Recent Advances in Tool Coatings and Materials for Superior Performance in Machining Nickel-Based Alloys †

Abstract

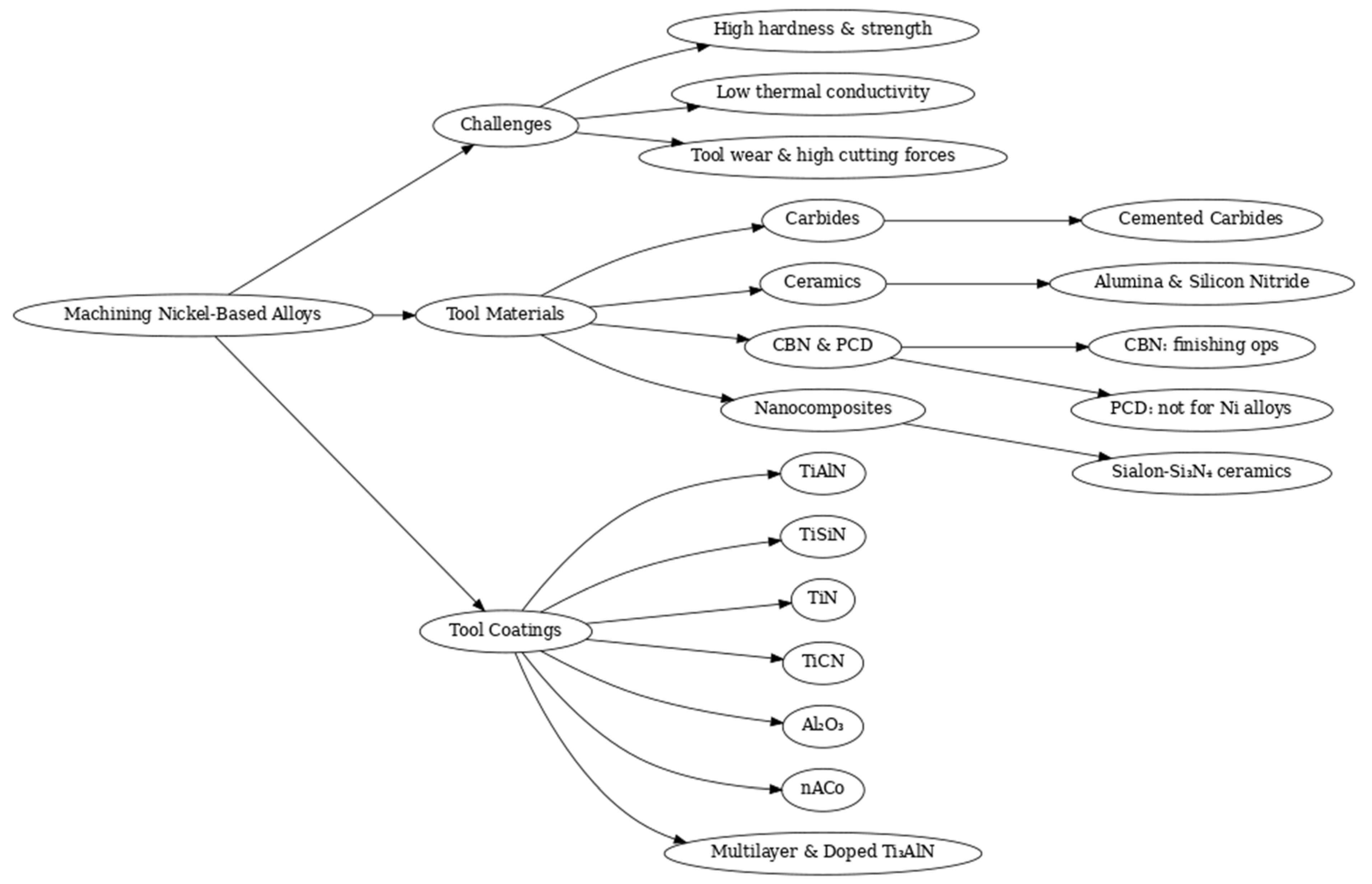

1. Introduction

1.1. Nickel-Based Alloy Types

1.2. Properties of Nickel-Based Superalloys

1.3. Machining of Nickel-Based Alloys

2. Tool Materials for Machining Nickel-Based Alloys

2.1. Carbide and Ceramic Tool Materials

2.2. Cubic Boron Nitride (CBN) and Polycrystalline Diamond (PCD)

2.3. Gradient Nanocomposite Ceramics

3. Tool Coatings for Machining Nickel-Based Alloys

3.1. Types of Tool Coatings Deposition Method and Their Performance

- (A)

- Physical Vapor Deposition (PVD) Coatings

- (B)

- Chemical Vapor Deposition (CVD) Coatings

- (C)

- Nanocomposite and Multilayer Coatings

- (D)

- Other Coatings

3.2. Tool Coating Types for Machining Nickel-Based Materials

3.3. TiAlN-Coated Tools in Machining Nickel-Based Alloys

3.4. TiSiN Coatings in Cutting Tools for Machining Nickel-Based Alloys

3.5. CrAlSiN Coatings in Cutting Tools for Machining Nickel-Based Alloys

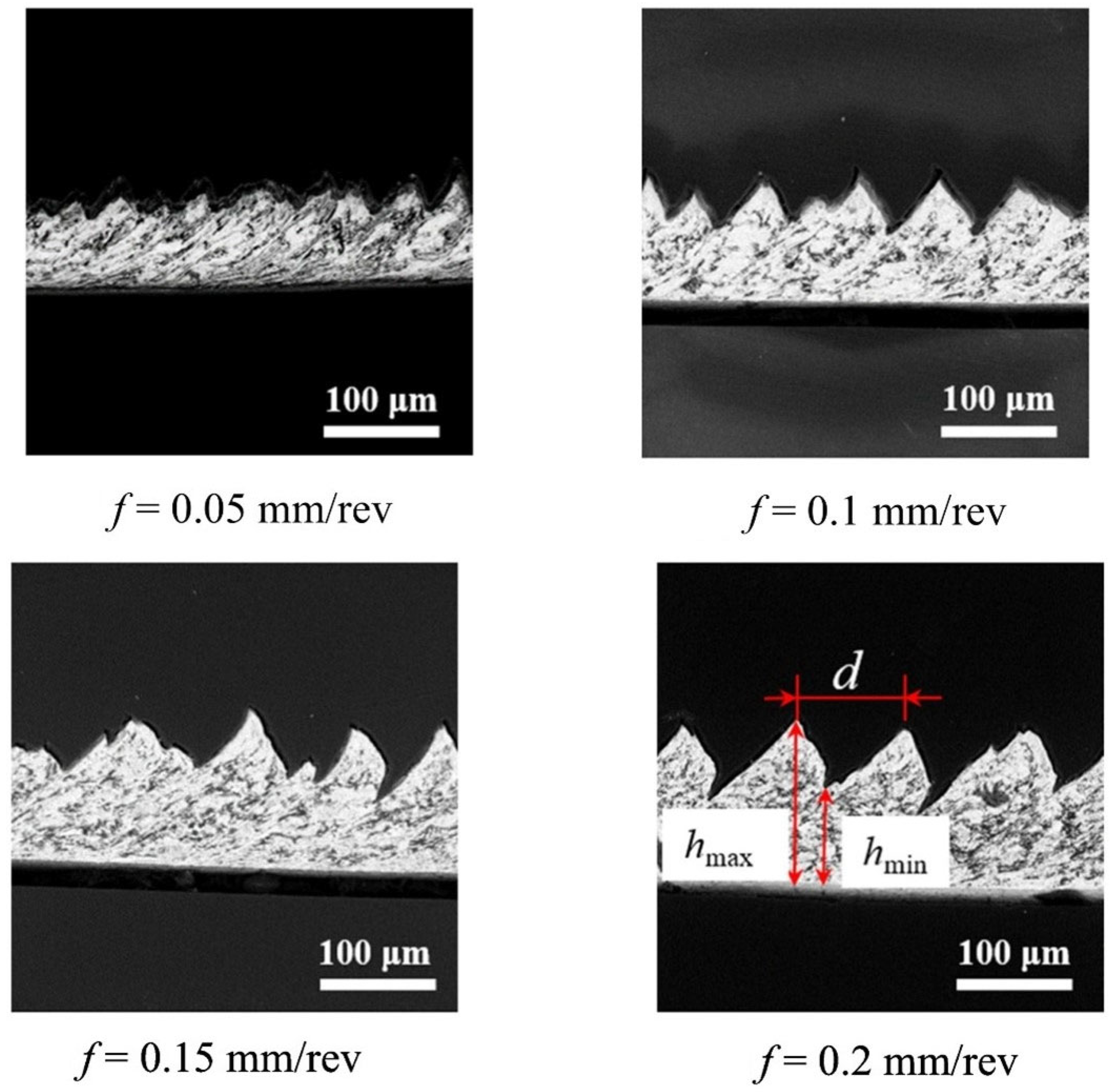

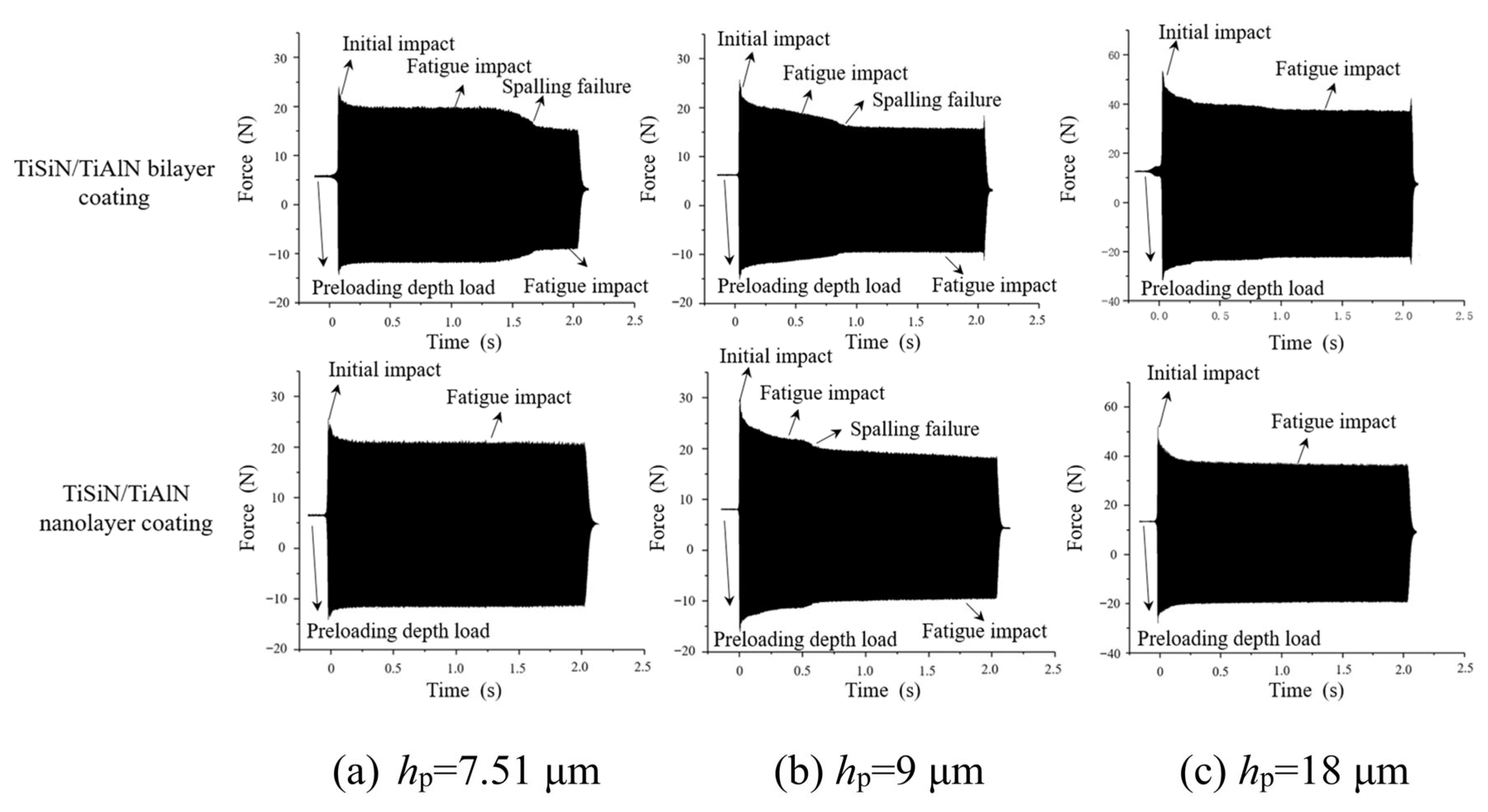

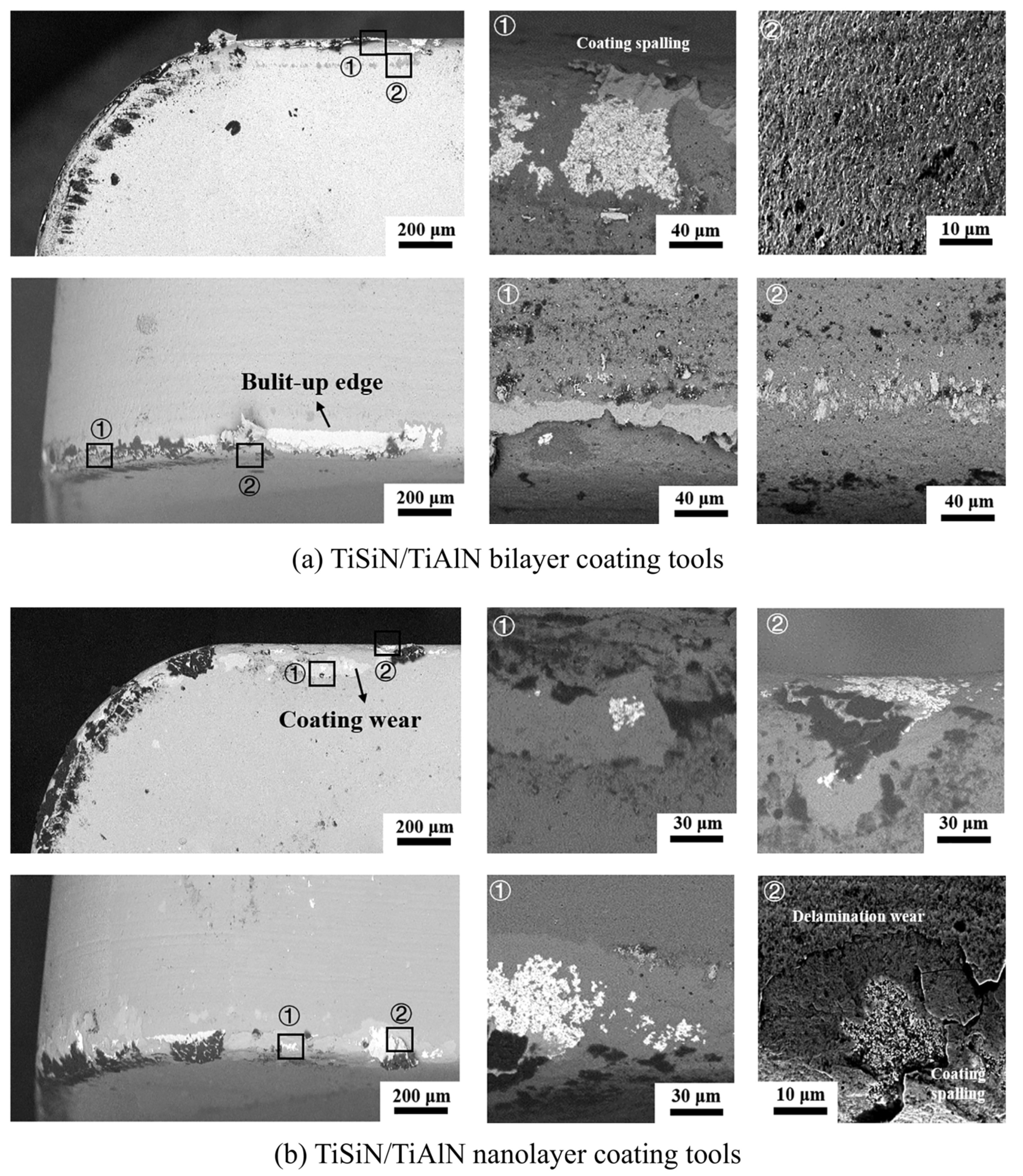

3.6. TiSiN/TiAlN Bilayer Coating Tool and TiSiN/TiAlN Nanolayer Coating Too

3.7. Comparative Analysis of TiAlN, TiSiN, and CrAlSiN Coatings for Machining Nickel-Based Alloys

4. Tool Life Optimization

5. Lubrication and Cooling Technologies

6. Cutting Techniques and Tool Wear Mitigation

7. Challenges in Machining Nickel-Based Alloys

8. Results and Discussion

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Davies, M. The use of nickel-containing alloys in the chemical industry. In Proceedings of the ESSC and DUPLEX 2019—10th European Stainless Steel Conference—Science and Market, 6th European Duplex Stainless Steel Conference and Exhibition, Vienna, Austria, 30 September–2 October 2019. [Google Scholar]

- Sridhar, N.; Hodge, F. Nickel and high nickel alloys. In Corrosion and Corrosion Protection Handbook, 2nd ed.; Routledge: New York, NY, USA, 2017. [Google Scholar] [CrossRef]

- Venkataraman, S. Cast high nickel-containing austenitic alloys for paper and pulp industry. In Proceedings of the Pulping, Engineering, Environmental and Recycling Sustainability Conference (PEERS 2019), St. Louis, MO, USA, 27–30 October 2019. [Google Scholar]

- Wang, X.; Wang, G.; Wang, W.; Liu, X.; Liu, Y.; Jin, Y.; Zhang, Y. Enhancing corrosion resistance of nickel-based alloys: A review of alloying, surface treatments, and environmental effects. J. Alloys Compd. 2025, 1032, 181014. [Google Scholar] [CrossRef]

- Delagnes, A.; Hamann, C.; Taché, O.; Toinin, J.; Bacroix, B.; De Carlan, Y. Study of the nanoprecipitation of γ′ (Ni3Al) phase in new nickel-based alloy for molten salt reactors. In Proceedings of the Euro PM 2024 Congress and Exhibition, Malmö, Sweden, 29 September–2 October 2024. [Google Scholar] [CrossRef]

- Ogunbiyi, O.F.; Jamiru, T.; Sadiku, E.R.; Adesina, O.T.; Beneke, L.N.; Adegbola, T. Spark plasma sintering of nickel and nickel-based alloys: A review. Procedia Manuf. 2019, 35, 1324–1329. [Google Scholar] [CrossRef]

- Thakur, A.; Gangopadhyay, S. Dry machining of nickel-based super alloy as a sustainable alternative using TiN/TiAlN coated tool. J. Clean. Prod. 2016, 129, 256–268. [Google Scholar] [CrossRef]

- Gupta, A.; Choudhari, A.; Rane, A.; Tiwari, A.; Sharma, P.; Gupta, A.; Sapale, P.; Tirumala, R.; Muthaiah, R.; Kumar, A. Advances in nickel-containing high-entropy alloys: From fundamentals to additive manufacturing. Materials 2024, 17, 3826. [Google Scholar] [CrossRef]

- Beiranvand, Z.M.; Ratnayake, R.M.C.; Rasoulinia, M.; Moradiani, A. Modeling of thermo-mechanical behavior of laser powder bed fusion of nickel-based superalloy parts used in oil gas industry. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering—OMAE, Hamburg, Germany, 5–10 June 2022; Volume 3. [Google Scholar] [CrossRef]

- Karasev, A.; Alekseeva, E.; Lukianov, A.; Jönsson, P. Characterization of non-metallic inclusions in corrosion-resistant nickel-based EP718 and 718 alloys by using electrolytic extraction method. E3S Web Conf. 2019, 121, 04004. [Google Scholar] [CrossRef]

- Deshpande, Y.V.; Andhare, A.B.; Padole, P.M. How cryogenic techniques help in machining of nickel alloys? A review. Mach. Sci. Technol. 2018, 22, 543–584. [Google Scholar] [CrossRef]

- Basak, A. Additive manufacturing of high-gamma prime nickel-based superalloys through selective laser melting (SLM). In Solid Freeform Fabrication 2019, Proceedings of the 30th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 12–14 August 2019; Available online: https://utw10945.utweb.utexas.edu/sites/default/files/2019/045%20Additive%20Manufacturing%20of%20High%20Gamma%20Prime%20Nickel.pdf (accessed on 16 July 2025).

- Sequeira, C.A.C.; Cardoso, D.S.P.; Amaral, L.; Šljukić, B.; Santos, D.M.F. On the performance of commercially available corrosion-resistant nickel alloys: A review. Corros. Rev. 2016, 34, 187–200. [Google Scholar] [CrossRef]

- Rathi, N.; Kumar, P.; Kumar, K.S.; Gupta, A. Non-conventional machining of nickel based superalloys: A review. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Pande, P.P.; Sambhe, R.U. Artificial intelligence machining predictions by fuzzy GUI for Inconel 718 with PVD coated carbide cutting tool. Int. J. Mech. Prod. Eng. Res. Dev. 2017, 7, 313–320. [Google Scholar] [CrossRef]

- Basha, S.K.; Raju, M.V.J.; Kolli, M. Experimental study of electrical discharge machining of Inconel X-750 using tungsten–copper electrode. Mater. Today Proc. 2018, 5, 11622–11627. [Google Scholar] [CrossRef]

- Bhattacharyya, D.; Davis, J.; Drew, M.; Harrison, R.; Edwards, L. Characterization of complex carbide–silicide precipitates in a Ni-Cr-Mo-Fe-Si alloy modified by welding. Mater. Charact. 2015, 105, 118–128. [Google Scholar] [CrossRef]

- Wang, Z.; Gao, S.; Li, S.; Zhang, W.; Lan, L.; Jiang, Y.; He, B. Research progress of laser additive manufacturing nickel-based alloy metal matrix composites. Metals 2023, 13, 129. [Google Scholar] [CrossRef]

- Zhu, G.; Luo, H.; He, J.; Tian, Y.; Wei, D.; Tan, Q.; Kong, D. Advances in additive manufacturing of nickel-based high-temperature alloys. Cailiao Gongcheng/J. Mater. Eng. 2024, 52, 1–15. [Google Scholar] [CrossRef]

- Cheng, X.; Xu, J.; Yang, Z.; Guo, Q.; Li, C.; Zhou, J.; Chen, S.; Liu, S.; Ma, Z. A novel nickel-based superalloy with excellent high temperature performance designed for laser additive manufacturing. Mater. Sci. Eng. A 2024, 911, 146926. [Google Scholar] [CrossRef]

- Linjie, L.; Quanwei, C.; Zhicheng, L.; Haoran, S.; Qiang, L.; Wanli, G. Research status on the effect of energy density on the forming microstructure and properties of nickel-based superalloys for laser additive manufacturing. J. Phys. Conf. Ser. 2024, 2845, 012021. [Google Scholar] [CrossRef]

- Tarasov, D.; Milder, O.; Tyagunov, A. Application of Bayesian artificial neural networks for modeling the dependence of nickel-based superalloys’ ultimate tensile strength on their chemical composition. In Proceedings of the 3rd International Conference on Control, Artificial Intelligence, Robotics and Optimization (ICCAIRO 2019), Majorca Island, Spain, 3–5 May 2019. [Google Scholar] [CrossRef]

- Olufayo, O.A.; Che, H.; Songmene, V.; Katsari, C.; Yue, S. Machinability of Rene 65 superalloy. Materials 2019, 12, 2034. [Google Scholar] [CrossRef]

- Raza, S.S.; Ahmad, T.; Kamran, M.; Zhang, X.; Basit, M.; Manzoor, M.; Inam, A.; Butt, O.; Abrar, M. Effect of hot rolling on microstructures and mechanical properties of Ni base superalloy. Vacuum 2020, 174, 109204. [Google Scholar] [CrossRef]

- Chen, N.; Zheng, D.; Niu, P.; Li, R.; Yuan, T. Laser powder bed fusion of GH3536 nickel-based superalloys: Processing parameters, microstructure and mechanical properties. Mater. Charact. 2023, 202, 113018. [Google Scholar] [CrossRef]

- Targhi, V.; Omidvar, H.; Hadavi, S.; Sharifianjazi, F. Microstructure and hot corrosion behavior of hot dip siliconized coating on Ni-base superalloy IN738LC. Mater. Res. Express 2020, 7, 056527. [Google Scholar] [CrossRef]

- Meng, X.; Lyu, S.; Xie, X.; Tang, C.; Yu, W.; Hou, W.; Wang, C.; Qu, J.; Du, J. Hot corrosion behavior and damage mechanism on yield property of nickel-based superalloy. Materials 2025, 18, 1749. [Google Scholar] [CrossRef]

- Tyagunov, A.; Milder, O.; Tarasov, D. Deep learning in simulation of nickel-based superalloys ultimate tensile strength: Accounting the role of alloying elements. WSEAS Trans. Environ. Dev. 2019, 15, 340–345. [Google Scholar]

- Tarasov, D.; Tyagunov, A.; Milder, O. BRANN forecast of superalloy tensile strength versus Larson–Miller parameter relation and its approximation by a sigmoidal function. Math. Methods Appl. Sci. 2023, 46, 16401–16414. [Google Scholar] [CrossRef]

- Yang, L.; Ren, X.; Ge, C.; Yan, Q. Status and development of powder metallurgy nickel-based disk superalloys. Int. J. Mater. Res. 2019, 110, 901–910. [Google Scholar] [CrossRef]

- Ulutan, D.; Pleta, A.; Henderson, A.; Mears, L. Comparison and Cost Optimization of Solid Tool Life in End Milling Nickel-Based Superalloy. Procedia Manuf. 2015, 1, 522–533. [Google Scholar] [CrossRef]

- Seenath, A.A.; Sarhan, A.A.D. A state-of-the-art review on cutting tool materials and coatings in enhancing the tool performance in machining the superior nickel-based superalloys. Arab. J. Sci. Eng. 2024, 49, 10203–10236. [Google Scholar] [CrossRef]

- Suárez, A.; López de Lacalle, L.N.; Polvorosa, R.; Veiga, F.; Wretland, A. Effects of high-pressure cooling on the wear patterns on turning inserts used on alloy IN718. Mater. Manuf. Process. 2017, 32, 678–686. [Google Scholar] [CrossRef]

- Bhise, V.Y.; Jogi, B.F. Some studies on cutting tools and coatings for machining of superalloys under dry and sustainable lubrication environment. Adv. Mater. Process. Technol. 2024, 10, 3662–3679. [Google Scholar] [CrossRef]

- Thellaputta, G.R.; Chandra, P.S.; Rao, C.S.P. Machinability of nickel-based superalloys: A review. Mater. Today Proc. 2017, 4, 3712–3721. [Google Scholar] [CrossRef]

- Da Silva, L.R.R.; Rodrigues Campos, F.D.A.; Sales, W.F.; Machado, A.R. Evaluation of the tool wear in the turning process of INCONEL 718 using PCD tools. Procedia Manuf. 2021, 53, 276–285. [Google Scholar] [CrossRef]

- Rodrigues, M.A.; Hassui, A.; Lopes da Silva, R.H.; Loureiro, D. Tool life and wear mechanisms during Alloy 625 face milling. Int. J. Adv. Manuf. Technol. 2016, 85, 1439–1448. [Google Scholar] [CrossRef]

- Fan, Y.H.; Wang, W.Y.; Hao, Z.P.; Yuan, H. Effect of workpiece atom diffusion into CBN tool on its mechanical properties in cutting Ni–Fe–Cr alloy based on molecular dynamics simulation. Int. J. Precis. Eng. Manuf. 2021, 22, 635–647. [Google Scholar] [CrossRef]

- Sugihara, T.; Nishimoto, Y.; Enomoto, T. Development of a novel cubic boron nitride cutting tool with a textured flank face for high-speed machining of Inconel 718. Precis. Eng. 2017, 48, 75–82. [Google Scholar] [CrossRef]

- Chen, S.-H.; Ho, Y.-L. Application of response surface methodology (RSM) to the prediction of the service life of cutters used in milling super-alloy Waspaloy. HKIE Trans. 2020, 27, 103–112. [Google Scholar] [CrossRef]

- Nadeem, M.; Jani, S.P.; Reddy, K.R.; Kumar, P.S.; Gupta, M. Machining nickel–iron alloy using tungsten cutting tool and its process parameter optimization using Adam–Gene genetic algorithm. Int. J. Interact. Des. Manuf. 2024, 18, 3305–3312. [Google Scholar] [CrossRef]

- Sirin, S.; Sarıkaya, M.; Yıldırım, Ç.V.; Kıvak, T. Machinability performance of nickel alloy X-750 with SiAlON ceramic cutting tool under dry, MQL and hBN mixed nanofluid-MQL. Tribol. Int. 2021, 153, 106673. [Google Scholar] [CrossRef]

- Darshan, C.; Jain, S.; Dogra, M.; Gupta, M.K.; Mia, M.; Haque, R. Influence of dry and solid lubricant-assisted MQL cooling conditions on the machinability of Inconel 718 alloy with textured tool. Int. J. Adv. Manuf. Technol. 2019, 105, 1835–1849. [Google Scholar] [CrossRef]

- Rinaldi, S.; Caruso, S.; Umbrello, D.; Filice, L.; Franchi, R.; Del Prete, A. Machinability of Waspaloy under different cutting and lubri-cooling conditions. Int. J. Adv. Manuf. Technol. 2018, 94, 3703–3712. [Google Scholar] [CrossRef]

- Tandekar, N.; Kumar, A.; Valleti, K. Machining of Ni-based superalloys using CAPVD coated carbide tools. Mater. Today Commun. 2024, 39, 109101. [Google Scholar] [CrossRef]

- Selvan, E.V.; Boopathy, G.; Saravanakumar, L.; Ramanan, N. Evaluations of Zirconium coated surface attributes on mechanical characteristics and wear behavior of nickel based super alloy material. AIP Conf. Proc. 2025, 3162, 020095. [Google Scholar] [CrossRef]

- Kulkarni, P.; Chinchanikar, S. A review on machining of nickel-based superalloys using nanofluids under minimum quantity lubrication (NFMQL). J. Inst. Eng. (India) Ser. C 2023, 104, 183–199. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Lai, H.-M. Wear behavior and cutting performance of CrAlSiN and TiAlSiN hard coatings on cemented carbide cutting tools for Ti alloys. Surf. Coat. Technol. 2014, 259 Pt B, 152–158. [Google Scholar] [CrossRef]

- Alves, U.C.; Ricci, V.P.; Mota, I.G.C.; Koga, G.Y.; Hassui, A.; Ventura, C.E.H. Mechanical and tribological characterization of TiAlN/TiN and TiSiN/AlTiN coating systems for cutting tools. J. Manuf. Process. 2025, 145, 522–535. [Google Scholar] [CrossRef]

- Chen, Z.; Lou, M.; Geng, D.; Xu, Y.X.; Wang, Q.; Zheng, J.; Zhu, R.; Chen, Y.; Kim, K.H. Effect of the modulation geometry on mechanical and tribological properties of TiSiN/TiAlN nano-multilayer coatings. Surf. Coat. Technol. 2021, 423, 127586. [Google Scholar] [CrossRef]

- Ghannem, S.; Aouadi, B.; Yallese, M.A.; Ben Fathallah, B. The Machinability of Nickel and Cobalt Based Alloys: Brief Review. In International Tunisian Congress of Mechanics; Springer Nature: Cham, Switzerland, 2023; pp. 432–439. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Volosova, M.A.; Fedorov, S.V.; Mitrofanov, A.P.; Gurin, V.D.; Okunkova, A.A. Creation of tool coatings based on titanium diboride for highly efficient milling of chromium–nickel alloys. J. Manuf. Mater. Process. 2024, 8, 210. [Google Scholar] [CrossRef]

- Rosnan, R.; Azmi, A.I.; Murad, M.N. Effects of cutting parameters on tool wear and thrust force in drilling nickel-titanium (NiTi) alloys using coated and uncoated carbide tools. Key Eng. Mater. 2018, 791, 111–115. [Google Scholar] [CrossRef]

- Swain, N.; Venkatesh, V.; Kumar, P.; Srinivas, G.; Ravishankar, S.; Barshilia, H.C. An experimental investigation on the machining characteristics of Nimonic 75 using uncoated and TiAlN coated tungsten carbide micro-end mills. CIRP J. Manuf. Sci. Technol. 2017, 16, 34–42. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, K.; Dang, J.; Tu, L.; Wang, Q.; Ming, W.; Wang, D.; Liu, Z.; Chen, M. Analysis of tool wear and cutting characteristics in milling of powder metallurgy nickel-based superalloy by various coatings. Wear 2024, 552–553, 205429. [Google Scholar] [CrossRef]

- Kursuncu, B.; Caliskan, H.; Guven, S.Y.; Panjan, P. Wear behavior of multilayer nanocomposite TiAlSiN/TiSiN/TiAlN coated carbide cutting tool during face milling of Inconel 718 superalloy. J. Nano Res. 2017, 47, 11–16. [Google Scholar] [CrossRef]

- Sasi, J.C.; Mathew, J.; George, A.; Kuriachen, B.; Dhanish, P.B.; Oommen, G.; Anoop, C.R. Wear behaviour of deep cryogenically treated coated tool during end milling of XH67MBTHO. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2025, 13506501251334698. [Google Scholar] [CrossRef]

- Rosnan, R.; Azmi, A.I.; Murad, M.N.; Ali, M.A.M. Evaluation of coated carbide drills when drilling Nickel-Titanium (NiTi) alloys with minimum quantity nano-lubricants. In Lecture Notes in Mechanical Engineering; Springer: Singapore, 2021; pp. 299–308. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, Z.; Gong, Z.; Liu, A.; Cai, Y.; Wang, B.; Song, Q.; Liang, X.; Zhang, Y.; Zhang, Z.; et al. Comparison of surface morphology and tool wear in the machining of Ti-6Al-4V alloys with uncoated and TiAlN tools under dry, minimum quantity lubrication, flood cooling, and low-temperature spray jet cooling conditions. Micromachines 2023, 14, 1263. [Google Scholar] [CrossRef]

- Mu, X.; Chen, Z.; Chen, H.; Meng, X.; Xiao, G.; Yi, M.; Zhang, J.; Zhou, T.; Xu, C. Mechanism of improving the surface integrity of self-lubricating ceramic tool in cutting nickel-based alloy. Int. J. Refract. Met. Hard Mater. 2025, 132, 107298. [Google Scholar] [CrossRef]

- Kumar, C.S.; Urbikain, G.; De Lucio, P.F.; De Lacalle, L.N.L.; Pérez-Salinas, C.; Gangopadhyay, S.; Fernandes, F. Investigating the self-lubricating properties of novel TiSiVN coating during dry turning of Ti6Al4V alloy. Wear 2023, 532–533, 205095. [Google Scholar] [CrossRef]

- International Organization for Standardization. Reference Materials—Selected Terms and Definitions (ISO Guide No. 30:2015). 2015. Available online: https://www.iso.org/standard/46209.html (accessed on 16 July 2025).

- Rajput, S.S.; Upadhyay, C.; Gangopadhyay, S.; Fernandes, F. High-temperature tribological behaviour and machining performance of self-lubricant CrAlNAg coatings for dry milling operations. Tribol. Int. 2024, 198, 109824. [Google Scholar] [CrossRef]

- Wang, T.; Zha, X.; Chen, F.; Wang, J.; Lin, L.; Xie, H.; Lin, F.; Jiang, F. Research on cutting performance of coated cutting tools by a new impact test method considering contact stress condition caused by segmented chips. J. Manuf. Process. 2021, 68 Pt A, 1569–1584. [Google Scholar] [CrossRef]

- Wu, Z.; Cheng, Z.; Zhang, H.; Xu, Z.; Wang, Y.; Zhou, F. Electrochemical and tribological properties of CrAlN, TiAlN, and CrTiN coatings in water-based cutting fluid. J. Mater. Eng. Perform. 2020, 29, 2153–2163. [Google Scholar] [CrossRef]

- Sui, X.; Li, G.; Qin, X.; Yu, H.; Zhou, X.; Wang, K.; Wang, Q. Relationship of microstructure, mechanical properties and titanium cutting performance of TiAlN/TiAlSiN composite coated tool. Ceram. Int. 2016, 42, 7524–7532. [Google Scholar] [CrossRef]

- Liu, J.Y.; Li, A.H.; Zhang, J.C.; Wang, Y.Q.; Feng, Z.H. Performance of high-speed steel drills in wet drilling Inconel 718 superalloy. Exp. Tech. 2023, 47, 395–406. [Google Scholar] [CrossRef]

- Vetri Velmurugan, K.; Venkatesan, K.; Devendiran, S.; Mathew, A.T. Investigation of parameters for machining a difficult-to-machine superalloy: Inconel X-750 and Waspaloy. In Innovative Design, Analysis and Development Practices in Aerospace and Automotive Engineering (I-DAD 2018); Lecture Notes in Mechanical Engineering; Springer: Singapore, 2019; pp. 199–215. [Google Scholar] [CrossRef]

- Vavruska, P.; Maly, J.; Novotny, A. Increasing tool life through adjustment of cutting edge and toolpath during milling of Inconel 718. MM Sci. J. 2022, 2022, 6283–6288. [Google Scholar] [CrossRef]

- Persson, H.; Johansson, D.; Chen, Z.; Lenrick, F.; M’Saoubi, R.; Gustafsson, D.; Bushlya, V.; Stahl, J.E.; Zhou, J.M. Modelling tool life in high speed machining of AD730. Procedia Manuf. 2018, 25, 316–321. [Google Scholar] [CrossRef]

- Liu, E.; An, W.; Xu, Z.; Zhang, H. Experimental study of cutting-parameter and tool life reliability optimization in inconel 625 machining based on wear map approach. J. Manuf. Process. 2020, 53, 34–42. [Google Scholar] [CrossRef]

- He, L.J.; Xu, J.H.; Su, H.H.; Chen, Y. Turning of cast Inconel 718 with coated carbide and whisker reinforced ceramic tools. Mater. Sci. Forum 2014, 770, 136–140. [Google Scholar] [CrossRef]

- Panji, C.; Yavagal, P.; Kulkarni, V.N.; Gurusiddayya, S.G.; Deeban Chakravarthy, N.; Rawal, Y. Analysis of Cutting Parameters for Enhanced Machining Efficiency and Tool Life in Milling of Nickel Titanium Alloy Through FE Simulation. Mater. Sci. Forum 2024, 1135, 3–14. [Google Scholar] [CrossRef]

- Del Prete, A.; Franchi, R.; Spagnolo, A. Wearing evaluation in nickel super-alloys turning for the development of a predictive model for CAM optimization. Key Eng. Mater. 2014, 611–612, 1264–1273. [Google Scholar] [CrossRef]

- Nath, C.; Brooks, Z.; Kurfess, T.R. Machinability study and process optimization in face milling of some super alloys with indexable copy face mill inserts. J. Manuf. Process. 2015, 20, 88–97. [Google Scholar] [CrossRef]

- Li, Q.; Wu, Z.; Ji, B.; Zhang, S.; Tu, R. Cutting performance of TiN/TiSiN coated tool during turning of Ti6Al4V titanium alloy. J. Mater. Eng. Perform. 2025, 34, 9374–9387. [Google Scholar] [CrossRef]

- Zębala, W. Optimization of nickel alloy turning considering the tool in different wear phases. Solid State Phenom. 2017, 261, 243–250. [Google Scholar] [CrossRef]

- Wang, J.; Luo, M.; Xu, K.; Tang, K. Generation of Tool-Life-Prolonging and Chatter-Free Efficient Toolpath for Five-Axis Milling of Freeform Surfaces. J. Manuf. Sci. Eng. Trans. ASME 2019, 141, 031001. [Google Scholar] [CrossRef]

- Xie, L.; Li, B.; Wang, Z.; Ye, P.; Zhang, H. Methods to improve wear prediction accuracy of nickel-based superalloy milling cutters under variable process conditions. Int. J. Adv. Manuf. Technol. 2025, 137, 5547–5563. [Google Scholar] [CrossRef]

- Jeong, H.-I.; Lee, C.-M. A study on improvement of tool life using a heat shield in laser assisted machining to Inconel 718. Opt. Laser Technol. 2021, 142, 107208. [Google Scholar] [CrossRef]

- Kónya, G.; Kovács, Z.F. Experimental investigation of the effects of cooling-lubricating methods on the slot milling process of GTD-111 type nickel-based superalloy. J. Manuf. Process. 2024, 119, 98–108. [Google Scholar] [CrossRef]

- Bagherzadeh, A.; Koc, B.; Budak, E.; Isik, M. High-speed machining of additively manufactured Inconel 718 using hybrid cryogenic cooling methods. Virtual Phys. Prototyp. 2022, 17, 419–436. [Google Scholar] [CrossRef]

- Che, C.; Wang, Y.; Liu, H.; Cheng, Y.; Li, J.; Han, L. Experimental research on turning nickel-based superalloy GH4169 under cryogenic cooling mixed lubrication jets. J. Phys. Conf. Ser. 2024, 2827, 012007. [Google Scholar] [CrossRef]

- Makhesana, M.A.; Patel, K.M. Optimization of parameters and sustainability assessment under minimum quantity solid lubrication-assisted machining of Inconel 718. Process Integr. Optim. Sustain. 2021, 5, 625–644. [Google Scholar] [CrossRef]

- Padhan, S.; Das, S.R.; Das, A.; Alsoufi, M.S.; Ibrahim, A.M.M.; Elsheikh, A. Machinability investigation of Nitronic 60 steel turning using SiAlON ceramic tools under different cooling/lubrication conditions. Materials 2022, 15, 2368. [Google Scholar] [CrossRef]

- Shokrani, A.; Newman, S.T. Hybrid cooling and lubricating technology for CNC milling of Inconel 718 nickel alloy. Procedia CIRP 2018, 77, 215–218. [Google Scholar] [CrossRef]

- Fedai, Y. Exploring the Impact of the Turning of AISI 4340 Steel on Tool Wear, Surface Roughness, Sound Intensity, and Power Consumption under Dry, MQL, and Nano-MQL Conditions. Lubricants 2023, 11, 442. [Google Scholar] [CrossRef]

- Kara, F. Investigation of the Effect of Al2O3 Nanoparticle-Added MQL Lubricant on Sustainable and Clean Manufacturing. Lubricants 2024, 12, 393. [Google Scholar] [CrossRef]

- Jamil, M.; Khan, A.M.; Hegab, H.; Anwar, S.; Mia, M. Effects of hybrid Al2O3-CNT nanofluids and cryogenic cooling on machining of Ti–6Al–4V. Int. J. Adv. Manuf. Technol. 2019, 102, 3895–3909. [Google Scholar] [CrossRef]

- Mehmood, T.; Khalil, M.S. Enhancement of Machining Performance of Ti-6Al-4V Alloy Though Nanoparticle-Based Minimum Quantity Lubrication: Insights into Surface Roughness, Material Removal Rate, Temperature, and Tool Wear. J. Manuf. Mater. Process. 2024, 8, 293. [Google Scholar] [CrossRef]

- Jemielniak, K. Review of new developments in machining of aerospace materials. J. Mach. Eng. 2021, 21, 22–55. [Google Scholar] [CrossRef]

- Zhou, S.; Wang, D.; Wu, S.; Gu, G.; Dong, G.; An, Q.; Guo, H.; Li, C. Minimum quantity lubrication machining nickel base alloy: A comprehensive review. Int. J. Adv. Manuf. Technol. 2024, 131, 2407–2445. [Google Scholar] [CrossRef]

- Gupta, M.K.; Jamil, M.; Wang, X.; Song, Q.; Liu, Z.; Mia, M.; Hegab, H.; Khan, A.M.; Collado, A.G.; Pruncu, C.I.; et al. Performance evaluation of vegetable oil-based nano-cutting fluids in environmentally friendly machining of Inconel-800 alloy. Materials 2019, 12, 2792. [Google Scholar] [CrossRef]

- Ross, N.S.; Srinivasan, N.; Amutha, P.; Gupta, M.K.; Korkmaz, M.E. Thermo-physical, tribological and machining characteristics of Hastelloy C276 under sustainable cooling/lubrication conditions. J. Manuf. Process. 2022, 80, 397–413. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Gupta, M.K.; Boy, M.; Yaşar, N.; Krolczyk, G.M.; Günay, M. Influence of duplex jets MQL and nano-MQL cooling system on machining performance of Nimonic 80A. J. Manuf. Process. 2021, 69, 112–124. [Google Scholar] [CrossRef]

- Elshwain, A.E.I.; Redzuan, N. Effect of cooling/lubrication using cooled air, MQL + cooled air, N2 and CO2 gases on tool life and surface finish in machining—A review. Adv. Mater. Res. 2014, 845, 889–893. [Google Scholar] [CrossRef]

- Iqbal, A.; Saelzer, J.; Nauman, M.M.; Biermann, D. Milling of nickel-based superalloys using throttle cryogenic cooling and micro-lubrication. Mater. Res. Proc. 2024, 41, 2093–2102. [Google Scholar] [CrossRef]

- Khalil, A.N.M.; Azmi, A.I.; Murad, M.N.; Annuar, A.F.; Ali, M.A.M. Coupled effects of vortex tube hybrid cooling with minimal quantity reinforced nanoparticle lubricants in turning NiTi alloys. Int. J. Adv. Manuf. Technol. 2019, 105, 3007–3015. [Google Scholar] [CrossRef]

- Bhowmik, A.; Kumar, R.; Thulasiram, R.; Karthikeyan, A.; Thatoi, D.N.; Bisht, Y.S.; Samal, P.; Kotteda, T.K.; Tejani, G.G.; Santhosh, A.J. A comprehensive review on the viability of minimum quantity lubrication technology for machining difficult-to-cut alloys. AIP Adv. 2025, 15. [Google Scholar] [CrossRef]

- Kasim, M.S.; Ngah, N.; Mohamed, S.B.; Rahman, Z.A.; Haron, C.H.C.; Yusof, S.N.A.; Ghani, J.A.; Mohamad, A. Machining surface quality evaluation of Inconel 718: A comparative study of various coolant and lubrication strategies in milling process. J. Tribol. 2023, 39, 17–35. [Google Scholar]

- Khan, M.A.; Wang, B.; Khan, A.M.; Liu, Z.; Cai, Y.; Song, Q. Integrating textured tools and diverse lubricooling approaches in machining performance of Ti and Ni-base alloys—A comprehensive review. Mach. Sci. Technol. 2024, 28, 323–391. [Google Scholar] [CrossRef]

- Magri, A.; Diniz, A.E.; Suyama, D.I. Evaluating the use of high-pressure coolant in turning process of Inconel 625 nickel-based alloy. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 232, 1182–1192. [Google Scholar] [CrossRef]

- Barthelmä, F.; Frank, H.; Schiffler, M.; Bartsch, A. Hard coatings to improve the machining of nickel-based materials. Procedia CIRP 2016, 46, 294–298. [Google Scholar] [CrossRef]

- Sasaki, W.; Natsu, W.; Xing, H. Study on wire electrochemical machining of nickel base alloy using fine wire electrode. In Proceedings of the JSME 2020 Conference on Leading Edge Manufacturing/Materials and Processing (LEMP 2020), Online, 3 September 2020; p. V001T09A004. [Google Scholar] [CrossRef]

- Sebbe, N.P.V.; Fernandes, F.; Silva, F.J.G.; Pedroso, A.F.V.; Sales-Contini, R.C.M.; Barbosa, M.L.S.; Durão, L.M.; Magalhães, L.L. Wear Behavior of TiAlVN-Coated Tools in Milling Operations of INCONEL® 718. Coatings 2024, 14, 311. [Google Scholar] [CrossRef]

- Smak, K.; Szablewski, P.; Legutko, S.; Petru, J.; Kratochwil, J.; Wencel, S. Evaluation of the Influence of the Tool Set Overhang on the Tool Wear and Surface Quality in the Process of Finish Turning of the Inconel 718 Alloy. Materials 2024, 17, 4465. [Google Scholar] [CrossRef]

- Thakur, D.G.; Ramamoorthy, B.; Vijayaraghavan, L. Effect of posttreatments on the performance of tungsten carbide (K20) tool while machining (turning) of Inconel 718. Int. J. Adv. Manuf. Technol. 2015, 76, 587–596. [Google Scholar] [CrossRef]

- Özbek, O. Evaluation of Nano Fluids with Minimum Quantity Lubrication in Turning of Ni-Base Superalloy UDIMET 720. Lubricants 2023, 11, 159. [Google Scholar] [CrossRef]

- Özbek, N.A.; Karadağ, M.İ.; Özbek, O. Optimization of flank wear and surface roughness during turning of AISI 304 stainless steel using the Taguchi method. Mater. Test. 2020, 62, 957–961. [Google Scholar] [CrossRef]

| Study | Nickel-Based Material | Cutting Tool Material | Cutting Parameters | Tool Wear Mechanisms | Key Findings | |

|---|---|---|---|---|---|---|

| 1 | Alloy 625 | Cemented Carbide | Various cutting speeds and feed rates | Oxidation wear | Lower wear rate observed, optimal conditions for face milling identified | [37] |

| 2 | Inconel 718 | Not specified | Different cutting speeds | BUE formation, tribo-chemical reaction, inhomogeneous deformation | Medium cutting speed reduces adhesion, high speed causes tool subsurface cracks | [38] |

| 3 | Waspaloy | Not specified | Cutting speed: 33.21 m/min, depth: 0.0367 mm, feed: 0.367 mm/tooth | Not specified | Regression analysis used to optimize tool life | [40] |

| 4 | Inconel 718 | CBN | High-speed cutting | Diffusion wear | Diffusion of Ni, Fe, Cr atoms decreases compressive strength and toughness of CBN tools | [38] |

| 5 | GH4061 | Monolithic Ceramic | Cutting speed: 602.88 m/min, depth: 0.3 mm, width: 6 mm, feed: 0.03 mm/z | Adhesive and diffusion wear | High-speed cutting improves surface quality, optimal parameters for dry milling identified | [41] |

| 6 | Nickel-Iron Alloy | Tungsten Carbide | Cutting speed: 50–150 m/min, feed: 0.075–0.125 mm/rev, depth: 0.1–0.3 mm | Flank wear | Slow speed reduces wear, high speed reduces machining time, optimization using Adam-Gene Algorithm | [42] |

| 7 | Nickel Alloy X-750 | Sialon Ceramic | Various cutting environments (dry, BF-MQL, NF-MQL) | Flank wear | NF-MQL improves surface roughness and cutting force, dry machining offers less tool wear | [43] |

| 8 | Inconel 718 | Nano-grain size ceramics | Different roughing conditions | Abrasion wear, chipping | Alumina base ceramics perform better than silicon nitride base ceramics | [43] |

| 9 | Inconel 718 | Textured tools | Cutting speed: 80–180 m/min | Flank and crater wear | NFMQL improves cooling and friction, better performance with textured tools under solid lubrication | [44] |

| 10 | Waspaloy | Not specified | Various lubri-cooling conditions (dry, wet, cryogenic) | Not specified | Effects of cutting parameters on tool wear, cutting forces, and chip morphology analyzed | [44] |

| Tool Coating Types for Machining Nickel-Based Materials Coating Type | Deposition Method | Material | Performance | Wear Mechanism | Citation |

|---|---|---|---|---|---|

| TiAlN/TiN | PVD | Incoloy 825 | Outperformed uncoated and CVD-coated tools due to excellent tribological properties | Adhesion, attrition, edge chipping, notch wear | [7] |

| TiN/TiAlN | PVD | Incoloy 825 | Reduced cutting force, tool wear, and surface roughness; sustainable dry machining | Not specified | [7] |

| Al2O3 | PVD | Nickel-based superalloy | High hardness, thermal stability, low adhesion tendency, improved tool life and MRR | Not specified | [52] |

| TiAlN | Not specified | Nickel-based superalloy | Improved wear resistance and reduced thrust force during drilling | Not specified | [53] |

| TiAlN | Reactive pulsed DC magnetron sputtering | Nimonic 75 | Superior tool life and reduced micro-burr formation compared to uncoated tools | Not specified | [54] |

| AlTiN, TiAlCrN, TiAlSiN | Not specified | FGH 4097 | TiAlCrN showed superior performance at high cutting speeds | Adhesive wear, abrasive wear (TiAlN) | [55] |

| Performance Parameter | TiAlN-Coated Tools | Uncoated Tools |

|---|---|---|

| Tool Wear | Significantly reduced [55] | Higher wear rates, especially at tool edges |

| Tool Life | Up to 1.7× longer [55] | Shorter life due to thermal and abrasive wear |

| Cutting Forces | 27% lower [56] | Higher forces due to increased friction and wear |

| Surface Roughness | Ra < 0.18 μm [55] | Poorer finish, especially under dry conditions |

| Wear Mechanisms | Adhesion, abrasion, edge chipping, Al2O3 film formation | Severe adhesive and abrasive wear; higher delamination |

| Best Machining Conditions | High-speed and dry machining [7,58] | Less effective without lubrication or cooling |

| Property | TiAlN | TiSiN | CrAlSiN |

|---|---|---|---|

| Hardness (GPa) | 27.9 [49]; 31 ± 1 [48]; 16.1 [65] | 34.1 [49] 36.8 in TiSiN/TiAlN multilayers [50] | 36 ± 2 [48] |

| Elastic Modulus (GPa) | 286 [49] | 315 [49] | High; not specified numerically [49] |

| Wear Resistance | Good; hardness decreases to 26 GPa after annealing at 700 °C [48,65] | High; lower adhesion leads to wear/delamination [49] multilayers form tribolayer [50] | Superior; tool life improved 2.9× vs. TiAlSiN and 4.2× vs. TiAlN [48] |

| Thermal Stability | Drops from 31 → 26 GPa at 700 °C | Maintains hardness in multilayers due to tribolayer and thermal barrier effect [50] | Retains ~36 GPa hardness at 700 °C [48] |

| Adhesion Strength | Strong, HF3–HF4 [49] | Weaker, HF5–HF6 [49] | Not numerically graded; inferred strong due to reduced chipping and stable performance [48] |

| Cutting Performance | Moderate; limited by hardness loss at high temperatures | Improved in high-speed turning due to nanocrystalline structure and oxidation resistance [66] | Outperforms TiAlN and TiSiN; best tool life and wear resistance in machining Ni alloys [48] |

| Study | Nickel-Based Material | Tool Type | Optimization Technique | Key Findings | |

|---|---|---|---|---|---|

| 1 | AD730® | CBN 170 | Tool life model (Colding) | High temperature properties, optimized for machining | [70] |

| 2 | Inconel 625 | Coated carbide | Tool wear map, reliability model | Optimal cutting parameters, tool life reliability evaluation | [71] |

| 3 | Waspaloy | Not specified | Response Surface Methodology (RSM) | Significant factors: speed, depth, feed rate; regression analysis for tool life | [40] |

| 4 | Nickel-based alloy | Coated carbide, whisker reinforced ceramic | Comparative analysis | Whisker reinforced ceramic tools more effective | [72] |

| 5 | NiTiNOL | Not specified | Finite Element (FE) simulation, RSM, Taguchi | Optimal settings: moderate speed, lower depth, highest feed rate | [73] |

| 7 | Inconel 718 | High-speed steels | Orthogonal cutting experiments, regression model | Optimized cutting parameters, tool wear mechanisms | [66] |

| 8 | Inconel 718 | Not specified | Predictive model for CAM optimization | Flank wear evaluation, maximized MRR | [74] |

| 9 | Nickel/Cobalt based alloys | Not specified | Review of optimization techniques | Poor machinability, tool life impact | [51] |

| 11 | Inconel 718, Inconel 625 | Indexable copy face mills | Extended Taylor’s tool life model | Machinability and cost optimization | [75] |

| 12 | Gamma-prime strengthened nickel-based superalloy | Solid carbide, ceramic tools | Cost-based model | Performance comparison, cost analysis | [76] |

| 13 | Inconel 718, Inconel 625 | Indexable copy face mills | Extended Taylor’s tool life model | Machinability and cost optimization | [75] |

| 14 | Nickel-based alloy | Not specified | Force material model | Optimization of feed rate, improved cutting process | [77] |

| 15 | Ni-based superalloy | Not specified | Multilayer toolpath generation | Reduced tool wear by 39% | [78] |

| 17 | Nickel-based high-temperature alloy | Not specified | MCL model, meta-learning | Enhanced tool wear prediction accuracy | [79] |

| 18 | Inconel 718 | Not specified | Laser assisted machining (LAM) | Improved tool life with heat shield application | [80] |

| Study | Lubrication/Cooling Technique | Materials | Key Findings | |

|---|---|---|---|---|

| 1 | Cryogenic machining, MQL, HPC, hybrid cutting processes | Nickel & titanium alloys | Hybrid cutting and cooling methods improve machining efficiency and surface integrity | [91] |

| 2 | MQL (vegetable oil-based, cryogenic, solid lubricant, electrostatic atomization) | Nickel alloys | Vegetable oil MQL improves surface quality by 30%; electrostatic atomization MQL reduces tool wear by 42.4% | [92] |

| 3 | Dry cutting, wet, MQL, compressed-air | Nitronic 60 steel | MQL reduces cutting force, temperature, and tool wear; enhances surface finish | [85] |

| 4 | Nano-cutting fluids (Al2O3, MoS2, graphite) under MQL | Inconel 800 | Graphite-based nanofluids provide superior cooling, reducing tool wear and surface roughness | [93] |

| 5 | High-pressure cooling (HPC) | Inconel 718 | HPC reduces flank wear by >30% and cutting forces by >10% | [33] |

| 6 | MQL with nanocarbon dots (CDs) | Hastelloy C276 | CDs in oil reduce surface roughness by 56–69% compared to dry machining | [94] |

| 7 | MQL and nano-MQL (different nozzle positions) | Nimonic 80A | Mixed-direction nano-MQL reduces tool wear by ~60% compared to dry cutting | [95] |

| 8 | Hybrid cryogenic cooling | Additively manufactured Inconel 718 | Improves tool life and balances cooling/lubrication efficiency | [82] |

| 9 | Gas-based coolants (air, N2, CO2) with MQL | Nickel & titanium alloys | N2 and cooled air with MQL identified as most effective | [96] |

| 10 | Throttle cryogenic cooling with MQL | Inconel 718, Incoloy 825, Waspaloy | Pulsed cryogenic + MQL improves cutting force and surface quality | [93,97] |

| 11 | Nano-MQL with vortex chilled air | NiTi alloys | Hybrid vortex cooling reduces tool wear and improves surface finish | [98] |

| 12 | Cryogenic cooling mixed lubrication | GH4169 superalloy | LN2 + emulsion reduces tool wear and improves surface integrity | [83] |

| 13 | MQL with vegetable oils, nanofluids, nanoplatelets | Nickel alloys | Eco-friendly MQL provides superior performance vs. flood lubrication | [99] |

| 14 | Chilled MQL, chilled air, dry | Inconel 718 | Chilled MQL increases tool life, lowers roughness, reduces forces | [100] |

| 15 | Textured tools + HPC, MQL, hybrid cryogenic/MQL | Ti & Ni alloys | Textured tools reduce tool wear and enhance lubrication | [101] |

| 16 | Solid lubricant-assisted MQL (graphene & MoS2) | Inconel 718 | Solid lubricants under MQL improve tribology, lowering cutting forces | [43] |

| 17 | Minimum quantity solid lubrication (MQSL) | Inconel 718 | Optimized MQSL reduces tool wear and improves sustainability metrics | [84] |

| 18 | Hybrid vortex + nanoparticle lubrication | Nickel alloys | Combination cooling lowers thermal load and extends tool life | [98] |

| 19 | Flood vs. cryogenic cooling (comparison study) | Inconel 718 | Cryogenic cooling reduces thermal cracks and extends tool life | [86] |

| 20 | Duplex MQL jets with nanofluids | Nimonic superalloys | Duplex MQL jets significantly enhance surface quality and tool wear resistance | [95] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sonowal, K.; Borthakur, P.P. Recent Advances in Tool Coatings and Materials for Superior Performance in Machining Nickel-Based Alloys. Eng. Proc. 2025, 105, 8. https://doi.org/10.3390/engproc2025105008

Sonowal K, Borthakur PP. Recent Advances in Tool Coatings and Materials for Superior Performance in Machining Nickel-Based Alloys. Engineering Proceedings. 2025; 105(1):8. https://doi.org/10.3390/engproc2025105008

Chicago/Turabian StyleSonowal, Kerolina, and Partha Protim Borthakur. 2025. "Recent Advances in Tool Coatings and Materials for Superior Performance in Machining Nickel-Based Alloys" Engineering Proceedings 105, no. 1: 8. https://doi.org/10.3390/engproc2025105008

APA StyleSonowal, K., & Borthakur, P. P. (2025). Recent Advances in Tool Coatings and Materials for Superior Performance in Machining Nickel-Based Alloys. Engineering Proceedings, 105(1), 8. https://doi.org/10.3390/engproc2025105008