Addressing Manufacturing and Cost Challenges Toward Solving Low-Cost In Situ Digital Holographic Microscopy Problems †

Abstract

1. Introduction

2. Materials and Methods

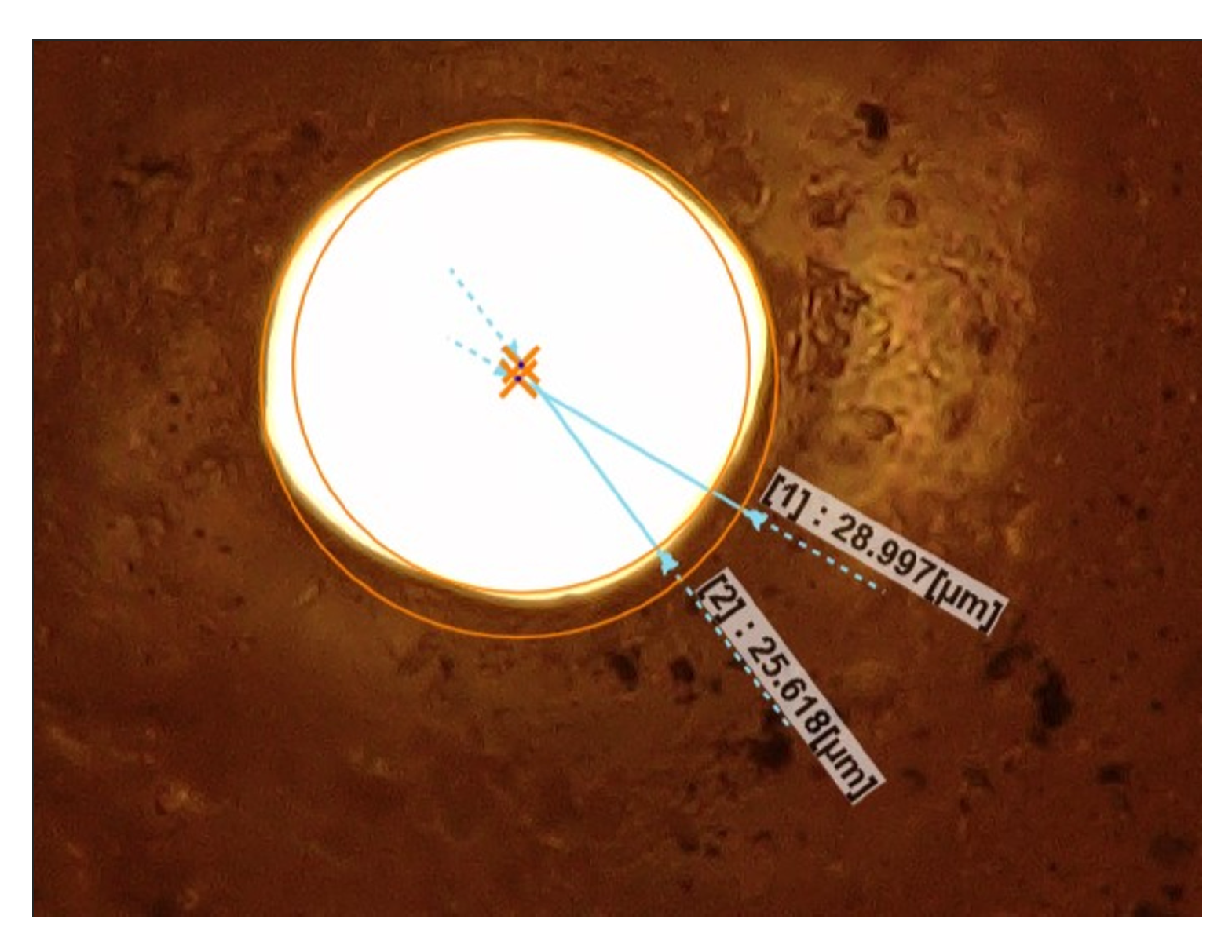

2.1. Sub-100 m Pinhole Manufacturing

2.2. FPGA Reconstruction Algorithm

3. Results

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ASIC | Application-specific integrated circuit |

| ASM | Angular spectrum method |

| DIHM | Digital in-line holographic microscope |

| FPGA | Field-programmable gate array |

| FOV | Field of view |

| LED | Light emitting diode |

| PCB | Printed circuit board |

| SNR | Signal-to-noise ratio |

| USAF | United States Air Force |

| UV | Ultraviolet |

References

- Ryle, J.P.; Sheridan, J.T.; McDonnell, S. Lensless multispectral digital in-line holographic microscope. J. Biomed. Opt. 2011, 16, 126004:1–126004:17. [Google Scholar] [CrossRef] [PubMed]

- McLeod, E.; Ozcan, A. Unconventional methods of imaging: Computational microscopy and compact implementations. Rep. Prog. Phys. 2016, 79, 076001:1–076001:30. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Ozcan, A. Lensless digital holographic microscopy and its applications in biomedicine and environmental monitoring. Methods 2018, 136, 4–16. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Sun, J.; Chen, Q.; Zuo, C. Resolution analysis in a lens-free on-chip digital holographic microscope. IEEE Trans. Comput. Imaging 2020, 6, 697–710. [Google Scholar] [CrossRef]

- Rostykus, M.; Soulez, F.; Unser, M.; Moser, C. Compact in-line lensfree digital holographic microscope. Methods 2018, 136, 17–23. [Google Scholar] [CrossRef] [PubMed]

- Precision Pinholes. Available online: https://www.edmundoptics.com/f/precision-pinholes/12073/ (accessed on 26 July 2024).

- Precision Pinholes. Available online: https://ealingcatalog.com/opto-mechanics/apertures/pinholes/precision-pinholes.html (accessed on 26 July 2024).

- Maritz, M.G.; Schoeman, J. Programmable aperture using a digital micromirror device for in-line holographic microscopy. IEEE J. Quantum Electron. 2022, 58, 1–8. [Google Scholar] [CrossRef]

- Frentz, Z.; Kuehn, S.; Hekstra, D.; Leibler, S. Microbial population dynamics by digital in-line holographic microscopy. Rev. Sci. Instrum. 2010, 81, 084301:1–084301:6. [Google Scholar] [CrossRef] [PubMed]

- Patiño-Jurado, B.; Botero-Cadavid, J.F.; Garcia-Sucerquia, J. Optical fiber point-source for digital lensless holographic microscopy. J. Light. Technol. 2019, 37, 5660–5666. [Google Scholar] [CrossRef]

- Boutilier, R.M.; Ahn, Y.J.; Park, J.S.; Lee, H. Development of an auto-interchangeable multi-pinhole array for confocal laser scanning microscopy systems using precision laser processing. Opt. Laser Technol. 2019, 116, 58–67. [Google Scholar] [CrossRef]

- Endrödy, C.; Mehner, H.; Grewe, A.; Hoffmann, M. Linear micromechanical stepping drive for pinhole array positioning. J. Micromech. Microeng. 2015, 25, 055009:1–055009:9. [Google Scholar] [CrossRef]

- Akhter, N.; Min, G.; Kim, J.W.; Lee, B.H. A comparative study of reconstruction algorithms in digital holography. Optik 2013, 124, 2955–2958. [Google Scholar] [CrossRef]

- Huaying, W.; Baoqun, Z.; Wei, L. Comparison of the reconstruction algorithms in digital micro-holography. In Proceedings of the IEEE International Conference on Intelligent Computing and Intelligent Systems, Shanghai, China, 20–22 November 2009; Volume 2, pp. 838–842. [Google Scholar]

- Goodman, J. Introduction to Fourier Optics; McGraw-Hill: New York, NY, USA, 1996; pp. 55–58. [Google Scholar]

| Laser Cutting Direction | Desired Pinhole Size | Pinhole Diameter on Layout | Outer Circle Minimum Size | Outer Circle Maximum Size | Inner Circle Mean Size | Outer Circle Mean Size | Inner Circle Standard Deviation | Outer Circle Standard Deviation | Average Circularity |

|---|---|---|---|---|---|---|---|---|---|

| Copper to substrate | 25 | 13.8 | 17.9 | 16.0 | 17.2 | 1.30 | 1.26 | 0.929 | |

| 40 | 28.9 | 35.6 | 28.4 | 31.3 | 1.73 | 1.99 | 0.907 | ||

| 65 | 51.9 | 60.1 | 51.1 | 56.3 | 2.37 | 2.71 | 0.907 | ||

| 95 | 86.4 | 97.8 | 81.8 | 92.5 | 4.71 | 3.85 | 0.885 | ||

| Substrate to copper | 25 | 17.4 | 23.0 | 17.0 | 20.8 | 0.97 | 1.43 | 0.817 | |

| 40 | 30.0 | 37.0 | 27.4 | 32.1 | 2.34 | 2.01 | 0.853 | ||

| 65 | 45.2 | 55.6 | 46.0 | 51.4 | 4.55 | 3.93 | 0.894 | ||

| 95 | 72.6 | 89.9 | 75.2 | 82.2 | 6.14 | 4.71 | 0.913 | ||

| Copper to substrate | 30 | 39 | 27.7 | 36.8 | 28.1 | 32.2 | 2.25 | 2.80 | 0.873 |

| 50 | 59 | 43.8 | 62.6 | 45.6 | 52.4 | 5.10 | 6.42 | 0.872 | |

| 80 | 85 | 63.3 | 86.4 | 65.6 | 73.6 | 7.34 | 9.10 | 0.892 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hurter, L.; Laue, H.E.A.; Schoeman, J. Addressing Manufacturing and Cost Challenges Toward Solving Low-Cost In Situ Digital Holographic Microscopy Problems. Eng. Proc. 2025, 109, 14. https://doi.org/10.3390/engproc2025109014

Hurter L, Laue HEA, Schoeman J. Addressing Manufacturing and Cost Challenges Toward Solving Low-Cost In Situ Digital Holographic Microscopy Problems. Engineering Proceedings. 2025; 109(1):14. https://doi.org/10.3390/engproc2025109014

Chicago/Turabian StyleHurter, Larissa, Heinrich Edgar Arnold Laue, and Johan Schoeman. 2025. "Addressing Manufacturing and Cost Challenges Toward Solving Low-Cost In Situ Digital Holographic Microscopy Problems" Engineering Proceedings 109, no. 1: 14. https://doi.org/10.3390/engproc2025109014

APA StyleHurter, L., Laue, H. E. A., & Schoeman, J. (2025). Addressing Manufacturing and Cost Challenges Toward Solving Low-Cost In Situ Digital Holographic Microscopy Problems. Engineering Proceedings, 109(1), 14. https://doi.org/10.3390/engproc2025109014