1. Introduction

Nuclear energy is a critical component of the future global energy mix due to its ability to produce large amounts of reliable, low-carbon electricity. As the world seeks to combat climate change and reduce greenhouse gas emissions, nuclear power offers a sustainable alternative to fossil fuels, emitting nearly zero carbon dioxide during operation [

1]. Unlike solar and wind, nuclear energy provides a stable baseload supply, ensuring grid reliability even when renewable sources are intermittent [

2]. Moreover, advancements in nuclear technology, such as small modular reactors (SMRs), promise safer, more efficient, and scalable energy solutions [

3]. Given these factors, nuclear energy is poised to play a vital role in achieving global decarbonisation goals and ensuring long-term energy security.

While nuclear energy offers significant benefits, its expansion raises serious concerns about proliferation and security. Civilian nuclear programmes involve dual-use technologies-such as enrichment and reprocessing—that can be diverted for weapons production [

4]. Widespread access to reactors also elevates risks related to sabotage and theft: both power and research reactors house radioactive fuel that could be stolen, tampered with, or destroyed to create “dirty bombs” or cause radiological disasters [

5]. Research reactors, in particular, have been identified as vulnerable targets due to often lax physical protection standards and potentially accessible spent fuel [

6]. Compounding these material risks, attacks like Stuxnet demonstrate that cyber-physical hacks can covertly disrupt reactor operations without overt intrusion, enabling sabotage while bypassing traditional safeguards [

7]. These technical and operational vulnerabilities require robust international security measures—from fortified physical infrastructure and strict personnel vetting to advanced cyber-defence systems—to prevent misuse and reduce proliferation threats.

A different approach of obtaining a nuclear weapon is through utilisation of production piles or dedicatedly designed nuclear reactors, such as the Hanford B reactor in the USA, the Magnox reactors in the UK, and Mayak in Russia/USSR. These reactors were typically graphite-moderated and air- or water-cooled, optimised to operate at low burnup levels to minimise the formation of higher isotopes such as Pu-240, which reduce the weapon-grade quality of the plutonium [

8]. By frequently removing fuel before it remained in the core for extended periods, production piles could yield plutonium with a high Pu-239 content-typically above 93%, which is classified as weapons-grade [

9]. This level of purity is crucial for reliable and efficient nuclear explosive design, as higher concentrations of Pu-240 increase the risk of pre-detonation due to its higher spontaneous fission rate.

On the other hand, plutonium produced in a typical Light Water Reactor (LWR), including Pressurised Water Reactors (PWRs), differs significantly from that generated in a production pile. LWRs operate at high fuel burnup levels to maximise energy output, resulting in plutonium that contains a mix of isotopes: Pu-239, Pu-240, Pu-241, and Pu-242. This so-called reactor-grade plutonium contains only about 55–70% Pu-239, making it less suitable for nuclear weapons without further isotopic separation [

10]. In addition, with introduction of high burnup in civilian reactors is essential for fuel economy and energy efficiency but directly contributes to the degraded isotopic quality of plutonium. Moreover, handling reactor-grade plutonium for weapons use presents serious technical challenges due to its greater radioactivity and heat output, complicating weapon design and posing significant safety risks [

11]. These characteristics serve as natural proliferation barriers, making spent fuel from commercial power reactors unattractive for direct weaponisation without complex isotopic separation processes. Consequently, the fuel cycle practices of civilian nuclear power systems inherently support non-proliferation objectives by producing plutonium that is technically inferior for use in nuclear explosives [

12].

While civilian nuclear power reactors are not designed to produce weapons-grade plutonium, it is theoretically possible to adapt their operation for that purpose under specific, deliberate conditions. The key requirement is to irradiate uranium fuel for only a short period—known as low burnup—allowing the accumulation of plutonium-239 (Pu-239) while minimising the formation of plutonium-240 (Pu-240) and other higher isotopes. To achieve this, the reactor would need to use fresh low-enriched uranium (LEU) fuel and discharge it after only a few weeks or months of irradiation, well before the normal energy extraction cycle is complete [

13]. This approach could yield plutonium with a Pu-239 content exceeding 90%, approaching weapons-grade quality. However, such early fuel removal is highly inefficient, economically costly, and easily detectable due to deviations from standard reactor operation and safeguard expectations [

14].

Furthermore, modern power reactors also lack the design features of historical plutonium production reactors, such as online refuelling capabilities and neutron flux profiles optimised for short irradiation. To use a civilian reactor for covert plutonium production would therefore require significant operational subversion, including the concealment of unusual fuel handling schedules, masking of reactor power histories, and circumvention of International Atomic Energy Agency (IAEA) safeguards [

15]. These deviations would likely raise red flags in routine inspections, as commercial reactors are subject to continuous monitoring, surveillance, and material accounting measures. Furthermore, the intense heat and radiation from freshly irradiated fuel complicate covert handling and reprocessing, requiring shielded facilities and trained personnel [

16]. In this context, while the physics of weapons-grade plutonium production in a power reactor are feasible, the practical, technical, and political barriers make such misuse highly detectable and risky under existing safeguards frameworks. However, given the fact that the non-proliferation treaty [

17] has its limitations, a better solution should be found to ensure that even if a sufficient quantity of fresh fuel is accumulated by a country, it will not be able to use it for military purposes.

This paper is focusing on the outcomes of a research project that was carried out in the last two years at Bangor and Derby University focusing on the potential of non-proliferation of various reactor technologies. The paper serves as the final point to this project bringing all the findings and considering the economic and social aspects associated with the non-proliferation of the nuclear fuel cycle.

2. Approach and Method

The origins of modern nuclear non-proliferation requirements can be traced back to the immediate aftermath of World War II, as the destructive potential of nuclear weapons became starkly evident following the bombings of Hiroshima and Nagasaki. The early Cold War period saw rising concerns among world powers regarding the spread of nuclear technology and expertise beyond the original nuclear-armed states. The Baruch Plan (1946), introduced by the United States at the United Nations, represented one of the earliest attempts to establish an international framework for the control of atomic energy. Although ultimately unsuccessful due to geopolitical tensions and distrust between the U.S. and the Soviet Union, it laid conceptual groundwork for future non-proliferation norms by proposing international ownership of fissile material and inspections of nuclear facilities [

17].

A pivotal moment in the formalisation of non-proliferation goals came with President Dwight D. Eisenhower’s Atoms for Peace speech to the United Nations General Assembly in 1953. Eisenhower’s vision was to redirect the destructive capacity of nuclear energy toward peaceful uses, particularly in power generation, medicine, and agriculture. This initiative led to the establishment of the International Atomic Energy Agency (IAEA) in 1957, which was tasked with promoting peaceful nuclear technology while simultaneously implementing safeguards to prevent its diversion for military purposes [

18]. However, Atoms for Peace also had unintended proliferation consequences: by facilitating the global distribution of nuclear materials, research reactors, and technical knowledge, it created dual-use vulnerabilities that continue to challenge the non-proliferation regime [

19]. Literature on this period underscores the paradox of Eisenhower’s policy-simultaneously enabling civilian nuclear development while attempting to prevent its militarisation. This tension shaped the architecture of non-proliferation treaties and safeguards that would follow, particularly the Treaty on the Non-Proliferation of Nuclear Weapons (NPT), which entered into force in 1970 [

20].

Since the launch of the Atoms for Peace initiative and the establishment of the International Atomic Energy Agency (IAEA) in 1957, safeguards have evolved significantly to address the growing complexity of the nuclear landscape. Initially, IAEA safeguards focused narrowly on verifying the use of nuclear materials and facilities supplied under bilateral or multilateral agreements, primarily for peaceful purposes [

21]. However, the entry into force of the Treaty on the Non-Proliferation of Nuclear Weapons (NPT) in 1970 expanded the Agency’s mandate, requiring non-nuclear-weapon states to conclude comprehensive safeguards agreements (INFCIRC/153-type) covering all nuclear material within their territory [

22]. Over time, the safeguards system has developed to encompass not just reactor sites and spent fuel storage, but also upstream stages of the fuel cycle—including uranium conversion, enrichment, and fuel fabrication facilities. The IAEA verifies declared inventories and production outputs through material accountancy, regular on-site inspections, and surveillance technologies such as seals, cameras, and flow monitors, enabling it to track nuclear material from source to reactor loading. The Agency also employs nuclear material balance evaluations to detect potential losses or diversions. Following revelations of undeclared nuclear activities in the 1990s, particularly in Iraq, the IAEA introduced the Additional Protocol in 1997, which granted expanded rights of access to information, locations, and environmental sampling to detect clandestine activities [

23]. Today, this integrated safeguards approach combines traditional verification with satellite imagery, remote monitoring, and data analytics. While enforcement remains dependent on state cooperation, the IAEA has become a central actor in the global non-proliferation regime, tasked with ensuring that nuclear energy remains solely in the service of peaceful development.

Despite significant advancements in verification tools and legal instruments, the IAEA safeguards system continues to face substantial challenges in preventing nuclear proliferation. One of the primary limitations lies in the system’s reliance on state declarations and voluntary cooperation. While the IAEA can verify declared materials and activities, it cannot compel access to undeclared sites unless the state has adopted the Additional Protocol, which remains optional and is not universally in force [

24]. Some key states, including those with advanced nuclear infrastructure, have yet to implement the protocol, weakening the IAEA’s ability to detect clandestine programmes. Furthermore, the timeliness and accuracy of nuclear material accountancy can be constrained by limited inspector access, the use of complex fuel cycles, or the presence of direct-use materials such as highly enriched uranium or separated plutonium [

25]. Technological challenges also persist: novel reactor types, such as molten salt or fast breeder reactors, pose new verification difficulties due to their continuous fuel processing and limited physical access points [

26]. Additionally, the growing risk of cyber intrusions and data manipulation threatens the integrity of digital monitoring systems, while geopolitical pressures can inhibit the Agency’s authority in politically sensitive cases. These challenges underscore the need for continued investment in safeguards innovation, greater legal standardisation, particularly universalising the Additional Protocol, and stronger political backing to ensure that verification mechanisms can keep pace with evolving nuclear technologies and global security dynamics.

One promising technical solution to enhance the proliferation resistance of civilian nuclear fuel cycles involves intentionally doping fresh reactor fuel with minor actinides, such as americium-241 (Am-241) or neptunium-237 (Np-237). When irradiated in a reactor, these isotopes contribute to the formation of plutonium-238 (Pu-238), a highly radioactive and heat-generating isotope that significantly complicates the weaponisation of plutonium. Pu-238 has a high spontaneous heat output (approximately 560 watts/kg), which makes the thermal management of a weapon core extremely difficult and increases the risk of pre-detonation or structural failure in a nuclear explosive device [

12]. While Pu-241 naturally contributes to proliferation resistance through its decay to Am-241, its presence in spent fuel is incidental and dependent on burnup history. In contrast, deliberately increasing Pu-238 concentrations through actinide doping represents a purposeful design strategy to degrade plutonium’s isotopic suitability for weapons use. Researchers have argued that such isotopic engineering could serve as a technical barrier to complement traditional safeguards, especially in advanced reactor systems and MOX-fuelled cores [

27,

28]. Studies by Y. Ronen have further demonstrated that doping low-enriched uranium (LEU) fuel with small percentages of Am-241 or Np-237 in both thermal and fast reactors can increase the Pu-238 content to levels that effectively render the plutonium unusable for weapons (above 6% of total plutonium produced), even if the fuel is discharged prematurely [

29,

30,

31,

32]. Recently, a similar analysis was carried out in the context of micro-reactors [

33] focusing on the Np-237 doping as a means for fuel cycle proliferation. This approach also supports minor actinide transmutation, reducing long-term radiotoxicity and contributing to more sustainable waste management. While technical challenges remain, particularly in fuel fabrication and safety analysis, this method represents a robust, intrinsic proliferation resistance strategy embedded within the fuel itself.

Building on this strategy of intrinsic proliferation resistance through isotopic engineering, several advanced fuel cycle concepts have been evaluated for their potential to incorporate such features while also addressing broader non-proliferation and waste management objectives [

28].

Table 1 summarises key characteristics of selected fuel cycle options, including their technical approach, proliferation resistance attributes, and implementation challenges. The various options are as follows:

PUREX/MOX: Plutonium URanium EXtraction with Mixed Oxide fuel, a conventional reprocessing method that separates pure plutonium for reuse.

UREX/MOX: Uranium EXtraction process that avoids pure plutonium separation by keeping it mixed with other actinides, thereby enhancing proliferation resistance.

DUPIC: Direct Use of spent PWR fuel In CANDU reactors, a dry process that reuses spent fuel without chemical separation.

IMF: Inert Matrix Fuel, a non-fertile fuel form designed to burn plutonium without generating new fissile material.

UREX + Np/Am Doping: UREX-based fuel doped with neptunium (Np) and/or americium (Am) to degrade plutonium isotopics and increase radiation barriers.

These options reflect a spectrum of technical maturity and proliferation resistance strategies, from conventional reprocessing to innovative fuel design.

Table 2 provides numerical indications of how well a fuel cycle option will perform in terms of time-integrated proliferation resistance (a 100-year measure). However, based on the expertise gained in the field, there is only one method that ensures the nuclear fuel cycle remains proliferation-resistant throughout all its stages, from fresh to spent fuel, as shown in the decision matrix presented in

Figure 1. The method that most directly addresses non-proliferation of fresh fuel, that is, preventing the misuse or diversion of fuel before it is irradiated in a reactor, is the neptunium and americium doping.

Past studies have explored the use of minor actinide doping to enhance the proliferation resistance of light water reactor (LWR) fuel, with a particular focus on Am-241 and Np-237. While both isotopes contribute to the in situ generation of Pu-238, a heat-generating isotope that complicates weaponisation, Am-241 offers several distinct advantages. Compared to Np-237, Am-241 exhibits significantly higher decay heat (~110 W/kg) and spontaneous fission rates, which enhance the detectability of fresh fuel and render it unsuitable for use in gun-type nuclear devices. Moreover, Am-241 acts as an effective burnable poison, enabling substantial reductions in conventional reactivity control materials without compromising fuel cycle length. In contrast, Np-237 is chemically separable, potentially weapons-usable, and contributes less to reactivity suppression. Simulation results indicate that a small admixture of Am-241 (e.g., 0.12 wt%) can elevate the Pu-238 content above the 6% of total plutonium threshold considered proliferation-resistant, with minimal impact on reactor performance. Thus, Am-241 presents a more favourable option for intrinsic proliferation resistance, combining isotopic denaturing with operational benefits in thermal reactor cores [

29,

30].

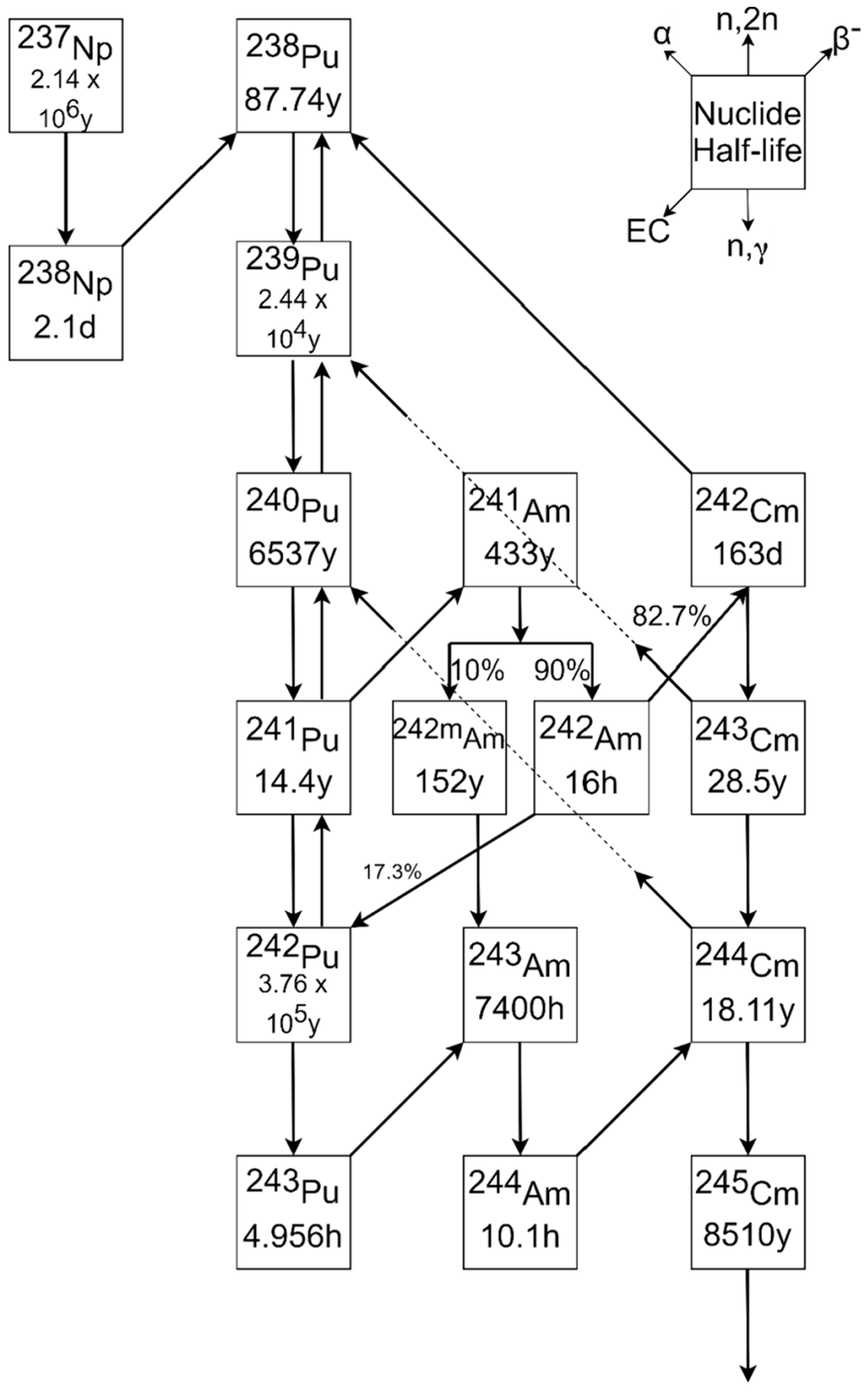

In both cases, that of Np-237 and Am-241, the increase in Pu-238 content resulting from actinide doping arises from specific transmutation pathways during reactor operation. When Am-241 absorbs a neutron, it forms Am-242, which rapidly decays to Cm-242. Cm-242 then undergoes alpha decay with a half-life of approximately 162 days to produce Pu-238. Similarly, Np-237 can capture a neutron to form Np-238, which beta decays to Pu-238. These pathways are illustrated in

Figure 2 and represent the key mechanisms by which doping with minor actinides leads to elevated Pu-238 concentrations in spent fuel.

In light of the statements above, a research programme established at Bangor University and the UK Atomic Energy Authority investigated the utilisation of Am-241 doping in various reactor types [

34,

35,

36,

37]. Unlike previous studies conducted by Ronen et al. [

29,

30,

31,

32], which focused on the unit cell level, the current programme on Potentials in “Nonproliferating” Nuclear Fuel focuses on the system level, modelling the fuel cycle as closely as possible to the industrial standard.

2.1. Computational Methods

The programme utilised two sets of software packages to analyse the various systems. The first is the CASMO4E/SIMULATE5 suite, one of the most widely used reactor physics code systems for nuclear core design, fuel cycle analysis, and operational optimisation of light water reactors (LWRs). Developed originally by Studsvik (now part of Westinghouse Electric Company, Cranberry Township, Pennsylvania, United States), CASMO4E is a multi-group, two-dimensional lattice physics code that performs detailed spectral and spatial neutron transport calculations for individual fuel assemblies. It generates homogenised few-group cross-sections that account for isotopic depletion, temperature feedback, burnable absorbers, and control rod insertion effects. These cross-sections are then supplied to SIMULATE5, a three-dimensional core simulator that models full reactor cores over time to predict power distributions, reactivity margins, and fuel burnup evolution with high accuracy [

38]. The CASMO4E/SIMULATE5 suite was utilised in the PWR and BWR analysis in the programme, as the suite is one of the industry-accepted standard codes.

The second is the Serpent Monte Carlo code, which was used to analyse the advanced nuclear system involved in the programme. The Serpent code is a continuous-energy Monte Carlo reactor physics tool developed at the VTT Technical Research Centre of Finland. Designed initially for high-fidelity spatial and spectral modelling of research reactors and small cores, it has since evolved into a versatile platform used for a broad range of nuclear engineering applications. Serpent solves the neutron transport equation using stochastic methods, tracking individual neutrons through three-dimensional geometries with continuous-energy cross-section data. Unlike deterministic codes, which rely on spatial homogenisation and multigroup energy discretisation, Serpent offers very high accuracy by explicitly treating geometrical and material heterogeneities without approximation [

39]. Serpent was utilised for the analysis of the molten salt reactor in this research programme due to its extensive capabilities and validation for those advanced systems.

2.2. Past Analysis

Previous studies have focused on the analysis of several thermal nuclear systems at the unit cell or assembly level, including a Pressurised Water Reactor (PWR) assembly [

29], CANada Deuterium Uranium (CANDU) [

31], and the Pebble Bed Modular Reactor (PBMR) [

32], where the main parameters are summarised in

Table 3. In those studies, the investigation was focused on the impact of Am-241 or Np-237 on the production of Pu-238 throughout the burnup process. The main findings are summarised in

Table 4. The analyses conducted on CANDU, PBMR, and PWR systems consistently demonstrate that doping nuclear fuel with minor actinides, particularly Am-241, is an effective strategy for enhancing proliferation resistance by increasing the ratio of

238Pu to total plutonium (hereafter referred as

238Pu/TotPu).

238Pu/TotPu in spent fuel beyond the 6% threshold. This isotopic shift significantly complicates the use of plutonium for weapons purposes due to increased decay heat and spontaneous fission rates. Across all systems, Am-241 was found to be more favourable than Np-237, requiring lower concentrations to achieve the same effect and offering additional benefits such as burnable poison functionality in PWRs. However, the integration of these dopants introduces system-specific trade-offs. In CANDU reactors, fuel enrichment must be increased to maintain burnup performance; in contrast, the fuel cycle in PBMRs is shortened by up to 40 full-power days. In PWRs, Am-241 enables a reduction in conventional burnable absorbers with minimal impact on fuel cycle length or safety coefficients. These findings underscore the importance of tailoring actinide-doping strategies to the geometry, fuel management, and operational characteristics of each reactor type, thereby balancing non-proliferation goals with reactor performance.

2.3. Systems Chosen for the Current Analysis

This project investigates the potential of enhancing the proliferation resistance of nuclear fuel by doping it with Am-241, building on prior findings that highlight its effectiveness in increasing the Pu-238 content in spent fuel. Plutonium with a high fraction of Pu-238 is considered unsuitable for weapons use due to its intense heat and radiation, and the proposed method aims to maintain this isotopic composition throughout the fuel cycle. The research focuses on evaluating the impact of Am-241 doping on the performance and safety of various thermal reactor technologies using advanced neutronic and thermal-hydraulic simulations on the full core scale. Additionally, the study considers the practical aspects of sourcing and incorporating Am-241 into fuel fabrication, emphasising its dual role in improving proliferation resistance and aiding reactivity control. If successful, this approach could facilitate the global expansion of nuclear energy by enabling safer fuel deployment in regions with heightened proliferation concerns, without requiring local reprocessing capabilities.

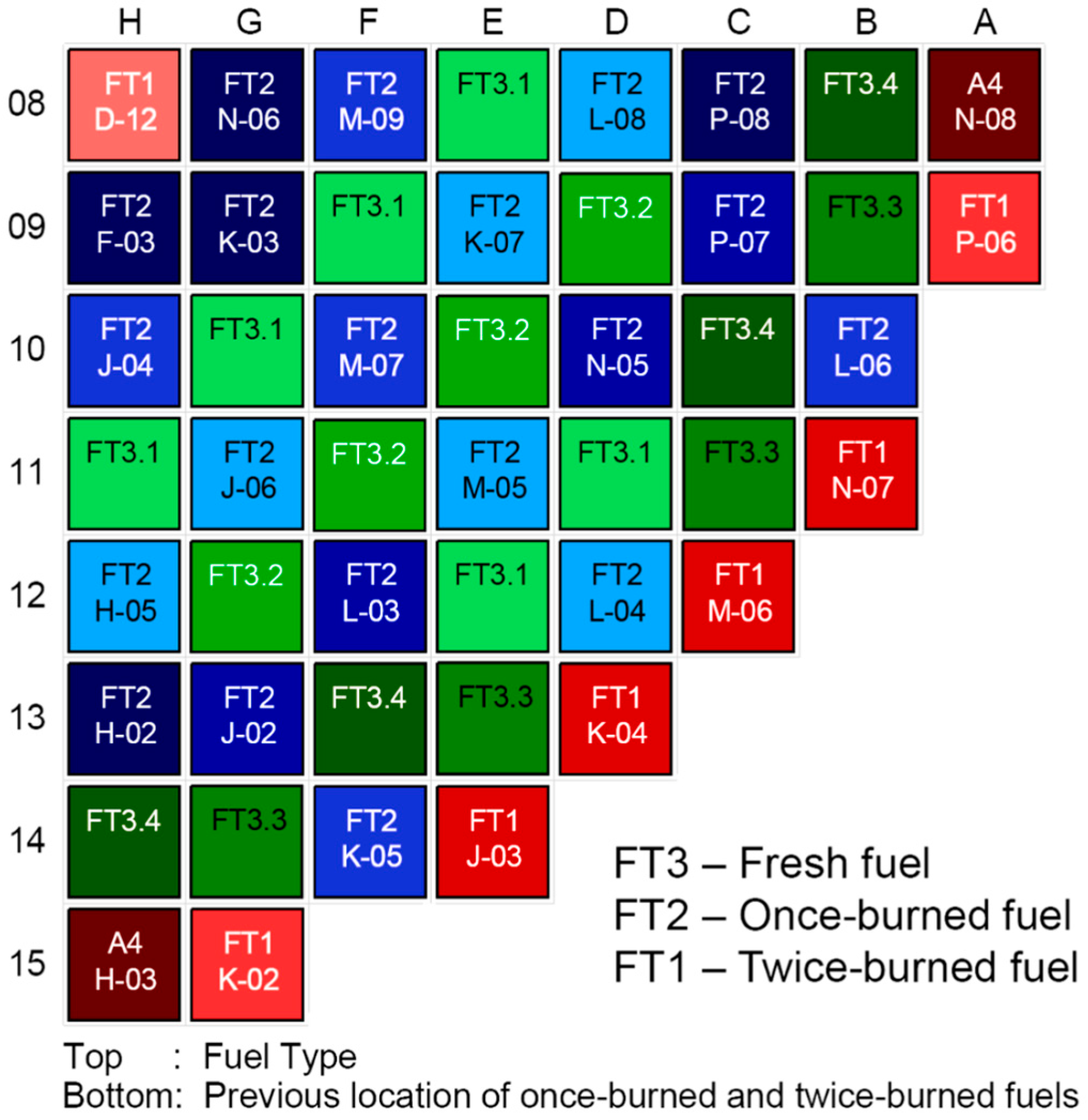

Table 5 and

Figure 3,

Figure 4 and

Figure 5 present the three systems that were investigated during the course of the programme.

3. Results and Discussion

It should be noted that the results presented in this section are derived from previously published studies by the authors, which focused individually on PWR [

34,

35], BWR [

36], and MSR [

37] systems. This paper serves as a consolidated summary of these works, bringing together the findings to provide a comparative perspective on proliferation resistance and serving as a basis for the economic implications of Am-241 doping across different reactor technologies presented in this paper.

3.1. Results of the Conducted Analysis

Across four studies, the integration of Am-241 into nuclear fuel has been explored as a promising strategy to enhance proliferation resistance in various reactor types. These investigations collectively demonstrate that Am-241 can effectively increase the fraction of Pu-238 in spent fuel, thereby rendering it unsuitable for weapons use due to its high heat output and spontaneous fission rate.

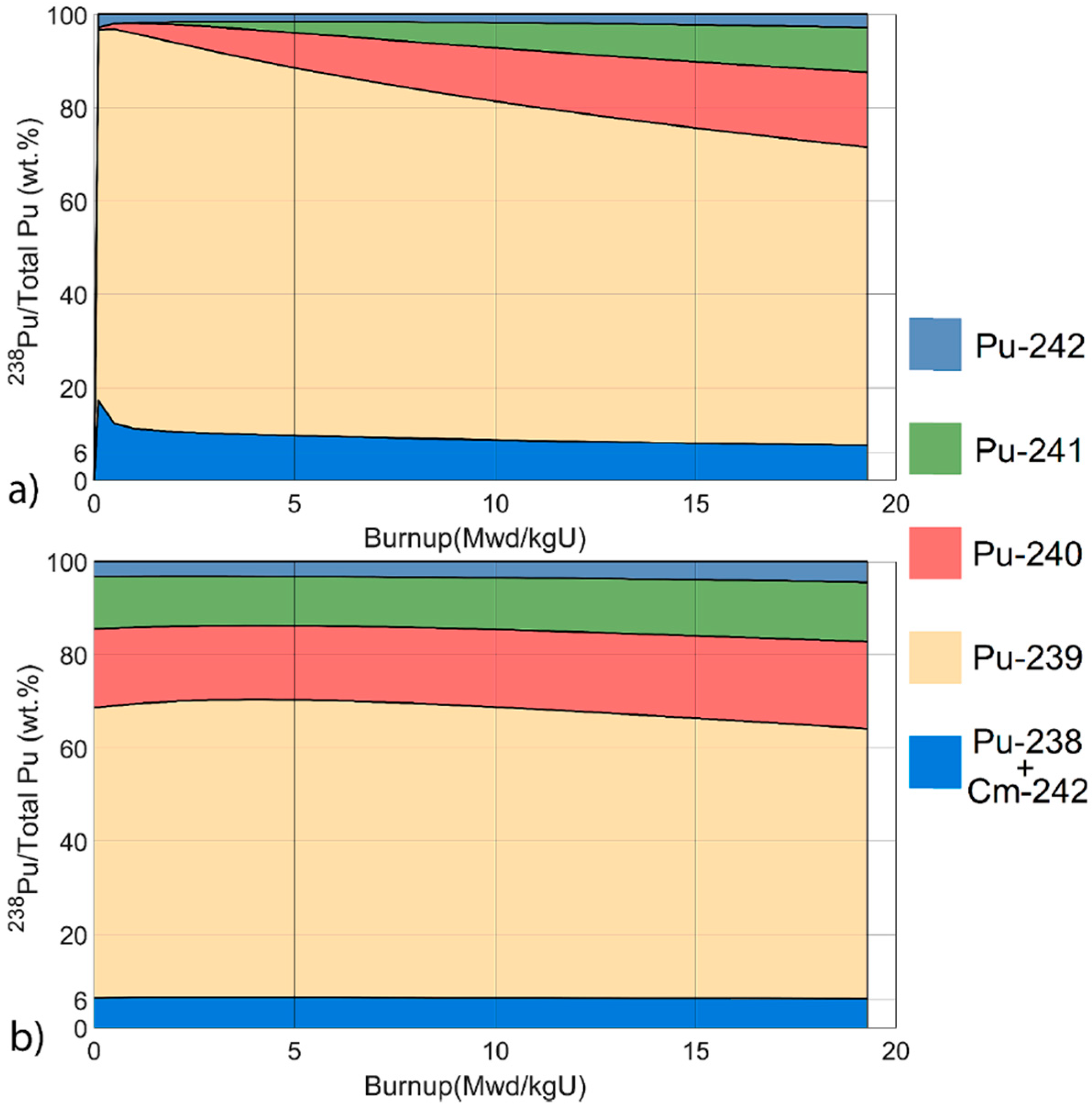

The two studies on the PWR system differ primarily in their approach to burnable absorbers. The first study investigates the use of Am-241 as an additive to conventional fuel that still includes Integral Fuel Burnable Absorbers (IFBAs) [

35], while the second study explores the possibility of replacing IFBAs entirely with Am-241 [

34]. This distinction is significant because IFBAs are complex and costly to fabricate, and their elimination could simplify fuel manufacturing [

40]. Both studies aim to achieve a proliferation-resistant fuel cycle by maintaining a Pu-238 to total plutonium ratio (

238Pu/TotPu) above 6%. Still, they differ in how they balance reactivity control, fuel cycle length, and operational safety.

In the first PWR study [

35], a minimum of 0.112 wt.% Am-241 was found necessary to keep the

238Pu/TotPu ratio above the threshold for resistance to proliferation. The addition of Am-241 reduced reactivity, requiring adjustments in fuel composition, but did not negatively impact key safety parameters such as peaking factors, shutdown margin, or reactivity feedback coefficients. The study concluded that Am-241-doped fuel could be safely used in conventional PWRs to improve proliferation resistance without compromising reactor performance.

The second PWR study extended this concept by assessing whether Am-241 could fully replace IFBAs. It showed that Am-241 not only acts as an effective burnable poison but also improves proliferation resistance, removing the need for IFBA coatings. Although using Am-241-doped fuel slightly reduced effective full power days (by about 5%, or 26 days), all safety and performance measures stayed within design limits. The study highlighted that Am-241 provides a dual benefit—streamlining fuel design and enhancing nonproliferation features.

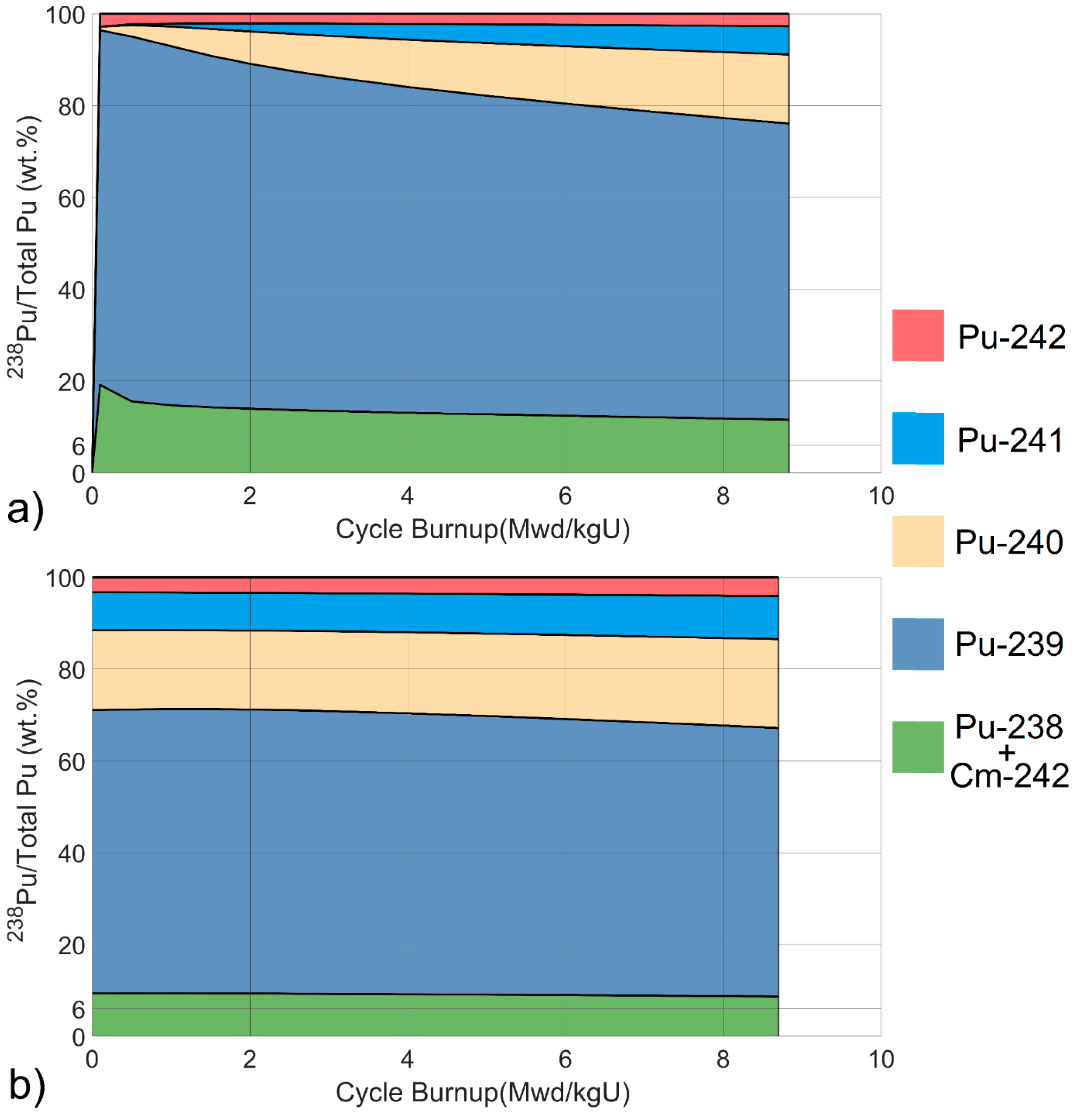

In the BWR study [

36], it was found that a minimum concentration of 0.142 wt.% was necessary to keep the

238Pu/TotPu ratio above 6% throughout the fuel’s lifetime. Although adding Am-241 required a slight increase in uranium enrichment to counter its neutron-absorbing properties, the reactor’s safety parameters—including shutdown margin, power profiles, and thermal characteristics-remained within acceptable limits. The study concluded that Am-241 doping is a feasible method for enhancing non-proliferation safeguards in BWRs without compromising safety or performance.

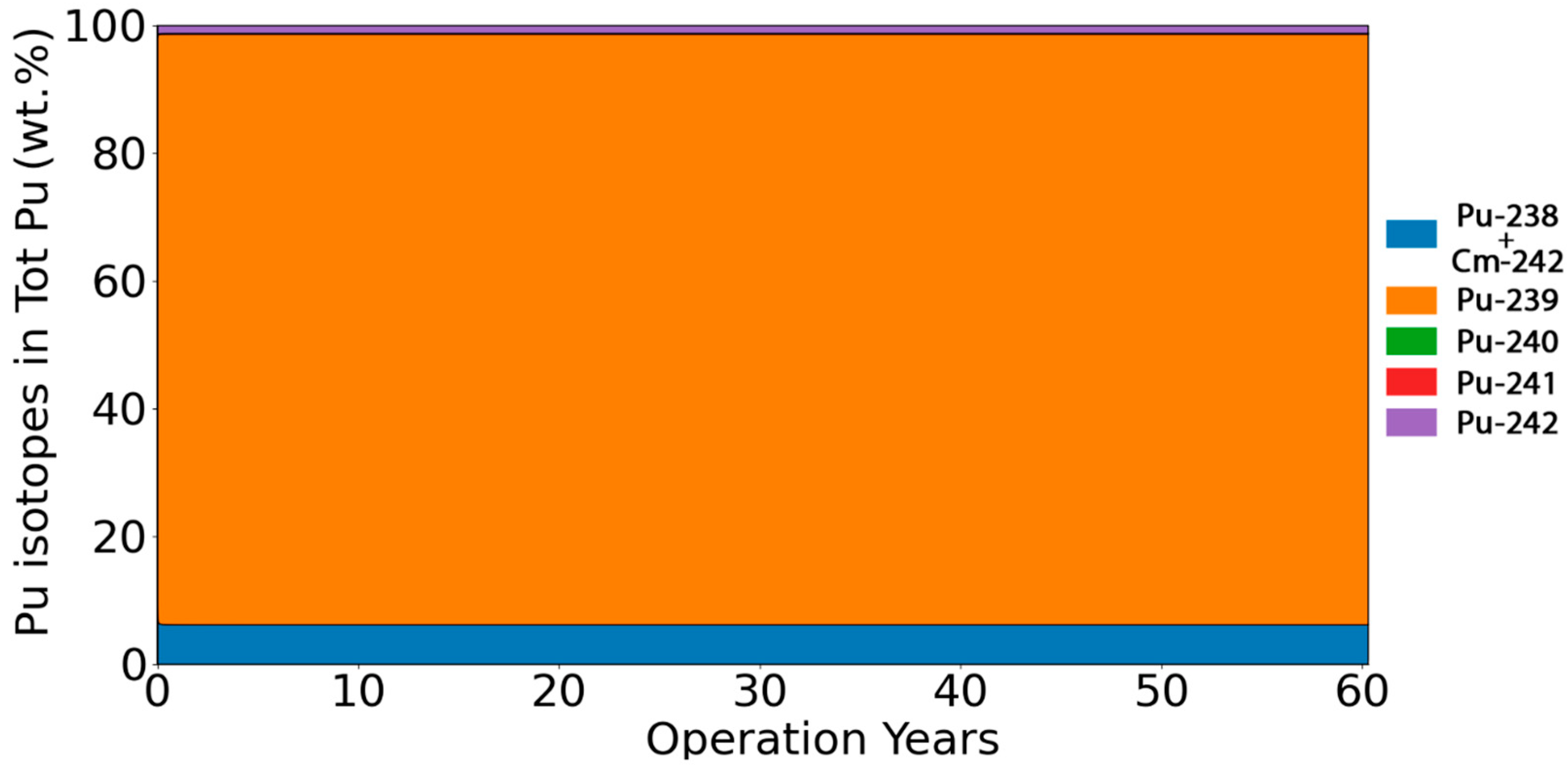

The MSR [

37] study examined the feasibility of using Am-241 in a Transatomic MSR to maintain a

238Pu/TotPu ratio above 6% over a simulated 60-year operational period. Continuous doping of the fuel with Am-241 at a rate of 7115 g/h successfully sustained the desired isotopic ratio. Although the addition of Am-241 led to a modest reduction in the effective multiplication factor (

keff), the reactor’s continuous refuelling and dynamic equilibrium allowed for stable operation. The study confirmed that MSRs can safely incorporate Am-241 without compromising power distribution or reactor performance, while significantly enhancing proliferation resistance.

Figure 6,

Figure 7 and

Figure 8 illustrate the typical plutonium vectors evolution obtained in various studies, while

Table 6 and

Table 7 summarise the final Am-241 loading in each one of the systems. These studies demonstrate that increasing the Pu-238 content in spent fuel makes Am-241 an effective deterrent against weaponisation, while still maintaining reactor safety and efficiency. The results support broader use of Am-241-doped fuel in different reactor types, offering a practical approach to developing safer and more secure nuclear energy systems.

3.2. Economic Impact of Utilisation of Am-241 in the Various Fuel Cycles

The economic implications of incorporating Am-241 into nuclear fuel cycles are influenced by both its chemical properties and historical pricing trends. As a by-product of plutonium decay, Am-241 has long been valued for its neutron-absorbing qualities and its role in improving proliferation resistance [

41]. According to Schulz in The Chemistry of Americium, published as part of the ERDA Critical Review Series, the U.S. Atomic Energy Commission initially offered Am-241 for sale in 1962 at

$1500 per gram, with prices decreasing to

$1000 per gram in 1969 and further to

$150 per gram by late 1970 [

42]. These fluctuations reflect changes in production capabilities and the strategic importance of Am-241 in nuclear applications. Additionally, according to a U.S. Department of Energy briefing on isotope supply, after the closure of the Rocky Flats Plant in 1989 and the depletion of domestic inventory by 2003, sealed source manufacturers have relied entirely on imports from Russia for Am-241 [

43]. Therefore, considering the current geopolitical climate and that the UK has only just begun [

44], the higher figure of

$1500/g will be used in this section. This section examines how such costs affect the levelised cost of electricity (LCOE) and fuel cycle economics across PWRs, BWRs, and MSRs, where Am-241 is utilised to develop proliferation-resistant fuel configurations.

The most effective way to evaluate the viability of Am-241 is to assess how doping affects the Levelised Cost of Electricity (LCOE) [

43]. The LCOE is a standard metric that indicates the average cost per unit of electricity generated over a power plant’s lifetime. It includes all relevant costs, such as capital investment, operations and maintenance (O&M), fuel, and financing, divided by the total electricity produced. Measured in units like dollars per megawatt-hour (

$/MWh), LCOE allows for comparison between different energy technologies by standardising costs over time and output. The mathematical formalism for LCOE is shown in Equation (1).

where

is the investment costs in year

,

is the O&M costs,

is the fuel costs,

electricity generated,

is the discount rate (set to 0 for comparison purposes) and

is the plant lifetime in years.

Table 8 summarises the impact of Am-241 doping on the PWR economy, with detailed calculations provided in

Appendix A.1. As previously mentioned, a conservative approach was taken by assuming americium’s price at its historic peak of

$1500/g. Additionally, the fuel cost for the doped fuel must account for extra expenses related to fabrication and enrichment modifications. According to De Roo and Parsons, the cost of producing UO

x from reprocessed uranium includes a 10% increase for enrichment and a 7% increase for fabrication. Since this study’s reprocessing price is already included in the Am-241 cost, an additional 200% markup on fresh UO

x production due to reprocessing is not applied. This is because the Am is used solely to dope fresh fuel. Therefore, the manufacturing cost of the Am-doped UO

x includes an extra 17%. Thus, given those assumptions, the impact on the LCOE of a typical PWR is minor at about

$5/MWh.

While the economic modelling in this study assumes a market-based acquisition of Am-241 at

$1500/g, it is essential to acknowledge that the addition of Am-241 to fresh fuel introduces radiological handling challenges. Am-241 is a gamma-emitting isotope with a relatively long half-life (433 years), and its presence increases the dose rate of the fabricated fuel before irradiation. This elevated dose rate may necessitate enhanced shielding, remote handling, or modified fabrication protocols, which could potentially increase production complexity and cost. Although these factors are not explicitly quantified in the current LCOE analysis, they are partially reflected in the assumed 17% fabrication cost premium, consistent with De Roo and Parsons [

45]. Future work should consider a more detailed radiological safety and cost assessment to fully capture the operational implications of Am-241-doped fuel.

A similar approach was applied in the BWR case as well, with a notable difference in the Am content required to reach the target

238Pu/TotPu ratio, which was 0.142%wt. The results of the Am-doping on the economics of a BWR cycle are summarised in

Table 9. As can be seen, the impact on the LCOE in the BWR case is not high in the BWR, this is despite the higher cost of Am involved in the process. The reason for that is the 5-batch loading pattern adopted in the BWR case, which leads to a lower loading of fresh Am in to the core each cycle.

In the MSR case, performing an LCOE analysis is challenging, as there is no reliable source that will describe the costs involved in the construction and operation of an MSR. Therefore, we will focus just on the contribution involved in added Am into the mix, as we have seen in the PWR and BWR case the fuel fabrication (without extraction) involving Pu is about 17% higher than Pu-free UO

x.

Table 10 shows the main parameters of the Transatomic MSR.

Based on the given above, and the assumption of thermal efficiency of 33%, the MSR average burnup is about 58 MWh/kgHM, given the 7.115 kg/h fresh fuel loading. Taking the loading of Am-241 of 2.27 g/h, over the life span of the reactor, this will constitute as 478.8 $/kgHM, which will make the cost of Am to be 8.25 $/MWh. This is higher in comparison to the PWR and BWR cases by a factor of 3–4. Including the 17% higher fuel production assumption, the total increase in LCOE might be higher than 10 $/MWh, which is not negligible, and a cost benefit analysis is required.

In summary, while the integration of Am-241 into nuclear fuel cycles introduces additional costs, particularly in MSRs due to continuous doping, the overall impact on the LCOE remains modest for PWRs and BWRs. These findings suggest that the economic trade-offs are justifiable when weighed against the significant gains in proliferation resistance in the PWR and BWR cases. For the MSR, this will rely on the maturity of the reactor and americium extraction technologies, as well as the optimisation of Am-241 utilisation, including from the processed fuel, which was not considered in this project. As such, Am-241 doping presents a viable and scalable strategy for enhancing nuclear security without imposing prohibitive financial burdens, especially in reactor types with established infrastructure and fuel supply chains.

3.3. Production and Availability of Americium-241

Americium-241 is primarily produced as a decay product of Pu-241, which itself is formed during neutron irradiation of uranium-238 in nuclear reactors. With a half-life of 14.3 years, Pu-241 gradually decays via beta emission to Am-241, which has a significantly longer half-life of 432.2 years. This transformation makes Am-241 a common constituent in aged plutonium stockpiles and spent nuclear fuel, particularly from thermal reactors such as PWRs [

45].

Historically, the United States manufactured Am-241 at the Rocky Flats Plant in Colorado from 1962 until production ceased in 1984. Following the plant’s closure in 1989, domestic inventories were depleted by 2004, leaving the U.S. reliant on imports-primarily from Russia. However, domestic production resumed in 2017 at Los Alamos National Laboratory, which now serves as the sole U.S. manufacturing site for Am-241 [

46]. In the UK, the National Nuclear Laboratory (UKNNL) has also developed laboratory-scale capabilities for Am-241 extraction from aged plutonium, supporting future applications such as space-based radioisotope thermoelectric generators (RTGs).

The global stockpile of Am-241 is not precisely documented due to its classification and the complexity of tracking isotopic inventories across civilian and military programmes. However, it is known that several kilograms have accumulated worldwide, primarily as a by-product of plutonium decay in stored nuclear weapons components and spent fuel assemblies [

46].

From a reactor operations perspective, the americium vector in discharged fuel from a typical PWR is dominated by Am-241, which arises from the decay of Pu-241 during and after irradiation. The concentration of Am-241 in spent fuel depends on the initial Pu-241 content and the cooling time post-discharge. Typically, Pu-241 constitutes around 12% of the total plutonium in spent PWR fuel at discharge. Over time, this decays to Am-241, with the americium content peaking approximately 70 years after discharge [

47]. A single PWR fuel assembly discharged and cooled for ~30 years can contain approximately 450 g of Am-241, depending on burnup and initial Pu production. This makes spent fuel a significant source of americium for reuse or extraction. From a typical PWR core with 192 fuel assemblies operating under a 3-batch fuel management strategy, approximately 28.8 kg of Am-241 would be produced per fuel cycle after 30 years of cooling. Hence, there is a huge stockpile of the isotope ready for extraction.

In terms of isotopic composition, the americium vector in spent PWR fuel is almost entirely Am-241, with trace amounts of heavier isotopes such as Am-243 formed via neutron capture. The presence of Am-241 contributes significantly to the radiotoxicity and heat load of spent fuel, complicating handling and disposal but also offering opportunities for reuse in proliferation-resistant fuel designs.

4. Conclusions

The current manuscript provides a summary and comparative discussion of Am-241 doping in PWR, BWR, and MSR systems that were analysed as part of the Potentials in “Nonproliferating” Nuclear Fuel project. By consolidating these findings, we aim to provide a broader perspective on the technical and economic implications of Am-241-doped, proliferation-resistant fuels across multiple reactor technologies.

The project has demonstrated that doping nuclear fuel with Am-241 offers a robust and technically viable pathway to enhance the intrinsic proliferation resistance of civilian reactor systems. Through detailed neutronic and thermal-hydraulic analyses across various systems, it was shown that Am-241 can reliably elevate the 238Pu/TotPu ratio above the 6% threshold, rendering the plutonium isotopically unsuitable for weapons use. Importantly, this enhancement was achieved without compromising reactor safety margins or operational performance, and with only modest increases in levelised cost of electricity (LCOE).

Beyond the technical merits, the findings of this project have implications for the broader nuclear regulatory landscape. Current safeguards frameworks—such as those administered by the IAEA—primarily rely on material accountancy and facility monitoring. While effective, these approaches are vulnerable to state-level non-compliance and technological circumvention. The integration of isotopic engineering strategies like Am-241 doping introduces a passive, fuel-intrinsic barrier to proliferation, which could complement existing safeguards and reduce reliance on external enforcement mechanisms.

To fully realise the benefits of this approach, regulatory bodies may need to revise fuel qualification standards, licencing procedures, and fabrication protocols to accommodate actinide-doped fuels (although this might not be a great challenge due to MOX manufacturing capabilities worldwide). This includes addressing challenges related to dopant handling, radiological safety, and supply chain logistics. However, such adjustments could ultimately remove key barriers to nuclear energy deployment in regions with heightened proliferation concerns, enabling broader access to low-carbon energy while maintaining global security commitments.

In conclusion, the outcomes of this project not only advance the technical frontier of proliferation-resistant fuel design but also offer a strategic opportunity to reshape the regulatory paradigm—shifting from reactive oversight to proactive prevention through fuel innovation.