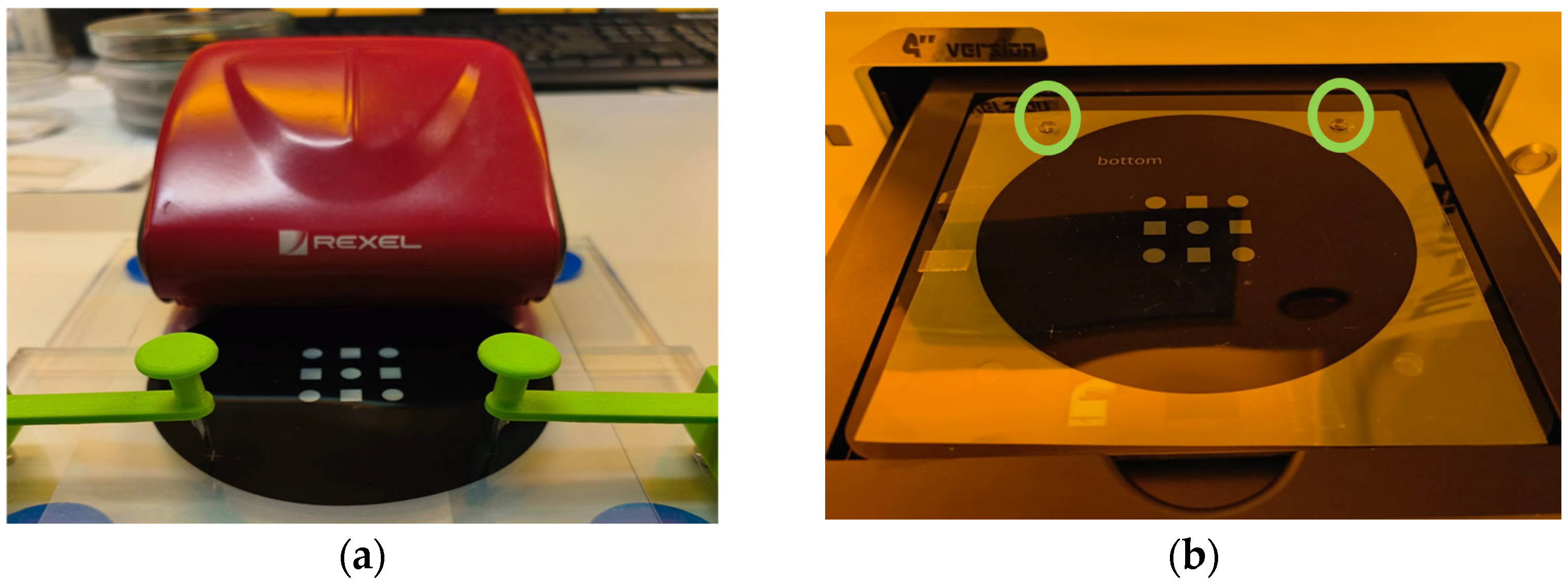

2.2. Mask Alignment and Silicon Wafer Holder for UV Exposure

2.3. SU-8 Mold Fabrication

3. Results and Discussions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhuang, J.; Yin, J.; Lv, S.; Wang, B.; Mu, Y. Advanced “lab-on-a-chip” to detect viruses—Current challenges and future perspectives. Biosens. Bioelectron. 2020, 163, 112291. [Google Scholar] [CrossRef] [PubMed]

- Zhu, H.; Fohlerová, Z.; Pekárek, J.; Basova, E.; Neužil, P. Recent advances in lab-on-a-chip technologies for viral diagnosis. Biosens. Bioelectron. 2020, 153, 112041. [Google Scholar] [CrossRef] [PubMed]

- Dkhar, D.S.; Kumari, R.; Malode, S.J.; Shetti, N.P.; Chandra, P. Integrated lab-on-a-chip devices: Fabrication methodologies, transduction system for sensing purposes. J. Pharm. Biomed. Anal. 2023, 223, 115120. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Sun, Y.; Qian, B.; Gao, H.; Zuo, D. Experimental study on mechanical performance of polydimethylsiloxane (PDMS) at various temperatures. Polym. Test. 2020, 90, 106670. [Google Scholar] [CrossRef]

- Liu, J.; Yao, Y.; Li, X.; Zhang, Z. Fabrication of advanced polydimethylsiloxane-based functional materials: Bulk modifications and surface functionalizations. Chem. Eng. J. 2021, 408, 127262. [Google Scholar] [CrossRef]

- Ariati, R.; Sales, F.; Souza, A.; Lima, R.A.; Ribeiro, J. Polydimethylsiloxane composites characterization and its applications: A review. Polymers 2021, 13, 4258. [Google Scholar] [CrossRef] [PubMed]

- Kang, H.; Lee, D.; Yang, Y.; Oh, D.K.; Seong, J.; Kim, J.; Jeon, N.; Kang, D.; Rho, J. Emerging low-cost, large-scale photonic platforms with soft lithography and self-assembly. Photonics Insights 2023, 2, R04. [Google Scholar] [CrossRef]

- Deng, J.; Jiang, L.; Si, B.; Zhou, H.; Dong, J.; Cohen, P. AFM-Based nanofabrication and quality inspection of three-dimensional nanotemplates for soft lithography. J. Manuf. Process. 2021, 66, 565–573. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, M.; Kong, N.; Liu, J. Lab-on-paper micro- and nano-analytical devices: Fabrication, modification, detection and emerging applications. Microchim. Acta 2016, 183, 1521–1542. [Google Scholar] [CrossRef]

- Gao, S.; Zhan, T.; Zhou, W.; Niu, F.; Min, S.; Xiao, A.; Xu, B. Mold Embossing-Based Soft Lithography for Fabrication of Complex Non-rectangular Channels. ACS Appl. Mater. Interfaces 2023, 15, 31755–31764. [Google Scholar] [CrossRef] [PubMed]

- Koucherian, N.E.; Yan, S.; Hui, E.E. Fabrication of Multilayer Molds by Dry Film Photoresist. Micromachines 2022, 13, 1583. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, T.; Sarkar, T.; Tran, T.; Moinuddin, S.M.; Saha, D.; Ahsan, F. Multilayer Soft Photolithography Fabrication of Microfluidic Devices Using a Custom-Built Wafer-Scale PDMS Slab Aligner and Cost-Efficient Equipment. Micromachines 2022, 13, 1357. [Google Scholar] [CrossRef] [PubMed]

- Scott, S.M.; Ali, Z. Fabrication methods for microfluidic devices: An overview. Micromachines 2021, 12, 319. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maesela, E.M.; Msimanga, M.; Kakaza, M.; Scriba, M.R. Rapid, Low-Cost Production of Multilayer Molds for PDMS Lab-on-Chip Devices. Eng. Proc. 2025, 109, 3. https://doi.org/10.3390/engproc2025109003

Maesela EM, Msimanga M, Kakaza M, Scriba MR. Rapid, Low-Cost Production of Multilayer Molds for PDMS Lab-on-Chip Devices. Engineering Proceedings. 2025; 109(1):3. https://doi.org/10.3390/engproc2025109003

Chicago/Turabian StyleMaesela, Eldas M., Mandla Msimanga, Masibulele Kakaza, and Manfred R. Scriba. 2025. "Rapid, Low-Cost Production of Multilayer Molds for PDMS Lab-on-Chip Devices" Engineering Proceedings 109, no. 1: 3. https://doi.org/10.3390/engproc2025109003

APA StyleMaesela, E. M., Msimanga, M., Kakaza, M., & Scriba, M. R. (2025). Rapid, Low-Cost Production of Multilayer Molds for PDMS Lab-on-Chip Devices. Engineering Proceedings, 109(1), 3. https://doi.org/10.3390/engproc2025109003