1. Introduction

Food quality has a straight effect on human health; hence, monitoring it is crucial. In the case of fruits—that is generally a type of food consumed in natura—this control is even more essential. However, a lack of a pattern to classify whether the fruit has an adequate quality or not for consumption makes this choice based on aesthetic characteristics with the purpose to gain the consumers using their visual senses. Due to that, the level of losses in fruit supply chains is very high.

Some studies revolve around the idea to establish better patterns to measure quality in food supply chains. Almeida [

1] points out that a classification method has the purpose of quality control, providing healthier food to the consumers, and assisting retailers to select products to be commercialized. The quality in the food supply chain is bonded to the intrinsic and extrinsic aspects that involve production, transformation, and distribution [

2,

3,

4]. Therefore, Mannes et al. [

5] highlight the importance of applying quality tools in the food sector to address health and market issues. Given that, we can infer that does not matter whether food is natural or processed, the quality of the product depends on the development and application of methods to ensure food safety and add value to consumers and, consequently, to the food supply chains.

Brazil is a big producer of agricultural products, and fruits and vegetables have an important role in the diet of its population. However, on the path between farm to fork, there are high rates of losses and waste due to the manipulation, incorrect storage and transportation, and lack of patterns of classification and quality among other issues. One of these fruit production chains that is facing the problem is the banana production sector. The Brazilian Program for the Modernization of Horticulture and Integrated Fruit Production (PBMH and PIF) establishes the standards for classifying bananas to be sold in supermarkets, grocery stores, and stands [

6]. This classification system will contribute to improving the process of banana selection, the correct destination of losses and wastes, optimizing logistical operations, reducing the lead time and rework, and reducing return rates due to inadequate quality standards.

The classification of bananas requires a strong relationship among players throughout the supply chain because is a product very sensitive to the environment. Rocha et al. [

7] argue that the rate of deterioration in the nutritional quality of bananas is related to the modification of flavor, change in texture and appearance, often caused by physiological damage due to operations from harvesting to distribution and associated with adverse weather conditions.

Brazil has big cities such as São Paulo and Rio de Janeiro and ensuring quality standards in a large area is a constant challenge because of the involvement of producers, freighters, intermediaries, central wholesalers, distributors, and several modalities of food service and retailers [

1].

It is necessary to consider the current consumer profile. Consumers have been changing the way we negotiate and sell products. They have more access to information and establish new concerns related to sustainability, quality, and food safety [

3,

8]. However, this does not necessarily mean they want to pay higher prices to meet the requirements pressuring food supply chains [

2,

8].

Finally, to understand the importance of banana production in Brazil, in 2020, the country’s production was 6.7 million tons with an average yield of 14.72 tons/ha [

9]. Bananas are one of the most consumed fruits by Brazilians and have nutritional value and high energy content [

7,

10]. Soares et al. reported that since it is a climacteric fruit, post-harvest management must be quick and careful to avoid issues in the quality of the fruit [

10].

Having said that, this study aims to analyze the current situation in markets regarding the classification system of the banana production chain in Brazil based on PBMH and PIF. Specifically, we studied the Cavendish Banana in the region in São Paulo metropolitan area, called Alto Tiête. This region receives this name because it is where an important Brazilian river was born, Tiête. The cities included are: Arujá, Biritiba Mirim, Ferraz de Vasconcelos, Guararema, Guarulhos, Itaquaquecetuba, Mogi das Cruzes, Poá, Salesópolis, Santa Branca, Santa Isabel e Suzano where aproximately three million people live.

2. Materials and Methods

2.1. Data Collect

For data collection, we created a checklist based on the quality criteria of the banana classification standards from PBMH and PIF [

6]. This checklist contained four distinct parts: (1) identification of the document on the data collection unit; (2) characteristics and quality references for evaluating and classifying

Cavendish bananas; (3) Sampling; and (4) observed characteristics.

The data collection was carried out in August 2021 in 12 retailers, covering the following cities of Alto Tiête: Biritiba Mirim, Guarulhos, Itaquaquecetuba, Mogi das Cruzes, Poá, and Suzano. We adopted in this study the exposed bananas to the customer considering as a homogeneous batch, formed by a stand and/or gondola. For sample composition, 20 banana fingers were collected per batch of each establishment, totalizing 240 fingers.

2.2. Cavendish Banana Classification Criteria

The Brazilian classification norms are the basis for updating the process of commercialization and transparency in commercial relationships [

6,

7]. PBMH and PIF consider the one variety group, class, subclass, and quality, as indicated following [

6]:

The banana class is determined by the length of the fruit (in cm), being 6 (bigger than 6 to 9), 9 (bigger than 9 to 12), 12 (bigger than 12 to 15), 15 (bigger than 15 to 18), 18 (bigger than 18 to 22), 22 (bigger than 22 to 26) and 26 (bigger than 26).

The subclass guarantees the ripe homogeneity (Von Loesecke scale): completely green (1), green with yellow traces (2), more green than yellow (3), more yellow than green (4), yellow with green (5), yellow (6) and yellow tip with brown areas (7).

The categories correspond to the analysis of defects, which can be absent, mild, or severe. Additionally, there is a minimum caliber required per fruit (mm) for each category.

Severe defects, such as cigar tips, rottenness, denting, in-deep damage, early ripening, past fruit, or moth-bearing fruit, are harmful to health. They make consumption unfeasible and significantly detract from the appearance and value of the product. Concerning mild defects, fingers, differentiated development, twins, and floral remains, they do not prevent human consumption but depreciate the product’s value [

6]. The quality criteria evaluated were related to external characteristics, such as class (external finger length, cm), subclass (ripe scale), minimum caliber, gross weight (fruit and peel), net weight (fruit), peel weight, observed defects (Extra, I, II and III categories).

2.3. Data Analysis

The variables analyzed were price (PR, values in BRL), gross weight (GW), peel weight (PW) and net weight (NW), in grams, external length (EL, in cm), and external caliber (EC, in mm). A scale and a measuring tape were the instruments used to assess the banana fingers. The scale weighed the banana fingers, obtaining the grams’ gross and peel weight. The net weight was calculated by subtracting the peel weight from the gross weight. Likewise, the measuring tape was applied to measure the external length and the diameter of the banana (external caliber). The external length of the finger was checked to calculate the fingers and classify them, while the central part of the banana was measured to evaluate the diameter. The guidelines of the PBMH and PIF were followed to assess the subclasses, observe the maturation scale, and calculate defects, which was carried out following the table in the Classification Standards manual and applying the concept from minor and severe defects [

6].

We tabulated data in an electronic spreadsheet (MS-Excel software) to organize them for statistical processing. After, we applied a normal test range using the Shapiro–Wilk to check the behavior of the variables and whether the distribution followed the Gaussian distribution.

In the sequence, we run a univariate descriptive statistic to understand the data. After, we processed non-parametric Kruskal–Wallis statistics and the Dunn test for multiple comparisons at 5% significance to compare the classes of banana fingers. Likewise, we applied χ2 statistic to compare the qualitative variables, based on the observed and expected values, considering the significance level of 5%.

3. Results

During the data collection, we missed one banana finger. Therefore, we analyzed the total of 239 bananas from the retailers in Alto Tietê totaling 37.62 Kg, a mean of 156.49 ± 39.62 g/finger.

The average price of the banana finger in the region during the study was 0.53 ± 0.21, and this variation showed the high price divergence among supermarkets in the region (~40%), as well as the deviation of the net weight (~30.5%).

The prices of fingers were found from BRL 0.16 to 1.36 and net weight from 53 to 214 g. The banana fingers collected were distributed among classes of 15, 18, and 22, so the fingers of the sample had a length above 15 and below and/or equal to 26 cm [

6].

Significant statistical differences (

p < 0.05) were observed among the classes of bananas in terms of quality criteria, gross weight, net, peel, length, and caliber. However, about the prices of the banana fingers, the difference was observed only between classes 15 and 18 or 22, but no results were obtained between classes 18 and 22 (

Table 1).

Regarding the classification by minimum caliber, 95% of the fingers indicated a caliber equal to or bigger than 32 mm (extra category), against 5% classified in category I (caliber between 30 and 31.99 mm). We observed that most banana fingers were classified into subclasses 7 (about 37.5%) and 6 (35%). Considering the maturation scale of Von Loesecke, fingers classified in subclasses 6 and 7 refer to those fruits with completely yellow skin and yellow with brown areas, respectively [

6].

We found that 62% of bananas presented grade II and III defects against 38% without defects and/or mild defects. We observed a statistical significance in banana fingers defects by cities (p < 0.05). Itaquaquecetuba showed the lowest rate of defects among banana fingers where the majority were classified in the extra category, and none indicated severe defects. In contrast, Biritiba Mirim presented 79.5% of its fruits classified in category III, considered severe defects, with spoiled fingers and signs of damage.

Our results indicated that retailers in research offer medium and large-size bananas (classes 15, 18, and 22), a ripe degree between subclasses 6 and 7, and categorized as extra (caliber bigger than 32 mm) considering the manual values. However, many defects per batch were found, reducing the quality of products sold.

4. Discussion and Conclusions

Retailers adopt a visual classification to select the bananas that meet marketing standards. Therefore, many products are rejected being discarded, an increasing loss rate. A classification process to determine which fruits are appropriate to be sold and consumed can contribute to the reduction of losses in the supply chain presenting several benefits as indicated by Kondo [

8,

11].

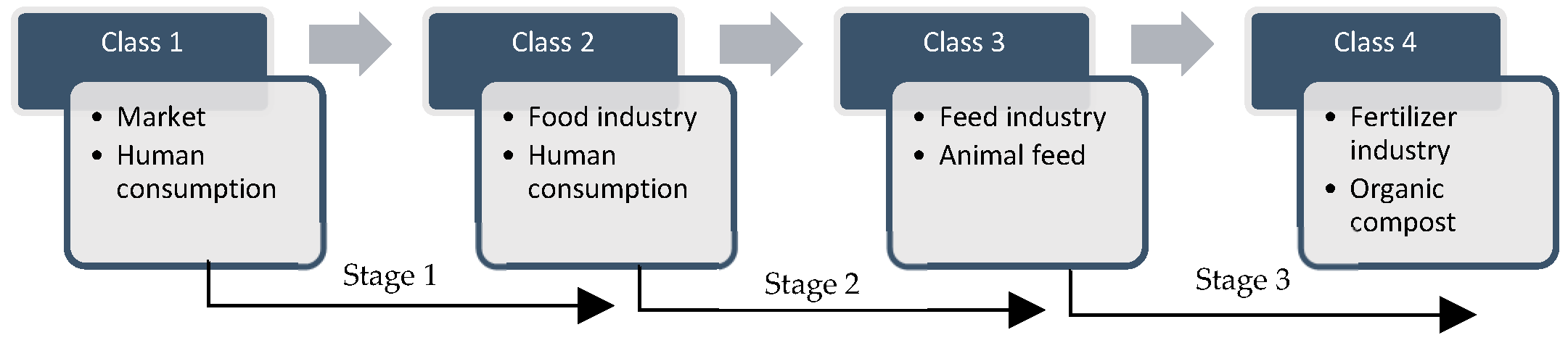

In our study, we proposed a conceptual framework for the banana supply-chain correct destination,

Figure 1.

Conceptual framework considerations in four classes and three stages are as a follows:

Class 1—products that attend quality standards accepted by the market (nutritional and appearance aspects). They must be destined for commercialization and human consumption.

Class 2—products that do not attend quality standards and present low value to the retailers and consumers but are suitable for human consumption (nutritional aspect). The food industry should process this banana in industrial products.

Class 3—products that do not attend quality standards and/or are not suitable for human consumption but are good for animal feed. They should be processed by the animal feeding industry.

Class 4—products that do not attend quality standards for human consumption or animal feed. They should be sent to the production of organic fertilizers.

Stage 1—banana that expires shelf life for being consumed in natural form.

Stage 2—banana that expires shelf life and is no longer suitable for human consumption.

Stage 3—banana that expires shelf life and is no longer ideal for animals’ feed.

A classification process integrated with the logistical flow of distribution is crucial to meet the specific requirements of perishable products and contribute to reducing losses [

3]. Yap et al. [

4] reported the use of rejected bananas for sale—as they do not have the size required by quality control—are used to produce puree in Australia. Rocha et al. [

7] corroborated this statement, indicating industrialization as an option for taking advantage of products with an appearance committed to consumption in the raw form.

Bananas are the most consumed fruits by Brazilians. The retailers’ lack of inspection and/or care for fruits with severe defects can cause health problems. In addition, unsold fruits become breakage and generate waste for retailers. In other words, the entire chain loses in an accounting of the lack of monitoring fruits alongside supply chains. An alternative to reduce losses in the fruit and vegetable sector is monitoring the fruits exposed for sale and adopting a daily removal of samples for classification. Soares et al. pointed out in their research that 74% of respondents in the study consume banana products from yogurt and ice cream to pasta and cakes [

10].

Another aspect is the adoption of quality management tools, but that requires time, investment, and training of employees. Companies in the food industry usually adopt management quality procedures as mandatory programs using sanitary surveillance and state inspection but do not adopt regular quality management programs [

7]. Some studies revealed that the lack of planning and management of transport operations affects the quality of food, especially fresh food that requires special care, such as applying the cold logistics chain [

2,

3,

12].

Banana is a product commercialized by retailers without any package. Among the 239 fingers evaluated, no labels are stating the origins of the products. In stands, they are sold by the unit, and in supermarkets, bananas are weighed and a barcode indicates the weight in kg and value to be paid. There is nothing related to quality and screening, which contradicts issues for transparency between the retailer and the consumer. Kondo establishes the importance of quality control and traceability generating credibility for the productive chain [

8]. Furthermore, the lack of control does not allow the selection of products for different uses, considering their quality, price differentiation, and reduction of marketing expenses.

Considering the 239 bananas fingers analyzed, 146 units (almost 61%) were incorrectly destinated. Rather than being available in markets, 43.5% should have gone to the fertilizer industry and 17.5% to the animal feed industry. Only 38% were within the standard considered suitable for human consumption in natural form. Additionally, 1% should have been sent to the food industry to be processed.

According to Soares et al., bananas can be the raw material to produce various dishes, such as yogurt, sweets, pasta, cakes, ice cream, flour, raisins, flakes, cereal bars, dehydrated, chips, puree, pies, etc. [

10]. This fact reinforces the need for a classification process for the correct destination reduction of food losses. The analysis in advance of the fruits and proper treatment would enable the production of more healthy foods and guarantee food safety.

The banana classification process permeates the production chain and requires a new behavior from everyone involved. However, it was evident that carrying out the classification among suppliers and retailers is not enough. It is necessary to monitor the bananas during the exhibition in supermarkets, grocery stores, and stands, ensuring food safety, and reducing food losses.

Despite the fact that this study is focused on the classification and destination of Cavendish bananas, the methodology can be adapted to the other kind of bananas or fruits.