Abstract

This study explores the application of 3D printing as a strategic tool in engineering education and robotics development. An embedded control system for a 3D-printed MK2 manipulator is implemented, including an Arduino microcontroller, servo motors, an analog joystick interface, and an LCD, with software developed in Arduino IDE. The design uses PLA material and a modular architecture for flexibility and extensibility. The platform is applied in laboratory training to develop algorithmic thinking and engineering creativity, demonstrating the potential of 3D printing as an integrated educational and engineering tool.

1. Introduction

Robots are increasingly entering industry, changing the paradigm in automation and intelligent systems. Although public perception often associates robotics with humanoid forms, real-world applications are mainly realized through specialized mechanisms tailored for specific tasks. Industrial robots and manipulators have been used in manufacturing for decades, but modern demands for personalization, rapid prototyping, and adaptability require new technological solutions.

This highlights the role of three-dimensional (3D) printing as a transformative technology in robotics development and training. The synergy between additive manufacturing and robotic systems allows for the rapid and inexpensive fabrication of customized components and the design of soft or rigid structures with high functionality [1,2]. In an educational context, 3D printing supports interdisciplinary learning, connecting theoretical knowledge with practical applications and developing key engineering and cognitive skills [3,4].

Numerous studies demonstrate the application of 3D printing in combination with environments such as MATLAB, LabVIEW, and Arduino for control, simulation, and visualization of robotic systems [5,6,7]. Projects using open hardware, such as the MK2 robotic arm, allow the construction of functional manipulators with low cost, making them accessible for educational, laboratory, and production purposes [8]. In this context, training experiments are also conducted with platforms such as the iArm [9], which integrates visual recognition, user interfaces, and PID control with improved responsiveness [10]. Similar approaches for the integration of 3D-printed robotic systems in industrial applications are also demonstrated in a study [11], which presents a robotic arm with precise kinematics for automating food packaging processes.

There are also several initiatives aimed at developing psychomotor and cognitive skills through educational robotics [12], including the use of augmented reality and individualized tasks, such as handwriting reproduction using industrial robots [13]. The design of robotic arms with four and six degrees of freedom using SolidWorks, CAM, and MATLAB Robotics Toolbox, demonstrates capabilities for testing, optimization, and simulation of kinematic parameters in a realistic environment [14,15].

Of particular interest is the application of mobile robots with parallel kinematics and analysis of platform stability depending on geometric and mass characteristics [16,17]. Combining all this, a new paradigm is emerging in the development of adaptive, economic, and educational robotic systems based on open technologies and 3D printing.

The present work focuses on the design, fabrication, and laboratory application of a 3D-printed robotic arm-type manipulator (MK2) to integrate hardware and software components in an educational environment. This approach combines technical innovation with pedagogical value and responds to the growing need for flexible and accessible tools for robotics education.

Based on the design limitations of MK2 and the actuators used, the hypothesis of the present study is that the manipulator will demonstrate stable operation at loads up to 200 g and will maintain functionality within the dynamic range of the system without feedback.

2. Materials and Methods

Training people to work with manipulators should begin with clarifying the basic principles that underlie the robot. A person without knowledge in the field cannot proceed to control any robot. The concept of training with robots can be divided into three main stages:

- Introduction to robotics: This stage examines the basic principles of robot control, kinematics, and the drive of individual axes. Without this level, training in the second and third stages is meaningless. There is no age limit for starting this stage. It can start from a very young age, taking into account the specifics of the age group, or include people who, at a certain point in their lives, encounter manipulators. The stage can be completed at different times. There is access to the manipulator at any time, and the main idea here is for a person to have one in laboratory conditions. At any time, he will be able to program it without fear of breaking a part, which he will reproduce using 3D technology. The student must become familiar with the basics of electronics, electrical engineering, programming, CAD design, and simulating models at a basic level.

- The second stage involves programming training robots that are identical to industrial robots. Here, programming can be performed in the specific language of the industrial robot. The price of this type of robot ranges from EUR 1000 to 5000, as there are also those produced using 3D technology on the market. This is a good option because if a part of the robot breaks, it can be easily restored. Here, experience will be gained in working with the specific robot, but at the same time, access to it will be limited. This type of manipulator can also be used in laboratory conditions, but the investment is high.

- The third stage is training to work with a specific industrial robot and the specific activities that it will perform. There is no room for error here; when designing the basic movements, working with simulation software, which is commercial, is of great importance. For each operation, the robot’s reaction can be simulated and predicted. This stage is within the capabilities of only companies using industrial robots. The exceptional importance of simulation environments and control algorithms in predicting the behavior of the robotic manipulator under real production conditions, including in 3D-printing systems with industrial materials, has been demonstrated in [18].

This publication is aimed at the first stage and includes the development and testing of an embedded control system for the MK2 manipulator.

3. Hardware Control Part

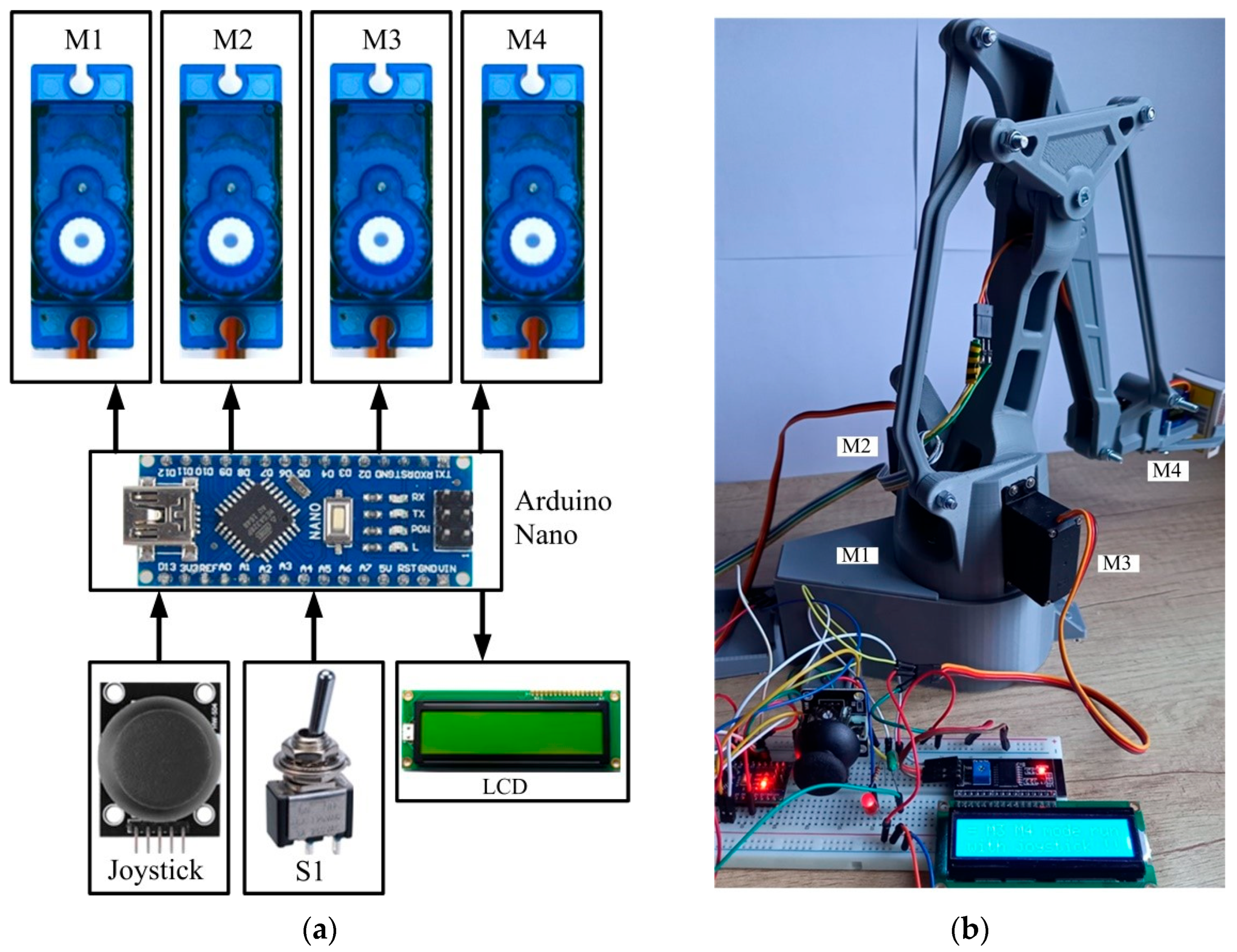

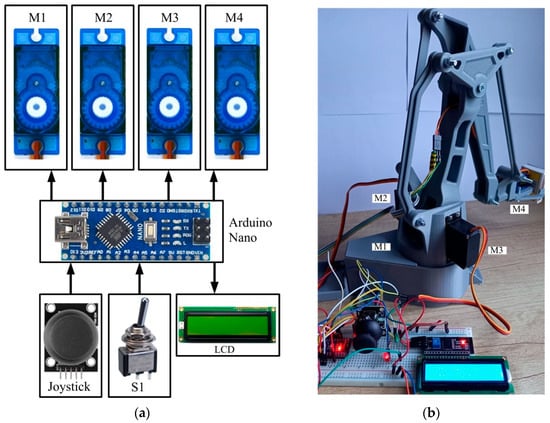

The hardware part for control includes an embedded system: a control unit and actuators. The embedded system consists of a microcontroller, four servo motors, a joystick, a switch, and an LCD. Figure 1a shows a block diagram of the hardware control part.

Figure 1.

A block diagram of the hardware control part and real staging of the manipulator: (a) a block diagram of the control hardware; (b) a picture of the manipulator.

At the heart of every embedded system is the microcontroller. There is a huge range of controllers from different manufacturers, but in this case, a cheap, familiar, and reliable solution is sought. For this particular report, the control is with an Arduino Nano development board at a price of about USD 4.

The manipulator is controlled with a joystick until a certain target is captured and moved. The joystick outputs two analog signals, indicating the presence of movement along the x- and y-axes. The analog signals from it are converted by the controller’s ADC, after which it produces a control signal to the motors in two operating modes: the first controlling motors M1 and M2 and the second for driving M3 and M4. An LED visualizes the choice of operating mode. The operating mode is selected with the S1 key, which is displayed on the LCD. At a later stage, parameters will be entered into the control using buttons. For the moment, the system is open, i.e., there is no feedback, and certain steps are followed until the final goal is achieved.

The microcontroller outputs a control PWM signal to each servo motor and controls the LCD with a driver board via the I2C interface.

The MK2 manipulator is manufactured using 3D-printing technology and PLA material with 15% fill. A picture of the robot can be seen in Figure 1b. The servo motors M1, M2, and M3 are from type MG996R (Microelectronics Technology Co., Ltd., Shenzhen, China) with metal gears and higher torque, and M4 is from the type SG90 to lighten the gripper. So, as consumption on the engine is high, they are powered by a separate source of tension, while the ruling module and joysticks are powered from the computer. All engines move in the range from 0 to 180 degrees, as M1 is for base movement, M2 is for up movement, M3 is for forward movement, and M4 is the gripper, as shown in the picture. The control part is on a breadboard, and the target is a matchbox.

Currently, there is no protection for the motors in case of improper operation or overload until the end position of the manipulator movement is reached.

4. Software Part

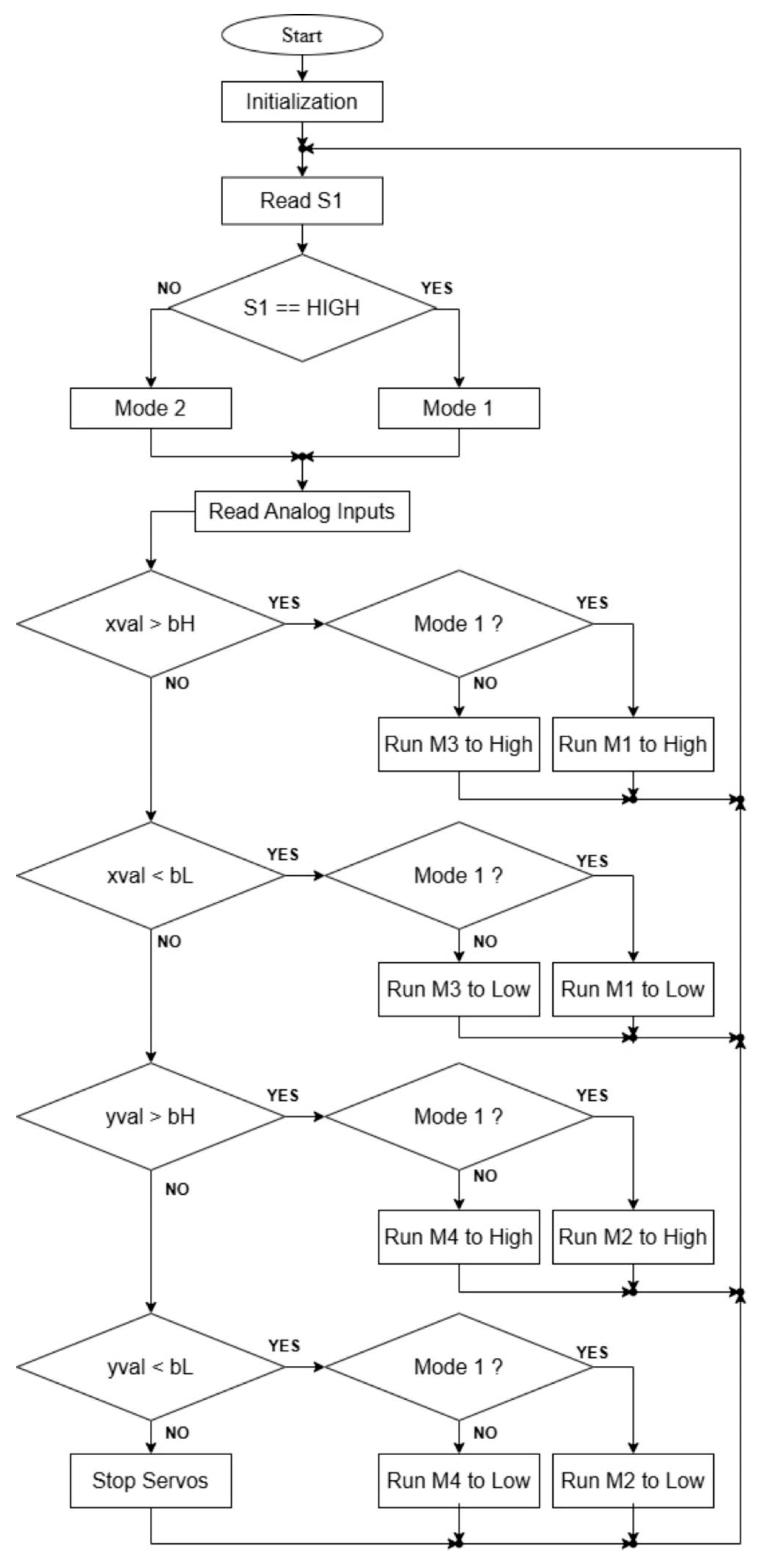

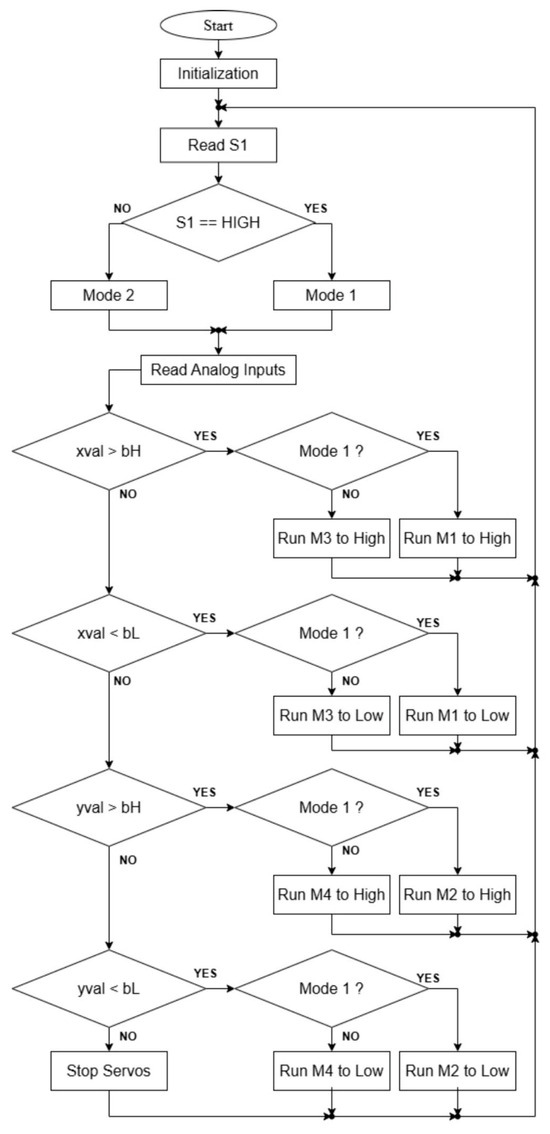

The open-source development platform Arduino IDE was chosen for the specific implementation. Initially, the variables were introduced and initialized. The switch (S1) was read, and the corresponding operating mode was set.

In the neutral position, the joystick outputs an analog signal along the x- and y-axes, with a value corresponding to half of the interval. The digital value after ADC conversion should be 512. Due to the sensitivity of the joystick and with imperceptible movements of the operator’s hand, this value fluctuates from 450 to 550. For this reason, a hysteresis zone was introduced around the neutral position and was assumed to be in the range from 400 to 600. In the block diagram in Figure 2, the lower (bL) and the upper (bH) limit of this zone are shown. The analog signals are read by the controller, and a check is made for their value (xval and yval) to establish whether it is outside the hysteresis. If this condition is true, a check is performed for xval and yval, from which movement to a position with a higher or lower value of motors M1 or M3 on the x-axis, respectively, or M2 or M4 on the y-axis, is selected, to move the manipulator arm in the desired direction. When the target position is reached, it is gripped and moved to the set position.

Figure 2.

A flowchart of the control program.

5. Results and Discussion

Several experiments were carried out within the framework of this study. The first investigated the load capacity of the developed MK2 manipulator to determine the maximum mass of the object that can be lifted and stably carried. The results (Table 1) show that the manipulator provides reliable gripping and moving of objects weighing up to 200 g, with a slight increase in vibrations observed at this load, but without loss of functionality. In experiments with higher masses, partial release of the object was observed at 250 g and a final inability to hold at 300 g, accompanied by a slight tilt towards the load.

Table 1.

An evaluation of the behavior of the MK2 manipulator under varying loads.

A comparison with other scientific studies in the field confirms the validity of the obtained results. The development of Reachy, which is a 3D-printed robotic manipulator with an anthropomorphic design, reported a maximum payload of 300 g, which is close to the values observed in the present study [19]. Additionally, another study of a high-reach open robotic arm reported a payload of up to 2 kg but with a significantly more massive structure and industrial components, which places it outside the applicable context of the present study for educational and laboratory environments [20]. Therefore, the achieved experimental results are in line with expectations for a manipulator built from PLA with 15% infill and using MG996R servo motors.

When analyzing the dynamic characteristics of the MK2 manipulator, the time for executing a predefined standard trajectory was measured, including gripping, moving the object to the maximum distance, and releasing it in the target position. The measured values ranged from 3.4 s at idle to 5.8 s at a maximum load of 200 g. The observed increase in time (Table 2) for execution with increasing load is fully consistent with the expected dynamics when working with servomotors of the MG996R class, especially in systems without a closed control loop. A similar relationship between the mass of the load and the time for executing manipulator operations was reported in a study analyzing the control algorithms of an industrial robot for 3D printing with concrete, where the influence of the load capacity on the dynamics of movement was also emphasized [18]. Although their robotic manipulator was designed for higher loads and with different technological parameters, the trends in the change in execution time with increasing load are confirmed, which validates the results observed in the present study.

Table 2.

Effect of object mass on standard trajectory execution time.

Tests were also performed for the determination of the maximum height of grip on the MK2 manipulator. They show that the system is in a state that operates at a vertical range of approximately 177 mm. This corresponds to constructive design on MK2 with arms at lengths of about 120 mm and 100 mm, as reported in the restriction on angular range in the used servomotors and the geometric restrictions imposed by the configuration on the manipulator.

Similar constructive parameters and working ranges are observed in the study HydraX, where a six-axis 3D-printed robotic arm was analyzed and adapted for hybrid production [21]. In the research, the specific height of grip is not explicitly indicated; however, by the presented kinematic schemes and configurations on the manipulator, it can be concluded that the worker’s range is comparable to our experimental results, which confirms the adequacy of the chosen constructive solutions.

Table 3 presents a comparative analysis of the MK2 manipulator compared to other 3D-printed solutions. It confirms that the developed platform successfully positions itself in the segment of educational and laboratory manipulators with a base load of up to 200 g. Compared to Reachy [19], MK2 demonstrates similar motion dynamics but with a simpler mechanical configuration and lower cost. The iArm platform [9] shows slightly better times for executing a standard trajectory but with a compromise in terms of payload and working range.

Table 3.

Comparative analysis of the parameters of MK2 and other 3D-printed manipulators.

Industrial-oriented solutions, such as PARA [20], significantly exceed the capabilities of MK2 in terms of payload and range, but they fall into a completely different price and application class. HydraX [21], a hybrid manufacturing manipulator, demonstrates similar design parameters but does not provide data on dynamic characteristics. This context places MK2 as a balanced training solution, where the combination of affordability, performance, and modular upgradeability meets the main criteria for a training platform.

Despite the demonstrated stability of the system within the experimental tests, some limitations and potential risks should be noted when working with the MK2 manipulator. The system operates without a closed control loop and does not have overload protection for the servo motors. This creates the possibility of mechanical damage or thermal stress on the drive elements, especially during prolonged operation with high loads or when the mechanism is blocked in the end position. These factors limit the operational life of the system and emphasize the need to integrate additional protective mechanisms in future developments. Also, the identified risks provide an additional basis for developing a simulation model that would allow virtual testing of the system’s behavior in critical operating modes.

In addition, the results of the MK2 timing analysis demonstrate a linear increase in execution time with increasing load, similar to the trends observed with Reachy and other studied systems. This confirms the reliability of the measurements made and validates the applicability of the developed system in the context of engineering education and testing of basic concepts in robotics.

In addition to its technical validity, the developed MK2 manipulator holds significant educational value. Designed as a modular, accessible, and low-cost solution, it is actively integrated into laboratory-based instruction within engineering disciplines. The platform supports the achievement of key learning objectives in the fields of mechatronics, embedded systems, and control systems.

During laboratory sessions, students engage in structured tasks involving the assembly of 3D-printed components, integration of the control system, and programming of the servo-driven manipulator using the Arduino IDE environment. These hands-on exercises foster not only technical skills but also interdisciplinary competencies. In particular, learners apply theoretical knowledge to real-world scenarios, solving authentic engineering problems.

To ensure targeted instruction, a set of specific learning tasks has been developed and is presented in Table 4. These tasks illustrate how the MK2 platform facilitates the development of practical skills through the integration of hardware and software components, as well as through the combination of hardware programming, mechanical assembly, and experimental analysis within the context of engineering education.

Table 4.

Examples of tasks performed by students using the MK2 platform and their corresponding learning outcomes.

As illustrated in Table 4, the MK2 platform enables the development of a wide range of educational tasks that bridge theory and practice. It fosters an iterative learning process in which students can test and refine their projects in a low-risk environment. The ability to reprint and replace components reinforces the principles of rapid prototyping, while the modular architecture encourages experimentation with alternative control strategies and actuator configurations. Taken together, these characteristics make the MK2 manipulator a flexible and effective tool for contemporary engineering education.

6. Conclusions

With the introduction of embedded systems in robotics, students will become familiar with their application in this specific field. On the other hand, it includes a wide range of knowledge and skills, without which a working mechanism cannot be created. For this reason, students must have basic concepts in mechatronics and the ability to apply specific solutions in practice. The proposed concept of staged training reveals the complexity of creating and controlling the robot. The first stage is mandatory, and the chosen solution is in line with the idea of accessibility. In subsequent developments, the complexity of working with the manipulator will increase to the point where it can be freely handled without fear of failure. The second and third stages of training with industrial robots may never be completed, but the skills acquired during the first stage will increase the students’ knowledge and skills for working in industrial conditions.

The experiments conducted show that the developed 3D-printed manipulator MK2, in combination with the built-in control system, successfully performs the tasks set in a learning environment at loads up to 200 g. The time for executing a standard trajectory varies from 3.4 to 5.8 s depending on the mass of the object. The results validate the applicability of the system for engineering education purposes and create a basis for future improvements.

As a natural continuation of this research, we plan to develop a digital simulation model of the MK2 manipulator using free and open-source software, such as FreeCAD, CoppeliaSim Edu, or other suitable platforms for three-dimensional modeling and simulation. This will allow for virtual testing of the control algorithms and dynamic behavior of the robot in various load and motion scenarios. The creation of a simulation twin will allow for optimization of the design and kinematic parameters, as well as for integrating feedback into the control system, to increase reliability and expand the applicability of the platform in engineering education.

The experimental results obtained confirm the initial hypothesis, demonstrating that the MK2 manipulator functions stably at loads up to 200 g and retains its operational functionality throughout the tested range of motion, despite the lack of a closed-loop control. Future development of a simulation model will allow for extended testing of the hypothesis in the context of higher loads and dynamic operating scenarios beyond the laboratory conditions of the present study.

Author Contributions

Conceptualization, N.K.; methodology, N.K. and Z.T.; software, N.K.; validation, N.K., Z.T. and M.T.; formal analysis, Z.T.; investigation, N.K., Z.T. and M.T.; resources, N.K. and M.T.; data curation, M.T.; writing—original draft preparation, Z.T. and M.T.; writing—review and editing, M.T.; visualization, N.K., Z.T. and M.T.; supervision, N.K., Z.T. and M.T.; project administration, N.K., Z.T. and M.T.; funding acquisition, M.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received internal funding from the University of Food Technologies (Science Fund).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Siemasz, R.; Tomczuk, K.; Malecha, Z. 3D printed robotic arm with elements of artificial intelligence. Procedia Comput. Sci. 2020, 176, 3741–3750. [Google Scholar] [CrossRef]

- Gul, J.Z.; Sajid, M.; Rehman, M.M.; Siddiqui, G.U.; Shah, I.; Kim, K.-H.; Lee, J.-W.; Choi, K.H. 3D printing for soft robotics—A review. Sci. Technol. Adv. Mater. 2018, 19, 243–262. [Google Scholar] [CrossRef] [PubMed]

- Munir, M.T.; Jamwal, P.K.; Li, B.; Carter, S.; Hussain, S. Revolutionising engineering pedagogy: The role of 3D printing in modern engineering education. Innov. Educ. Teach. Int. 2024, 62, 575–593. [Google Scholar] [CrossRef]

- Chong, S.; Pan, G.-T.; Chin, J.; Show, P.L.; Yang, T.C.K.; Huang, C.-M. Integration of 3D printing and Industry 4.0 into engineering teaching. Sustainability 2018, 10, 3960. [Google Scholar] [CrossRef]

- Li, K. A mechanical arm based him/her image recognition and remote control. J. Phys. Conf. Ser. 2023, 2649, 012031. [Google Scholar] [CrossRef]

- Deng, H.; Zhu, L.; Wang, J.; Chen, M.; Wu, H.; He, C. Kinematics modeling and trajectory planning of KUKA manipulator based on MATLAB. J. Phys. Conf. Ser. 2022, 2216, 012056. [Google Scholar] [CrossRef]

- Zamarrón, D.S.; Casas, N.I.A.d.L.; Grajeda, E.G.; Ávila, J.F.A.; Uday, N.A.J. Educational robot arm development. Comput. Y Sist. 2020, 24, 1387–1401. [Google Scholar] [CrossRef]

- Ananias, E.; Gaspar, P.D. A low-cost collaborative robot for science and education purposes to foster the Industry 4.0 implementation. Appl. Syst. Innov. 2022, 5, 72. [Google Scholar] [CrossRef]

- Zeng, C.; Zhou, H.; Ye, W.; Gu, X. iArm: Design an educational robotic arm kit for inspiring students’ computational thinking. Sensors 2022, 22, 2957. [Google Scholar] [CrossRef] [PubMed]

- Lee, H. The study of mechanical arm and intelligent robot. IEEE Access 2020, 8, 119624–119634. [Google Scholar] [CrossRef]

- Andrade, E.; Cerecerez, G.; Garzòn, M.; Quito, A. Design and implementation of a robotic arm prototype for a streamlined small chocolate packaging process. Eng. Proc. 2023, 47, 1. [Google Scholar] [CrossRef]

- Buditjahjanto, I.G.P.A.; Ardi, P.; Munoto, M.; Samani, M. Evaluating and analyzing of robotic arm as learning media based on partial least square method. TEM J. 2020, 9, 672. [Google Scholar] [CrossRef]

- Quintana, J.J.; Diaz, M.; Ferrer, M.A. Stirring Up the Learning to Program Robotic Arms Through the Generation of Student Handwriting. In Proceedings of the 2018 XIII Technologies Applied to Electronics Teaching Conference (TAEE), La Laguna, Spain, 20–22 June 2018; IEEE: New York, NY, USA, 2018; pp. 1–6. [Google Scholar]

- Tung, T.T.; Van Tinh, N.; Thao, D.T.P.; Minh, T.V. Development of a prototype 6 degree of freedom robot arm. Results Eng. 2023, 18, 101049. [Google Scholar] [CrossRef]

- Elfasakhany, A.; Yanez, E.; Baylon, K.; Salgado, R. Design and development of a competitive low-cost robot arm with four degrees of freedom. Mod. Mech. Eng. 2011, 1, 47. [Google Scholar] [CrossRef]

- Tsolov, S.; Dimitrova, R.; Nikolov, S. Problems in Designing Robots with Parallel Kinematics. Eng. Proc. 2024, 70, 5. [Google Scholar] [CrossRef]

- Lilov, S.; Markova, V.; Popov, N.; Shopov, V. Longitudinal Stability of Wheeled Mobile Robots-Permissible Forces and Accelerations. In Proceedings of the International Conference Automatics and Informatics (ICAI), Varna, Bulgaria, 5–7 October 2023; IEEE: New York, NY, USA, 2023; pp. 174–178. [Google Scholar]

- Calderon-Cordova, C.; Sarango, L.; Chamba, D.; Sarango, R.; Castro, R. Performance Analysis of Motion Control Algorithms of an Industrial Robot Arm Applied to 3D Concrete Printing Systems. Eng. Proc. 2023, 47, 9. [Google Scholar] [CrossRef]

- Mick, S.; Lapeyre, M.; Rouanet, P.; Halgand, C.; Benois-Pineau, J.; Paclet, F.; Cattaert, D.; Oudeyer, P.-Y.; de Rugy, A. Reachy, a 3D-printed human-like robotic arm as a testbed for human-robot control strategies. Front. Neurorobotics 2019, 13, 65. [Google Scholar] [CrossRef] [PubMed]

- Tai, A.; Chun, M.; Gan, Y.; Selamet, M.; Lipson, H. PARA: A one-meter reach, two-kg payload, three-DoF open source robotic arm with customizable end effector. HardwareX 2021, 10, e00209. [Google Scholar] [CrossRef] [PubMed]

- Krimpenis, A.A.; Papapaschos, V.; Bontarenko, E. HydraX, a 3D printed robotic arm for hybrid manufacturing. Part I: Custom design, manufacturing and assembly. Procedia Manuf. 2020, 51, 103–108. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).