1. Introduction

Industry 4.0 has transformed manufacturing technology by integrating cyber-physical systems (CPS), industrial Internet of Things (IIoT) technologies, and advanced automation. These innovations enable real-time monitoring, data-driven control, and system interconnectivity for modern productivity and flexibility. In Industry 4.0, programmable logic controllers (PLCs) remain essential to execute time-critical control across diverse processes. However, increasing complexity and interconnectivity pose challenges for fault detection and diagnosis (FDD). Traditional methods based on manual inspection or basic signal logic often struggle with real-time demands, scalability, and comprehensive fault coverage. This necessitates intelligent, simulation-based, power-aware diagnostics. Therefore, we developed a power and fault behavior monitoring tool for programmable logic controllers (PFBMTP), which enhances previous models by incorporating power signal analysis (current and voltage). In a cyber-physical system (CPS)-based Automation Studio® (Version 7.2, Famic Technologies Ltd., Montreal, QC, USA) simulation, PFBMTP was validated to improve fault detection, predictive maintenance, and system resilience.

2. Literature Review

PLC fault detection has evolved from theoretical models to intelligent, hybrid frameworks. Early approaches, such as Ghosh et al.’s FBMTP [

1], used deterministic finite-state automata (DFA) to track control system states. However, these methods were constrained by PLC scan cycles and real-time scalability. The improved FBMTP (IFBMTP) addressed these issues by incorporating analog signal monitoring, expanding fault coverage. Still, it lacked sensitivity to complex power signal variations in dynamic, high-load systems, limiting real-world effectiveness [

2]. To address these problems, real-time feedback obtained from power and vibration sensors was used to detect early anomalies. Hybrid artificial intelligence (AI)-driven tools, such as the model-based power fault detection tool (MPFDT) [

3], integrate automata logic with power profiling, achieving over 98% accuracy by correlating control and power deviations. The supervisory control theory (SCT) [

4] prevents deadlock in discrete event simulation (DES) frameworks. In this study, we improved and validated PFBMTP in a CPS-based simulation.

3. Methods

We developed PFBMTP using electrical characteristic signals such as active power and power factors as diagnostic indicators to establish a PLC fault detection model of the conveyor system. By monitoring changes in electrical parameters under various load conditions, the tool promptly detects abnormalities, thereby preventing equipment failures, avoiding production line interruptions, and enhancing the stability and operational efficiency of the control system. Ultimately, the system strengthens the safety and reliability of smart manufacturing lines in industrial automation applications.

3.1. Simulation Platform and Control Program

Automation Studio

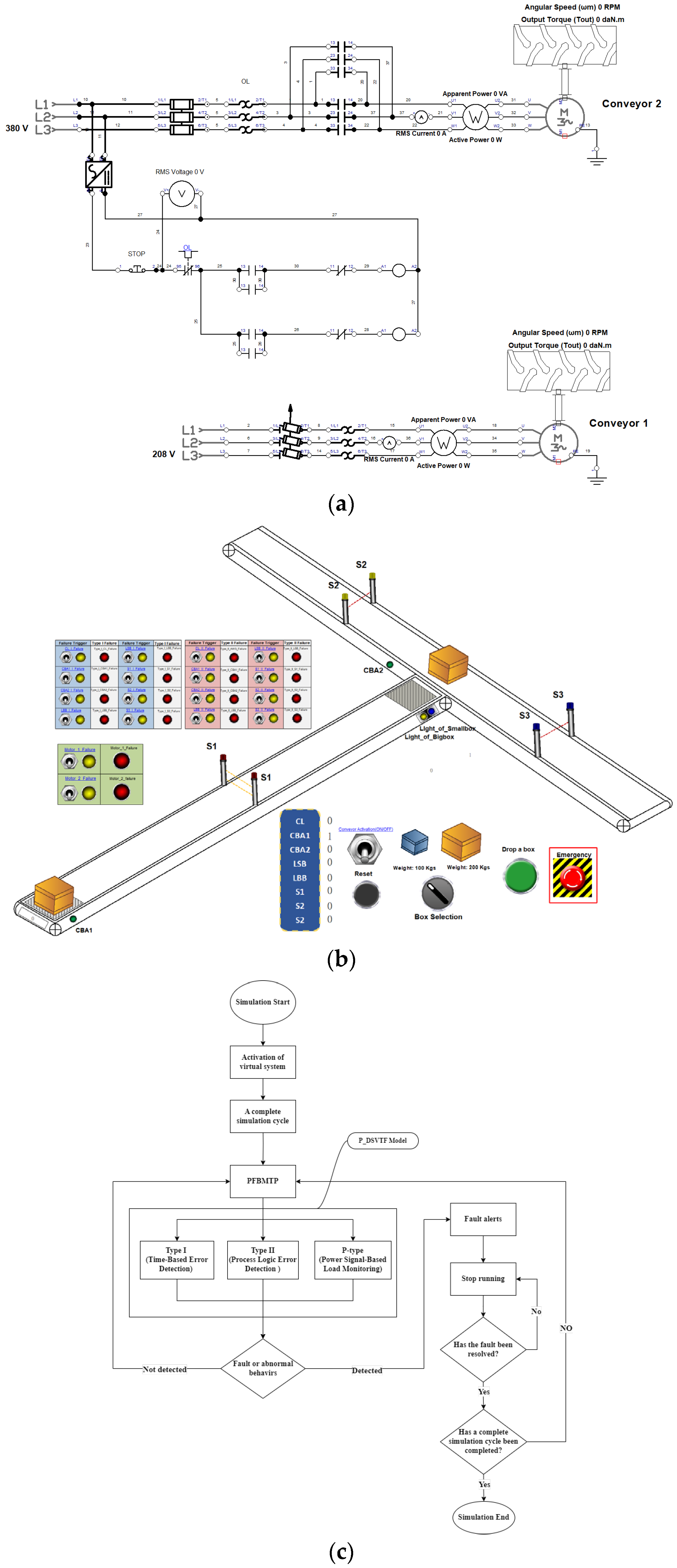

® was used as the simulation platform to build a representative T-shaped conveyor system to simulate material transportation and fault conditions (

Figure 1a). The conveyor consisted of two belts and four pulleys, integrated with motors, sensors, and a PLC control module. The control program was written in the structured text (ST) language to manage motor start, stop, direction, and speed, as well as other control elements, including sensors.

Electrical characteristic parameter monitoring: Active power and power factors were introduced as key diagnostic indicators in addition to Type I and II fault detection [

2]. By analyzing anomalies in these parameters under varying load conditions, the tool triggers warnings or initiates automatic shutdowns when the motor’s load tolerance is exceeded.

Electrical diagram, motor control simulation, and model verification: A simulation of a three-phase asynchronous motor was conducted using electrical circuits (

Figure 1a), incorporating components of contactors and thermal relays to realistically replicate the interactions of an industrial power control system. All modules were integrated to simulate various operating conditions and fault scenarios. The diagnostic model was then verified in terms of its real-time responsiveness, accuracy, and practical adaptability.

3.2. Deterministic Finite State Automaton: Generalized State Transition Automaton ()

To enhance state behavior modeling and expand parameter coverage, we extended the

model in the IFBMTP framework.

is an improved version of the traditional general state transition model (

), which retains the original time-based logic design (such as the time-out function) and further incorporates analog signal processing capabilities. This enables the model to better accommodate real-world sensor inputs [

1,

2]. To further improve electrical anomaly detection, we used

, an extended version of

that integrates power-related parameters.

introduces the following power-assist function.

(

: Set of states containing analog signals,

: Set of events,

:

, Time-out function,

: State transition function,

: Output function,

: Initial state,

: Set of final (terminal) states,

:

: The active power measured by the system at time

t;

: The power factor calculated by the system at time

t).

With this power-assist function, the

model considers digital logic, time constraints, and power parameter variations at every state and time point, significantly improving its sensitivity and capability in describing abnormal equipment behavior. The status of digital signals

is defined using Boolean vectors as follows.

The model, while preserving ’s capabilities in time-based logic and analog signal handling, introduces the power-assist function to construct a more comprehensive system state monitoring framework. This lays a foundation for the development of the subsequent DSVTF-P model and the PFBMTP platform.

3.3. Power Feature-Oriented State Transition Model: Deterministic State Vector Transition Function with Power Factors (DSVTF-P)

To accurately describe the changes in events associated with state transitions in complex systems, DSVTF-P was proposed based on the traditional DSVTF model. While the original DSVTF model determines signal on/off states solely based on changes in Boolean vectors, real-world anomalies and equipment faults are closely related to power parameters. This DSVTF-P model introduces a new set of analog signal parameters, denoted as

, as auxiliary indicators for fault detection. The power parameters include the following two electrical features: active power (

P) and power factor (

PF). When the system transitions from state

to

the model analyzes the difference between the Bean vectors

and

to determine signal activation and deactivation and the power parameters measured before

and after

transitions.

During a state transition, if any of the following power-related anomalies are detected, the model generates corresponding abnormal event signals: <1> A rise in active power from below to above the threshold accompanied by a low power factor

) triggering

. <2> A drop in active power from above to below the threshold while the power factor remains low (

) triggering

. <3> A significant decrease in power factor across the transition

, triggering

.

where

represents the threshold of active power, a predefined value used to determine whether a transition involves a significant change in power level. This threshold serves as a critical reference point for detecting abnormal increases or decreases in power, especially when accompanied by low power factor values (i.e.,

). If none of the above conditions are met, the event set is defined as an empty set.

Through this dual-criteria detection mechanism, the DSVTF-P model effectively integrates digital control behaviors with power anomaly characteristics, achieving higher sensitivity and improved accuracy in fault detection.

3.4. Three-Layer Monitoring Logic

The developed PFBMTP enhanced the accuracy and real-time capabilities of the traditional IFBMTP tool in industrial applications. This improved diagnostic system incorporated a three-layer monitoring logic that utilizes time, process, and power signals as the basis for detecting anomalies. Integrated with the Automation Studio® virtual simulation platform, the developed PFBMTP enabled real-time and complex PLC fault identification.

The time-based monitoring logic compares the execution timing of process nodes. Based on predefined time conditions, such as when a sensor must be triggered or when a motor must start/stop. If the system fails to perform the expected operation within the specified timeframe, it is identified as a process delay or failure. This method allows for real-time detection of common issues such as signal delays, untriggered components, or process interruptions, improving operational stability. Process logic monitoring enables a correspondence between Boolean signals and the logical sequence of operations. When logical errors occur during the PLC execution, such as incorrect sensor order or advancing to the next step without proper triggering, the system compares the input and output conditions against the expected process flow. If a mismatch is found, an error alert is triggered. This mechanism effectively prevents unintended operations caused by programming errors or distorted input signals.

To address the limitations of the first two layers to actual load variations, we introduced power signal monitoring as the third layer and core innovation of the PFBMTP tool. By continuously monitoring the motor’s active power and power factor, the tool assesses the real operational load in real time. Traditional methods that rely solely on current measurements are prone to misjudgments due to power factor fluctuations. The developed tool employs cross-analysis of dual power parameters, significantly improving the accuracy and timeliness of fault detection. This layer identifies abnormal loads, motor overloads, or potential failures.

During operation, state transitions include events such as motor start, stop, directional changes, and sensor activations. Type I diagnostics are fundamental and indispensable, regardless of which diagnostic method is selected. Type II diagnostics are optional according to system requirements. For each state transition, this fault detection mechanism verifies whether the action is completed within the appropriate time window (time logic) and optionally checks whether it follows the correct procedural order (sequence logic). Simultaneously, the system performs real-time cross-analysis of active power and power factors to determine if the load condition is abnormal. This “synchronous triple detection” (

Figure 1c) significantly enhances the accuracy and responsiveness of fault identification, improving overall system stability and safety in applications involving highly variable loads.

3.5. Virtual System Testing Model

For flexible control system development and cyber-physical integration in smart manufacturing, we used Automation Studio

® as the simulation platform, which supports analog signals and multi-domain technology integration within an intuitive graphical environment [

2]. Automation Studio

® also supports IEC 61131-3 languages, including sequential function charts (SFC) and ST, enabling structured and readable control programming. We used the National Electrical Manufacturers Association (NEMA) standard electrical circuits to operate a three-phase motor in a virtual conveyor system, enhancing consistency with systems. The simulation integrates the developed IFBMTP tool, which leverages active power and power factors to detect abnormal load conditions during dynamic operation. It repeats testing, parameter tuning, and verification without physical hardware, improving fault diagnosis accuracy, development efficiency, and overall system reliability. A testing T-shape virtual conveyor system was designed to classify different types of objects as shown in

Figure 1b. The user selects the different types of testing boxes placed onto the conveyor. While the box moves along the conveyor path, corresponding sensors CL, CBA1, CBA2, LSB, LBB, S1, S2, and S3 are triggered sequentially depending on the box type. The system displays the current state vector to reflect the real-time status with indicators and readings. Different types of errors (Type I, II, or Type-P) are implemented randomly to examine the performance of the detection mechanisms.

4. Results and Discussion

Various processes and fault scenarios were simulated to validate the feasibility of PFBMTP logic and performance on the T-Shape virtual conveyor system. The visual, interactive environment allowed thorough validation and parameter tuning without physical hardware. The core of the developed PFBMTP tool is a three-layer concurrent monitoring system: time-based logic, process logic, and power signal analysis (

Figure 1c). If a fault condition is triggered, the tool issues an alert, halts operation, and initiates fault-handling to improve safety and response time. Each layer effectively addresses different fault types -time-based logic detects motion delays, process logic identifies sensor or sequencing errors, and power analysis captures load anomalies via active power and power factors. The experimental results confirmed the model’s diagnostic accuracy and showed that the developed PFBMTP tool enabled a scalable, effective solution for smart manufacturing fault detection.

5. Conclusions

We developed a PFBMTP tool, an advanced diagnostic framework that integrates power signal analysis into traditional logic-based fault detection. By extending the IFBMTP with the GSTAP and DSVTF-P models, it incorporates active power and power factors as core indicators, enabling the precise and robust detection of system faults. Through simulation on the Automation Studio® platform, the developed PFBMTP tool demonstrated strong fault coverage across three diagnostic layers-timing, process logic, and power-based analysis. By combining digital and analog signal monitoring, real-time responsiveness is greatly enhanced and reduces false positives. The triple detection mechanism further ensures fault identification even in systems with variable loads or complex transition logic. A further study is necessary to extend the model to multi-machine coordination scenarios and validate its performance in hybrid physical-virtual testbeds.

Author Contributions

Conceptualization, K.-C.H., T.-H.C., M.B., W.-N.H. and H.-T.L.; methodology, K.-C.H.; software, T.-H.C.; validation, M.B., W.-N.H. and H.-T.L.; funding acquisition, K.-C.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the National Science and Technology Council (NSTC), Taiwan. [grant number: 114-2914-I-033-008-A1].

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available upon request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ghosh, A.; Qin, S.; Lee, J.; Wang, G.-N. FBMTP: An Automated Fault and Behavioral Anomaly Detection and Isolation Tool for PLC-Controlled Manufacturing Systems. IEEE Trans. Syst. Man Cybern. Syst. 2017, 47, 3397–3408. [Google Scholar] [CrossRef]

- Huang, K.-C.; Ku, H.-C.; Chuang, T.-H.; Huang, W.-N. Improved Fault Diagnosis Method for PLC-Based Manufacturing Processes with Validation through a Cyber-Physical System. In Proceedings of the 2024 IEEE 4th International Conference on Electronics, Information, IoT and Big Data (ICEIB), Taipei, Taiwan, 19–21 April 2024; pp. 706–712. [Google Scholar] [CrossRef]

- Ghosh, A.; Wang, G.-N.; Lee, J. A Novel Automata and Neural Network Based Fault Diagnosis System for PLC Controlled Manufacturing Systems. Comput. Ind. Eng. 2019, 139, 106188. [Google Scholar] [CrossRef]

- Fritz, R.; Zhang, P. Overview of Fault-Tolerant Control Methods for Discrete Event Systems. IFAC-PapersOnLine 2018, 51, 88–95. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).