Abstract

Agriculture and agriculture-related industries generate many different forms of by-products and waste, whose integration into the circular economy still requires experimental studies and research. This research aimed to obtain innovative coatings containing agro-industrial by-products and animal waste, characterizing the thermal insulation potential of the resulting products, and determining the durability of the respective coatings by exposing them to the action of an aggressive environment with large temperature variations.

1. Introduction

One of the methods to create buildings with a low environmental impact is by utilizing natural materials, provided these initiatives do not result in environmental imbalances. Within the construction industry, a primary goal for researchers is to identify alternative solutions for building more cost-effectively, in an eco-friendlier manner, while also using durable materials. The objective is to produce such construction materials primarily from natural or recycled raw materials. The production of these materials should have minimal impact on the environment, consuming less energy and utilizing renewable resources like by-products or waste from building demolitions, and plant or animal agricultural waste.

Embracing the principles of the circular economy, ecological design, and the use of recyclable materials can lead to significant savings both for businesses and on a societal level. Consumers stand to benefit from innovative, durable, and reasonably priced products that will not only enhance their quality of life but also help them save money over time.

Each year, vast amounts of agricultural waste result from the industrial processing of agricultural products. For instance, cereal industries produce husks, coffee companies generate coffee pulp waste, and fruit and vegetable processing lead to discarded peels. These are just a few examples of sectors that contribute to the large-scale production of waste [1]. While agro-industrial waste presents potential for reuse and repurposing, the sheer volume in which they are produced poses significant disposal challenges [2,3].

On the one hand, sectors like agriculture and its related industries, including food and textiles, generate various by-products and waste. Incorporating these into the circular economy requires further experimental studies and research [1,4]. Publications from the scientific community in recent years show an increasing interest in natural materials, with a particular emphasis on hemp, straw, flax, wood, coconut husk, corn, and sunflower [1,2,3,5].

Conversely, synthetic materials have traditionally been used for the thermal insulation of buildings. Some of these, such as fiberglass, can pose respiratory risks, potentially leading to severe conditions like lung cancer. Consequently, many studies have sought to develop thermal insulation materials from natural fibers, offering eco-friendly and renewable alternatives [5].

The research objective was to create innovative coatings made with additions of animal waste (low-quality sheep wool waste) and agro-industrial by-products resulting from the edible oil industry (sunflower seed husk), characterizing innovative coatings from the point of view of their thermal insulation potential, as well as determining their durability by exposing the coatings to the action of an aggressive environment with large temperature variations, simulated in laboratory-accelerated conditions.

2. Materials and Methods

Three innovative coatings (F1, F2, and F3) were developed. Each was crafted from a distinct bio composite material composed of 3 ÷ 5 of the following ingredients: an acrylic binder, sunflower seed husk, low-quality sheep’s wool waste, expanded perlite granules, and a polyvinyl acetate adhesive in aqueous dispersion. The latter also served a binding purpose. The primary binding component (B) was a film-forming finish based on acrylic resin. It had a density exceeding 1.20 g/cm3 and contained more than 50% non-volatile substances. It was designed for outdoor applications and exhibited robust resistance to harsh environmental conditions. Furthermore, it incorporated biocidal agents to enhance resistance against external factors and, in this study, to mitigate the biodegradation of plant-based wastes over time.

The sunflower seed husks utilized were of a fraction with a maximum size (φ) of 4 mm. The sheep’s wool waste (W) originated from a mattress crafted from wool waste. A sample from this mattress was processed in the laboratory, being cut to average dimensions of approximately 3–4 mm.

Expanded perlite granules (PRs), finely granulated and primarily ranging between 0.3 and 9 µm [6], aided in augmenting the mixture’s cohesion and promoting its homogenization. The adhesive based on polymer resin (AD) was employed to bolster the composite material’s cohesion, homogenization, and adhesion to the underlying substrate.

Each of the three coatings was applied in three consecutive layers: a primer layer followed by two distinct bio composite layers. These layers varied both in terms of the materials incorporated and their respective quantities. Table 1 delineates the total amounts of each material used to produce the three-layer coatings, F1, F2, and F3, as well as their average thicknesses when set upon gypsum board surfaces.

Table 1.

Total quantities of each type of material used for the three-layer coatings, F1, F2, F3, and average thicknesses of the resulting coatings.

The design of the three-layer coatings was such that their final layer, possessing a compact structure, was consistently crafted from the same bio composite material, containing the acrylic binder B, the φ4 plant waste, and the AD adhesive. This ensured that the diverse characteristics and behaviors of the coatings were primarily influenced by the composition of the bio composite material used in their second layer. Consequently, all three coatings presented an identical external appearance, which was representative of the final layer. For visualization, Figure 1 shows the case of the appearance of the F3 coating, enhanced with sunflower seed husks and sheep’s wool waste, when applied to a gypsum board surface.

Figure 1.

Visual representation of the three-layer F3 coating on a gypsum board plate.

2.1. Evaluating the Thermal Insulation Capabilities of the Coatings

To assess the thermal insulation capabilities of the novel three-layer coatings F1, F2, and F3, each was applied to both sides of a 30 × 30 × 12.5 cm gypsum board. The primer layer was applied with a brush after preparing it by diluting the acrylic binder according to product-specific guidelines. Once the primer set, the bio composite materials were applied with a stainless-steel trowel, ensuring a 24 h drying period between the second and third layers. Based on this application technique, the average thickness of the coatings on one side of the gypsum board samples were 4.11 mm for specimen F1 (with coating F1), 4.10 mm for specimen F2 (with coating F2), and 4.09 mm for specimen F3 (with coating F3). Given that the average thicknesses of these systems are relatively thin in comparison to traditional construction materials with insulating properties, directly measuring the thermal resistance would have been unfeasible. Another distinctive feature of the tested coatings was their need for a supportive substrate for practical application; they were not intended as standalone materials. This necessitated the use of the gypsum board as a base layer, which had a substantial thickness (nominal thickness being 12.50 mm, while the actual thickness ranged between 12.6 and 12.89 mm).

The procedure, elaborated upon in the preceding sections, was structured as follows:

- Preparing sample substrates from the gypsum board and labeling them for easy identification in subsequent stages;

- Conditioning these gypsum board sample substrates;

- Measuring the thermal resistance and thermal conductivity of each substrate under steady-state conditions using the Lambdameter E500e equipment, in accordance with SR EN 12667:2002 (https://magazin.asro.ro/ro/standard/29334 accessed on 1 October 2023) and SR EN 12664:2002 standards (https://magazin.asro.ro/ro/standard/29333 accessed on 1 October 2023);

- Applying the coatings, which are based on an acrylic binder in aqueous dispersion, enhanced with additives from agricultural waste of both plant and animal origins, among others;

- Allowing time for the coating to mature and ensuring that any necessary chemical reactions take place;

- Conditioning the coated specimens under conditions like those set for the original gypsum board substrates;

- Measuring the thermal resistance and thermal conductivity of each composite sample (i.e., the gypsum board combined with the respective coating) under steady-state conditions, using the Lambdameter E500e equipment;

- Evaluating the thermal properties of the tested coatings, specifically:

- The thermal resistance, determined using the appropriate calculation formula tailored for a steady-state heat transfer regime:where —thermal resistance of the paint layers; —thermal resistance of the gypsum board specimen covered on both sides with the test paint; —thermal resistance of the gypsum board specimen;

- Thermal conductivity of the tested coatings:where —thermal conductivity of the paint; —thickness of the paint layers.

The evaluation of the thermal transfer properties for the three coatings was conducted utilizing the guarded hot plate method, as prescribed by the SR EN 12667:2002 and SR EN 12664:2002 standards. This steady-state measurement approach offers the benefit of providing highly accurate results.

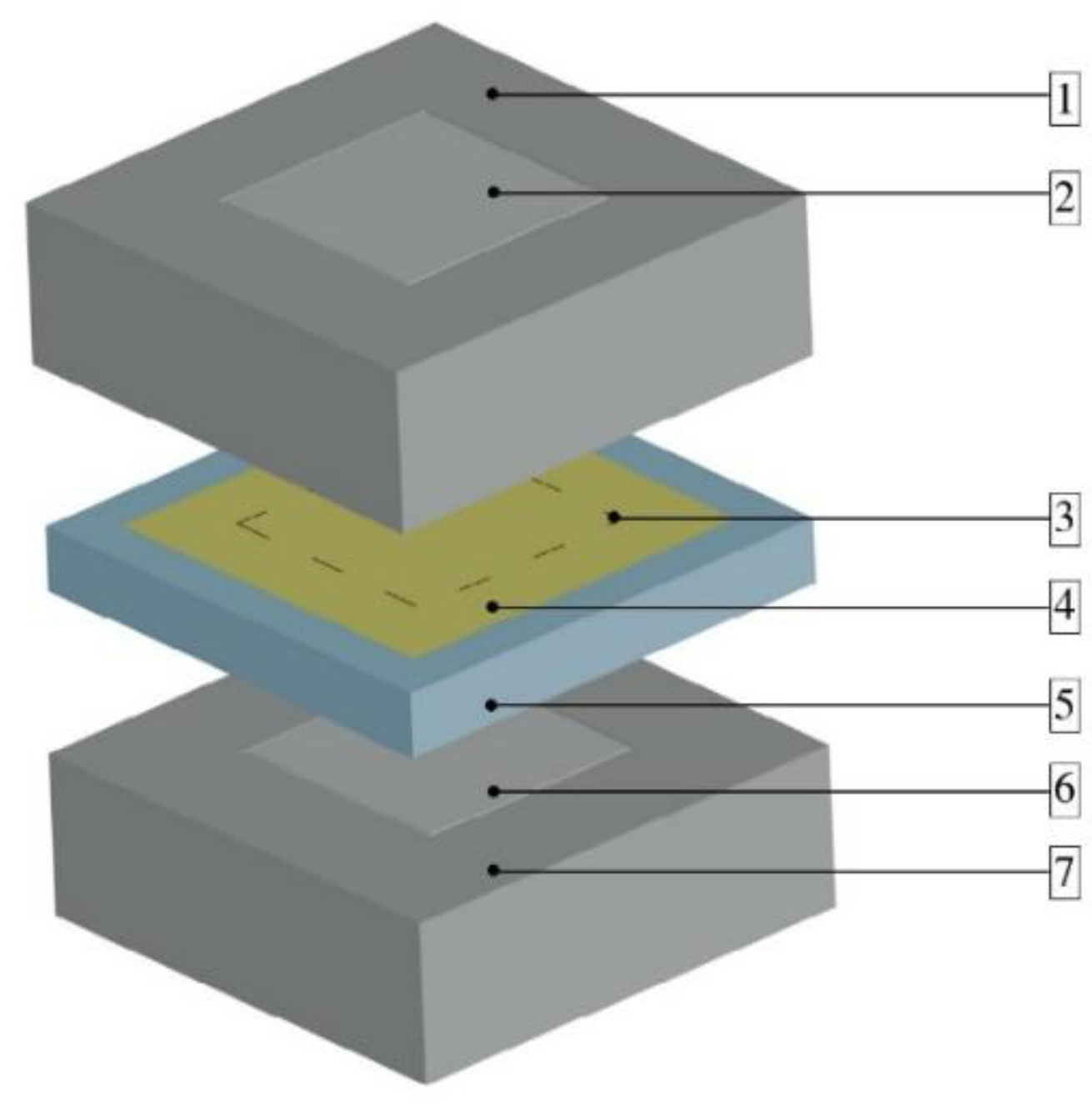

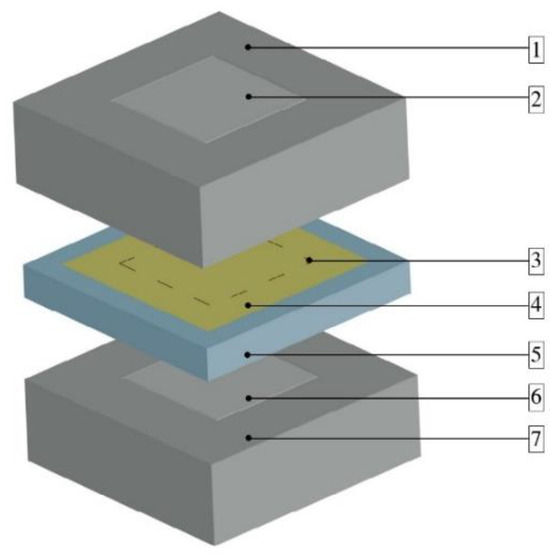

Essentially, to measure the thermal resistance of a sample, it is necessary to maintain a consistent unit thermal flux q [W/m2] between the two sides of the sample. This occurrence takes place in the testing zone, which is situated close to the center of each sample, as depicted in Figure 2.

Figure 2.

Schematic of the thermal resistance measurement device. 1—cold guarded marginal plate; 2—cold measuring plate; 3—sample testing zone; 4—parts of the sample in contact with the guarded marginal plates; 5—frame for fixing the sample (only for bulk materials); 6—hot measuring plate; 7—hot guarded marginal plate.

The components surrounding the testing zone are referred to as the guarded marginal zones. Their primary function is to eliminate heat transfer through the lateral edges of the testing zone. This ensures that heat transfer through the sample occurs solely between the two main faces, which is precisely where the thermal resistance is intended to be gauged.

Once a steady thermal state is achieved, the heat flux, Q [W], that moves through the sample in the testing zone is recorded. The unit heat flux is then calculated by dividing the measured heat flux by the surface area of the testing zone. Concurrently, as the heat flux, Q, is being measured, the temperatures on both sides of the sample are also recorded. This is done using temperature sensors situated on the equipment surfaces that are in direct contact with the sample.

2.2. Assessing the Durability of Coatings under Significant Temperature Fluctuations

The durability of the three innovative coatings was evaluated based on their adherence to a cement mortar surface and their thermal conductivity after being applied to plasterboard panels. For this assessment, two sets of samples were prepared: a control set, which was consistently maintained under standard laboratory conditions (T = (23 ± 2)°C, Ur = (50 ± 5)%), and a test set, which was exposed to aggressive conditions simulated in the laboratory. These aggressive conditions consisted of cycles of 16 h in a refrigerator at Tmin = (−20)°C, followed by 8 h under standard laboratory conditions at Tmax = 23 °C. Two evaluations were performed on the control sample set: adhesion to the substrate (for finishes applied to cement mortar) and thermal conductivity (for finishes applied to plasterboard). During the exposure to the aggressive environment, the coatings’ durability was assessed by examining the test set. This involved tracking the evolution of adhesion to the mortar (7 and 28 days post-application, and then after 2 and 4 weeks of exposure, respectively) and the thermal conductivity (before and after 4 weeks, or 30 exposure cycles).

3. Results

3.1. Evaluation of the Thermal Insulation Capabilities of Coatings F1, F2, and F3

Table 2 shows the cases of the outcomes of the tests carried out to gauge the thermal insulation properties of coatings F1, F2, and F3. Each sample comprised a plasterboard substrate with a coating, which incorporated additives derived from animal-based agricultural waste and agro-industrial by-products, among other components.

Table 2.

Outcomes from the assessments to determine the thermal insulation properties of coatings F1, F2, and F3.

From the results, it becomes evident that the three innovative coatings under investigation, despite their notably thinner average total thickness (approximately 4 mm), still shows properties characteristic for traditional thermal insulation materials. This distinction is striking given the significant difference in thickness when compared to standard thermal insulation materials. An analysis of the thermal conductivity coefficient’s progression over the course of the evaluation implies a notable consistency and homogeneity in the tested materials, indicating an absence of air voids or inclusions.

3.2. Evaluating the Durability of Coatings F1, F2, and F3 under Significant Temperature Fluctuations

3.2.1. Analysis of the Durability for Coatings Applied to a Cement Mortar Base

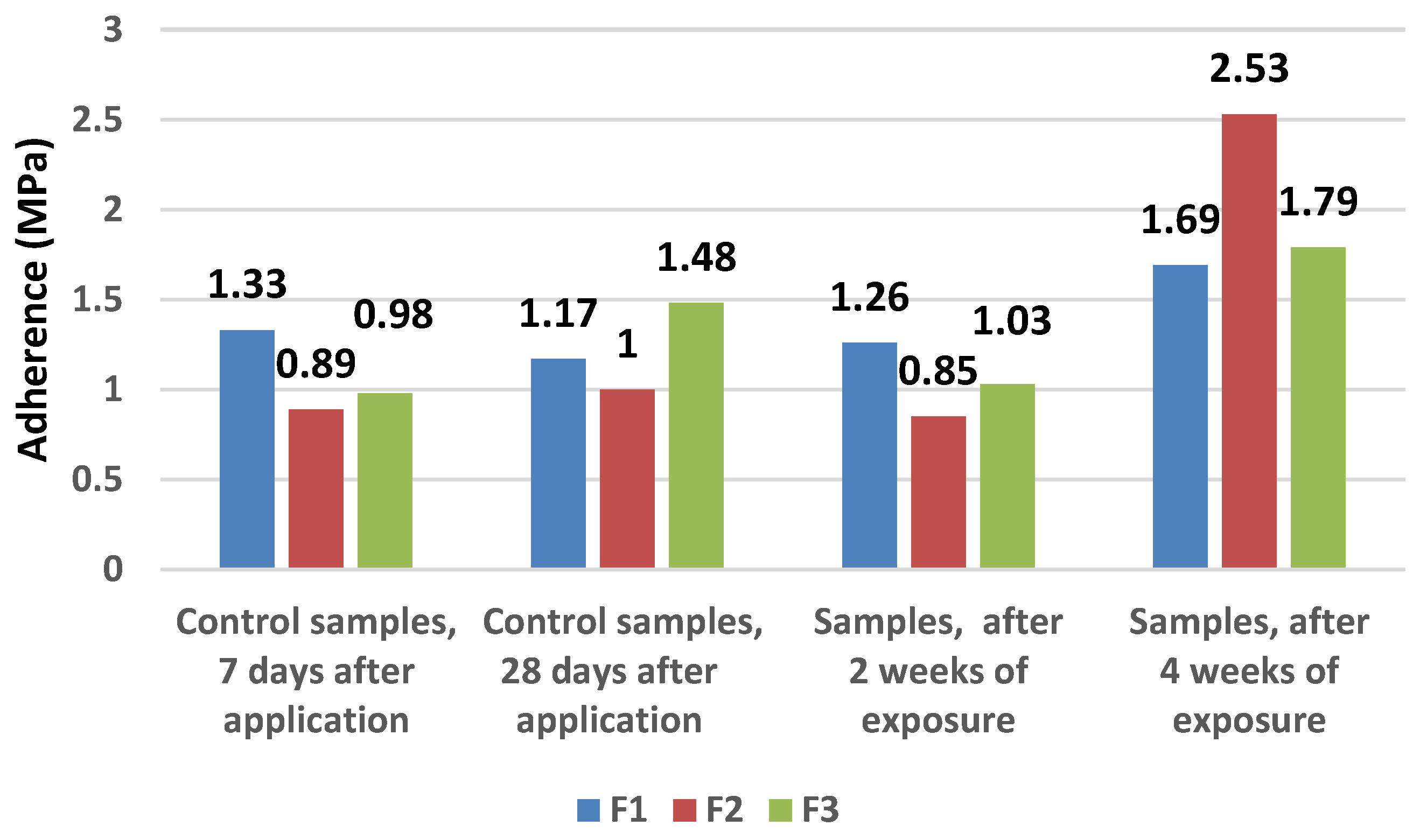

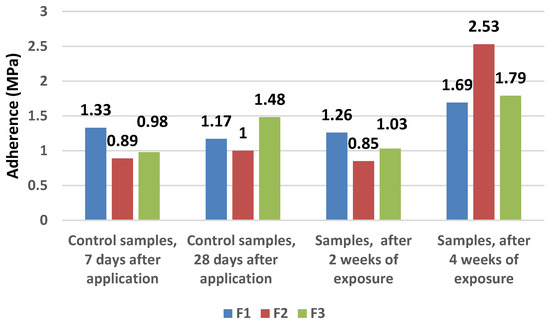

Figure 3 presents the findings from tests assessing the adhesion of the innovative coatings F1, F2, and F3 to cement mortar. This assessment was conducted both pre and post their exposure to the aggressive conditions characterized by substantial temperature shifts.

Figure 3.

Adhesion of the coatings to cement mortar before, during, and after exposure to significant temperature fluctuations.

Despite their relatively thin nature, measuring at approximately 4 mm, the coatings exhibited increased adhesion to the cement mortar across all samples. This was particularly pronounced in the specimens exposed to aggressive environmental conditions, where the adhesion achieved values typical for an acrylic finish. The adhesion values for the three coatings varied from 0.89 MPa to 1.33 MPa (7 days post-application), from 1 MPa to 1.48 MPa (28 days post-application), from 0.85 MPa to 1.26 MPa (after 2 weeks of exposure), and from 1.69 MPa to 2.53 MPa (after 4 weeks of exposure). Over a one-month span, the control samples displayed a consistent upward trend in adhesion. In contrast, those subjected to the aggressive environment exhibited both rises and falls in their adhesion values. However, by the conclusion of the exposure duration, all three coatings showcased greater adhesion compared to any prior reference points in the study. This dynamic in adhesion progression could stem from the effects of cyclical ambient humidity variations in the bio composite structure.

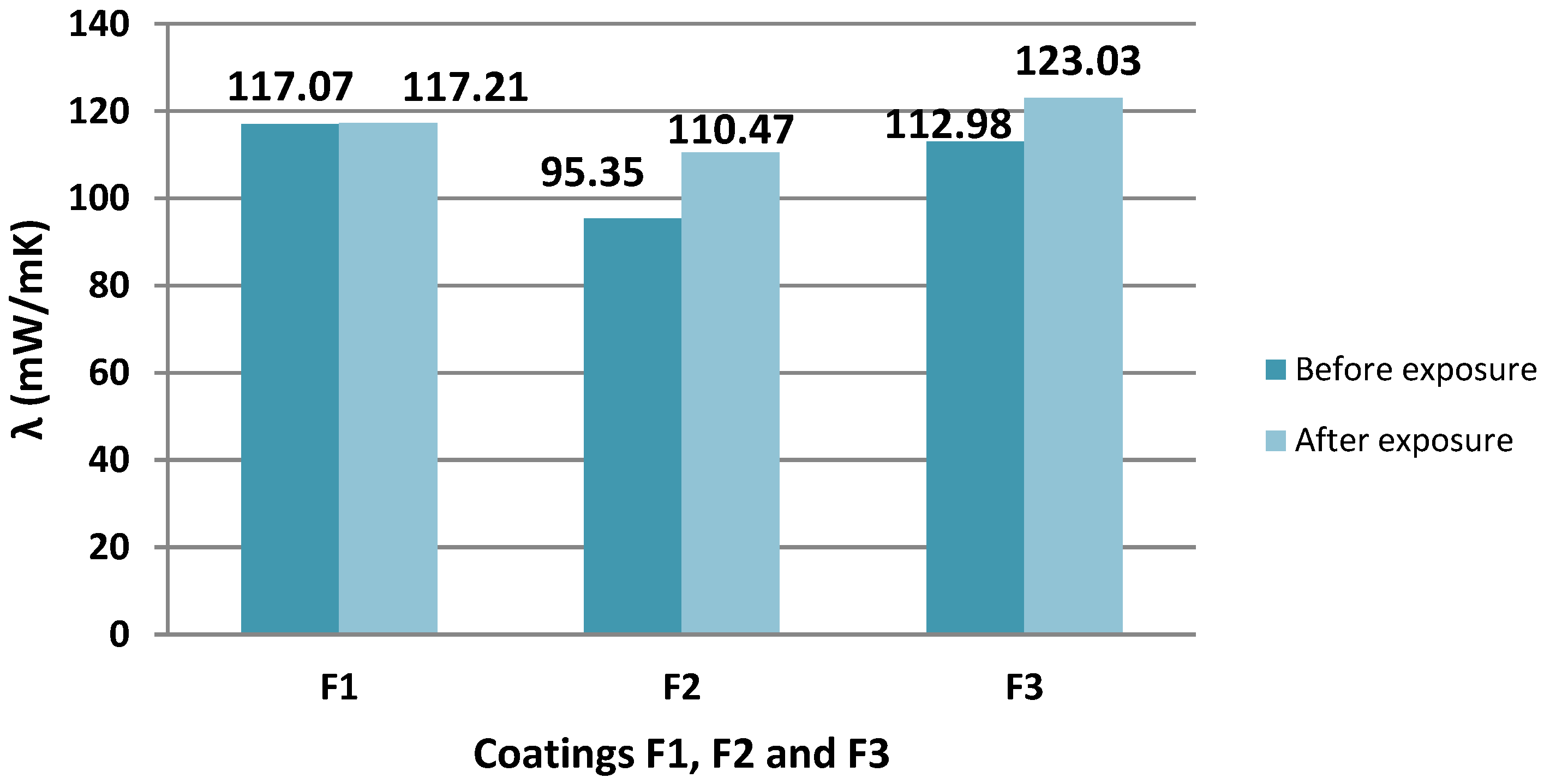

3.2.2. Analysis of the Durability for Coatings Applied to a Plasterboard Base

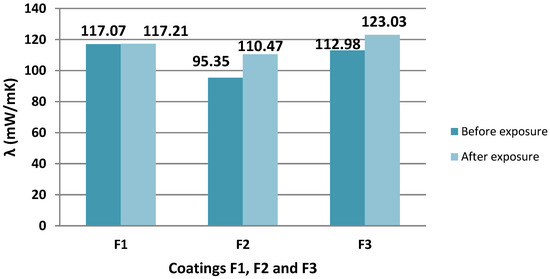

Figure 4 depicts the findings from tests assessing the thermal conductivities of the coatings when applied to plasterboard, both before and after their exposure to the aggressive conditions, characterized by substantial temperature shifts.

Figure 4.

Thermal conductivities of the coatings before, during, and after exposure to significant temperature fluctuations in an aggressive environment.

The initial thermal conductivity values for the coatings varied from 93.35 mW/m·K to 117.07 mW/m·K. During the exposure, the thermal insulation capabilities of the coatings increased by 0.14 mW/m·K for finish F1 and by 15.12 mW/m·K and 10.05 mW/m·K for finishes F2 and F3, respectively.

From the obtained results regarding the thermal protection properties of the coatings F1, F2, and F3, several observations can be drawn:

- Among the tested coatings, F1 exhibited the most favorable time-dependent evolution of conductivity. Its formulation contained, besides the acrylic binder and adhesive, only the agro-industrial additive or by-product of vegetable origin;

- The most impressive thermal conductivity readings, both initially and at the conclusion of the exposure interval, were attributed to coating F2. Its composition integrated the acrylic binder and adhesive, complemented solely by additives derived from both vegetable and animal sources.

- When considering thermal conductivity, the influence of the perlite additive appears to be less significant compared to the natural additives used.

4. Conclusions

Based on the experimental results obtained from this research, the following conclusions can be drawn:

- The three innovative coatings each displayed characteristics consistent with thermal protection materials, despite having thicknesses significantly less than traditional thermal insulation materials.

- The observed evolution of the thermal conductivity coefficient during the test period suggests that the coatings are relatively homogeneous and free of air inclusions.

- The experimental findings suggest that both thermal conductivity and adherence to the substrate can serve as indicators of the durability for such finishes.

- Coatings F1, F2, and F3 are multifunctional. They not only possess the basic attributes typical of finishes—such as a decorative appearance and adhesion to cement mortar surfaces—but they also exhibit resilience under conditions with significant temperature fluctuations (provided there is not the high humidity associated with precipitation) and possess thermal insulation qualities.

- The development of these innovative coatings may represent a new method of integrating and valorizing waste of animal origin and vegetal agro-industrial by-products in construction.

- Innovative coatings, which incorporate lower-quality sheep’s wool and sunflower seed husks, have an aerated structure. This suggests their potential use as finishes with insulating properties. Further research is required to comprehensively understand their properties and their potential as sustainable construction materials.

Author Contributions

Conceptualization, I.P., C.P. and A.M.; methodology, I.P. and C.P.; validation, I.P., C.P., and A.M.; formal analysis, I.P., C.P. and A.M.; investigation, I.P., C.P. and A.M.; resources, I.P. and A.M.; data curation, I.P. and C.P.; writing—original draft preparation, I.P.; writing—review and editing, C.P. and A.M.; project administration, I.P.; funding acquisition, I.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Romanian Government Ministry of Research Innovation and Digitization, project no. PN 23 35 02 01 “Synergies of innovation and digitalization in the design of eco materials and multifunctional products for sustainable constructions, with an impact on the environment and the circular economy” and also PN 19 33 04 02: “Sustainable solutions for ensuring the population health and safety within the concept of open innovation and environmental preservation”.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

This work was carried out through the Core Program, supported by the Ministry of Research, Innovation and Digitization, through the project no. PN 19 33 04 02 and the project no. PN 23 35 02 01.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Yaashikaa, P.R.; Senthil Kumar, P.; Varjani, S. Valorization of agro-industrial wastes for biorefinery process and circular bioeconomy: A critical review. Bioresour. Technol. 2022, 343, 126126. [Google Scholar] [CrossRef] [PubMed]

- Cintura, E.; Nunes, L.; Esteves, B.; Faria, P. Agro-industrial wastes as building insulation materials: A review and challenges for Euro-Mediterranean countries. Ind. Crops Prod. 2021, 171, 113833. [Google Scholar] [CrossRef]

- Bakatovich, A.; Davydenko, N.; Gaspar, F. Thermal insulating plates produced on the basis of vegetable agricultural waste. Energy Build. 2018, 180, 72–82. [Google Scholar] [CrossRef]

- Fuentes, R.A.; Berthe, J.A.; Barbosa, S.E.; Castillo, L.A. Development of biodegradable pots from different agroindustrial wastes and byproducts. Sustain. Mater. Technol. 2021, 30, e00338. [Google Scholar] [CrossRef]

- Binici, H.; Aksogan, O.; Dıncer, A.; Luga, E.; Eken, M.; Isikaltun, O. The possibility of vermiculite, sunflower stalk and wheat stalk using for thermal insulation material production. Therm. Sci. Eng. Prog. 2020, 18, 100567. [Google Scholar] [CrossRef]

- Fiat, D.; Lazăr, M.; Baciu, V.; Hubcă, G. Aspects Concerning the Perlite Recovery in Addition with Polymeric Additives for Constructions Materials. Mater. Plast. 2010, 47, 64–68. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).