Investigation of the Outflow and Spreading-Solidification Behaviour of Stratified Molten Metal

Abstract

:1. Introduction

- ①

- ②

- A lot of seawater was injected into the PCV in 1F NPPs. Therefore, the sea salt might dissolve into the fuel debris [4], which did not happen in Chernobyl.

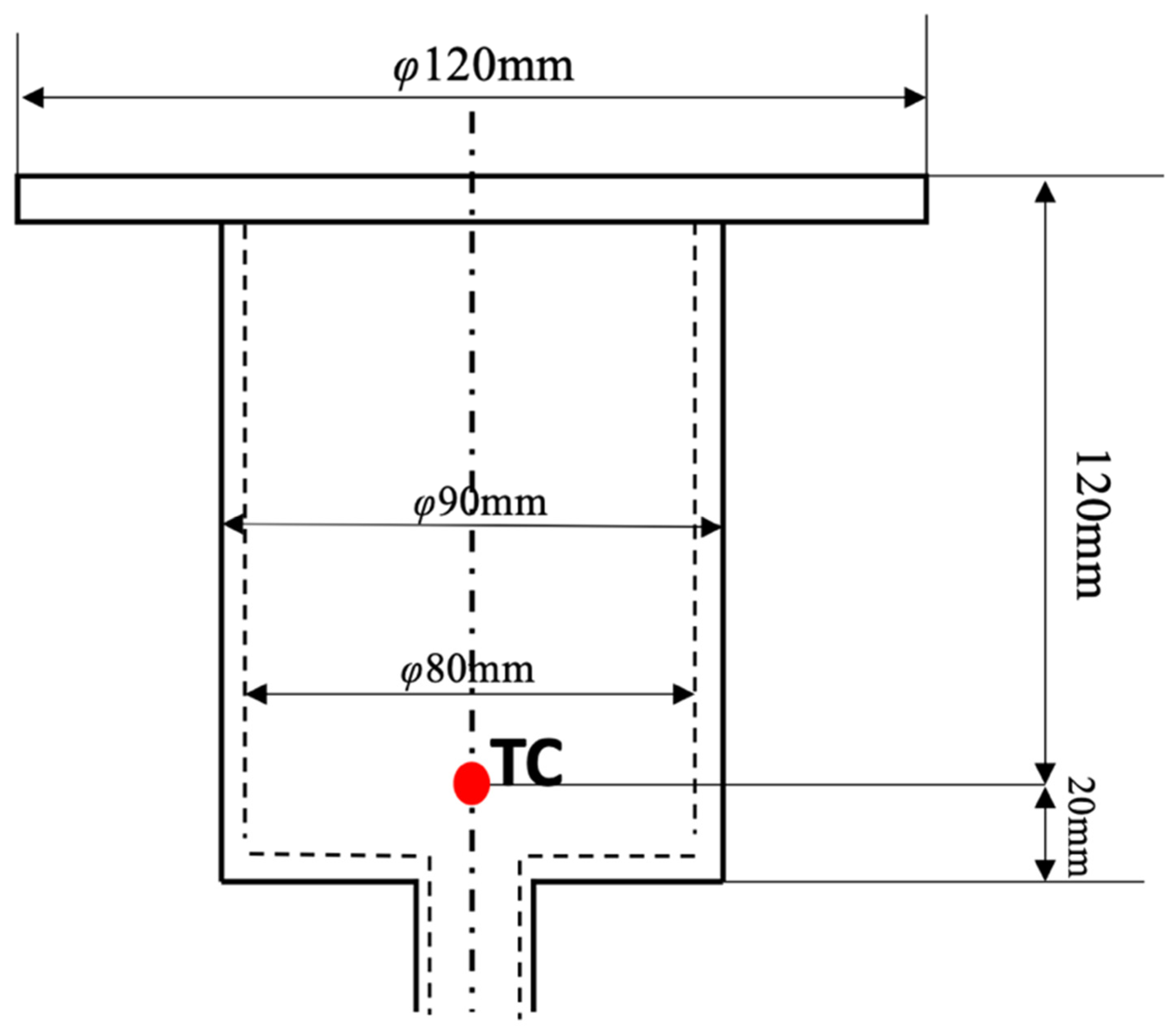

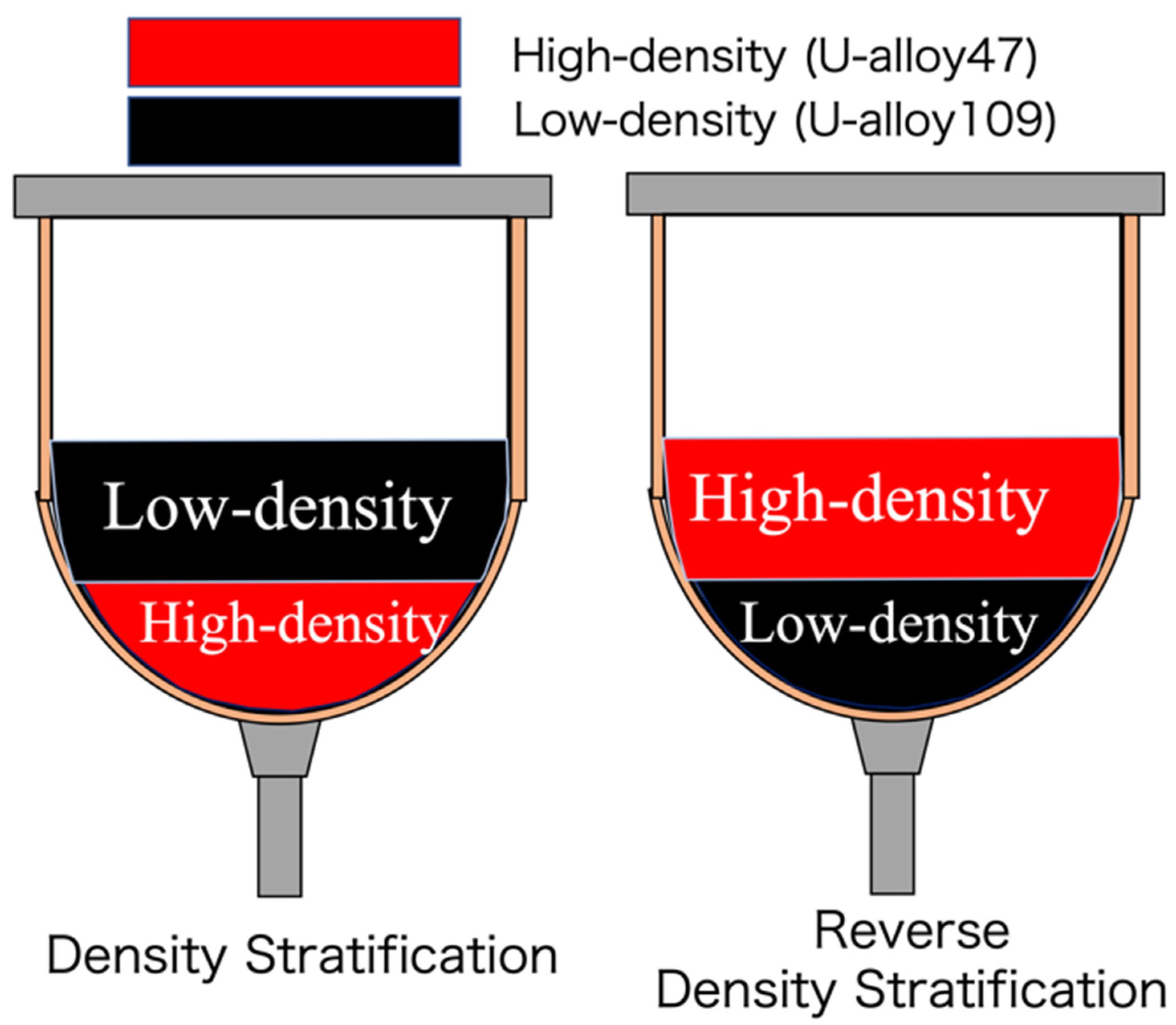

2. Experimental Set-Up

3. Experimental Results

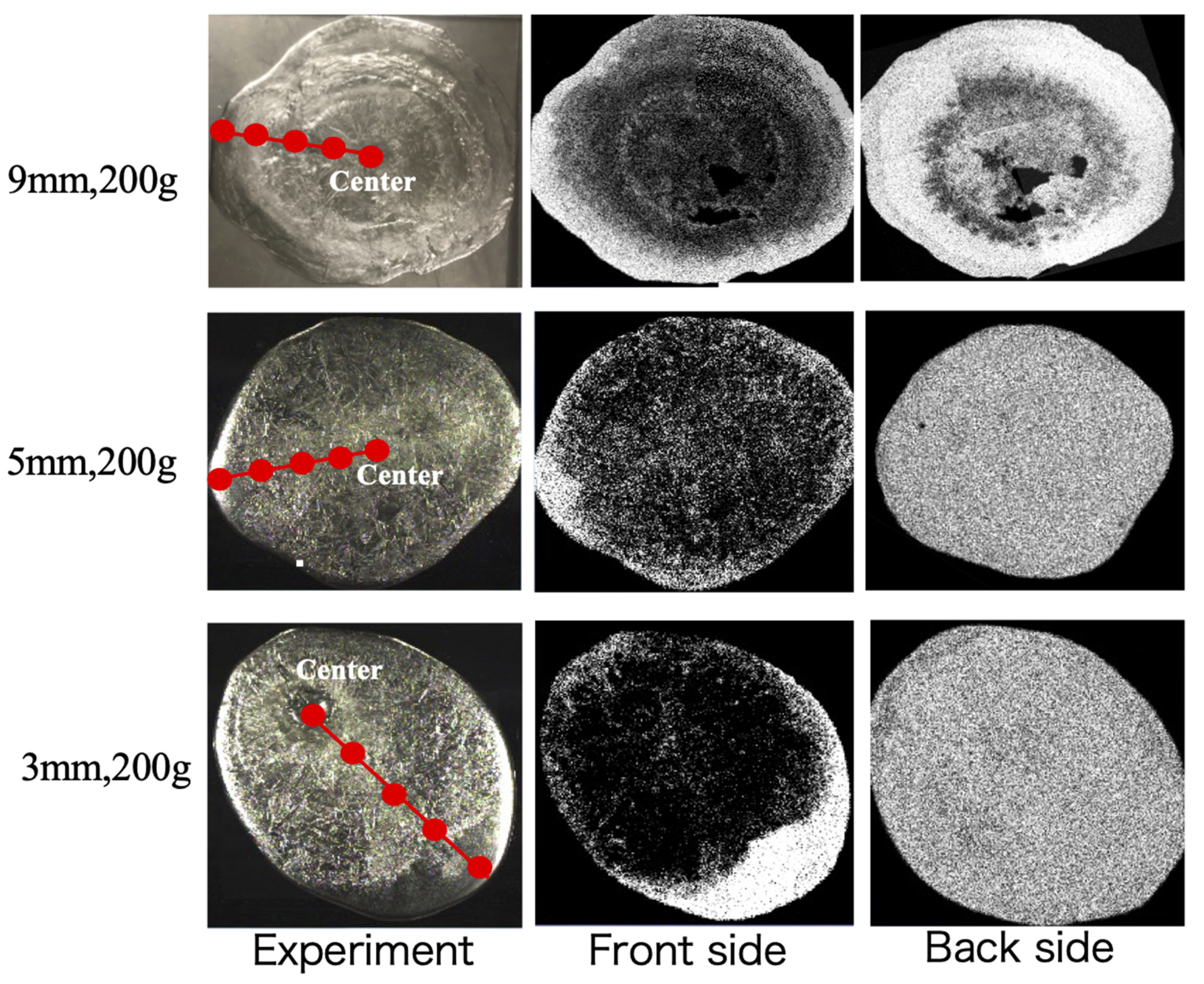

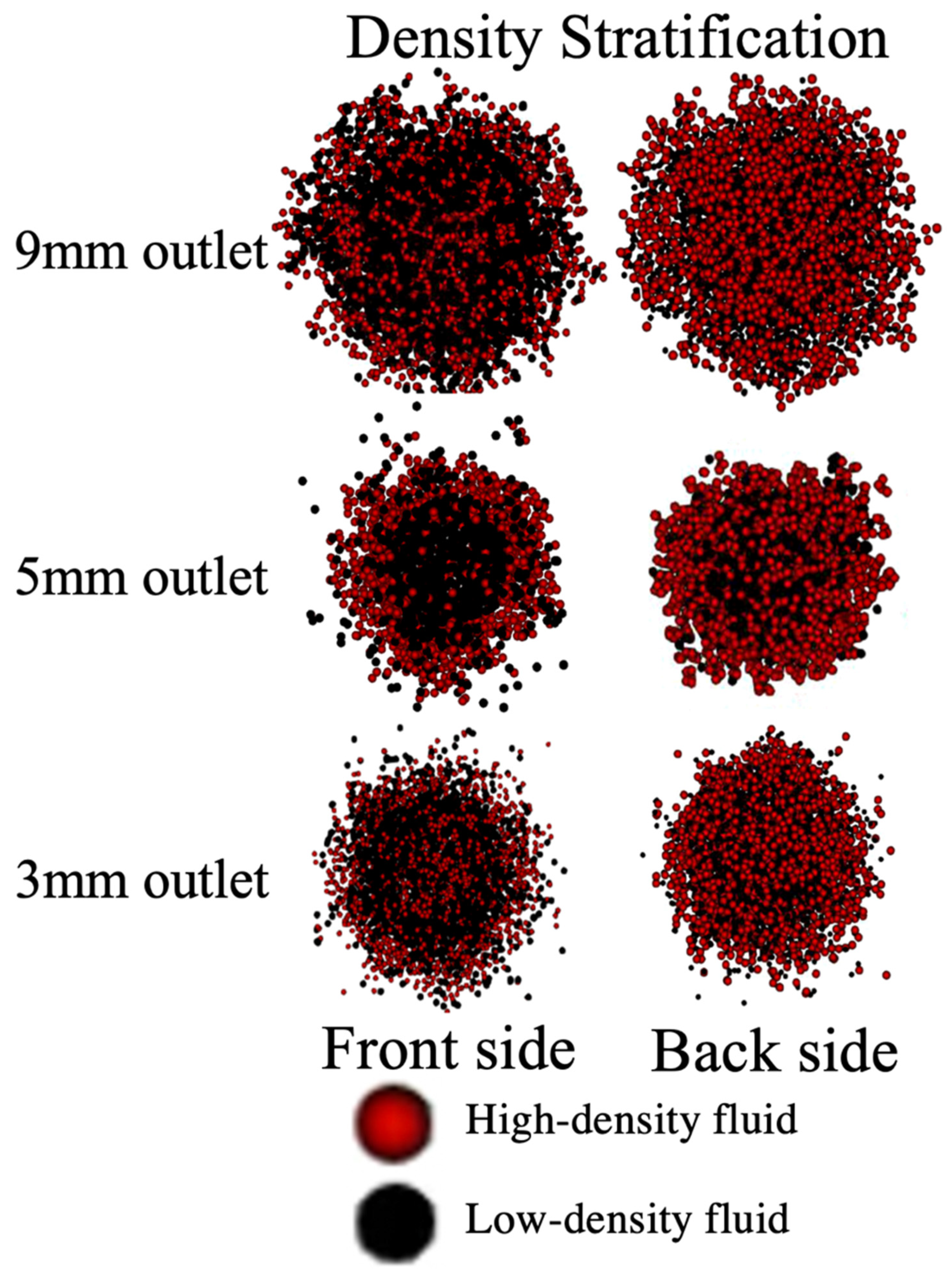

3.1. X-ray Analysis Results under the Density Stratification Condition

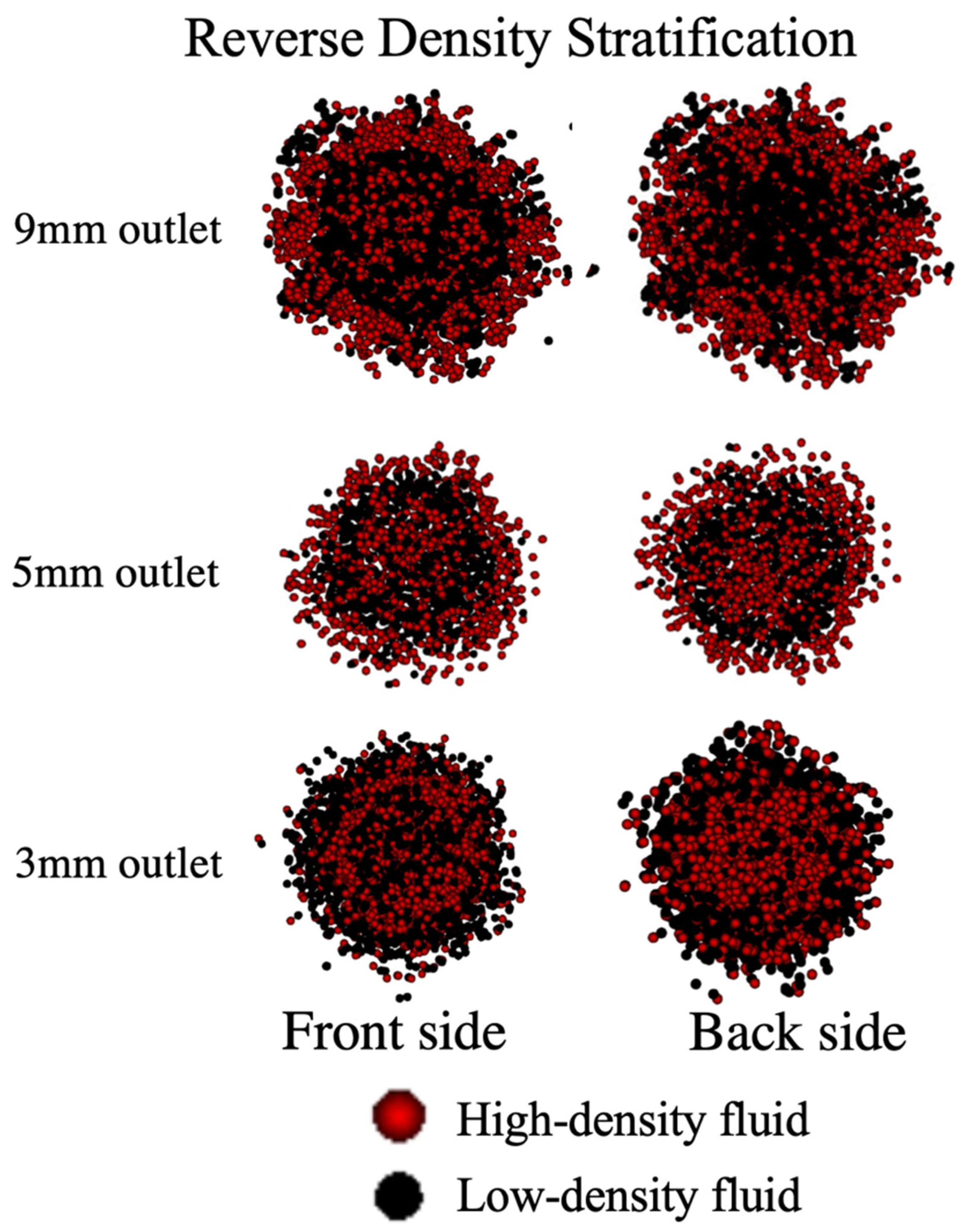

3.2. X-ray Analysis Results under the Reverse Density Stratification Condition

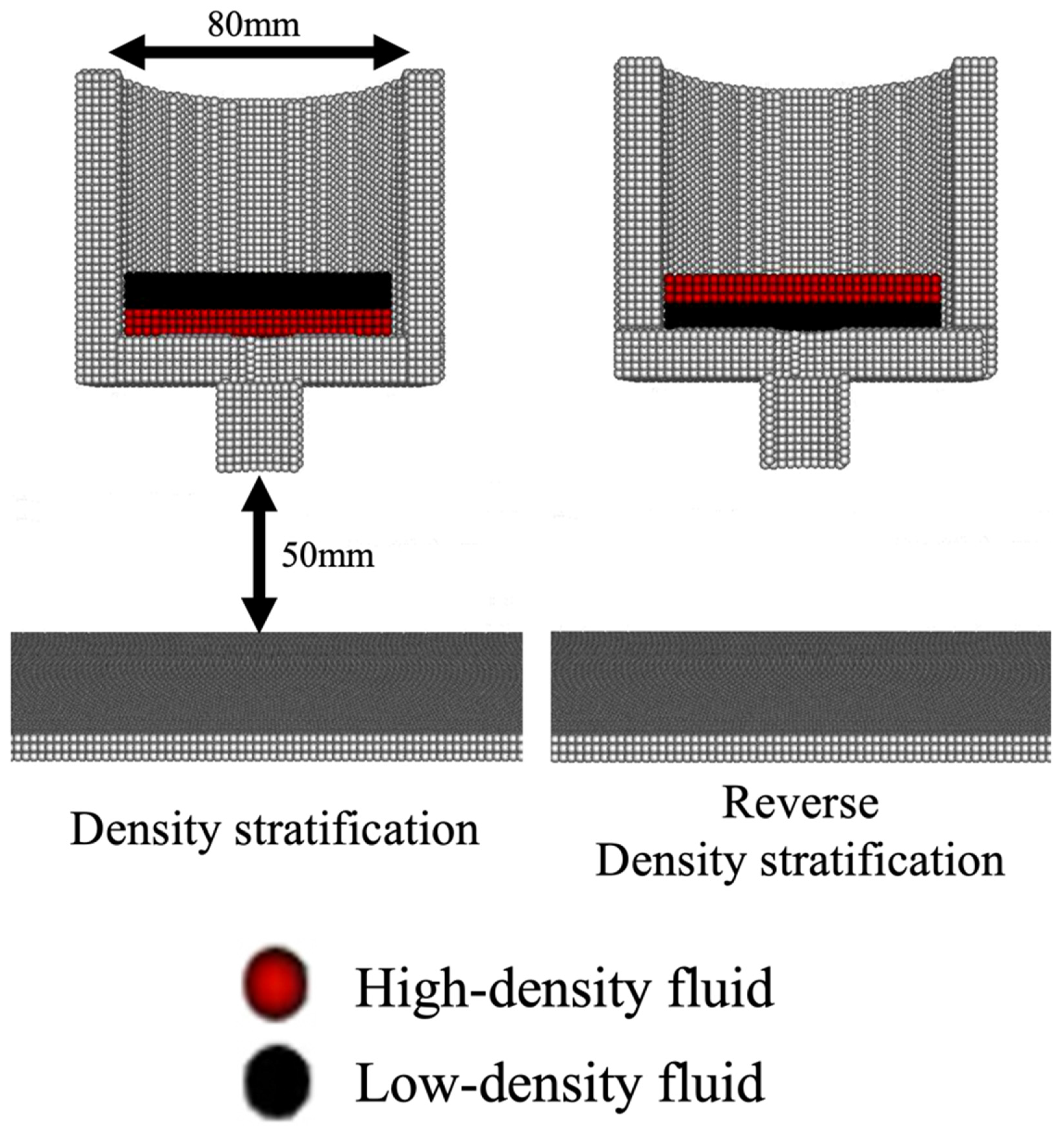

4. Numerical Method

4.1. Basic MPFI Method

4.2. Heat Transfer Model

4.3. Phase Change Model

5. Numerical Simulation Results

5.1. Simulation Results in the Density Stratification

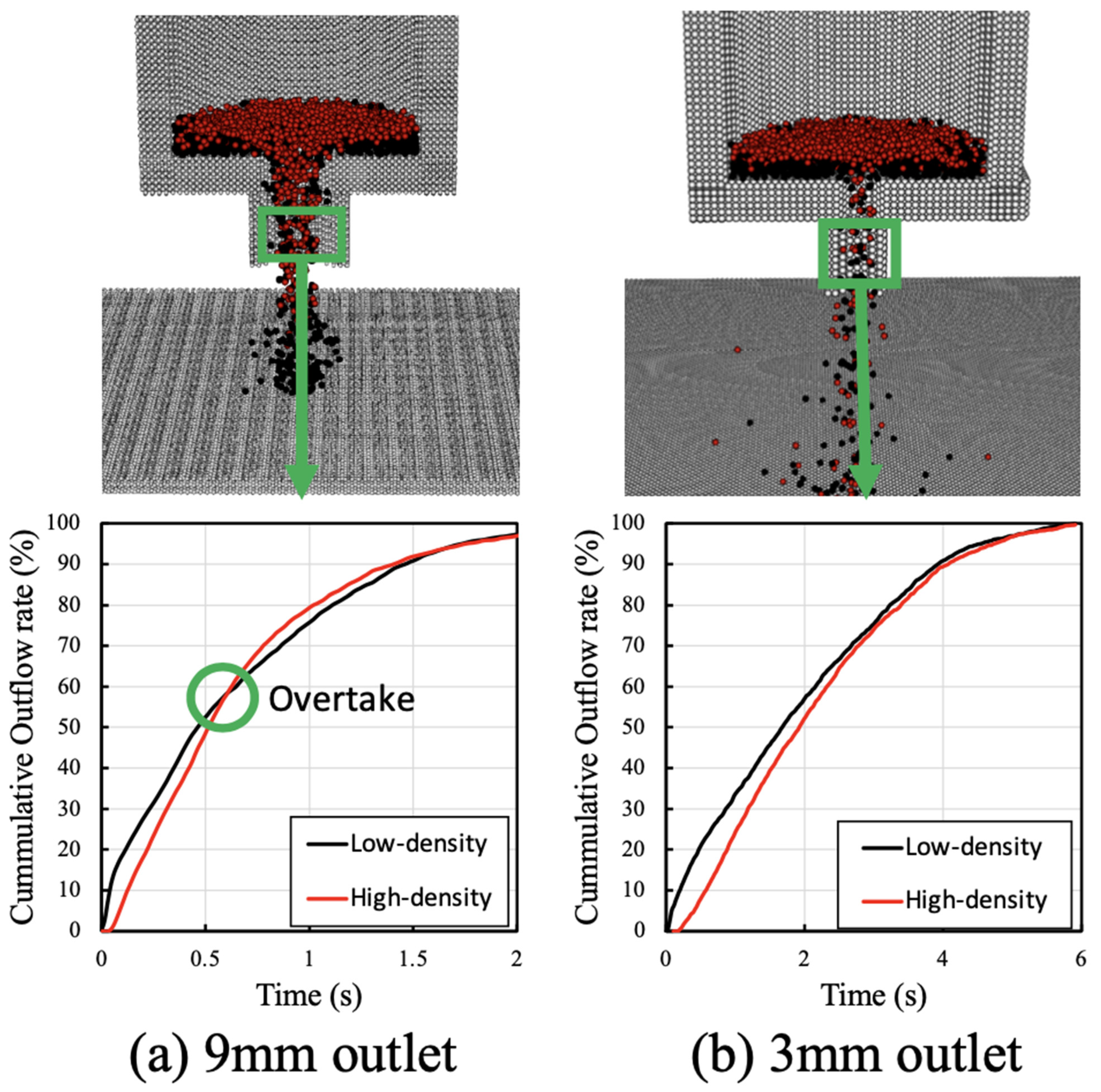

5.2. Simulation Results in the Reverse Density Stratification

6. Discussion

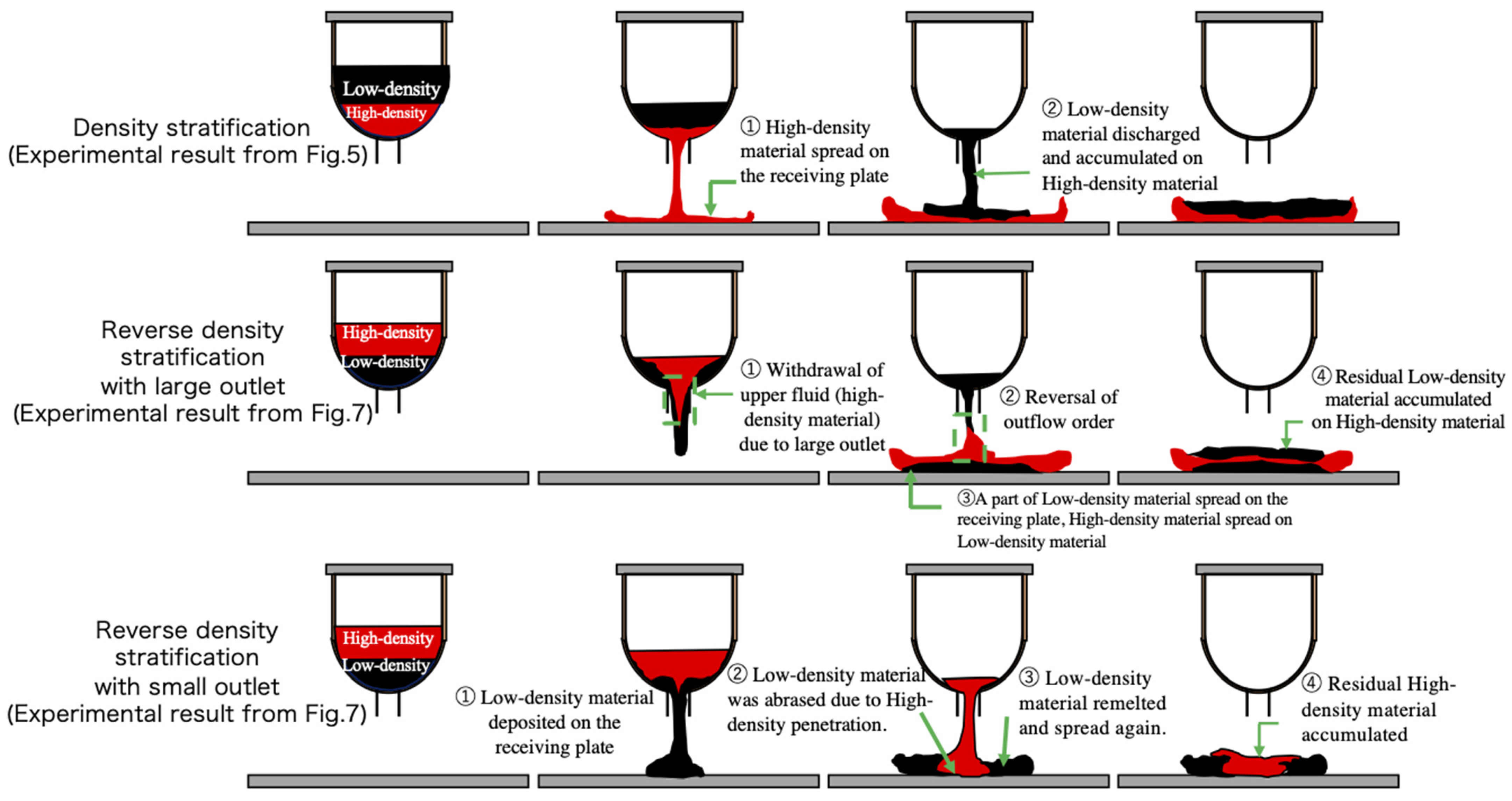

6.1. Summary of the Spreading and Deposition Progression of the Stratified Material

- <Density stratification condition>

- ①

- High-density material was first discharged, spread on the receiving plate, and solidified.

- ②

- Low-density material spread on the high-density fluid and accumulated around the centre region.

- ③

- After solidification, the low-density material was observed only near the centre on the front side.

- <Reverse density stratification with large outlet>

- ①

- A part of the low-density material was discharged and spread on the receiving plate, but shortly thereafter, the high-density material was sucked into the nozzle and preferentially flowed out, and the high-density material spread on the low-density material.

- ②

- The residual low-density material was deposited on the high-density material.

- ③

- On both sides, the low-density material was observed at the edge, and the high-density material was around the centre.

- <Reverse density stratification with small outlet>

- ①

- Most of the low-density material was discharged and deposited on the receiving plate.

- ②

- High-density material flowed out and accumulated around the centre region.

- ③

- After solidification, high-density material accumulated around the centre region, and low-density material accumulated around the edge region.

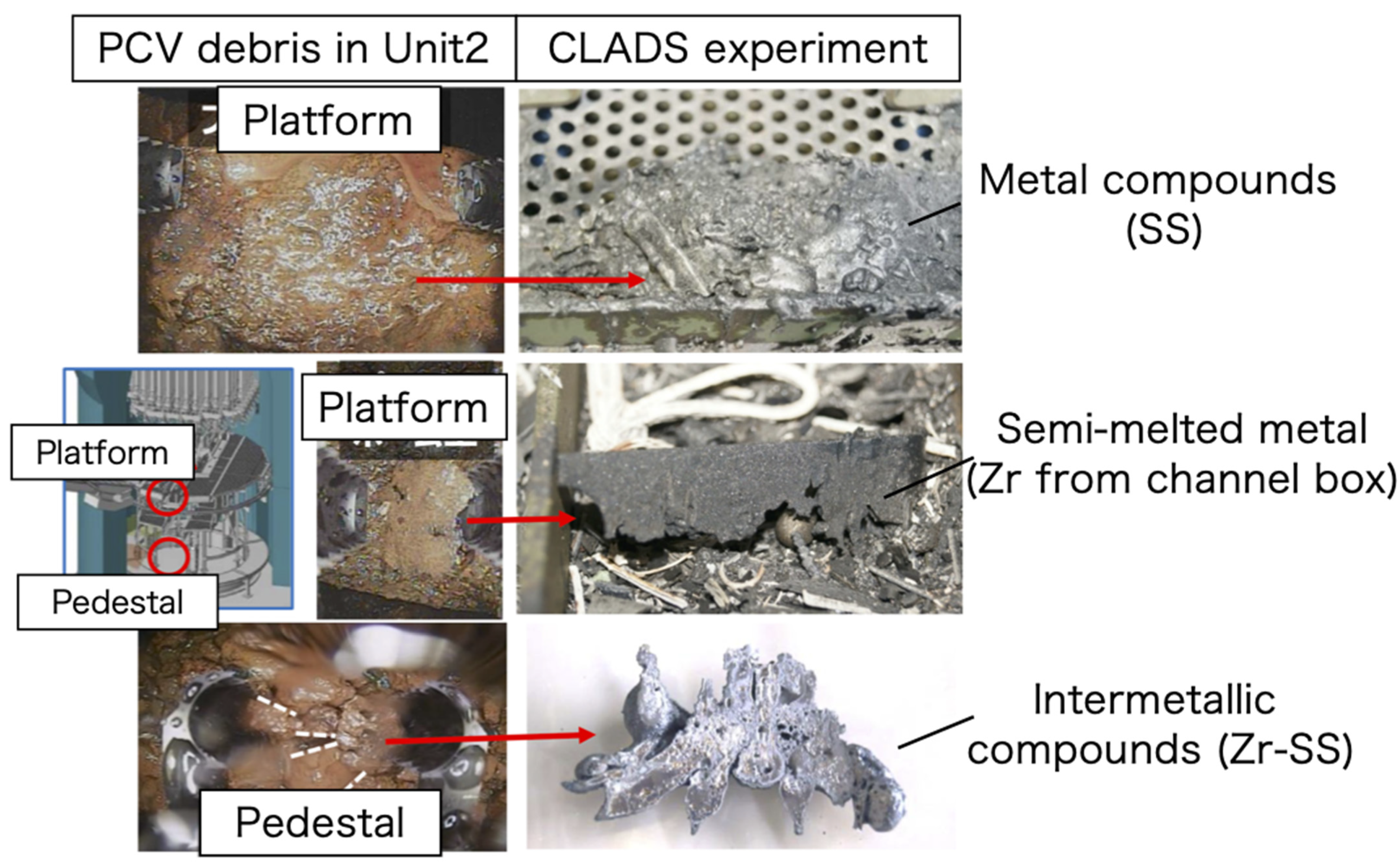

6.2. Comparative Study on the Fuel Debris Distribution between Present Study and the Fuel Debris in 1F Unit 2

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Pshenichnikov, A.; Nagase, Y.; Kurata, M. Comparison of the observed Fukushima Daiichi Unit 2 debris with simulated debris from the CLADS-MADE-01 control blade degradation test. J. Nucl. Sci. Technol. 2020, 58, 416–425. [Google Scholar] [CrossRef]

- Pschenichnikov, A.; Yamazaki, S.; Bottomley, D.; Nagase, Y.; Kurata, M. Features of a control blade degradation observed in situ during severe accident conditions in boiling water reactors. J. Nucl. Sci. Technol. 2019, 56, 440–453. [Google Scholar] [CrossRef]

- Pshenichnikov, A.; Kurata, M.; Bottomley, D.; Sato, I.; Nagae, Y.; Yamazaki, S. New research programme of JAEA/CLADS to reduce the knowledge gaps revealed after an accident at Fukushima-1: Introduction of boiling water reactor mock-up assembly degradation test programme. J. Nucl. Sci. Technol. 2019, 57, 370–379. [Google Scholar] [CrossRef]

- Takano, M.; Nishi, T. High temperature reaction between sea salt deposit and (U,Zr)O2 simulated corium debris. J. Nucl. Mat. 2013, 443, 32–39. [Google Scholar] [CrossRef]

- Unit 3 Primary Containment Vessel Internal Investigation. Available online: http://www.tepco.co.jp/en/nu/fukushima-np/handouts/2017/images/handouts_171130_03-e.pdf (accessed on 26 January 2021).

- Fukushima Daiichi Nuclear Power Station Unit 2 Primary Containment Vessel Internal Investigation Results. Available online: http://www.tepco.co.jp/en/nu/fukushima-np/handouts/2018/images/handouts_180119_01-e.pdf (accessed on 26 January 2021).

- Pellegrini, M.; Dolganov, K.; Herranz, E.; Bonneville, D.; Luxat, D.; Sonnenkalb, M.; Ishikawa, J.; Song, J.H.; Gaunt, R.O.; Fernandez, M.L.; et al. Benchmark Study of the Accident at the Fukushima Daiichi NPS: Best-Estimate Case Comparison. Nucl. Technol. 2016, 196, 198–210. [Google Scholar] [CrossRef]

- Dinh, T.N.; Knovalikhin, M.J.; Sehgal, B.R. Core Melt Spreading on a reactor Containment Floor. Prog. Nucl. Energy 2000, 36, 405–468. [Google Scholar] [CrossRef]

- Veteau, J.M. Corine Program, OECD/CSNI/NEA. In Proceedings of the Workshop on Large Molten Pool Heat Transfer, Grenoble, France, 9–11 March 1994; pp. 531–548. [Google Scholar]

- Green, G.A.; Finrock, C.; Klages, J.; Schwards, C.E.; Burton, S.B. Experimental studies on Melt Spreading, Bubbling Heat Transfer and Coolant Layer Boiling. In Proceedings of the 16th Water Reactor Safety Meeting, NUREG/CP-0097, Gaithersburg, MD, USA, 24 October 1988; pp. 341–358. [Google Scholar]

- Suzuki, H.; Matsumoto, T.; Mitadera, T.; Matsumoto, M.; Zama, T. Fundamental experiment and analysis for melt spreading on concrete floor. In Proceedings of the 2nd ASME/JSME Nuclear Engineering Conference 1, San Francisco, CA, USA, 21–24 March 1993; pp. 403–407. [Google Scholar]

- Eppinger, B.; Fieg, G.; Schuetz, W.; Stegmaier, U. KATS experiments to simulate corium spreading in the EPR core catcher concept. In Proceedings of the 9th International Conference on Nuclear Engineering (ICONE-9), Nice Acropolis, France, 8–12 April 2001; p. 32068804. [Google Scholar]

- Alsmeyer, H.; Cron, T.; Messemer, G.; Häfner, W. ECOKATS-2: A Large Scale Experiment on Melt Spreading and Subsequent Cooling by Top Flooding. In Proceedings of the ICAPP’04 (International Conference Advances in nuclear Power Plants), Pittsburg, KS, USA, 3–17 June 2004. Communication No. 4134. [Google Scholar]

- Alsmeyer, H.; Crin, T.; Foit, J.J.; Messemer, G.; Schmidt-Stiefel, S.; Häfner, W.; Kriscio, H. Test Report of the Melt Spreading Tests ECOKATS-V1 and ECOKATS-1; SAM-ECOSTAR-D15/FZKA 7064; FZKA: Karlsruhe, Germany, 2004. [Google Scholar]

- Steinwarz, W.; Alemberti, A.; Häfner, W.; Alkan, Z.; Fischer, M. Investigations on the phenomenology of ex-vessel core melt behaviour. Nucl. Eng. Des. 2001, 209, 139–146. [Google Scholar] [CrossRef]

- Tromm, W.; Foit, J.J.; Magallon, D. Dry and wet spreading experiments with prototypic materials at the FARO facility and the theoretical analysis. In Proceedings of the OECD workshop on ex-vessel debris coolability, Karlsruhe, Germany, 15–18 November 1999. FZKA—6475. [Google Scholar]

- Journeau, C.; Boccacio, E.; Brayer, C.; Cognet, G.; Hanquet, J.F.; Jégou, C.; Piluso, P.; Monerris, J. Ex-vessel corium spreading: Results from the VULCANO spreading tests. Nucl. Eng. Des. 2003, 223, 75–102. [Google Scholar] [CrossRef]

- Ogura, T.; Matsumoto, T.; Miwa, S.; Mori, M.; Hibiki, T. Experimental study on molten metal spreading and deposition behaviors. Ann. Nucl. Energy 2018, 118, 353–362. [Google Scholar] [CrossRef]

- An, S.M.; Song, J.H.; Kim, J.Y.; Kim, H.Y.; Naitoh, M. Experimental Investigation on Molten Pool Representing Corium Composition at Fukushima Daiichi Nuclear Power Plant. J. Nucl. Mater. 2016, 478, 164–171. [Google Scholar] [CrossRef]

- Ogura, T.; Matsumoto, T.; Miwa, S.; Hibiki, T.; Mori, M. Experimental Study on Molten Metal Spreading and Deposition Behaviors on Wet Surface. Prog. Nucl. Energy 2018, 106, 72–78. [Google Scholar] [CrossRef]

- Matsumoto, T.; Sakurada, K.; Miwa, S.; Sakashita, H.; Mori, M. Scaling analysis of the spreading and deposition behaviors of molten-core-simulated metals. Ann. Nucl. Energy 2017, 108, 79–88. [Google Scholar] [CrossRef]

- Sahboun, N.; Miwa, S.; Sawa, K.; Yamamoto, Y.; Watanabe, Y.; Ito, T. A molten metal jet impingement on a flat spreading surface. J. Nucl. Sci. Technol. 2020, 57, 1111–1120. [Google Scholar] [CrossRef]

- Yokoyama, R.; Suzuki, S.; Okamoto, K.; Harada, M. Scale effect of amount of molten corium and outlet diameters on corium spreading. Prog. Nucl. Energy 2020, 130, 103535. [Google Scholar] [CrossRef]

- Kang, K.H.; Park, R.J.; Hong, S.H.; Hong, S.W.; Ha, K.S. An experimental study on layer inversion in the corium pool during a severe accident. Nucl. Eng. Des. 2014, 278, 163–170. [Google Scholar] [CrossRef]

- Li, G.; Oka, Y.; Furuya, M. Experimental and numerical study of stratification and solidification/melting behaviors. Nucl. Eng. Des. 2014, 272, 109–117. [Google Scholar] [CrossRef]

- Takano, M.; Nishi, T.; Shirasu, N. Characterization of solidified melt among materials of UO2 fuel and B4C control blade. J. Nucl. Sci. Technol. 2014, 51, 859–875. [Google Scholar] [CrossRef] [Green Version]

- Journeau, C.; Roulet, D.; Porcheron, E.; Piluso, P.; Chagnot, C. Fukushima Daiichi fuel debris simulant materials for the development of cutting and collection technologies. J. Nucl. Sci. Technol. 2018, 55, 985–995. [Google Scholar] [CrossRef]

- Miwa, S.; Takase, G.; Imoto, J.; Nishioka, S.; Miyahara, N.; Osaka, M. Boron chemistry during transportation in the high temperature region of a boiling water reactor under severe accident. J. Nucl. Sci. Technol. 2020, 57, 291–300. [Google Scholar] [CrossRef]

- Monaghan, J.J. Simulating free surface flows with SPH. J. Comput. Phys. 1994, 110, 399–406. [Google Scholar] [CrossRef]

- Koshizuka, S.; Oka, Y. Moving Particle semi-implicit method for fragmentation of incompressible fluid. Nucl. Sci. Eng. 1996, 123, 421–434. [Google Scholar] [CrossRef]

- Kondo, M. A physically consistent particle method for incompressible fluid flow calculation. Comput. Part. Mech. 2021, 8, 69–86. [Google Scholar] [CrossRef] [Green Version]

- Kondo, M.; Ueda, S.; Okamoto, K. Melting simulation using a particle method with angular momentum conservation. In Proceedings of the 25th international Conference on Nuclear Engineering ICONE25, Shanghai, China, 2–6 July 2017; p. 67588. [Google Scholar]

- Kondo, M. A New Particle Method for Incompressible flow with Thermodynamic Consistency. In Proceedings of the 9th XJTU-UT-SJTU Joint Symposium on Nuclear Science and Technology, Shanghai, China, 13–15 November 2016. [Google Scholar]

- Kawahara, T.; Oka, Y. Ex-vessel molten core solidification behavior by moving particle semi-implicit method. J. Nucl. Sci. Technol. 2012, 49, 1156–1164. [Google Scholar] [CrossRef] [Green Version]

- Chai, P.; Erkan, N.; Kondo, M.; Okamoto, K.; Wei, H. Experimental research and numerical simulation of moving molten metal pool. Mech. Eng. Lett. 2015, 1, 15-00367. [Google Scholar] [CrossRef]

- Chai, P.; Kondo, M.; Erkan, N.; Okamoto, K. Numerical simulation of MCCI based on MPS method with different types of concrete. Ann. Nucl. Energy 2017, 103, 227–237. [Google Scholar] [CrossRef]

- Duan, G.; Yamaji, A.; Journeau, C.; Buffe, L.; Haquet, J.F. Investigation on corium spreading over ceramic and concrete substrates in VULCANO VE-U7 experiment with moving particle semi-implicit method. Ann. Nucl. Energy 2020, 141, 107266. [Google Scholar] [CrossRef]

- Yasumura, Y.; Yamaji, A.; Futruya, M.; Ohishi, Y.; Duan, G. Investigation on influence of crust formation on VULCANO VE-U7 corium spreading with MPS method. Ann. Nucl. Energy 2017, 107, 119–127. [Google Scholar] [CrossRef]

- Duan, G.; Yamaji, A.; Koshizuka, S. A novel multiphase MPS algorithm for modeling crust formation by highly viscous fluid for simulating corium spreading. Nucl. Eng. Des. 2019, 343, 218–231. [Google Scholar] [CrossRef]

- Yamaji, A.; Li, X. Development of MPS Method for Analyzing Melt Spreading Behavior and MCCI in Severe Accident. In Proceedings of the 6th Asian Physics Symposium, Bandung, Indonesia, 19–20 August 2015; Volume 739, p. 012002. [Google Scholar] [CrossRef] [Green Version]

- Ramacciotti, M.; Journeau, C.; Sudreau, F.; Cognet, G. Viscosity models for corium melts. Nucl. Eng. Des. 2001, 204, 377–389. [Google Scholar] [CrossRef]

- Spencer, D.B.; Mehrabian, R.; Flemings, M.C. Rheological behavior of Sn-15 Pct Pb in the Crystallization Range. Metall. Mater. Trans. B 1972, 3, 1925–1932. [Google Scholar] [CrossRef]

- Joly, P.A.; Mehrabian, R. The rheology of a partially solid alloy. J. Mater. Sci. 1976, 11, 1393–1418. [Google Scholar] [CrossRef]

- Koyaguchi, T. Magma mixing in a conduct. J. Volcanol. Geothem. Res. 1985, 25, 365–369. [Google Scholar] [CrossRef]

- Blake, S.; Ivey, G.N. Magma-mixing and the dynamics of withdrawal from stratified reservoirs. J. Volcanol. Geothem. Res. 1986, 27, 153–178. [Google Scholar] [CrossRef]

- Tokyo Electric Power Company Holdings, Inc. Fukushima Dai-Ichi Nuclear Power Plant Results of Investigation inside Unit 2 PCV. Available online: https://www.meti.go.jp/earthquake/nuclear/decommissioning/committee/osensuitaisakuteam/2019/02/3-3-3.pdf#page=6 (accessed on 22 April 2021).

| Unit 1 in 1F NPPs | Unit 2 in 1F NPPs | Unit 3 in 1F NPPs |

|---|---|---|

| 1 h: Stop cooling by IC | 70 h: Stop RCIC cooling | 41 h: Control rod start melting |

| 5 h: Fuel start melting | 78 h: Control rod start melting | 42 h: Fuel rod melting |

| 24 h: Open PCV vent system | 81 h: Fuel start melting | 50 h: Fuel debris fall down onto PCV |

| 25 h: Reactor building is destroyed by explosion | 82 h: Corium relocated to lower head | |

| 50 h: PCV shell attack, MCCI | 90 h: Degradation of lower head | |

| 120 h: Corium discharge from RPV |

| High-Density (U-alloy47) | Low-Density (U-alloy109) | |

|---|---|---|

| Density, (kg/m3) | 9360 | 8640 |

| Composition, (at.%) | Bi44.7, Pb22.6, Sn12.3, Cd5.3, In17.1 | Bi66, In34 |

| Melting Temperature, (°C) | 47 | 109 |

| Thermal Conductivity, k (W/m K) | 36 | 30 |

| Specific Heat, Cp (J/kg K) | 190 | 250 |

| Viscosity, μ (Pa s) | 3.3 × 10−4 | 6.4 × 10−4 |

| Thermal expansion coefficient, β (K−1) | 2.4 × 10−5 | 3.9 × 10−5 |

| Values | |

|---|---|

| Sample amount, M (g) | 200 |

| Sample temperature, T (°C) | 170 |

| Outlet diameter, D (mm) | 3,5,7,9 |

| Falling height from vessel to receiving plate, H (mm) | 50 |

| Environmental temperature, Te (°C) | 30 ± 0.5 |

| Receiving plate temperature, Tr (°C) | 25 ± 1.0 |

| Rayleigh number, Ra (-) | Approximately 1000 |

| High-Density Fluid | Low-Density Fluid | |

|---|---|---|

| Particle spacing (mm) | 0.009 | |

| Impact radius (mm) | 0.017 | |

| Sample amount, M (g) | 100 | 100 |

| Nozzle diameter, D (mm) | 3,5,9 | 3,5,9 |

| Specific heats for the solid and liquid, , (J/kg K) | 190 | 250 |

| Melting point, Tm (°C) | 60 | 90 |

| Thermal conductivity, k (W/m K) | 36 | 30 |

| Latent heat, h1 − h0 (J/kg) | 25,000 | 30,000 |

| Initial viscosity (170 °C), (Pa s) | 3.3 × 10−4 | 6.3 × 10−4 |

| Stephan-Boltzmann constant, | 5.67 × 10−8 | |

| Emissivity, | 0.15 | |

| Environmental temperature, Te (°C) | 30 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yokoyama, R.; Kondo, M.; Suzuki, S.; Harada, M.; Okamoto, K. Investigation of the Outflow and Spreading-Solidification Behaviour of Stratified Molten Metal. J. Nucl. Eng. 2021, 2, 168-189. https://doi.org/10.3390/jne2020017

Yokoyama R, Kondo M, Suzuki S, Harada M, Okamoto K. Investigation of the Outflow and Spreading-Solidification Behaviour of Stratified Molten Metal. Journal of Nuclear Engineering. 2021; 2(2):168-189. https://doi.org/10.3390/jne2020017

Chicago/Turabian StyleYokoyama, Ryo, Masahiro Kondo, Shunichi Suzuki, Masaru Harada, and Koji Okamoto. 2021. "Investigation of the Outflow and Spreading-Solidification Behaviour of Stratified Molten Metal" Journal of Nuclear Engineering 2, no. 2: 168-189. https://doi.org/10.3390/jne2020017

APA StyleYokoyama, R., Kondo, M., Suzuki, S., Harada, M., & Okamoto, K. (2021). Investigation of the Outflow and Spreading-Solidification Behaviour of Stratified Molten Metal. Journal of Nuclear Engineering, 2(2), 168-189. https://doi.org/10.3390/jne2020017