1. Introduction

Olive oil is a vegetable lipid highly appreciated for its beneficial effects on human health [

1]. Olive oil quality is normally assessed by chemical analysis as well as sensory analysis to detect the presence of organoleptic defects. Two of the most important parameters that define the quality of olive oil are free acidity, defined as the amount of fatty acids no longer linked to their parent triglyceride molecules, which is affected by the quality of the olives used to produce the oil as well as the production process, and the peroxide index, expressed as milliequivalents of active oxigen for a kg of oil, which is an indicator of the oil primary oxidation and is affected by the storage conditions [

2]. The official techniques for measuring these chemical parameters are manual titration procedures that must be carried out in a laboratory by trained personnel [

3].

In the case of small industrial environments, such as olive oil mills and small packaging centers, which cannot afford an internal laboratory for quality analysis, the olive oil samples to be tested must be shipped to an external laboratory, and this results in high costs for the analysis and long response times. Thus, the development of simple and quick techniques for the analysis of quality grade of olive oil is important to allow in situ measurements directly in the industrial environment. A substantial research has been carried out in recent years towards the development of portable and low-cost sensor systems for the quality analysis of food products. Some examples include a portable biosensor system for bacterial concentration detection in raw milk [

4], a system for the detection of chicken meat freshness [

5], a low-cost handheld system for rapid non-destructive testing of fruit firmness [

6], a system for the characterization of ice-cream properties with electrical impedance [

7], a system for the determination of solid fat content in fats and oils [

8] and an optical system for the assessment of lycopene content in tomatoes [

9]. Many portable sensor systems presented in the literature are designed using a microcontroller as the core device of the system as well as commercial electronic chips to realize the analog measurement system and the communication system with an external PC. More recently, substantial research has been carried out for the development of smartphone-based sensor systems, since modern mobile phones integrate powerful processors for data analysis, a rich sensor set (camera, accelerometer, gyroscope, light sensor, etc.) as well as peripherals for wireless and wired communication [

10].

In this paper, a battery-operated portable sensor system for the quality analysis of olive oil is presented. The system working principle is based on the measurement of the electrical characteristics of an emulsion between a hydro-alcoholic solution and the olive oil sample [

11]. Tests on a set of 17 olive oils have shown how the system can discriminate between extra virgin olive oils (EVOOs) lower-quality grade olive oils and thus represents a low-cost and accurate alternative to standard laboratory analysis for in situ olive oil quality assessment in a real production environment.

2. Materials and Methods

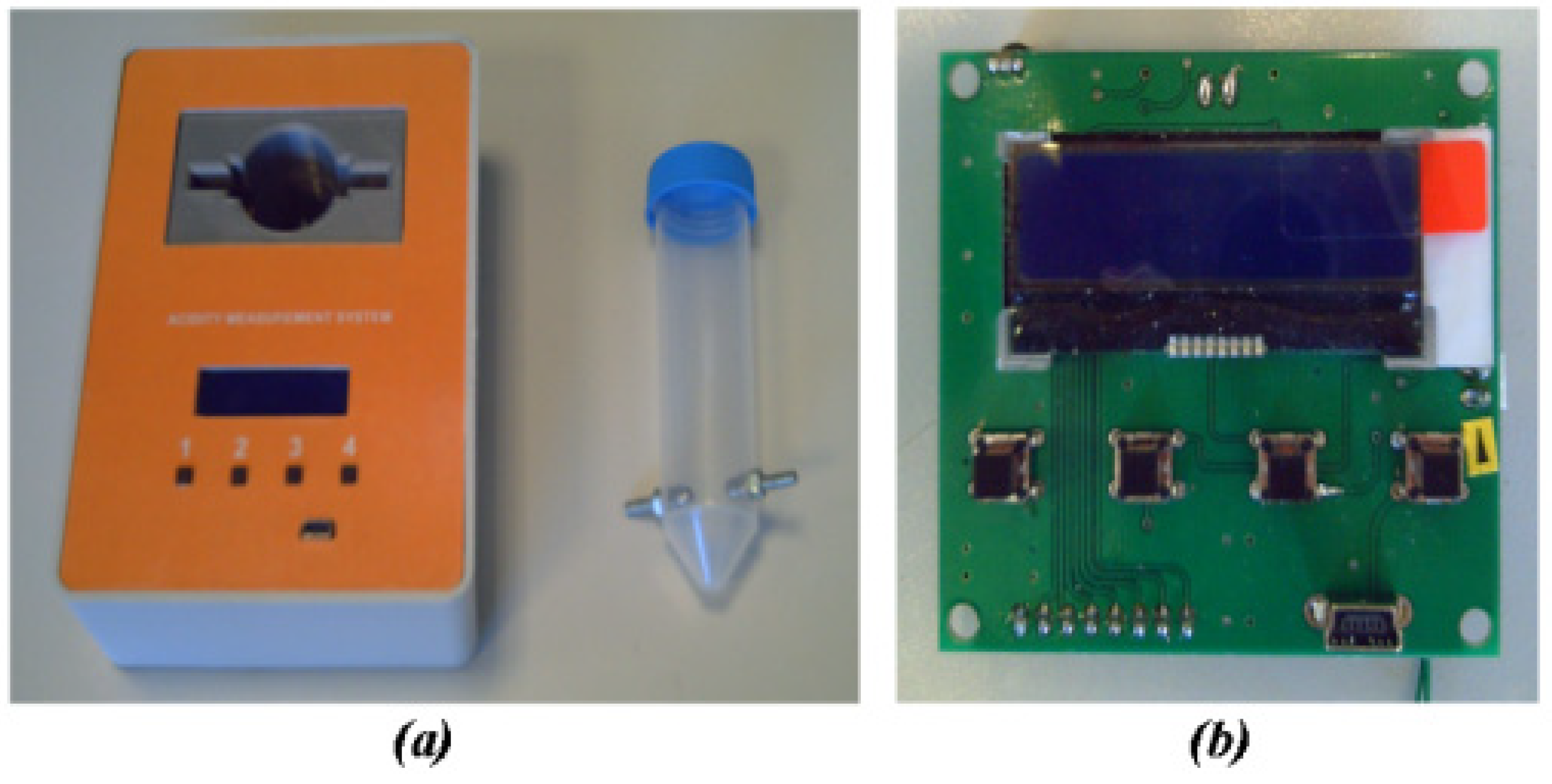

A portable sensor system to evaluate the quality grade of olive oil samples has been designed and built. The system, shown in

Figure 1a, is characterized by small size (11 × 15 × 5 cm), light weight (350 g), quick measurement response (30 s) and can be powered by a USB port or batteries (3 AAA alkaline batteries).

The system working principle is based on electrical impedance spectroscopy (EIS) measurements [

12] on an emulsion between a hydro-alcoholic solution and the olive oil tested. The emulsion electrical properties were measured using a 50 mL Falcon vial modified with a couple of cap-shaped stainless-steel electrodes (hereafter the sensor). In more detail, the following steps were carried out:

The reagent (15 mL), a hydro-alcoholic solution of 60% ethanol and 40% distilled water, was added to the sensor vial.

The reagent electrical conductance was measured using the portable system to check if it was suitable for the measurement (i.e., it was not degraded).

The olive oil being tested (1 mL) was added to the sensor vial.

The sensor vial was vigorously stirred for about 15 s to create the emulsion.

The emulsion electrical conductance and the environmental temperature were measured using the portable system, and these values were used to estimate the olive oil quality grade.

The system’s primary function is the measurement of the olive oil free acidity. In fact, in presence of the hydro-alcoholic solution, the free fatty acid molecules dissociate and generate ions that contribute to the increase in the emulsion electrical conductance which, once compensated for by variations of the environmental temperature, can be used to estimate the olive oil’s free acidity. In the case of fresh olive oil samples, which are characterized by low values of peroxide index, a very good correlation exists between the emulsion electrical conductance and the oil free acidity measured with the standard titration technique. However, when olive oil storage conditions are not adequate, that is, if the oil is exposed to heath or light, oxidation takes place, and this results in the generation of non-volatile compounds (such as aldehydes, ketones and hydrocarbons) that also contribute to the increase in the emulsion electrical conductance. Thus, by setting a threshold for the emulsion electrical conductance, olive oil top quality grade (EVOO) can be distinguished from lower-quality grades, virgin olive oils (VOOs) and lampante olive oils (LOOs).

All electrical measurements, data processing and data filing are carried were using the electronic board that is shown in

Figure 1b. The electronic board integrates a LCD screen to display the measurement results, four buttons for user interaction and a USB port that can be used to power the sensor system as well as to transfer the measured data to a PC for further data analysis. The core device of the electronic board is a microcontroller produced by ST Microelectronics (STM32L152RCT6A) that is responsible for the generation of the test signal, the signals acquisitions, the signals processing and the control of all the electronic components of the board. Different commercial electronic chips are integrated on the electronic board to design the analog circuits for the measurement of the emulsion electrical conductance G

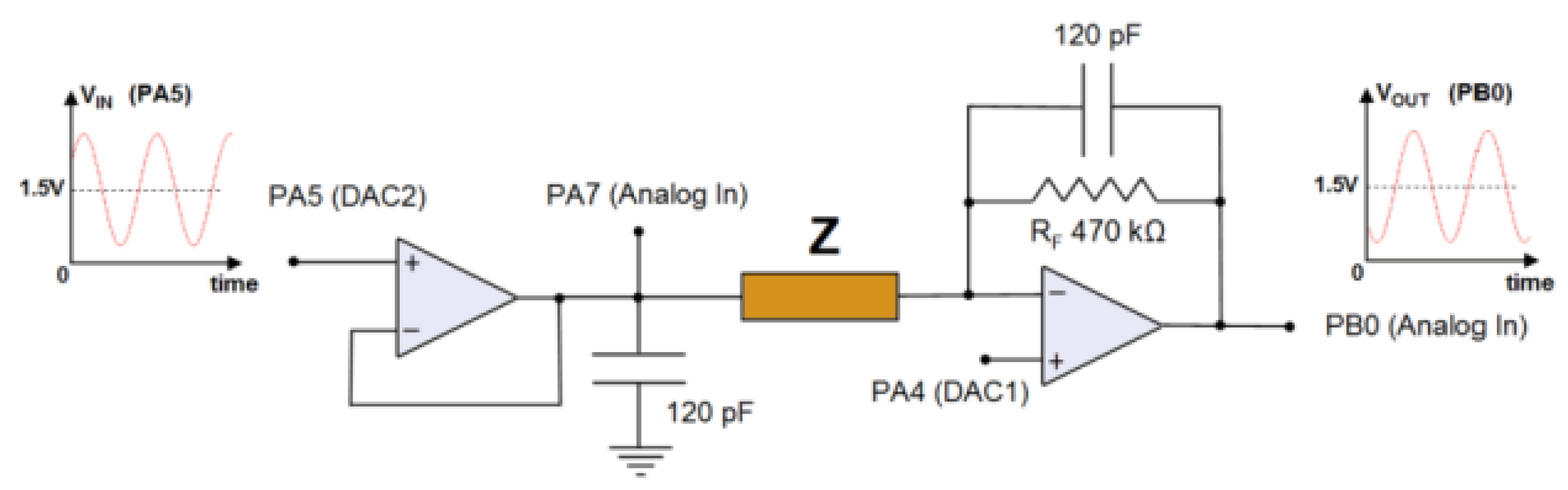

m. A schematic diagram of the measurement circuit is shown in

Figure 2. A sinewave test signal V

IN(t) is generated with the 12-bit DAC integrated in the microcontroller and applied to the sensor vial electrodes. The current through the electrodes is converted to a voltage signal V

OUT(t) using a trans-impedance amplifier. The sinewave voltage signals V

IN(t) and V

OUT(t) are acquired with the 12-bit ADC integrated in the microcontroller, processed to calculate the sinewave parameters and the emulsion electrical conductance G

m. A temperature sensor (MCP9700A) is integrated in the electronic board to make measurements of environmental temperature to compensate variations of G

m with temperature.

The estimation of the olive oil free acidity is carried out with the following steps:

The emulsion electrical conductance at a generic temperature Gm,T and the value of temperature T are measured.

A compensation model, implemented in the microcontroller, calculates the emulsion electrical conductance at 23.5 °C Gm,23.5°C from the measured values of Gm,T and T.

The olive oil free acidity is estimated from the calculated Gm,23.5°C using a calibration curve equation stored in the microcontroller memory.

3. Results and Discussion

The portable sensor system was used to evaluate the quality grade of a set of 17 olive oil samples (11 fresh olive oil samples characterized by a peroxide index < 20 and 6 oxidized olive oil samples characterized by a peroxide index > 20). All samples were tested with the portable sensor system, the quality parameters (free acidity and peroxide index) were determined using the reference manual titration techniques, and the oil quality category was defined as suggested by the EU Reg. 2019-1604.

3.1. Analysis of Fresh Olive Oil Samples

The subset of 11 olive oil samples characterized by a peroxide index < 20 was tested with the portable sensor system. In

Figure 3 the emulsion electrical conductance at 23.5 °C (G

m,23.5 °C) is plotted vs. the free acidity determined by the reference titration technique. A correlation exists between G

m,23.5 °C and the olive oil free acidity. The best-fit curve that correlates the two parameters is defined by the following equation:

Equation (1) was used to estimate the free acidity for all the tested olive oil samples. The values of the estimated free acidity as well as the free acidity determined with the reference titration technique are reported in

Table 1. As can be seen the free acidity estimated with the portable sensor system is very close to the value obtained with the reference titration technique, and the error in the estimated free acidity is never higher than 0.23%.

3.2. Analysis of the Full Set of Olive Oil Samples

The full set of 17 olive oil samples (6 EVOOs, 3 VOOs and 8 LOOs) was tested with the portable sensor system. In the case of oxidized samples, characterized by a peroxide index > 20, the presence of non-volatile compounds contributes to the increase in the emulsion electrical conductance. This was verified by performing the following experiment: a sample, with a free acidity of 0.42% and peroxide index of 11.07 meq O

2/kg of oil, was subjected to UV radiation for a total time of 3 weeks, and the emulsion electrical conductance at 23.5 °C was measured at time intervals of 1 week. The results, presented in

Table 2, confirm that even after 1 week there was a substantial increase in the emulsion electrical conductance due to the products of oil oxidation.

The results for the full set of samples is presented in

Figure 4, where each sample is represented by a circle of different color depending on the quality grade (EVOO, VOO and LOO), while the circle diameter represents the emulsion electrical conductance at 23.5 °C. In general, samples of lower-quality grades were characterized by higher values of the circle diameter. The results show that by setting a suitable threshold value for the emulsion electrical conductance at 23.5 °C (G

m,23.5°C,TH = 2.7 µS), EVOOs can be distinguished from lower-quality oils (VOOs and LOOs) with good accuracy. In this case, all 11 samples of lower-quality grades (3 VOOs and 8 LOOs) were correctly classified. In the case of EVOOs, five samples were correctly classified, and the only misclassified sample featured a free acidity value (0.76%) that was close to the threshold between EVOO and VOO (0.8%).

4. Conclusions

A portable battery-operated sensor system for the evaluation of olive oil quality grade has been presented. The system is characterized by its small size, light weight and quick measurement response. It can be used for the in situ evaluation of olive oil quality grade in small industrial environments that cannot afford an internal laboratory.

The system working principle is based on the measurement of the electrical conductance of an emulsion between a hydro-alcoholic solution and the olive oil sample. The emulsion electrical conductance is mainly affected by the free acidity as well as the oxidation level of the sample. Tests on 17 olive oil samples demonstrated how EVOO samples can be differentiated from lower quality oils with good accuracy.

Author Contributions

Conceptualization, M.G.; methodology, M.G. and A.B.; software, M.G.; validation, M.G. and A.B.; investigation, M.G., E.V. and A.B.; data curation, M.G. and A.B.; writing—original draft preparation, M.G.; writing—review and editing, M.G., E.V. and A.B.; supervision, T.G.T. and B.R.; project administration, T.G.T.; funding acquisition, T.G.T. All authors have read and agreed to the published version of the manuscript.

Funding

This work was developed in the context of the project OLEUM “Advanced solutions for assuring authenticity and quality of olive oil at global scale” funded by the European Commission within the Horizon 2020 Programme (GA no. 635690).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bendini, A.; Cerretani, L.; Carrasco-Pancorbo, A.; Gomez-Caravaca, A.M.; SeguraCarretero, A.; Fernandez-Gutierrez, A.; Lercker, G. Phenolic molecules in virgin olive oils: A survey of their sensory properties, health effects, antioxidant activity and analytical methods. An overview of the last decade. Molecules 2007, 12, 1679–1719. [Google Scholar] [CrossRef]

- Tena, N.; Wang, S.C.; Aparicio-Ruiz, R.; García-Gonzaléz, D.L.; Aparicio, R. Indepth assessment of analytical methods for olive oil purity, safety, and quality characterization. J. Agric. Food Chem. 2015, 63, 4509–4526. [Google Scholar] [CrossRef]

- European Commission. Commission Regulation (EEC) No 2568/91 of 11 July 1991 on the characteristics of olive oil and olive-residue oil and on the relevant methods of analysis. Off. J. Eur. Union 1991, 248, 1–83. [Google Scholar]

- Grossi, M.; Lanzoni, M.; Pompei, A.; Lazzarini, R.; Matteuzzi, D.; Riccò, B. A portable biosensor system for bacterial concentration measurements in cow’s raw milk. In Proceedings of the 4th IEEE International Workshop on Advances in Sensors and Interfaces, Savelletri di Fasano, Italy, 28–29 June 2011; pp. 132–136. [Google Scholar]

- Magwili, G.V.; Cruz, F.R.G.; De Pedro, R.A.C.; Evangelista, R.L.C.; Icaro, K.P.G.; Villarosa, K.A. Non-invasive Moisture Content Prediction and Characterization of Chicken Meat Freshness by Bioelectrical Impedance Spectroscopy. In Proceedings of the 11th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment, and Management (HNICEM), Laoag, Philippines, 29 November–1 December 2019; pp. 1–5. [Google Scholar]

- Das, A.J.; Wahi, A.; Kothari, I.; Raskar, R. Ultra-portable, wireless smartphone spectrometer for rapid, non-destructive testing of fruit ripeness. Sci. Rep. 2016, 6, 32504. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Grossi, M.; Lanzoni, M.; Lazzarini, R.; Riccò, B. Automatic ice-cream characterization by impedance measurements for optimal machine setting. Measurement 2012, 45, 1747–1754. [Google Scholar] [CrossRef]

- Grossi, M.; Valli, E.; Glicerina, V.T.; Rocculi, P.; Gallina Toschi, T.; Riccò, B. Practical determination of solid fat content in fats and oils by single-wavelength near-infrared analysis. IEEE Trans. Instrum. Meas. 2020, 69, 585–592. [Google Scholar] [CrossRef]

- Mignani, A.G.; Ciaccheri, L.; Mencaglia, A.A.; Tuccio, L.; Agati, G. Application of a LED-based reflectance sensor for the assessing in situ the licopene content of tomatoes (Lycopersicon esculentum Mill.). Sens. Agric. Food Qual. Saf. 2015, 9488, 948806. [Google Scholar] [CrossRef]

- Grossi, M. A sensor-centric survey on the development of smartphone measurement and sensing systems. Measurement 2019, 135, 572–592. [Google Scholar] [CrossRef]

- Grossi, M.; Di Lecce, G.; Gallina Toschi, T.; Riccò, B. Fast and accurate determination of olive oil acidity by electrochemical impedance spectroscopy. IEEE Sens. J. 2014, 14, 2947–2954. [Google Scholar] [CrossRef]

- Barsoukov, E.; Macdonald, J.R. Impedance Spectroscopy: Theory, Experiment, and Applications, 2nd ed.; John Wiley & Sons: New York, NY, USA, 2005. [Google Scholar]

- Grossi, M.; Palagano, R.; Bendini, A.; Riccò, B.; Servili, M.; García-González, D.L.; Gallina Toschi, T. Design and in-house validation of a portable system for the determination of free acidity in virgin olive oil. Food Control 2019, 104, 208–216. [Google Scholar] [CrossRef] [Green Version]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).