Modeling and Control of Permanent Magnet Generators with Fractional-Slot Concentrated Windings Working with Active Converters for Wind Power †

Abstract

1. Introduction

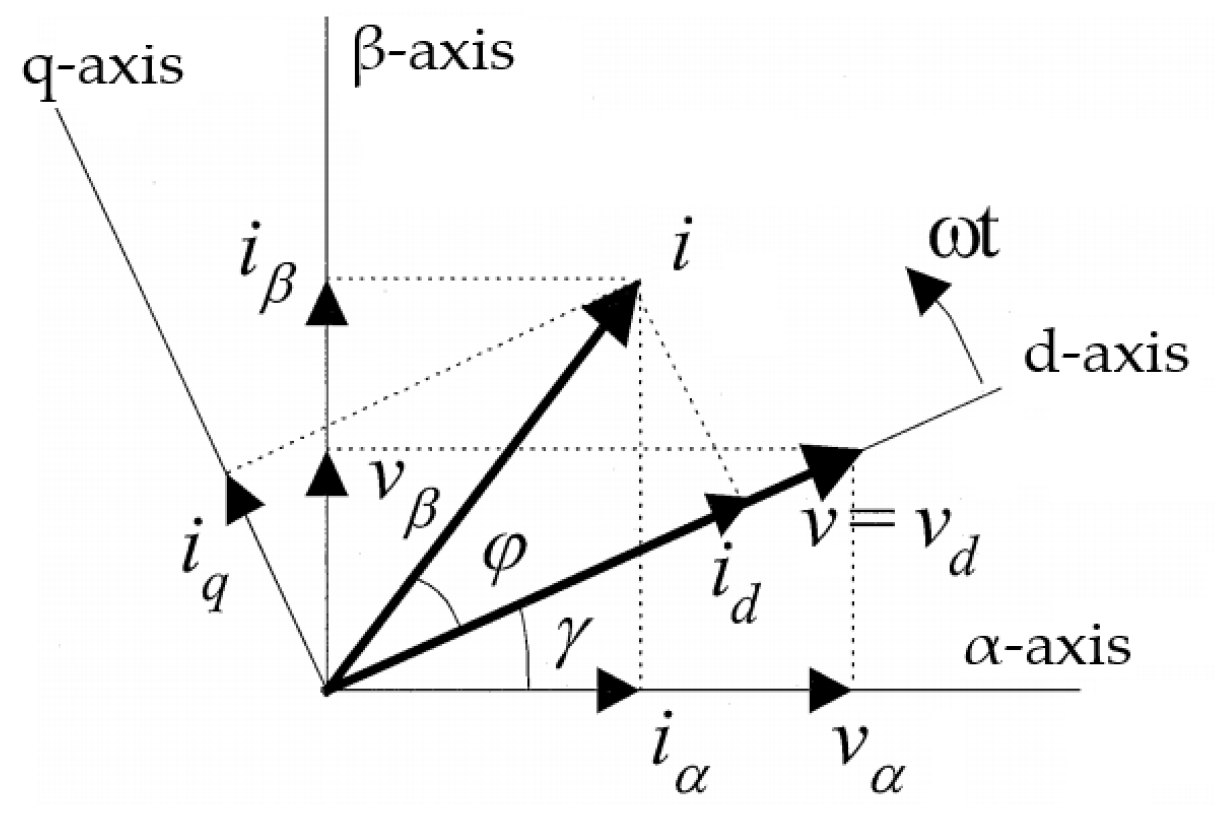

2. The d-q Model of the PM Machine

2.1. The d-q Model

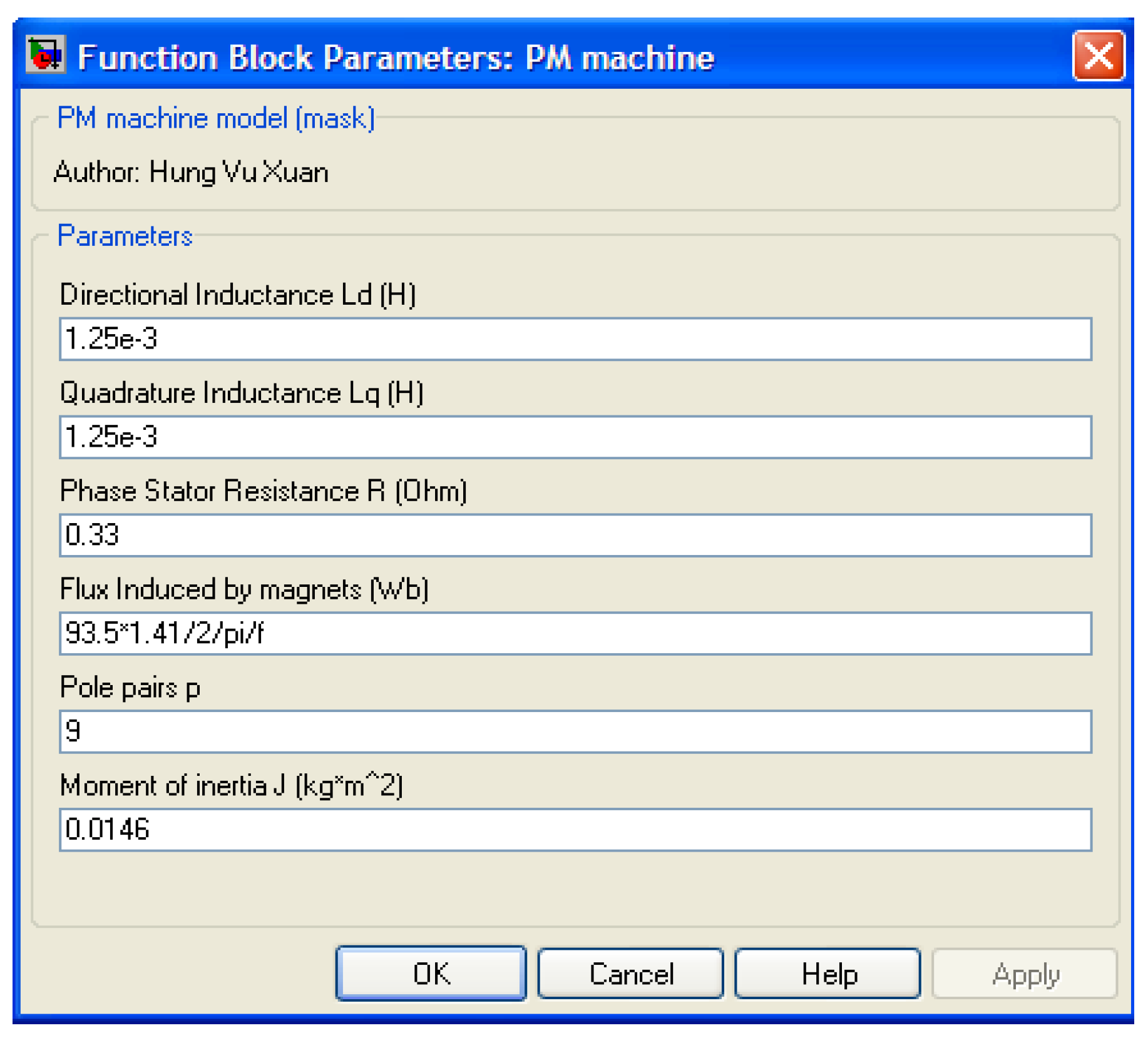

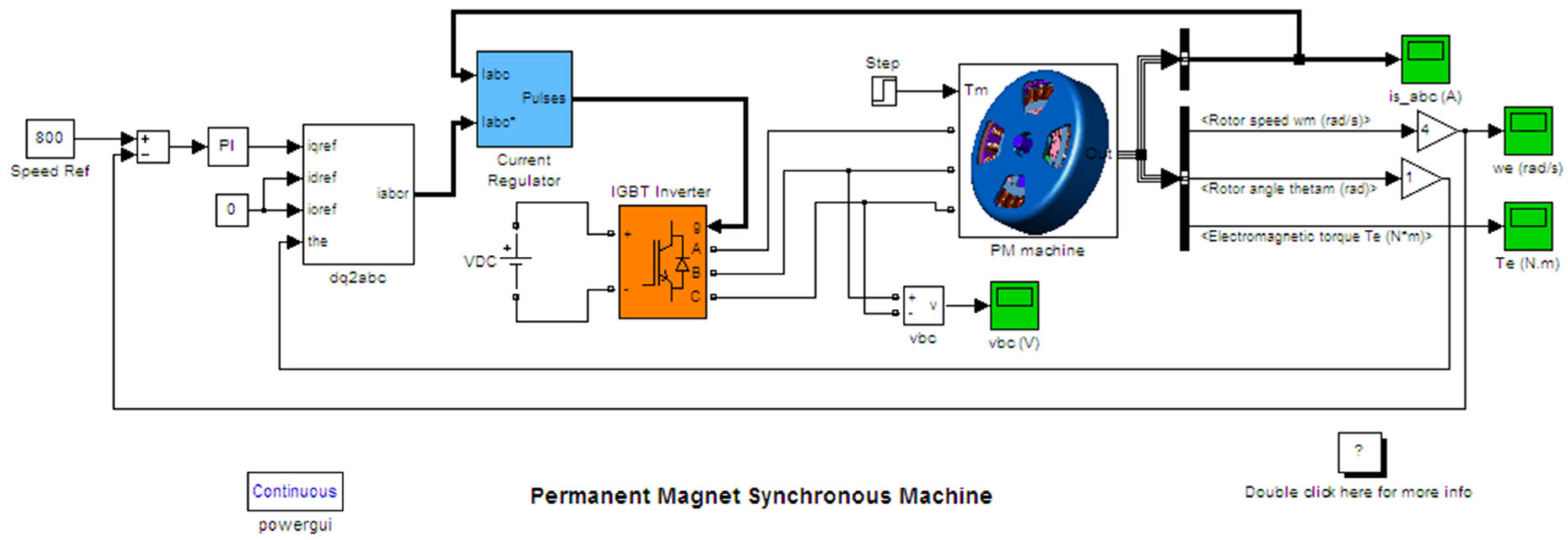

2.2. Simulation Model in Matlab/Simulink®

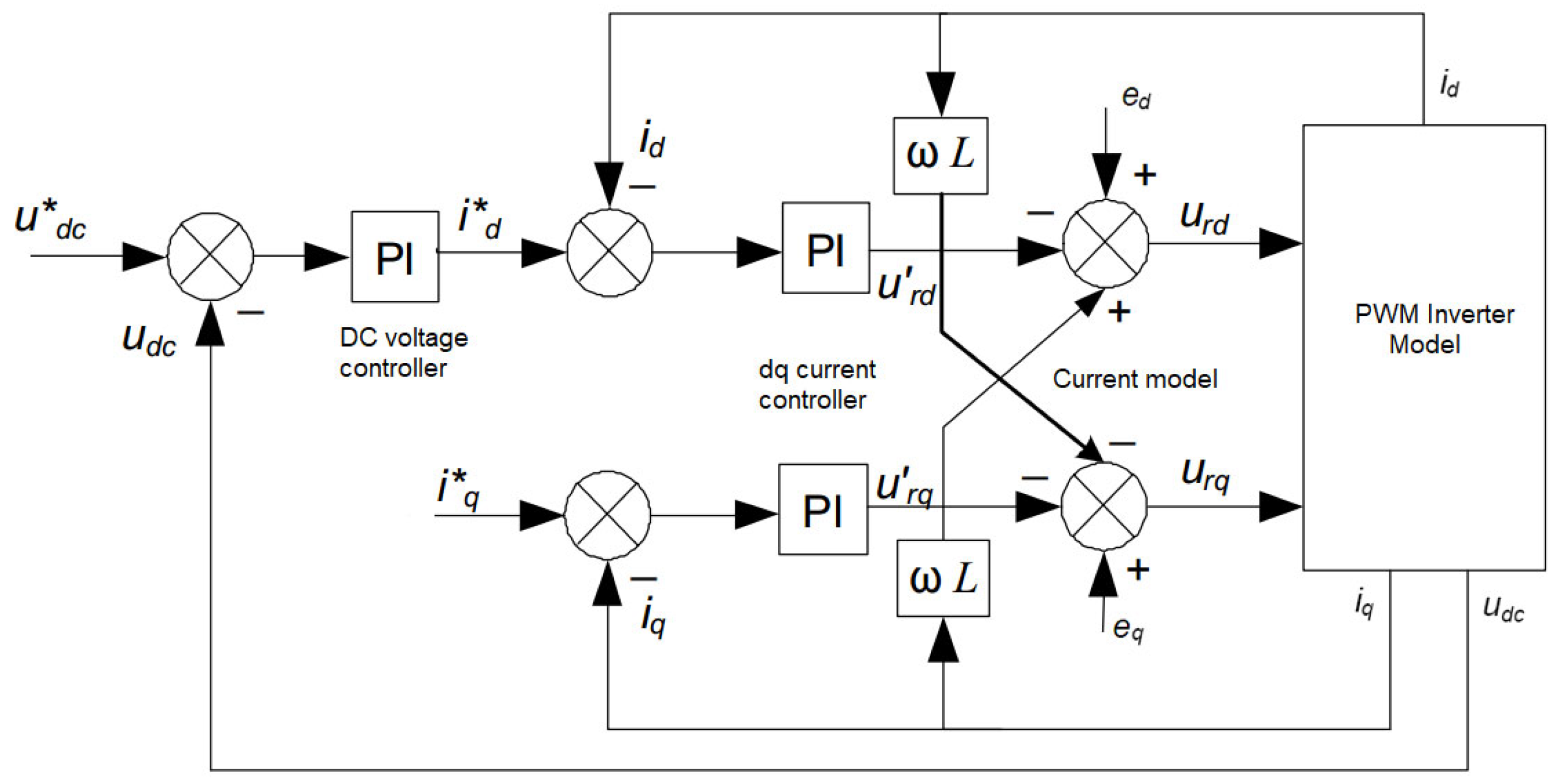

3. PM Generator Working with PWM Rectifier with Power Factor Controller

3.1. Mathematical Model for the PWM Rectifier in the (a, b, c) Frame Reference

3.2. The Mathematic Model for the PWM Rectifier in the (d-q) Coordinator

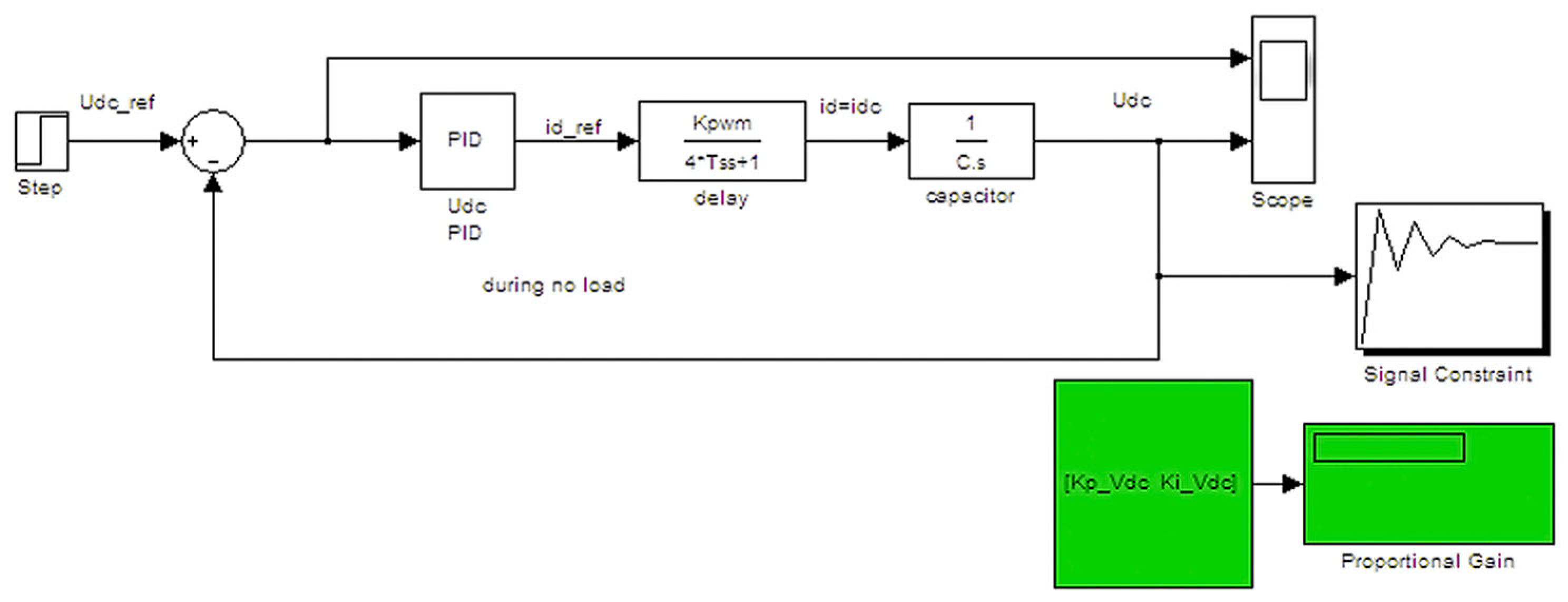

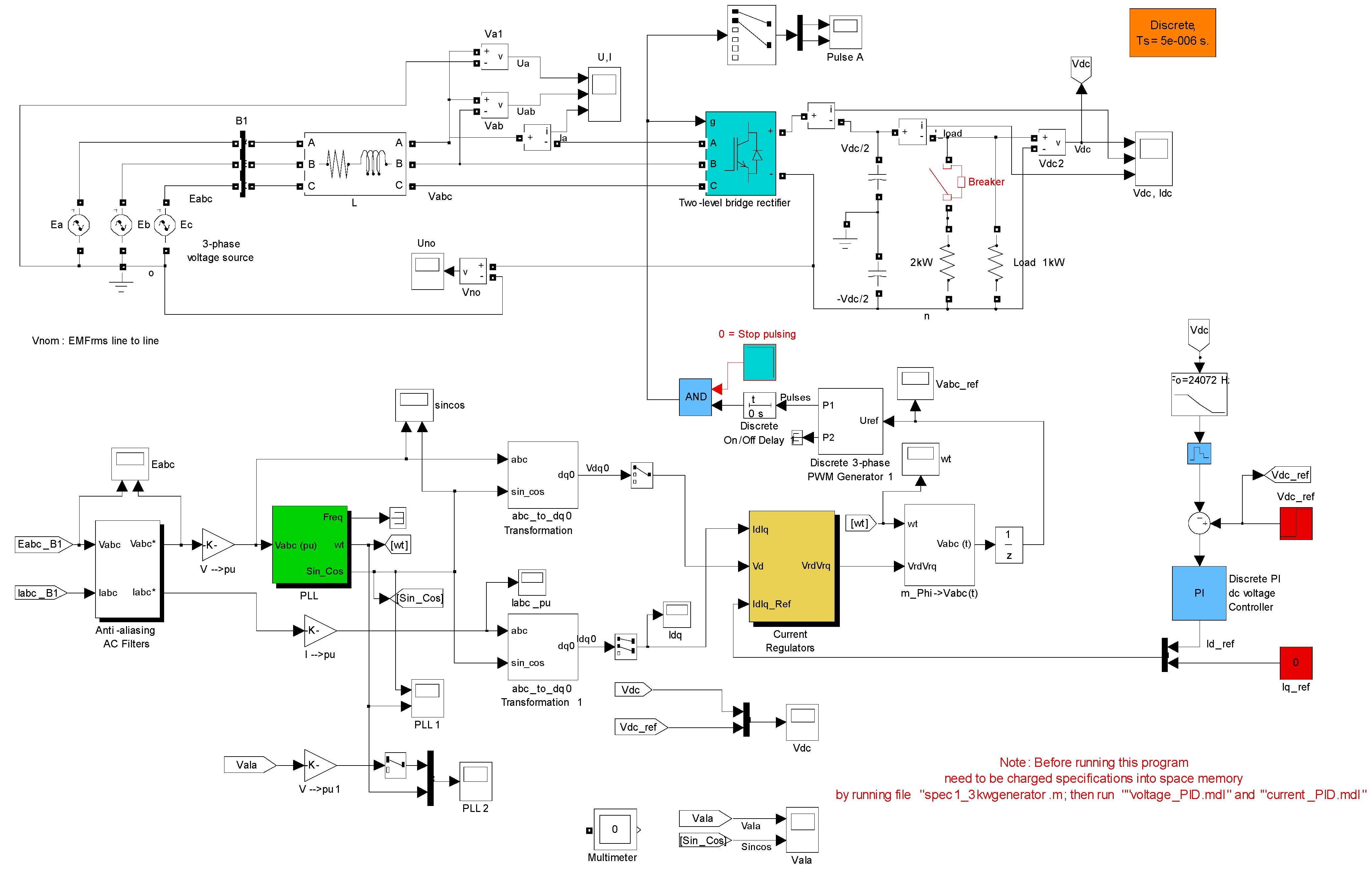

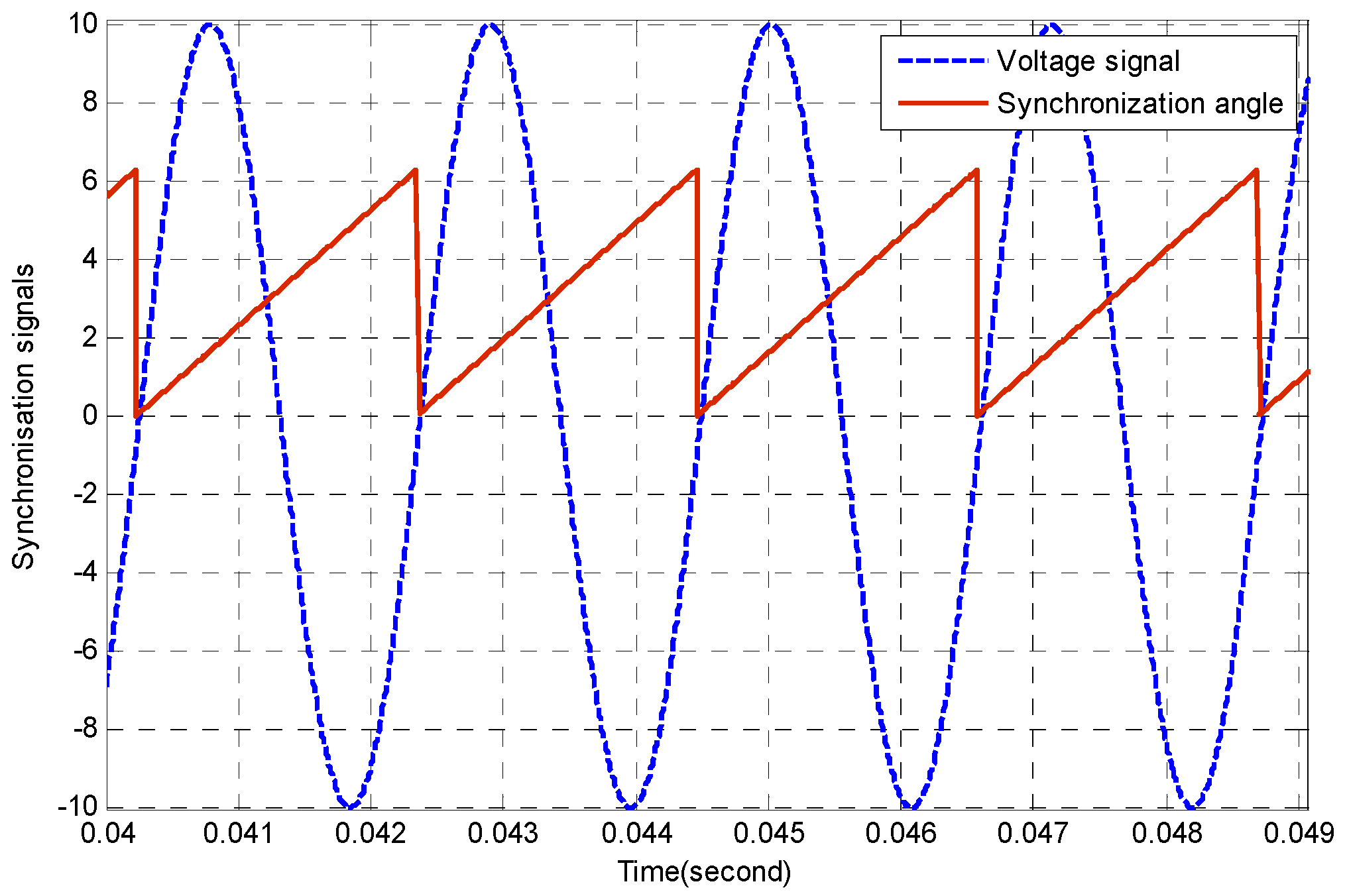

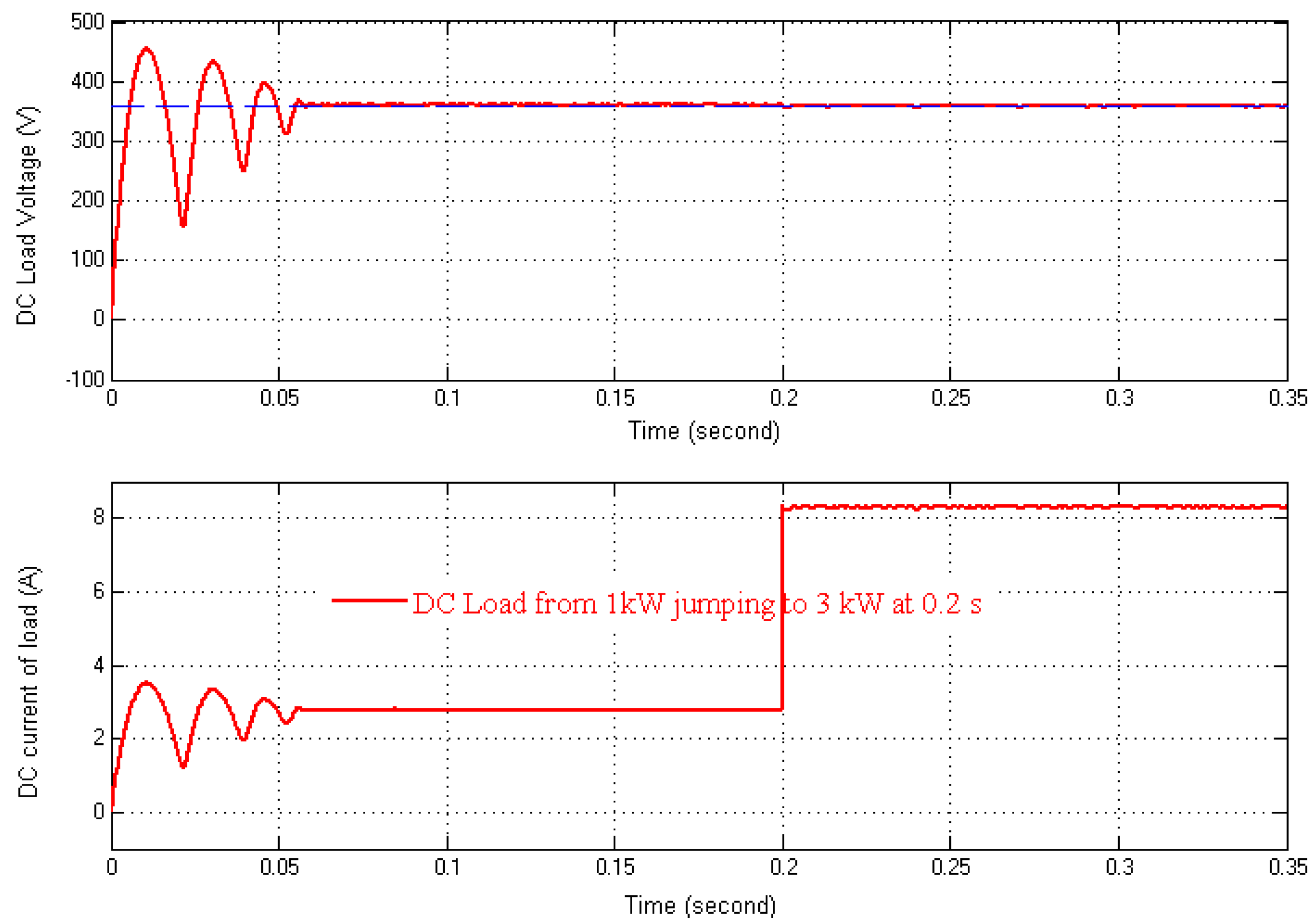

3.3. Simulation PWM Rectifier

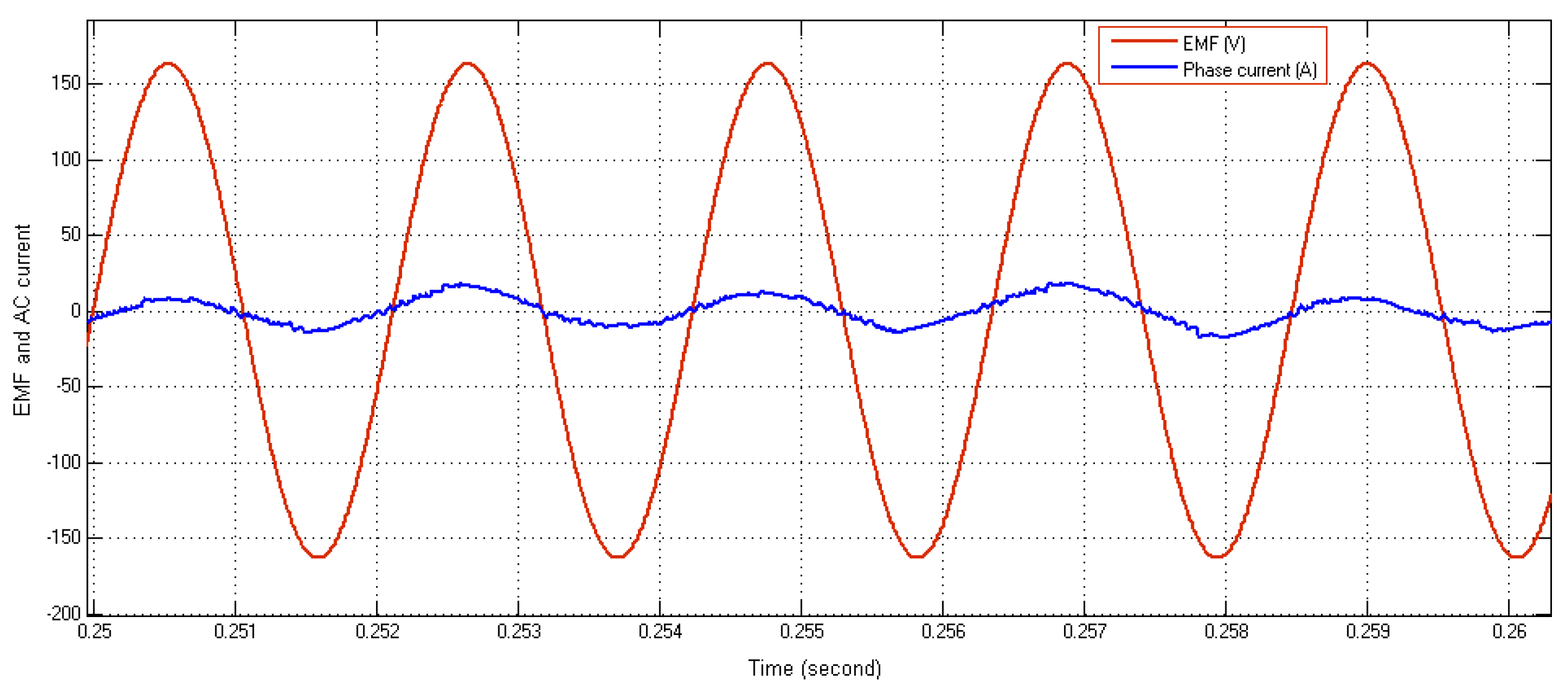

- Capacitor: C = 1.8 mF;

- Phase inductance of PM machine: L = 1.25 mH;

- Phase resistance of PM machine: R = 0.33 Ω;

- Line–line electromotive force of PM machine at 3000 rpm: EMF = 162 V;

- Carrier frequency or switching frequency: fc = 51 * f = 51 * 472 = 24,072 Hz;

- Sampling time and sampling frequency: Ts = 5 μs, fs =1/Ts = 200 kHz.

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CVT | Converter |

| PMG | Permanent Magnet Generator |

| PMM | Permanent Magnet Machine |

| PWM | Pulse Width Modulation |

| PLL | Phase-Locked Loop |

| VOC | Voltage-Oriented Control |

| FOC | Field-Oriented Control |

| RFC | Rotor Field Coordinator |

References

- Kang, S.-P.; Kim, D.-Y.; Kim, J.-M. Enhanced Voltage Sensorless Control for a PWM Converter with DSOGI-FLL Under Grid Disturbances. Energies 2025, 18, 2199. [Google Scholar] [CrossRef]

- Malinowski, M.; Kazmierkowski, M.P.; Hansen, S.; Blaabjerg, F.; Marques, G.D. Virtual-Flux-Based Direct Power Control of Three-Phase PWM Rectifiers. IEEE Trans. Ind. Appl. 2001, 37, 1019–1027. [Google Scholar] [CrossRef]

- Noguchi, T.; Tomiki, H.; Kondo, S.; Takahashi, I. Direct Power Control of PWM Converter without Power-Source Voltage Sensors. IEEE Trans. Ind. Appl. 1998, 34, 473–479. [Google Scholar] [CrossRef]

- Malinowski, M.; Kazmierkowski, M.P.; Trzynadlowski, A.M. A Comparative Study of Control Techniques for PWM Rectifiers in AC Adjustable Speed Drives. IEEE Trans. Power Electron. 2003, 18, 1390–1396. [Google Scholar] [CrossRef]

- Alonso-Martínez, J.; Carrasco, J.E.-G.; Arnaltes, S. Table-Based Direct Power Control: A Critical Review for Microgrid Applications. IEEE Trans. Power Electron. 2010, 25, 2949–2961. [Google Scholar] [CrossRef]

- Sato, A.; Noguchi, T. Voltage-Source PWM Rectifier–Inverter Based on Direct Power Control and Its Operation Characteristics. IEEE Trans. Power Electron. 2011, 26, 1559–1567. [Google Scholar] [CrossRef]

- Singh, B.; Singh, B.N.; Chandra, A.; Al-Haddad, K.; Pandey, A.; Kothari, D.P. A Review of Single-Phase Improved Power Quality AC-DC Converters. IEEE Trans. Ind. Electron. 2003, 50, 962–981. [Google Scholar] [CrossRef]

- Singh, B.; Singh, B.N.; Chandra, A.; Al-Haddad, K.; Pandey, A.; Kothari, D.P. A Review of Three-Phase Improved Power Quality AC-DC Converters. IEEE Trans. Ind. Electron. 2004, 51, 641–660. [Google Scholar] [CrossRef]

- Rajendran, S.; Diaz, M.; Cárdenas, R.; Espina, E.; Contreras, E.; Rodriguez, J. A Review of Generators and Power Converters for Multi-MW Wind Energy Conversion Systems. Processes 2022, 10, 2302. [Google Scholar] [CrossRef]

- Chimurkar, P.; Kothavade, P. A Review of Different Power Converter Topologies for PMSGs Wind Turbine. In Proceedings of the 2016 International Conference on Communication and Electronics Systems (ICCES), Coimbatore, India, 21–22 October 2016; pp. 1–6. [Google Scholar]

- Hannan, M.A.; Al-Shetwi, A.Q.; Mollik, M.S.; Ker, P.J.; Mannan, M.; Mansor, M.; Al-Masri, H.M.K.; Mahlia, T.M.I. Wind Energy Conversions, Controls, and Applications: A Review for Sustainable Technologies and Directions. Sustainability 2023, 15, 3986. [Google Scholar] [CrossRef]

- Baroudi, J.A.; Dinavahi, V.; Knight, A.M. A Review of Power Converter Topologies for Wind Generators. In Proceedings of the IEEE International Conference on Electric Machines and Drives, San Antonio, TX, USA, 15 May 2005; pp. 458–465. [Google Scholar]

- Vu Xuan, H.; Ani, S.O.; Lahaye, D.; Polinder, H.; Ferreira, J.A. Validation of Non-Linear Dynamic FEM Model for Design of PM Machines with Concentrated Windings in Ship Application. In Proceedings of the 2011 14th European Conference on Power Electronics and Applications, Birmingham, UK, 30 August–1 September 2011; Available online: https://ieeexplore.ieee.org/abstract/document/6020450 (accessed on 6 June 2025).

- Vu Xuan, H. Modeling of Exterior Rotor Permanent Magnet Machines with Concentrated Windings. Dissertation (TU Delft). Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, September 2012. [Google Scholar]

- Vu Xuan, H.; Lahaye, D.; Polinder, H.; Ferreira, J.A. Influence of Stator Slotting on the Performance of Permanent-Magnet Machines With Concentrated Windings. IEEE Trans. Magn. 2013, 49, 929–938. [Google Scholar] [CrossRef]

- Shivarudraswamy, R.; Tangi, S.; Kaup, A. Advancements in PMSM-Based Commercial Fan Control: Hardware, FOC Implementation, and Performance Evaluation. Eng. Proc. 2024, 70, 49. [Google Scholar] [CrossRef]

- Ahmad, M.S.; Ishak, D.; Leong, T.T.; Mohamed, M.R. Analytical Subdomain Model for Double-Stator Permanent Magnet Synchronous Machine with Surface-Mounted Radial Magnetization. Eng. Proc. 2021, 12, 37. [Google Scholar] [CrossRef]

- Debdouche, N.; Benbouhenni, H.; Deffaf, B.; Anwar, G.; Zarour, L. Predictive Direct Power Control with Phase-Locked Loop Technique of Three-Level Neutral Point Clamped Inverter Based Shunt Active Power Filter for Power Quality Improvement. Int. J. Circuit Theory Appl. 2024, 52, 3306–3340. [Google Scholar] [CrossRef]

- He, Z.; Shinshi, T. Torque Regulation Theory and Sensorless Control Technology for Unipolar Salient Synchronous Permanent Magnet Motor Based on Unified Models. IEEE Trans. Power Electron. 2025, 40, 5672–5684. [Google Scholar] [CrossRef]

- Peng, L.; Fu, Z.; Xiao, T.; Qian, Y.; Zhao, W.; Zhang, C. An Improved Dual Second-Order Generalized Integrator Phased-Locked Loop Strategy for an Inverter of Flexible High-Voltage Direct Current Transmission Systems under Nonideal Grid Conditions. Processes 2023, 11, 2634. [Google Scholar] [CrossRef]

- Xuan, H.V.; Duc, H.V. Design and Comparison of Control Methods for Grid-Connected Solar Converters. In Proceedings of the 2024 5th International Conference on Communications, Information, Electronic and Energy Systems (CIEES), Veliko Tarnovo, Bulgaria, 20–22 November 2024; pp. 1–10. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xuan, H.V. Modeling and Control of Permanent Magnet Generators with Fractional-Slot Concentrated Windings Working with Active Converters for Wind Power. Eng. Proc. 2025, 104, 26. https://doi.org/10.3390/engproc2025104026

Xuan HV. Modeling and Control of Permanent Magnet Generators with Fractional-Slot Concentrated Windings Working with Active Converters for Wind Power. Engineering Proceedings. 2025; 104(1):26. https://doi.org/10.3390/engproc2025104026

Chicago/Turabian StyleXuan, Hung Vu. 2025. "Modeling and Control of Permanent Magnet Generators with Fractional-Slot Concentrated Windings Working with Active Converters for Wind Power" Engineering Proceedings 104, no. 1: 26. https://doi.org/10.3390/engproc2025104026

APA StyleXuan, H. V. (2025). Modeling and Control of Permanent Magnet Generators with Fractional-Slot Concentrated Windings Working with Active Converters for Wind Power. Engineering Proceedings, 104(1), 26. https://doi.org/10.3390/engproc2025104026