Numerical Investigation of Fluid–Structure Interaction of Foreign Objects in Steam Generator Tube Bundles

Abstract

1. Introduction

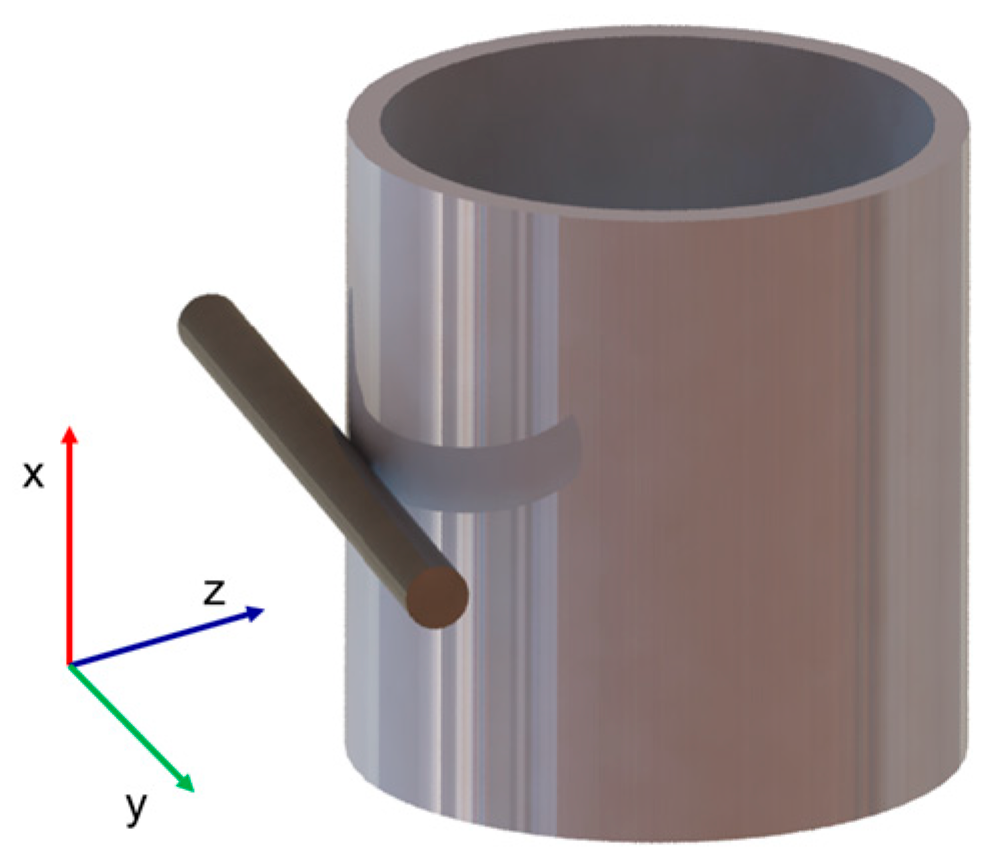

2. Development of the Fluid–Structure Interaction (FSI) Model for Foreign Objects

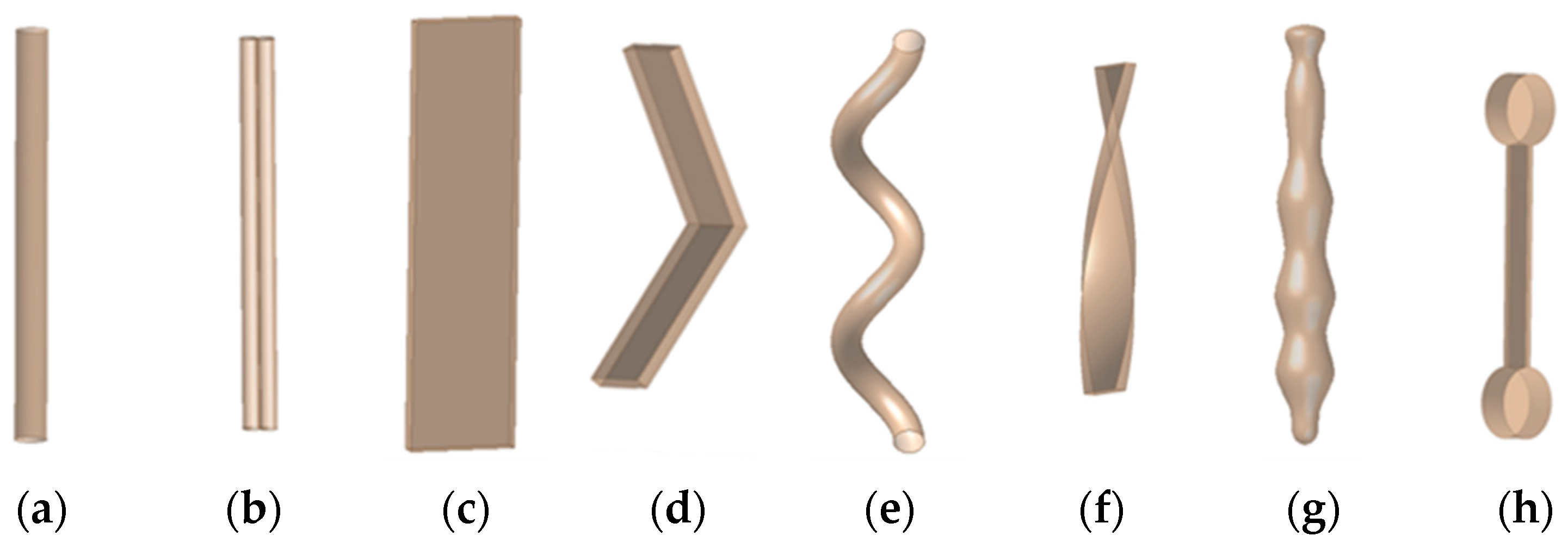

2.1. Simplification of the Foreign Object Structure

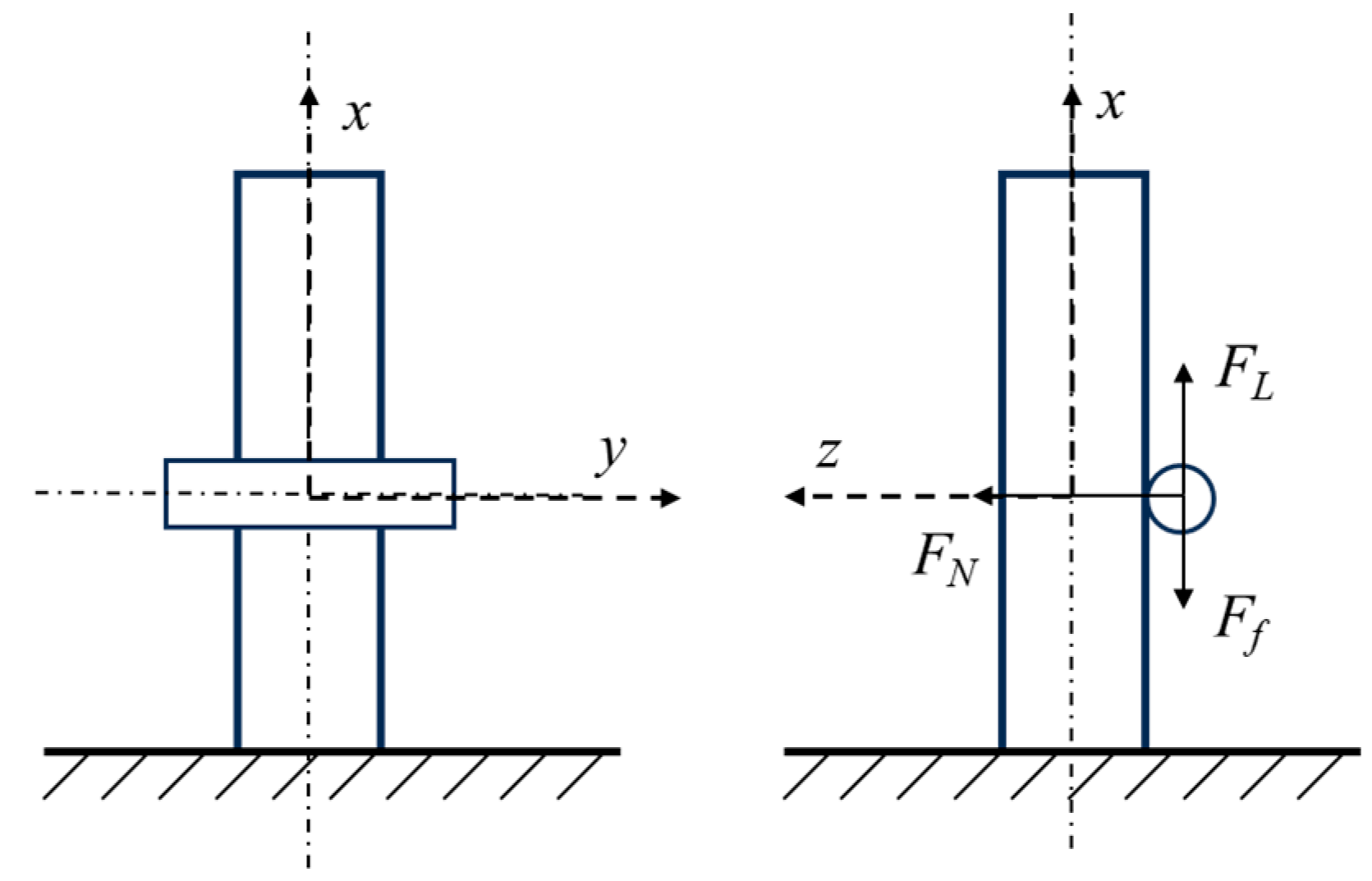

2.2. Dynamic Model of the Foreign Object

3. Numerical Model and Methodology

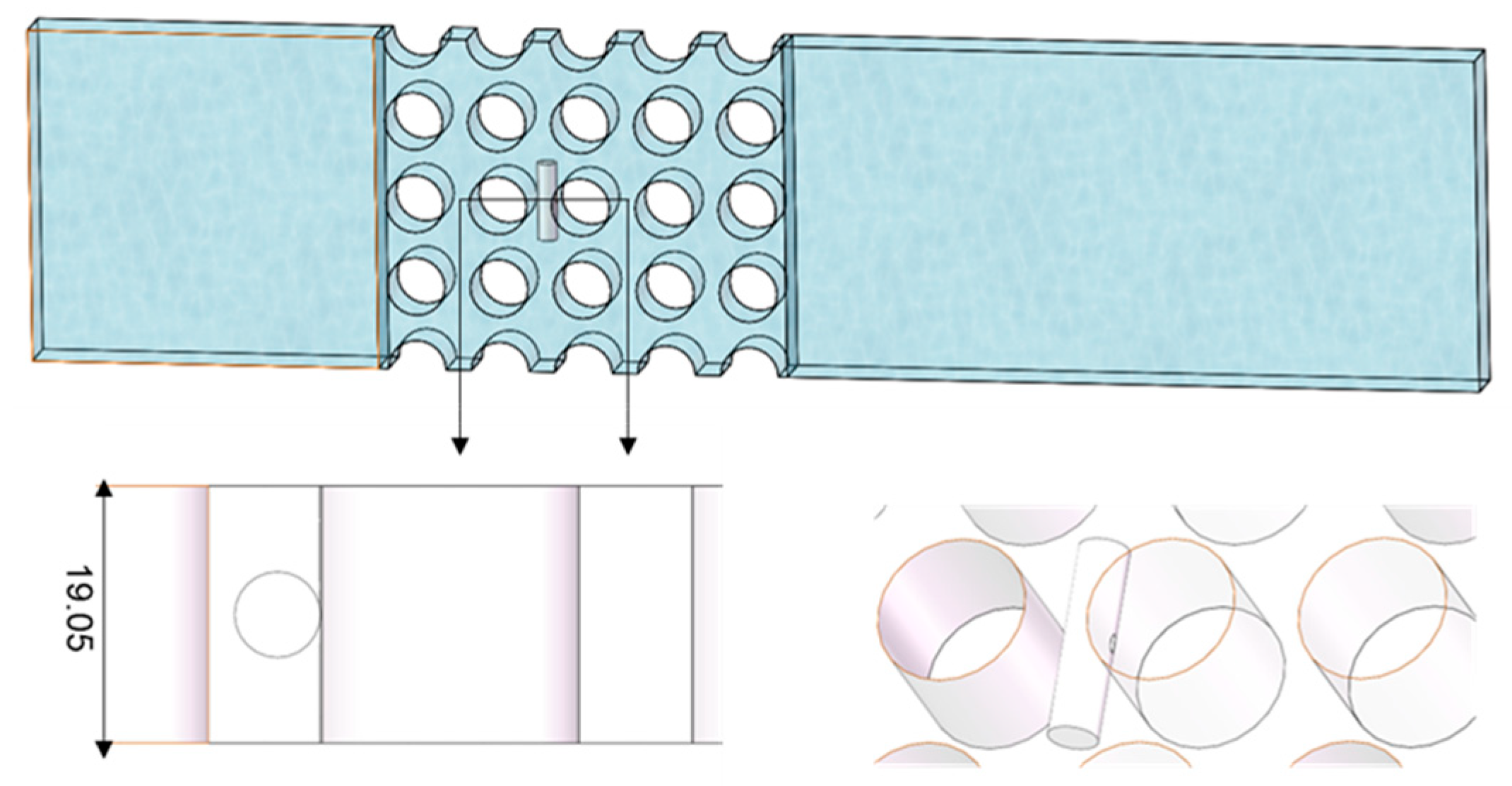

3.1. Establishment of the Foreign Object Model

3.2. Development of the Numerical Model

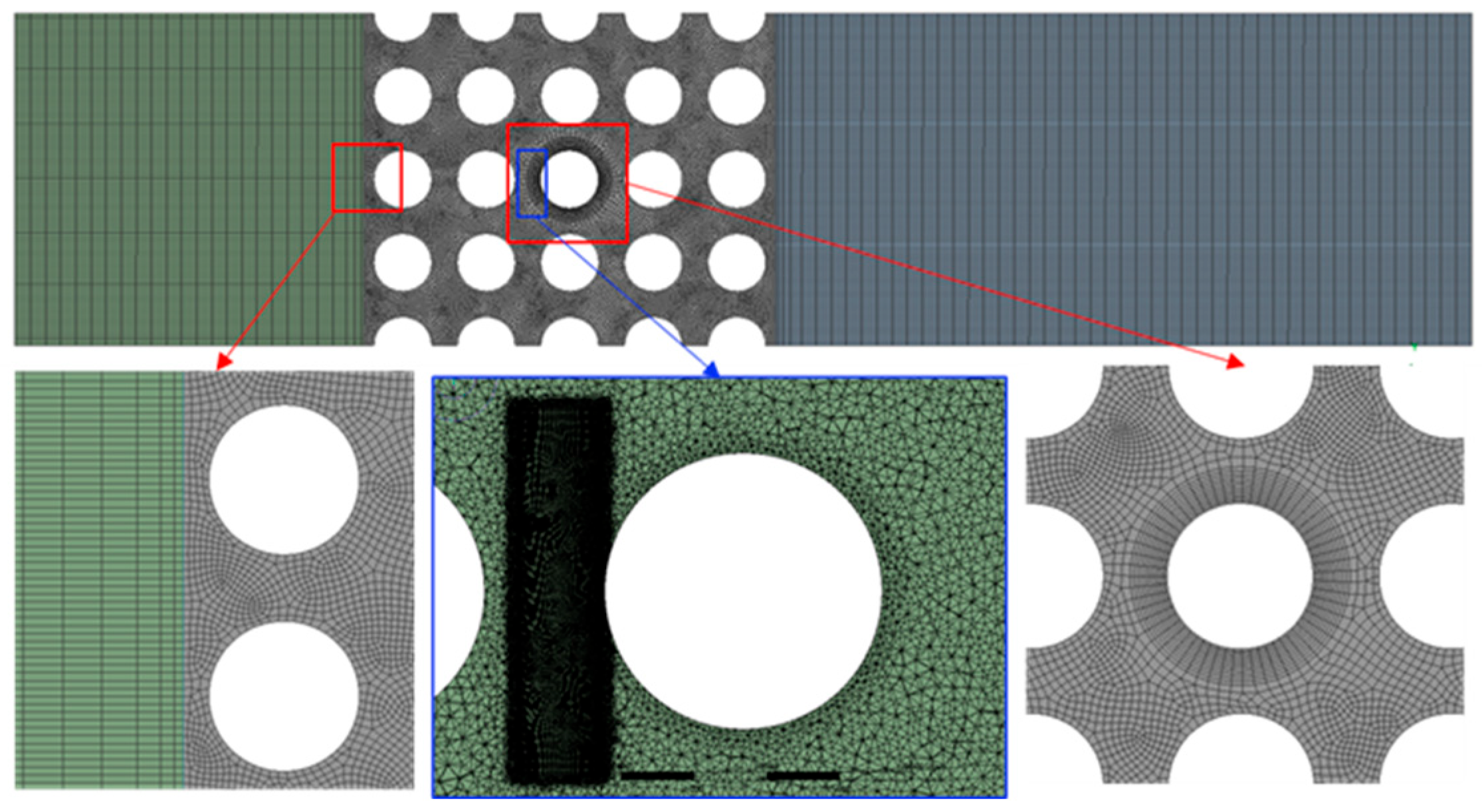

3.3. Grid Parameter Settings

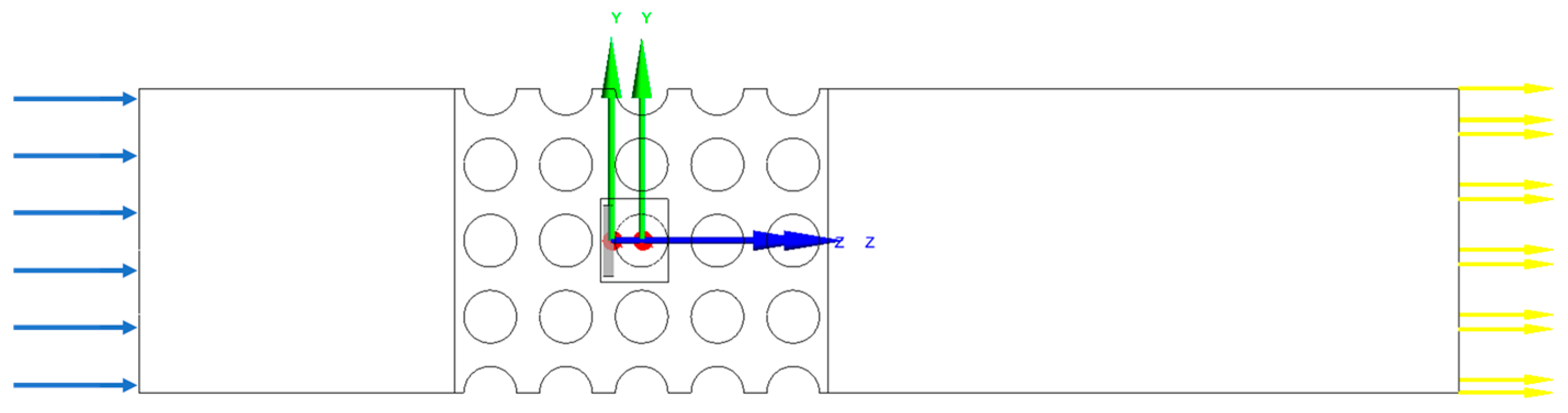

3.4. Simulation Boundary Condition

3.5. Feasibility Analysis of Numerical Simulation Method

4. The Impact of Foreign Object Shape on Secondary Side Wear in Steam Generators

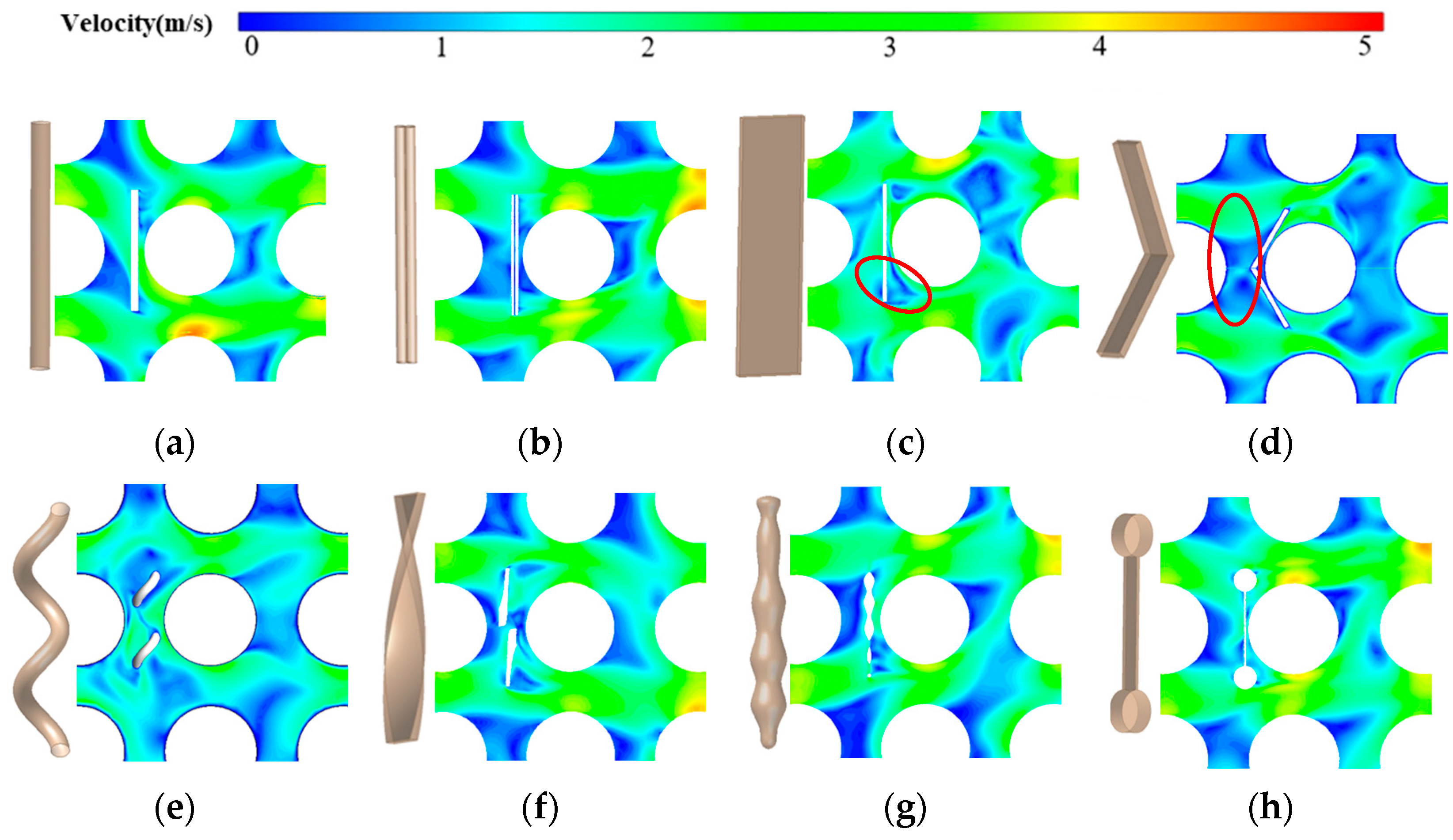

4.1. Flow Field Analysis

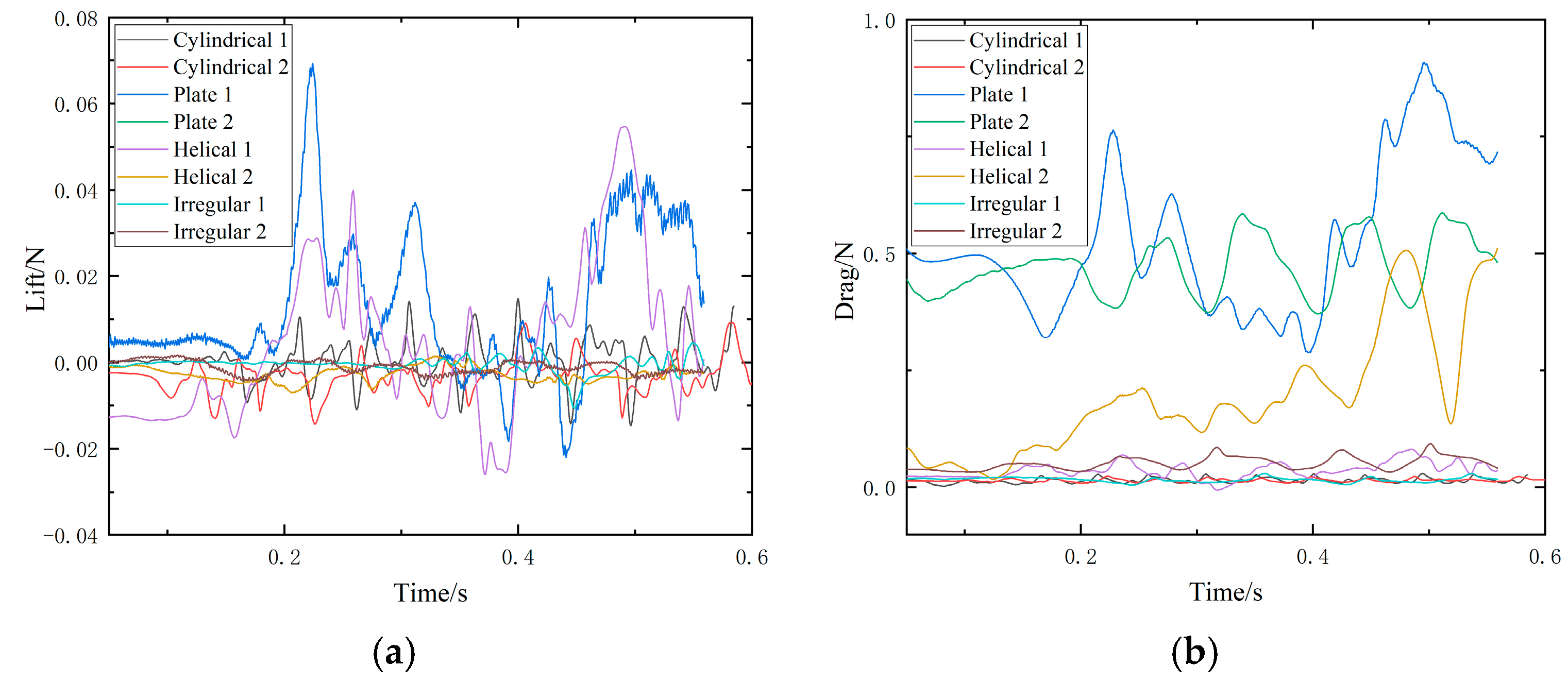

4.2. Lift Forces and Drag Forces Analysis

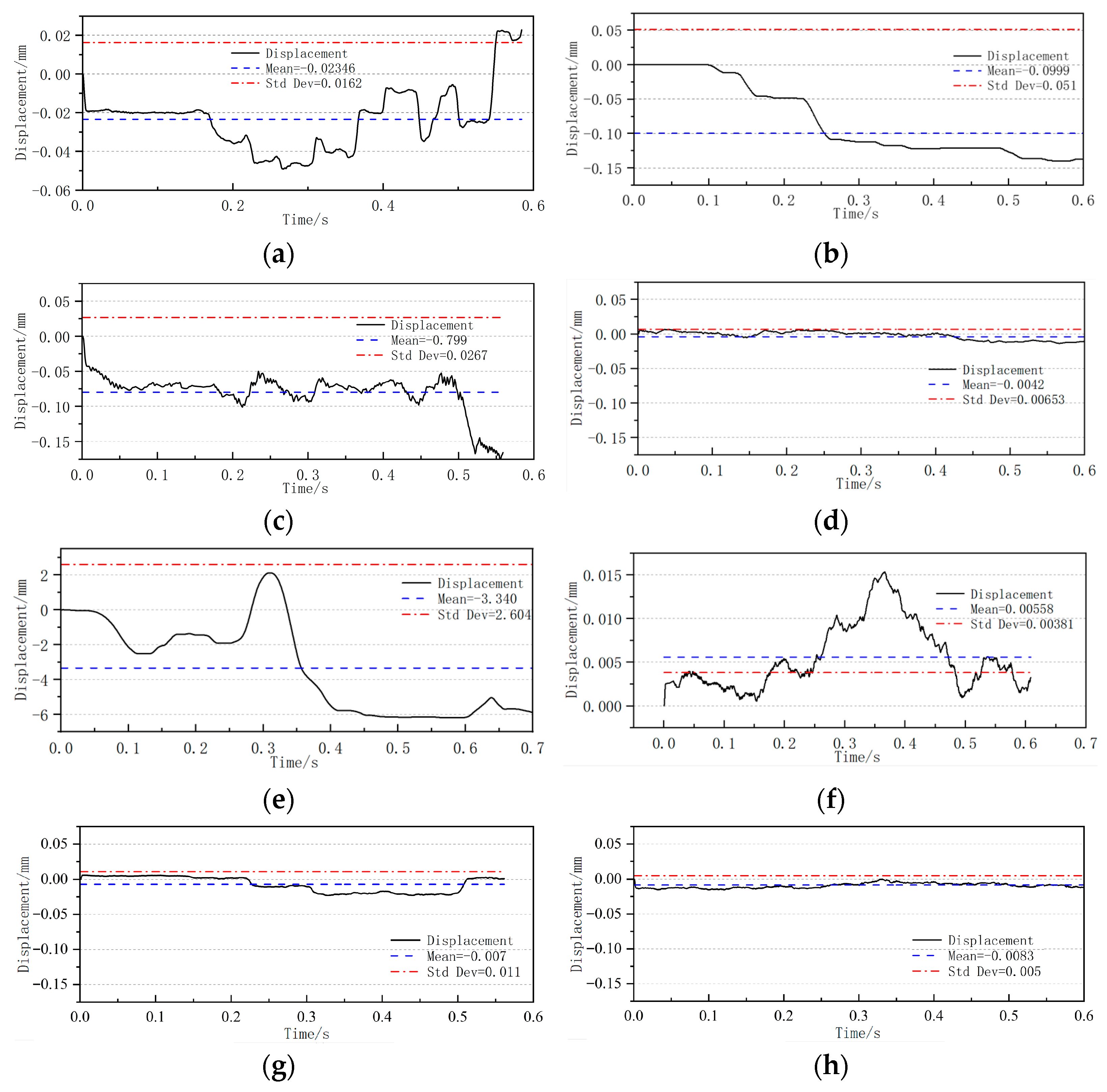

4.3. Displacement Analysis

5. Discussion on the Influence of Foreign Object Geometry on Flow-Induced Vibrations

6. Conclusions

- Validation of Numerical Methodology: A three-dimensional fluid–structure interaction (FSI) simulation framework, combining CFD with a single-degree-of-freedom rigid-body model, was established. Comparison with EPRI data demonstrates that the proposed approach reliably captures the unsteady flow forces and displacement responses of foreign objects, with deviations within acceptable limits.

- Impact of Object Geometry on Flow-Induced Forces: The shape of foreign objects significantly affects flow separation, vortex shedding, and force fluctuations. Cylindrical and irregular objects produce relatively stable and low-amplitude lift and drag forces, whereas plate-shaped objects exhibit higher drag fluctuations due to large projected areas and symmetric contact points. Helical objects generate complex, coupled axial–radial vortices, leading to the most pronounced force variations.

- Displacement Response Characteristics: Geometry governs vibration amplitude and patterns. Cylindrical and irregular objects maintain small, stable displacements; plate-shaped objects show constrained motion due to drag area and symmetric contacts; helical objects experience the largest oscillations, reflecting coupled translational and rotational motions induced by their complex geometry.

- Implications for Steam Generator Safety: The interplay between drag area, lift distribution, and geometric complexity is key to understanding secondary-side foreign object behavior. Symmetric or simple-shaped objects lead to predictable, low-risk vibrations, while complex geometries like helical shapes amplify coupled oscillations, increasing wear potential. These findings provide a valuable reference for assessing the dynamic behavior of foreign objects in steam generators.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hanbo, L.I.N.; Lichen, T.A.N.G.; Hao, Q.I.A.N.; Runluo, C.H.E.N.; Changxun, W.A.N.G.; Linjun, X.I.E. Fretting fatigue test and damage mechanism analysis of nuclear power 690 for alloy heat transfer tube. Tribology 2022, 42, 954–965. [Google Scholar]

- Wang, J.; Yang, C.; Zhang, L.; Meng, F.; Shi, X. Pitting corrosion resistance of alloy 690TT for steam generation heat exchanger tube. Corros. Prot. 2016, 37, 821–825. Available online: https://fsyfh.mat-test.com/cn/article/doi/10.11973/fsyfh-201610009 (accessed on 16 July 2024).

- Li, Z.H.; Lu, Y.H.; Hong, C.; Zhao, Y.G.; Zhang, W.D.; Shoji, T. Effects of foreign object damage on high-cycle fatigue behavior of Inconel Alloy 690TT steam generator tubes. Eng. Fract. Mech. 2023, 292, 109660. [Google Scholar] [CrossRef]

- Mu, D.; Rong, J.; Wang, M.; Tian, W.; Qiu, S.; Su, G. Investigating the Motion Characteristics of Complex-Shaped Foreign Objects on the Secondary Side of a Steam Generator Based on CFD-DEM Method. In International Conference on Nuclear Engineering; American Society of Mechanical Engineers: New York, NY, USA, 2024; Volume 88315, p. V011T15A056. [Google Scholar]

- Zhong, X.; Han, E.H.; Wu, X. Corrosion behavior of alloy 690 in aerated supercritical water. CorrosionScience 2013, 66, 369–379. [Google Scholar] [CrossRef]

- Zhang, Y.; Ming, H.; Tang, L.; Wang, J.; Qian, H.; Han, E.H. Effect of the frequency on fretting corrosion behavior between alloy 690TT tube and 405 stainless steel plate in high-temperature pressurized water. Tribol. Int. 2021, 164, 107229. [Google Scholar] [CrossRef]

- Zhongliang, M.A. Corrosion and protection mechanism of 690 alloy heat tube for steam generator. Mater. Prot. 2019, 52, 133–137. Available online: https://link.cnki.net/doi/10.16577/j.cnki.42-1215/tb.2019.06.024 (accessed on 16 July 2024). (In Chinese).

- Guo, X.; Lai, P.; Li, L.; Tang, L.; Zhang, L. Progress in studying the fretting wear/corrosion of nuclear steam generator tubes. Ann. Nucl. Energy 2020, 144, 107556. [Google Scholar] [CrossRef]

- Bian, W.W.; Hong, C.; Xin, L.; Kang, L.Z.; Han, Y.M.; Liu, H.; Shoi, T.; Lu, Y.H. Effect of the cycle number on fretting wear behavior of alloy 690TT tube in high-temperature pressurized water. J. Nucl. Mater. 2022, 567, 153828. [Google Scholar] [CrossRef]

- Yun, J.Y.; Park, M.C.; Shin, G.S.; Heo, J.H.; Kim, D.I.; Kim, S.J. Effects of amplitude and frequency on the wear mode change of Inconel 690 SG tube mated with SUS 409. Wear 2014, 313, 83–88. [Google Scholar] [CrossRef]

- Soria, S.R.; Tolley, A.; Yawny, A. Running condition and material response fretting maps of incoloy 800 steam generator tube sagainst AISI 304L pads in air and room temperature. Tribol. Int. 2019, 135, 408–420. [Google Scholar] [CrossRef]

- Mahey. Flow-Induced Vibrations of Foreign Objects Inside Steam Generator’s Tube Bundle. Ph.D. Thesis, University of Waterloo, Waterloo, ON, Canada, 2017.

- Kima; Choa. Predicted wear on the tube outside surface due to foreign object in the secondary side of steam generator. In Proceedings of the KNS Autumn Meeting, Kyoungju, Republic of Korea, 24–26 October 2012; p. 2. [Google Scholar]

- Mureithi; Cucuel; Saber-Cherif; Olala; Ashrafi. Characteristics of Turbulence and Drag Forces on Foreign Objects in Tube Arrays. In Pressure Vessels and Piping Conference; American Society of Mechanical Engineers: New York, NY, USA, 2016; Volume 50404, p. V004T04A018. [Google Scholar]

- Zhipeng, F.; Yixiong, Z.; Xuan, H.; Shuai, L.; Huanhuan, Q.; Fengchun, C. Fluid-structure Interaction Simulation and Data-driven Modeling of Tube Bundle Based on OpenFOAM. Nucl. Power Eng. 2022, 43, 158–164. [Google Scholar]

- Sun, J.; Sun, R.; Qiao, P.; Tan, S.; Tian, R. Numerical Study of Flow-induced Vibration in Square Tube Bundle Structures. At. Energy Sci. Technol. 2025, 59, 1044–1054. [Google Scholar]

- Ding, Z.; Bai, X.; Zhai, Y.; Yang, J.; Liu, D.; Yang, Y.; Tang, D. Numerical simulation research on the vibration of helical tube arrays under transverse flow. Energies 2022, 15, 9082. [Google Scholar] [CrossRef]

- EPRI. Steam Generator Management Program: Steam Generator Foreign Object Wear Estimation Model-Volume I: Fundamental Model and Simulation Results. 2017. Available online: https://www.epri.com/research/products/000000000001019039 (accessed on 16 July 2024).

- EPRI, Steam Generator Management Program: Foreign Object Prioritization Strategy for Triangular Pitch Steam Generators. 2010. Available online: https://www.epri.com/research/products/000000000001020989 (accessed on 30 July 2024).

- Bernard, J.E. The simulation of Coulomb friction in mechanical systems. Simul. Trans. Soc. Model. Simul. Int. 1980, 34, 11–16. [Google Scholar] [CrossRef]

- Pennestrì, E.; Rossi, V.; Salvini, P.; Valentini, P.P. Review and comparison of dry friction force models. Nonlinear Dyn. 2016, 83, 1785–1801. [Google Scholar] [CrossRef]

- Rathee, R. Numerical modeling and simulation of friction models for mechanical systems: A brief review. Mater. Today: Proc. 2023. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, J.; Zhao, Q.; Tian, F.; Peng, W.; Xia, P. Migration and Distribution of Objects in Steam Generators Secondary Side at Pressurized Water Reactor Nuclear Power Plants. Energy Res. Manag. 2025, 17, 17-22+189. Available online: https://link.cnki.net/doi/10.16056/j.2096-7705.2025.03.003 (accessed on 16 July 2024). (In Chinese).

- Hao, W.U.; Wei, T.A.N.; Qing-de, N. A numerical model for fluid-elastic instability of a square tube array. J. Vib. Shock 2013, 32, 102–106. [Google Scholar]

- Rodriguez, A.; Adansi, R.; Enriquez, A.; Habib, N.; Olvera, G.; Love, N.; Kumar, V. Reynolds Numbers: The K-epsilon (k-e) Turbulence Model vs. Laminar Model for Flow Over a Circular Cylinder. Preprint 2021, 3–22. [Google Scholar] [CrossRef]

- Wilcox, D.C. Turbulence Modeling for CFD; DCW Industries Inc.: La Canada, CA, USA, 2006. [Google Scholar]

| Parameters | Numerical Values |

|---|---|

| tube diameter (mm) | 19.05 |

| pitch-to-diameter Ratio | 1.44 |

| arrangement | Square arrangements |

| span (mm) | 900 |

| wall thickness (mm) | 1.09 |

| unit mass (kg) | 0.72 |

| material | Alloy 690 |

| density (kg/m3) | 8140 |

| Poisson’s ratio | 0.289 |

| elastic modulus (GPa) | 211 |

| Parameters | Numerical Values |

|---|---|

| diameter (mm) | 2 |

| Length (mm) | 25.4 |

| shape | cylindrical, square, helical, irregular |

| position | 0.1 mm in front of the heat transfer tube |

| material | Alloy 690 |

| friction coefficient | 0.3 |

| density (kg/m3) | 8140 |

| Grid Size (mm) | Number of Mesh | Mean Drag Force (N) | Percentage Difference (%) |

|---|---|---|---|

| 0.05 | 11,621,602 | 0.199 | — |

| 0.1 | 6,893,215 | 0.201 | 1.00 |

| 0.3 | 5,630,854 | 0.195 | 2.01 |

| 0.5 | 4,539,351 | 0.191 | 4.02 |

| 1.0 | 1,429,034 | 0.216 | 8.54 |

| Parameters | Setting |

|---|---|

| Analysis Type | Transient Analysis |

| Analysis Duration | 0.6 s |

| Time Step | 0.0005 s |

| Inlet Condition | Uniform inflow |

| Outlet Condition | Zero-pressure outlet |

| Turbulence Model | k–ε model |

| Wall Function | Scalable wall function |

| Convergence Control | Minimum coefficient loops: 1; Maximum coefficient loops: 20 |

| Residuals | 1 × 10−4 |

| Inlet Velocity | 1 m/s |

| Fluid Material | Liquid water (998 kg/m3) |

| Case | EPRI | Present Simulation | Percentage Difference (%) |

|---|---|---|---|

| Mean Lift (N) | 3.5 × 10−2 | 3.7 × 10−2 | −5.71% |

| Mean Drag (N) | 7.0 × 10−2 | 6.5 × 10−2 | 7.14% |

| Std Dev Lift (N) | 5.7 × 10−2 | 5.6 × 10−2 | 1.75% |

| Std Dev Drag (N) | 3.5 × 10−2 | 3.6 × 10−2 | −2.86% |

| Displacement (mm) | 7.9 | 6.59 | 16.58% |

| Shape | Std Dev Lift (×10−3 N) | Std Dev Drag (×10−3 N) |

|---|---|---|

| Cylindrical 1 | 0.33 | 14.8 |

| Cylindrical 2 | 3.75 | 3.65 |

| Plate 1 | 16.4 | 161 |

| Plate 2 | 1.89 | 94.3 |

| Helical 1 | 14.70 | 17.8 |

| Helical 2 | 19.70 | 23.6 |

| Irregular 1 | 2.42 | 5.89 |

| Irregular 2 | 1.32 | 18 |

| Shape | Std Dev Displacement (×10−2 mm) | Mean Displacement (×10−2 mm) |

|---|---|---|

| Cylindrical 1 | 1.62 | 2.35 |

| Cylindrical 2 | 5.1 | 100 |

| Plate 1 | 2.67 | 80 |

| Plate 2 | 0.653 | 0.42 |

| Helical 1 | 260 | 334 |

| Helical 2 | 0.381 | 0.558 |

| Irregular 1 | 1.1 | 0.7 |

| Irregular 2 | 0.5 | 0.83 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hang, Y.; Wang, H.; Liu, Y.; Cai, Z.; Zhu, B.; Mei, J.; Zhu, G. Numerical Investigation of Fluid–Structure Interaction of Foreign Objects in Steam Generator Tube Bundles. J. Nucl. Eng. 2025, 6, 47. https://doi.org/10.3390/jne6040047

Hang Y, Wang H, Liu Y, Cai Z, Zhu B, Mei J, Zhu G. Numerical Investigation of Fluid–Structure Interaction of Foreign Objects in Steam Generator Tube Bundles. Journal of Nuclear Engineering. 2025; 6(4):47. https://doi.org/10.3390/jne6040047

Chicago/Turabian StyleHang, Yuhua, Heng Wang, Yuanqing Liu, Zhen Cai, Bin Zhu, Jinna Mei, and Guoru Zhu. 2025. "Numerical Investigation of Fluid–Structure Interaction of Foreign Objects in Steam Generator Tube Bundles" Journal of Nuclear Engineering 6, no. 4: 47. https://doi.org/10.3390/jne6040047

APA StyleHang, Y., Wang, H., Liu, Y., Cai, Z., Zhu, B., Mei, J., & Zhu, G. (2025). Numerical Investigation of Fluid–Structure Interaction of Foreign Objects in Steam Generator Tube Bundles. Journal of Nuclear Engineering, 6(4), 47. https://doi.org/10.3390/jne6040047