1. Introduction

Unmanned Aerial Vehicles (UAVs), commonly known as drones, have gained significant attention in various fields due to their versatility, cost-effectiveness, and ability to operate in challenging environments. UAVs are widely used in military reconnaissance, surveillance, aerial photography, scientific research, agricultural monitoring, and other industrial applications. These aircraft can be controlled remotely by a human operator or operate autonomously using onboard computers [

1].

UAVs are generally classified into three main categories: fixed-wing, rotary-wing (multirotor), and Vertical Takeoff and Landing (VTOL) UAVs. Fixed-wing UAVs are known for their extended flight duration and efficiency, making them suitable for long-range missions, though they require runways for takeoff and landing. In contrast, rotary- wing UAVs, such as quadcopters, hexacopters, and octocopters, offer exceptional maneuverability, hovering capabilities, and vertical takeoff and landing, making them ideal for applications requiring stability and precision. VTOL UAVs combine aspects of both configurations, allowing operation in confined spaces while maintaining improved flight endurance [

2,

3].

Despite these advancements, fixed-wing UAVs struggle with maneuverability, while rotary-wing UAVs face limitations in flight duration. To address these challenges, this research proposes the development of a hybrid UAV—the biplane quadrotor. This innovative design integrates the stability and lift efficiency of a biplane with the VTOL capabilities and maneuverability of a quadrotor. By combining these features, the biplane quadrotor aims to enhance flight endurance while maintaining the ability to operate in constrained environments. This paper explores the design, functionality, and potential applications of this hybrid UAV, highlighting its advantages over conventional UAV systems [

4,

5].

2. Design Considerations

The development of Unmanned Aerial Vehicles (UAVs) has rapidly evolved in recent years, leading to various configurations optimized for specific applications. Among these, the biplane quadrotor has emerged as a promising design that combines the advantages of multirotor maneuverability with the enhanced aerodynamic efficiency of a biplane wing structure. This unique configuration presents opportunities for increased payload capacity, improved endurance, and better flight stability, making it suitable for applications such as surveillance, search and rescue, and cargo transport [

6] as shown in

Figure 1.

The illustration depicts the different flight modes of a biplane quadrotor, highlighting its ability to transition between vertical takeoff and landing (VTOL) mode, transition mode, and forward flight mode. In VTOL mode, the quadrotor operates similarly to a conventional multirotor, using vertical thrust for hovering and low-speed maneuvers. During transition mode, the aircraft gradually tilts forward, adjusting the orientation of its rotors to generate both lift and forward thrust. Finally, in forward flight mode, the quadrotor behaves more like a fixed-wing aircraft, with its wings providing lift while the rotors contribute to propulsion, improving aerodynamic efficiency and extending flight range. This design combines the advantages of rotorcraft and fixed-wing aircraft, offering enhanced maneuverability, stability, and efficiency for applications such as reconnaissance, cargo transport, and aerial mapping.

To achieve an optimal biplane quadrotor design, several critical factors must be considered [

8]. First, aerodynamic efficiency plays a crucial role, as the biplane wing configuration must be optimized to maximize lift while minimizing drag. The interaction between the rotor downwash and the wing surfaces should also be carefully analyzed to reduce flow disturbances and enhance flight efficiency. Second, vertical take-off and landing (VTOL) capability must be integrated seamlessly with forward flight aerodynamics, ensuring smooth transition phases and minimal energy loss [

6].

Structural integrity is another vital consideration, as the design must balance lightweight construction with sufficient strength to withstand dynamic loads during flight. The use of advanced composite materials and efficient load distribution strategies can enhance durability without compromising performance [

9,

10]. Additionally, flight control and stability are paramount, requiring sophisticated control algorithms to manage the complex aerodynamics and maintain precise maneuverability in various flight conditions [

11,

12,

13].

Furthermore, energy efficiency and power management are key design aspects, as a well-designed biplane quadrotor should minimize energy consumption while maximizing flight duration. This involves selecting efficient propulsion systems, optimizing battery capacity, and incorporating regenerative energy strategies where possible [

14]. Finally, modularity and adaptability should be integrated into the design, allowing for customization based on mission requirements and operational environments [

15]. The biplane configuration can lead to improved energy efficiency during forward flight due to reduced power consumption, making it a viable solution for applications requiring extended flight durations and higher payload capacities.

3. Methodology

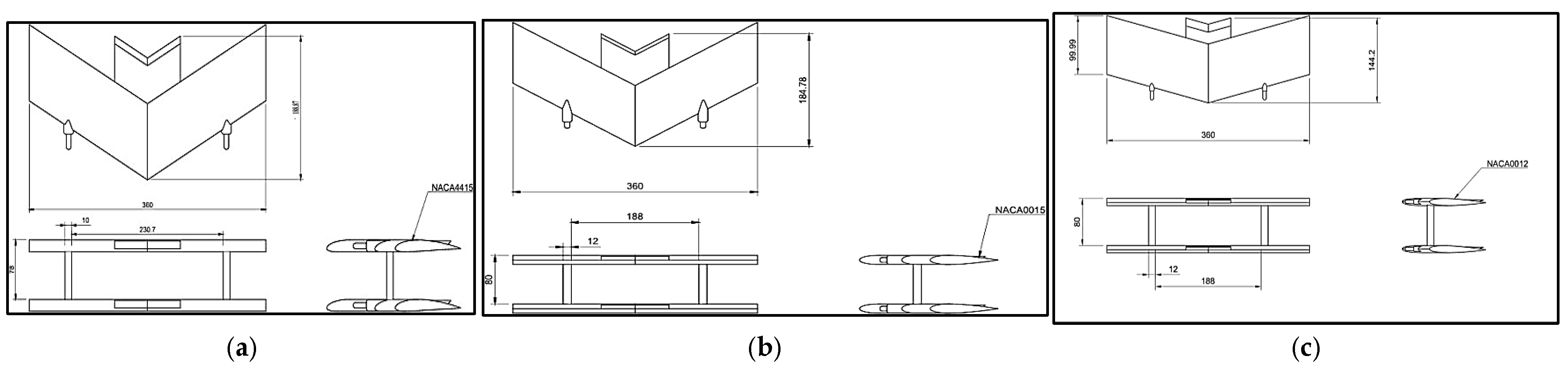

The methodology for this research focuses on the design, analysis, and optimization of a biplane quadrotor UAV, integrating the maneuverability of multi rotors with the aerodynamic efficiency of fixed-wing aircraft to enhance flight endurance and reduce energy consumption. The study follows a structured approach, beginning with the conceptual design phase, where the UAV is modeled in CATIA V5 with biplane wings integrated into a quadrotor frame. The primary objectives include achieving VTOL capability, optimizing the wing configuration to minimize power consumption, and ensuring structural integrity using lightweight materials. Various airfoil designs (NACA 4415, NACA 0015, and NACA 0012) are tested to determine the most aerodynamically efficient configuration. The configuration of the design can be seen in

Figure 2.

Following the design phase, aerodynamic analysis is conducted using Computational Fluid Dynamics (CFD) simulations in ANSYS Fluent to evaluate the drag force, lift-to-drag ratio, and flow interactions between the rotor downwash and the biplane wings. The aim is to identify the optimal configuration that minimizes drag while maintaining stable lift forces for efficient forward flight. In parallel, a hybrid flight control system is developed to ensure a smooth transition between hover and forward flight. The control system integrates Backstepping Control (BSC) for stability, Integral Terminal Sliding Mode Control (ITSMC) for precise trajectory tracking, and adaptive algorithms to handle aerodynamic disturbances. These control mechanisms are tested in a simulated environment to optimize the UAV’s maneuverability and response to dynamic conditions [

16].

The final phase involves simulation-based performance validation, where structural stress analysis is performed to ensure the UAV’s durability under varying flight conditions. Additionally, CFD-based aerodynamic simulations verify the drag reduction and energy efficiency improvements. The control system is further evaluated using MATLAB/Simulink simulations (R2023a), focusing on transition stability and flight performance. The results are compared with a conventional quadrotor UAV, demonstrating the effectiveness of the biplane quadrotor design in reducing power consumption and increasing flight duration. This comprehensive methodology ensures a systematic and data-driven approach to UAV design, integrating aerodynamic efficiency, energy optimization, and flight stability for improved UAV performance across multiple applications.

4. Design and Analysis

The biplane quadrotor is structured to optimize lift generation while minimizing drag, achieved through the strategic integration of biplane wings. Unlike conventional quadrotors that rely solely on thrust for lift, the additional wing surfaces in the biplane configuration contribute to passive lift generation during forward flight. This reduces the overall power requirement for propulsion, effectively extending flight duration. The selection of airfoil designs, such as NACA 4415, NACA 0015, and NACA 0012, plays a crucial role in determining aerodynamic efficiency [

17,

18]. Additionally, lightweight materials like carbon fiber are used to maintain structural integrity while minimizing weight, ensuring improved performance without excessive energy consumption [

9,

10]. The parameters are presented in the following

Table 1.

The drag force acting on the conventional quadcopter was measured at 1.7 N, which serves as the baseline for comparison. By incorporating biplane wings with different airfoils, the drag force was substantially reduced:

Biplane quadrotor with NACA4415 airfoil: 0.67 N (reduction of 60.58%);

Biplane quadrotor with NACA0015 airfoil: 0.64 N (reduction of 62.35%);

Biplane quadrotor with NACA0012 airfoil: 0.42 N (reduction of 75.29%).

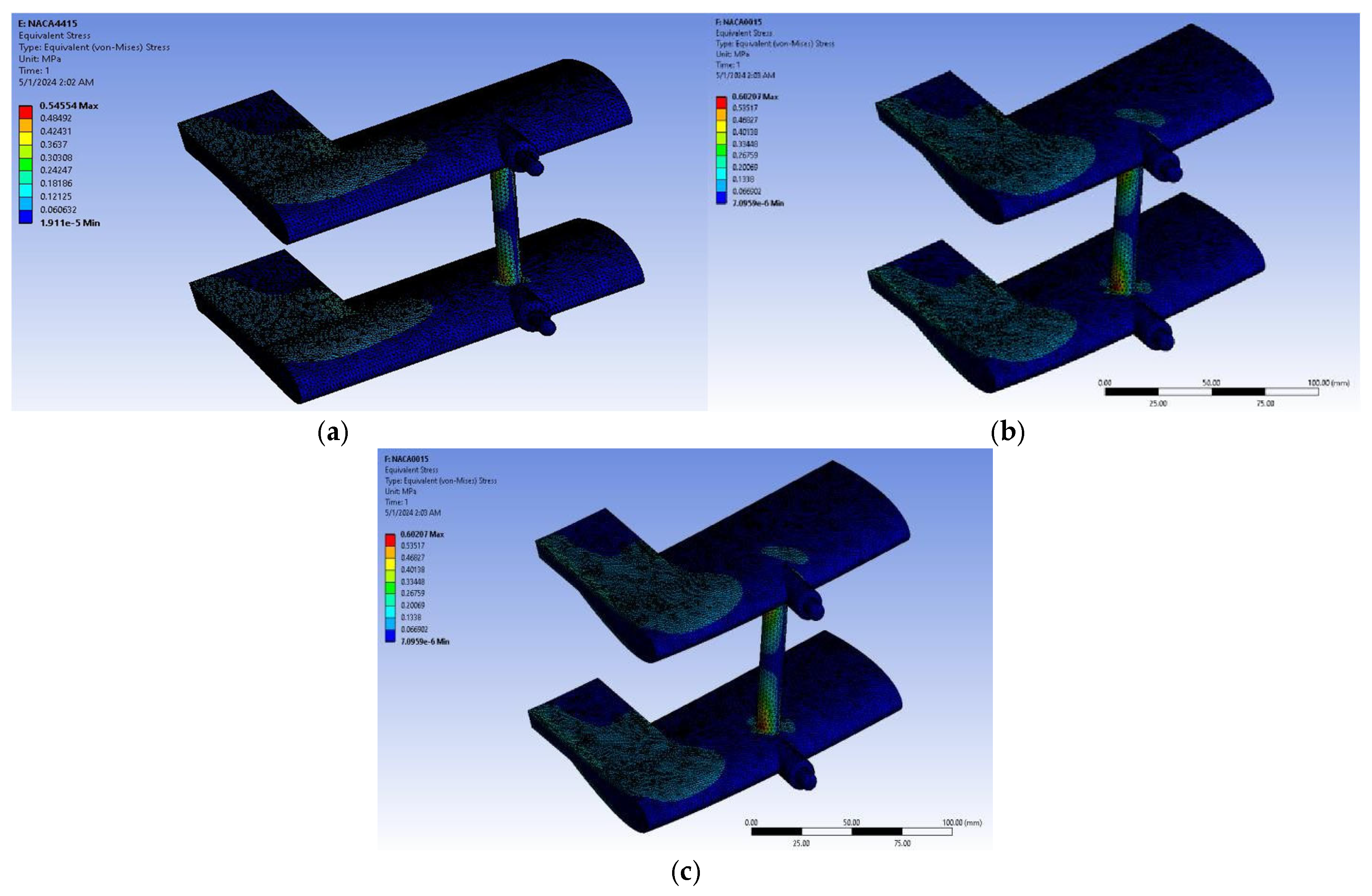

These results shown in

Figure 3 demonstrate that the NACA0012 airfoil provided the greatest reduction in drag, making it the most aerodynamically efficient choice among the tested configurations. This improvement translates to lower energy consumption, as less power is required to overcome air resistance, ultimately extending the UAV’s operational range.

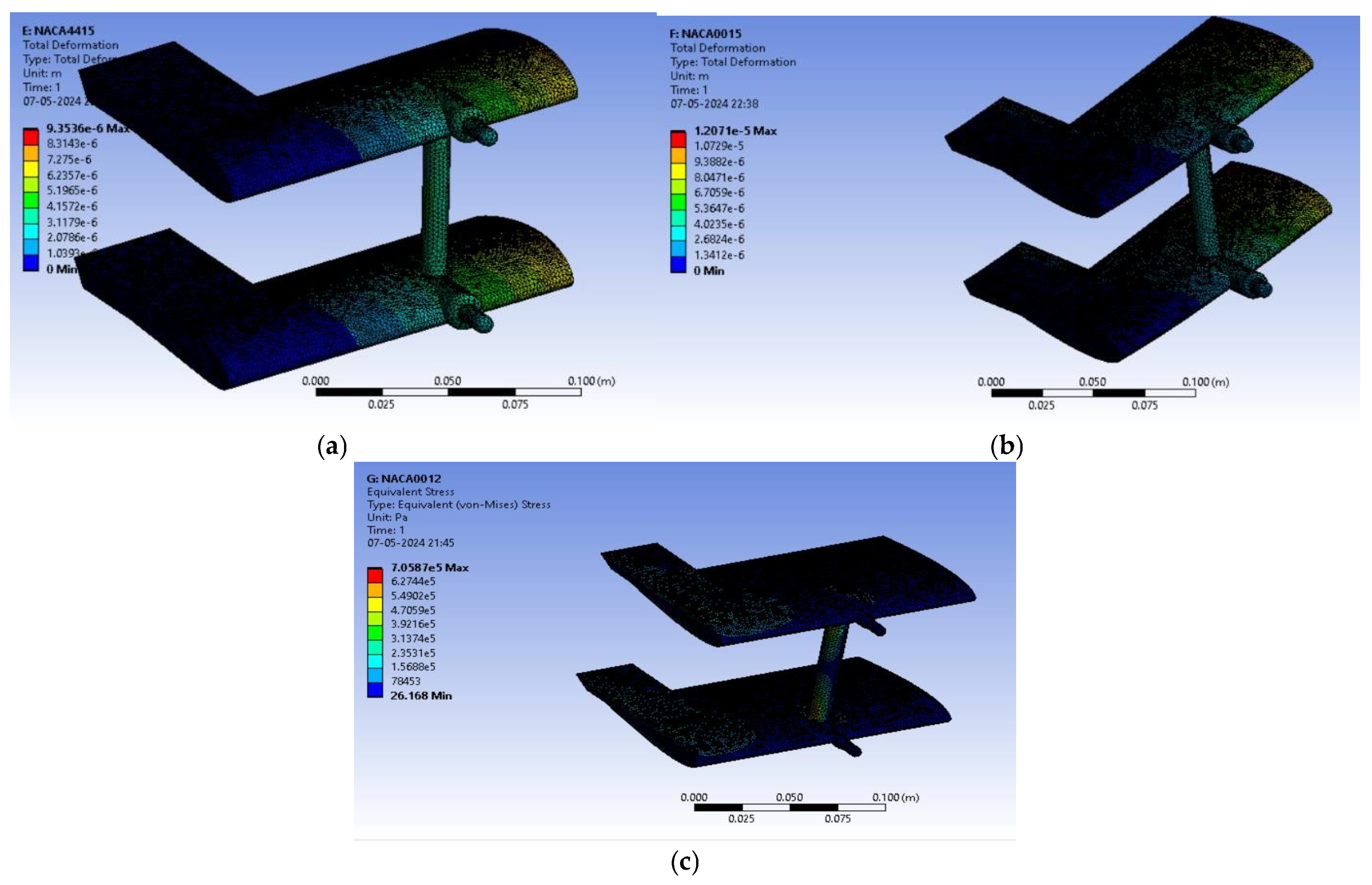

The variation in drag reduction across different airfoil configurations in the biplane quadrotor UAV is influenced by multiple aerodynamic and structural factors, including airfoil shape, thickness, camber, rotor downwash interaction, and material properties. The NACA4415 airfoil, with its highly cambered profile and 15% thickness, generates significant lift but also induces higher pressure drag, leading to a 60.58% reduction in drag compared to the conventional quadcopter. The NACA0015 airfoil, which shares the same thickness but is symmetric, reduces pressure drag effects, resulting in a slightly higher 62.35% drag reduction. The most aerodynamically efficient configuration is the NACA0012 airfoil, which features a thinner (12%) symmetric profile, minimizing flow separation, vortex formation, and surface friction, achieving the highest drag reduction of 75.29%. The interaction between rotor downwash and wing surfaces further influences drag, as thicker airfoils tend to generate stronger pressure gradients, leading to increased induced drag. In contrast, the thinner NACA0012 airfoil stabilizes airflow more effectively, reducing turbulence and improving overall efficiency [

18]. Additionally, the lift-to-drag (L/D) ratio plays a crucial role, as cambered airfoils (NACA4415) provide higher lift but at the cost of increased aerodynamic resistance, whereas symmetric airfoils (NACA0015 and NACA0012) offer a more balanced L/D ratio, enhancing efficiency during forward flight [

8,

19,

20]. Structural and material considerations also contribute to drag reduction, as smooth, lightweight composite materials reduce skin friction drag, further optimizing performance as given in

Figure 4 and

Figure 5.

These differences in stress and deformation behavior directly impact the structural integrity, aerodynamic efficiency, and flight performance of the UAV. A design that reduces localized stress concentrations minimizes material fatigue, extending the operational lifespan of the aircraft. Furthermore, minimizing deformation ensures that the airfoil maintains its intended aerodynamic profile, preventing efficiency losses due to unwanted shape distortion. The results suggest that NACA0012 is the most effective airfoil for a biplane quadrotor UAV, as it achieves the best balance between structural strength and aerodynamic efficiency, ultimately leading to improved UAV endurance and durability.

Overall, the results of

Table 2 confirm that integrating biplane wings significantly enhances UAV performance by reducing both drag and structural stress, leading to improved energy efficiency, stability, and durability. The findings suggest that NACA0012 is the most effective airfoil for minimizing drag, while NACA4415 provides the best structural efficiency. The selection of the optimal airfoil for a biplane quadrotor UAV should consider a balance between aerodynamic efficiency and structural integrity, depending on mission requirements. Future research could explore reinforced composite materials or hybrid airfoil designs to further improve both drag reduction and structural resilience, ensuring enhanced performance and longevity of the UAV in various operational scenarios.

5. Conclusions

The findings of this study demonstrate that the biplane quadrotor UAV effectively integrates the maneuverability of multi rotors with the aerodynamic efficiency of fixed-wing aircraft, leading to enhanced flight endurance and reduced energy consumption. The implementation of biplane wings significantly reduces drag force, with the NACA0012 airfoil achieving the highest reduction of 75.29%, making it the most aerodynamically efficient choice.

Additionally, structural analysis confirms that the biplane quadrotor experiences significantly lower stress levels compared to a conventional quadcopter, with the NACA4415 airfoil exhibiting the greatest reduction in stress (95.45%), indicating superior structural integrity and load distribution. These improvements contribute to longer operational lifespans, increased energy efficiency, and enhanced UAV stability.

The integration of advanced flight control mechanisms, including Backstepping Control (BSC) and Integral Terminal Sliding Mode Control (ITSMC), ensures precise trajectory tracking and smooth transition between hover and forward flight modes. Computational simulations validate that the biplane quadrotor UAV reduces power consumption while maintaining high aerodynamic performance, making it a viable alternative for long-range missions requiring both VTOL capabilities and extended endurance.

Author Contributions

Conceptualization, Formal analysis, Methodology, Data curation, Writing, S.N.S.; Idea drafting, Design Analysis and Data curation, A.P.J.; Supervision, M.C.; Writing—review & editing, P.E.B.; Data Curation, T.S.; Analysis, Software simulation, F.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author due to the confidentiality of the proposed research work.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Raj, N.; Simha, A.; Kothari, M.; Abhishek; Banavar, R.N. Iterative Learning Based Feedforward Control for Transition of a Biplane-Quadrotor Tailsitter UAS. In Proceedings of the 2020 IEEE International Conference on Robotics and Automation (ICRA), Paris, France, 31 May–31 August 2020; pp. 321–327. [Google Scholar] [CrossRef]

- Govindarajan, B.; Sridharan, A. Conceptual Sizing of Vertical Lift Package Delivery Platforms. J. Aircr. 2020, 57, 1170–1188. [Google Scholar] [CrossRef]

- Dalwadi, N.; Deb, D.; Ozana, S. Performance Evaluation of RW-Quadrotor and Bi-Quadrotor for Payload Delivery. IET Intell. Transp. Syst. 2023, 17, 2221–2236. [Google Scholar] [CrossRef]

- Gunarathna, J.K.; Munasinghe, R. Development of a Quad-Rotor Fixed-Wing Hybrid Unmanned Aerial Vehicle. In Proceedings of the 2018 Moratuwa Engineering Research Conference (MERCon), Moratuwa, Sri Lanka, 30 May–1 June 2018; pp. 72–77. [Google Scholar] [CrossRef]

- Swarnkar, S.; Parwana, H.; Kothari, M.; Abhishek, A. Biplane-Quadrotor Tail-Sitter UAV: Flight Dynamics and Control. J. Guid. Control Dyn. 2018, 41, 1049–1067. [Google Scholar] [CrossRef]

- Hrishikeshavan, V.; Bogdanowicz, C.; Chopra, I. Design, Performance and Testing of a Quad Rotor Biplane Micro Air Vehicle for Multi Role Missions. Int. J. Micro Air Veh. 2014, 6, 155–173. [Google Scholar] [CrossRef]

- Qiao, Z.; Wang, D.; Xu, J.; Pei, X.; Su, W.; Wang, D.; Bai, Y. A Comprehensive Design and Experiment of a Biplane Quadrotor Tail-Sitter UAV. Drones 2023, 7, 292. [Google Scholar] [CrossRef]

- Sivakumar, N.S.; Thilak, V.M.M. Optimal design and static simulation of a hybrid solar vehicle. Int. Res. J. Adv. Sci. Hub (IRJASH) 2019, 1, 62–66. [Google Scholar] [CrossRef]

- Sivakumar, N.S.; Thangarasu, V.S.; Soundararajan, R.; Jayaseelan, V. Mechanical and machining behavior of betel nut fiber/leather/chitin-toughened epoxy hybrid composite. Biomass Convers. Biorefinery 2023, 13, 4365–4372. [Google Scholar] [CrossRef]

- Venkatesan, S.; Giridharan, P.K.; Sivakumar, N.S. Tribological behaviour of AA7168 hybrid composite sheets for aerospace structures fabricated through COMPO casting. Adv. Mater. Process. Technol. 2021, 8 (Suppl. S2), 402–410. [Google Scholar] [CrossRef]

- Nguyen, N.; Ting, E.; Chaparro, D.; Drew, M.; Swei, S. Multi-Objective Flight Control for Drag Minimization and Load Alleviation of High-Aspect Ratio Flexible Wing Aircraft. In Proceedings of the 58th AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Grapevine, TX, USA, 9–13 January 2017. [Google Scholar] [CrossRef][Green Version]

- Giannakis, E.; Savaidis, G. Structural Integrity Aspects of a Lightweight Civil Unmanned Air Vehicle. Int. J. Struct. Integr. 2016, 7, 773–787. [Google Scholar] [CrossRef]

- Quintana, A.; Graves, G.; Hassanalian, M.; Abdelkefi, A. Aerodynamic Analysis and Structural Integrity for Optimal Performance of Sweeping and Spanning Morphing Unmanned Air Vehicles. Aerosp. Sci. Technol. 2021, 110, 106458. [Google Scholar] [CrossRef]

- Gupta, S.; Kothari, M.; Abhishek. Optimal Transition Trajectory of a Quadrotor Biplane Tailsitter. IFAC-PapersOnLine 2023, 56, 2500–2505. [Google Scholar] [CrossRef]

- Xiong, H.; Hu, J.; Diao, X. Optimize Energy Efficiency of Quadrotors via Arm Rotation. J. Dyn. Syst. Meas. Control Trans. ASME 2019, 141, 9. [Google Scholar] [CrossRef]

- Dalwadi, N.; Deb, D.; Rath, J.J. Biplane Trajectory Tracking Using Hybrid Controller Based on Backstepping and Integral Terminal Sliding Mode Control. Drones 2022, 6, 58. [Google Scholar] [CrossRef]

- Kepekci, H. Comparative Numerical Aerodynamics Performance Analysis of NACA0015 and NACA4415 Airfoils. Int. J. Eng. Sci. Inf. Technol. 2022, 2, 144–151. [Google Scholar] [CrossRef]

- Yilmaz, M.; Köten, H.; Çetinkaya, E.; Coşar, Z. A Comparative CFD Analysis of NACA0012 and NACA4412 Airfoils. J. Energy Syst. 2018, 2, 145–159. [Google Scholar] [CrossRef]

- Ramesh, J.P.; Mugendiran, V.; Sivaraj, G. Increasing L/D Ratio of Wing by Delaying Flow Separation for Better Aerodynamic Performance. J. Appl. Fluid Mech. 2024, 17, 2720–2733. [Google Scholar] [CrossRef]

- Koçyiğit, S. Investigating the Relation Between Symmetric Properties and Lift/Drag Coefficients for Airfoils. 2015. Available online: https://api.semanticscholar.org/CorpusID:116395601 (accessed on 4 April 2025).

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).