Characterization of Lignocellulose Nanofibril from Desilicated Rice Hull with Carboxymethylation Pretreatment

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of LCNF Rice Hull in Different Degree of Substitution (DS)

2.3. Preparation of Hydrogel LCNF Rice Hull with Various DS

2.4. Analysis of Chemical Composition

2.5. Analysis of Degree of Substitution after Carboxymethylation Treatment

2.6. Zeta Potential

2.7. Nanoparticles Analysis

3. Result and Discussion

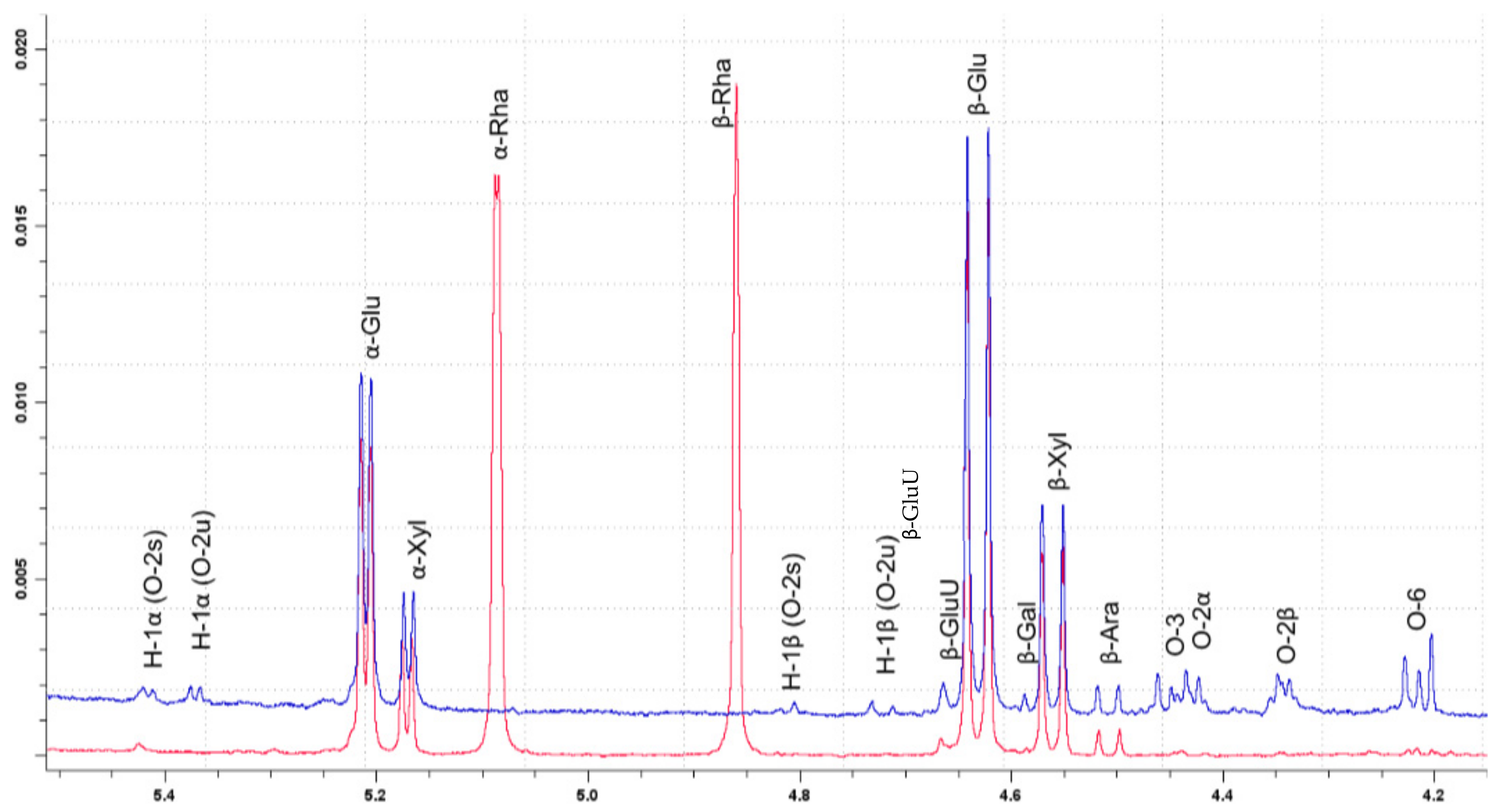

3.1. Carbohydrate Compositional Analysis of Various LCNF DS Desilicated Rice Hulls

3.2. Analysis of the Degree of Substitution of Carboxymethylated LCNF Desilicated Rice Hull

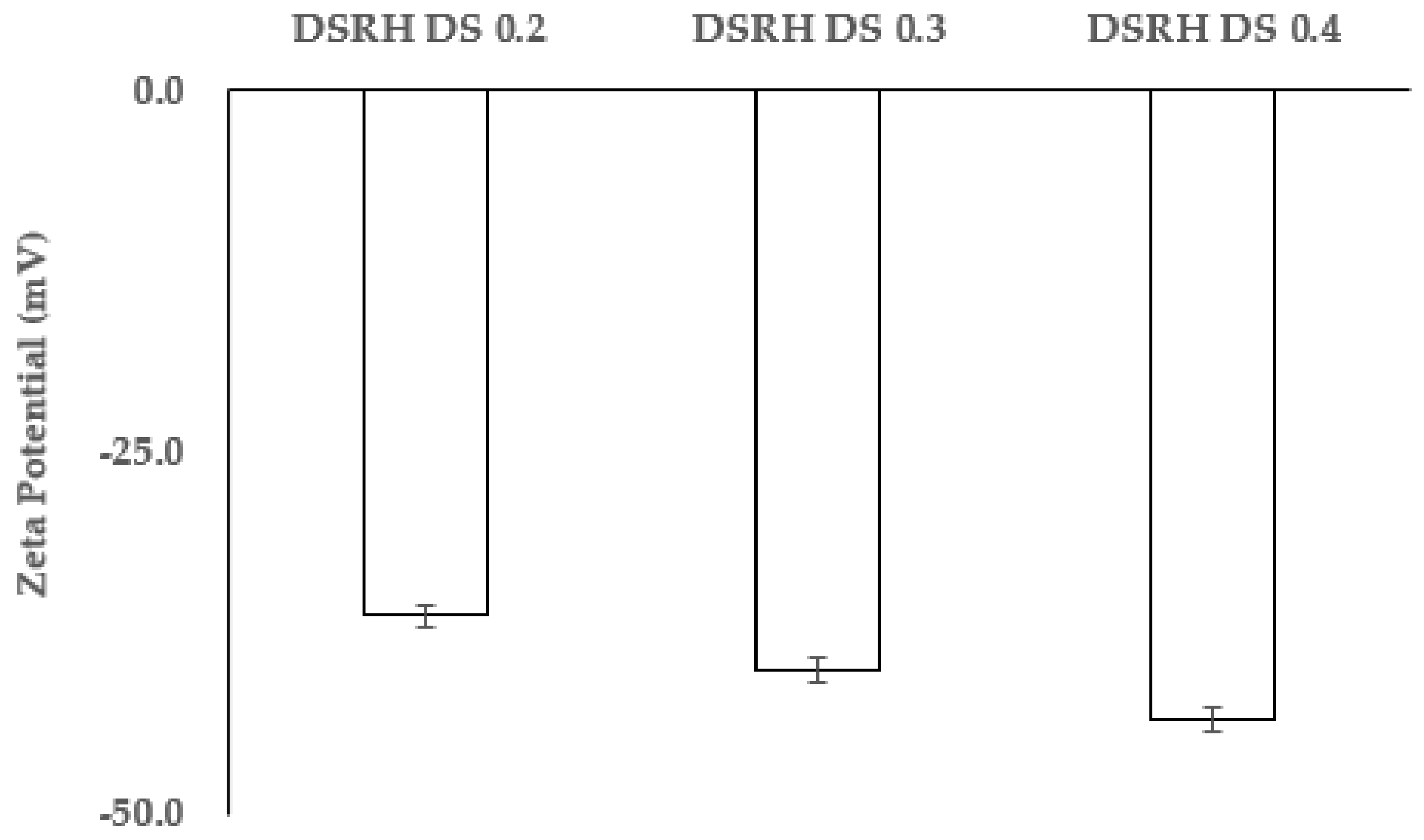

3.3. Zeta Potential of Various LCNF DS Desilicated Rice Hull

3.4. Size of LCNF DS Desilicated Rice Hull

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Antar, M.; Lyu, D.; Nazari, M.; Shah, A.; Zhou, X.; Smith, D.L. Biomass for a sustainable bioeconomy: An overview of world biomass production and utilization. Renew. Sustain. Energy Rev. 2021, 139, 110691. [Google Scholar] [CrossRef]

- Yang, C.; Lü, X. Composition of plant biomass and its impact on pretreatment. In Advances in 2nd Generation of Bioethanol Production; Woodhead Publishing: Cambridge, UK, 2021; pp. 71–85. [Google Scholar] [CrossRef]

- Zhou, M.; Tian, X. Development of different pretreatments and related technologies for efficient biomass conversion of lignocellulose. Int. J. Biol. Macromol. 2022, 202, 256–268. [Google Scholar] [CrossRef] [PubMed]

- Hemati, A.; Nazari, M.; Asgari Lajayer, B.; Smith, D.L.; Astatkie, T. Lignocellulosics in plant cell wall and their potential biological degradation. Folia Microbiol. 2022, 67, 671–681. [Google Scholar] [CrossRef] [PubMed]

- Kumar, J.A.; Sathish, S.; Prabu, D.; Renita, A.A.; Saravanan, A.; Deivayanai, V.C.; Hosseini-Bandegharaei, A. Agricultural waste biomass for sustainable bioenergy production: Feedstock, characterization and pre-treatment methodologies. Chemosphere 2023, 331, 138680. [Google Scholar] [CrossRef] [PubMed]

- Iglesias, M.C.; Gomez-Maldonado, D.; Via, B.K.; Jiang, Z.; Peresin, M.S. Pulping processes and their effects on cellulose fibers and nanofibrillated cellulose properties: A review. For. Prod. J. 2020, 70, 10–21. [Google Scholar] [CrossRef]

- Papavasileiou, P.; Koutras, S.; Koutra, E.; Ali, S.S.; Kornaros, M. A novel rice hull-microalgal biorefinery for the production of natural phenolic compounds comprising of rice hull acid pretreatment and a two-stage Botryococcus braunii cultivation process. Bioresour. Technol. 2023, 387, 129621. [Google Scholar] [CrossRef] [PubMed]

- Goodman, B.A. Utilization of waste straw and husks from rice production: A review. J. Bioresour. Bioprod. 2020, 5, 143–162. [Google Scholar] [CrossRef]

- Singh, A.D.; Bakshi, P.; Kumar, P.; Kour, J.; Dhiman, S.; Ibrahim, M.; Bhardwaj, R. Effects of Agricultural Wastes on Environment and Its Control Measures. In Agricultural and Kitchen Waste; CRC Press: Boca Raton, FL, USA, 2022; pp. 219–239. [Google Scholar]

- Balkissoon, S.; Andrew, J.; Sithole, B. Dissolving wood pulp production: A review. Biomass Convers. Biorefin. 2023, 13, 16607–16642. [Google Scholar] [CrossRef]

- Damasceno, A.; Carneiro, L.; Andrade, N.; Vasconcelos, S.; Brito, R.; Brito, K. Simultaneous prediction of steam production and reduction efficiency in recovery boilers of pulping process. J. Clean. Prod. 2020, 275, 124103. [Google Scholar] [CrossRef]

- Khadraoui, M.; Khiari, R.; Brosse, N.; Bergaoui, L.; Mauret, E. Combination of Steam Explosion and TEMPO-mediated Oxidation as Pretreatments to Produce Nanofibril of Cellulose from Posidonia oceanica Bleached Fibres. BioResources 2022, 17, 2933–2958. [Google Scholar] [CrossRef]

- Zahra, A.; Gao, S.; Park, J.M.; Shin, S.-J. Impact of Carboxymethylation Pretreatment on the Rheology of Cellulose Nanofiber from Bleached Rice Hull. J. Korea TAPPI 2022, 54, 63–72. [Google Scholar] [CrossRef]

- Gao, X.; Lim, S.-K.; Song, W.-Y.; Shin, S.-J.; Seong, H.A. Impact of Carboxymethylation Pretreatment on Bleached Rice Hull Nanofiber by Grinding. J. Korea TAPPI 2021, 53, 146–156. [Google Scholar] [CrossRef]

- Saini, J.K. Lignocellulose-based nanomaterials for diagnostic and therapeutic applications. In Nanobioanalytical Approaches to Medical Diagnostics; Woodhead Publishing: Cambridge, UK, 2022; pp. 285–302. [Google Scholar] [CrossRef]

- Yi, T.; Zhao, H.; Mo, Q.; Pan, D.; Liu, Y.; Huang, L.; Xu, H.; Hu, B.; Song, H. From Cellulose to Cellulose Nanofibrils—A Comprehensive Review of the Preparation and Modification of Cellulose Nanofibrils. Materials 2020, 13, 5062. [Google Scholar] [CrossRef]

- Yu, O.; Kim, K.H. Lignin to Materials: A Focused Review on Recent Novel Lignin Applications. Appl. Sci. 2020, 10, 4626. [Google Scholar] [CrossRef]

- Lee, D.; Oh, Y.; Yoo, J.K.; Yi, J.W.; Um, M.K.; Park, T. Rheological study of cellulose nanofiber disintegrated by a controlled high-intensity ultrasonication for a delicate nano-fibrillation. Cellulose 2020, 27, 9257–9269. [Google Scholar] [CrossRef]

- Balea, A.; Monte, M.C.; Fuente, E.; Sanchez-Salvador, J.L.; Tarrés, Q.; Mutjé, P.; Delgado-Aguilar, M.; Negro, C. Fit-for-Use Nanofibrillated Cellulose from Recovered Paper. Nanomaterials 2023, 13, 2536. [Google Scholar] [CrossRef]

- Ahn, J.; Lee, D.; Youe, W.J.; Lee, B.T.; Lee, T.J.; Seo, J.; Gwon, J. Mechanical Processing Control in Manufacturing Nanofibrillated Cellulose by Interpreting its Rheological Properties. BioResources 2022, 17, 2906–2916. [Google Scholar] [CrossRef]

- Tyagi, P. Nanocellulose-Based Sustainable Barrier and Antimicrobial Coatings. Ph.D. Thesis, North Carolina State University, Raleigh, NC, USA, 2019. [Google Scholar]

- Solala, I.; Iglesias, M.C.; Peresin, M.S. On the potential of lignin-containing cellulose nanofibrils (LCNFs): A review on properties and applications. Cellulose 2020, 27, 1853–1877. [Google Scholar] [CrossRef]

- Rivière, G. Transformation of Lignin and Lignocellulose into Nanoparticles: Structure-Property Relationship and Applications. Ph.D. Thesis, Aalto University, Espoo, Finland, 2021. [Google Scholar]

- Zahra, A.; Lim, S.-K.; Shin, S.-J. Separation of Cellulose from Rice Hull. J. Korea TAPPI 2021, 53, 28–34. [Google Scholar] [CrossRef]

- Kiemle, D.J.; Stipanovic, A.J.; Mayo, K.E. Proton NMR Methods in the Compositional Characterization of Polysaccharides; ACS Publications: Washington, DC, USA, 2004; pp. 122–139. [Google Scholar] [CrossRef]

- Shin, S.J.; Cho, N.S. Conversion factors for carbohydrate analysis by hydrolysis and 1 H-NMR spectroscopy. Cellulose 2008, 15, 255–260. [Google Scholar] [CrossRef]

- Song, W.-Y. Analysis of Degree of Substitution and Substitution Position from Different Carboxymethylation Reaction Condition. Master’s Thesis, Chungbuk National University, Cheongju-si, Republic of Korea, 2018. [Google Scholar]

- ISO 22412; Particle Size Analysis—Dynamic Light Scattering (DLS). ISO: Geneva, Switzerland, 2008.

- Abbas, A.; Ansumali, S. Global potential of rice husk as a renewable feedstock for ethanol biofuel production. BioEnergy Res. 2010, 3, 328–334. [Google Scholar] [CrossRef]

- Ma’ruf, A.; Pramudono, B.; Aryanti, N. Lignin isolation process from rice husk by alkaline hydrogen peroxide: Lignin and silica extracted. AIP Conf. Proc. 2017, 1823, 020013, AIP Publishing LLC. [Google Scholar] [CrossRef]

- Rosado, M.J.; Rencoret, J.; Marques, G.; Gutiérrez, A.; Del Río, J.C. Structural characteristics of the guaiacyl-rich lignins from rice (Oryza sativa L.) husks and straw. Front. Plant Sci. 2021, 12, 640475. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Zhou, Y.; Zheng, G.; Liu, D. Microwave pretreatment of substrates for cellulase production by solid-state fermentation. Appl. Biochem. Biotechnol. 2010, 160, 1557–1571. [Google Scholar] [CrossRef] [PubMed]

- Onyianta, A.J.; Dorris, M.; Williams, R.L. Aqueous morpholine pre-treatment in cellulose nanofibril (CNF) production: Comparison with carboxymethylation and TEMPO oxidisation pre-treatment methods. Cellulose 2018, 25, 1047–1064. [Google Scholar] [CrossRef]

- Md Azman, S.A.H.; Sagadevan, S.; Ahmad, I.; Kassim, M.H.M.; Imam, S.S.; Nguyen, K.D.; Kaus, N.H.M. Integration of carboxymethyl cellulose isolated from oil palm empty fruit bunch waste into bismuth ferrite as photocatalyst for effective anionic dyes degradation. Catalysts 2022, 12, 1205. [Google Scholar] [CrossRef]

- Lavoine, N.; Desloges, I.; Dufresne, A.; Bras, J. Microfibrillated cellulose–Its barrier properties and applications in cellulosic materials: A review. Carbohydr. Polym. 2012, 90, 735–764. [Google Scholar] [CrossRef] [PubMed]

- Zahra, A.; Lim, S.-K.; Shin, S.-J.; Yeon, I.-J. Properties of Green Tea Waste as Cosmetics Ingredients and Rheology Enhancers. Appl. Sci. 2022, 12, 12871. [Google Scholar] [CrossRef]

- Masruchin, N.; Amanda, P.; Kusumaningrum, W.B.; Suryanegara, L.; Nuryawan, A. Particle size distribution and yield analysis of different charged cellulose nanofibrils obtained by TEMPO-mediated oxidation. In IOP Conference Series: Earth and Environmental Science, Proceedings of the 9th International Symposium for Sustainable Humanosphere, Bogor, Indonesia, 28–29 October 2019; IOP Publishing: Bristol, UK, 2020; Volume 572, p. 012045. [Google Scholar] [CrossRef]

- Zhai, L.; Kim, H.C.; Kim, J.W.; Kim, J. Simple centrifugal fractionation to reduce the size distribution of cellulose nanofibers. Sci. Rep. 2020, 10, 11744. [Google Scholar] [CrossRef]

- Liao, J.; Pham, K.A.; Breedveld, V. Rheological characterization and modeling of cellulose nanocrystal and TEMPO-oxidized cellulose nanofibril suspensions. Cellulose 2020, 27, 3741–3757. [Google Scholar] [CrossRef]

- Song, W.Y.; Juhn, S.; Gwak, J.H.; Shin, S.J.; Seong, H.A. Width Length Measurement of Cellulose Nanofibril by Nanoparticle Analyzer: Comparison with TEM Image Analysis. J. Korea TAPPI 2019, 51, 121–127. [Google Scholar] [CrossRef]

- Balea, A.; Blanco, A.; Delgado-Aguilar, M.; Monte, M.C.; Tarres, Q.; Mutjé, P.; Negro, C. Nanocellulose Characterization Challenges. BioResources 2021, 16, 4382–4410. [Google Scholar] [CrossRef]

- Boyd, R.D.; Pichaimuthu, S.K.; Cuenat, A. New approach to inter-technique comparisons for nanoparticle size measurements; using atomic force microscopy, nanoparticle tracking analysis and dynamic light scattering. Colloids Surf. A Physicochem. Eng. Asp. 2011, 387, 35–42. [Google Scholar] [CrossRef]

- Eshel, G.; Levy, G.J.; Mingelgrin, U.; Singer, M.J. Critical evaluation of the use of laser diffraction for particle-size distribution analysis. Soil Sci. Soc. Am. J. 2004, 68, 736–743. [Google Scholar] [CrossRef]

- Siró, I.; Plackett, D. Microfibrillated cellulose and new nanocomposite materials: A review. Cellulose 2010, 17, 459–494. [Google Scholar] [CrossRef]

- Iwamoto, S.; Lee, S.H.; Endo, T. Relationship between aspect ratio and suspension viscosity of wood cellulose nanofibers. Polym. J. 2014, 46, 73–76. [Google Scholar] [CrossRef]

- Han, J.; Zhou, C.; Wu, Y.; Liu, F.; Wu, Q. Self-assembling behavior of cellulose nanoparticles during freeze-drying: Effect of suspension concentration, particle size, crystal structure, and surface charge. Biomacromolecules 2013, 14, 1529–1540. [Google Scholar] [CrossRef]

- Sofla, M.R.K.; Brown, R.J.; Tsuzuki, T.; Rainey, T.J. A comparison of cellulose nanocrystals and cellulose nanofibres extracted from bagasse using acid and ball milling methods. Adv. Nat. Sci. Nanosci. Nanotechnol. 2016, 7, 035004. [Google Scholar] [CrossRef]

| Degree of Substitution (DS) | Grinding (Passes) | High-Pressure Homogenization (Passes) |

|---|---|---|

| 0.2 | 3 | 3 |

| 6 | 6 | |

| 9 | 9 | |

| 0.3 | 3 | 3 |

| 6 | 6 | |

| 9 | 9 | |

| 0.4 | 3 | 3 |

| 6 | 6 | |

| 9 | 9 |

| Sample | Yield | Extractives | Lignin | Polysaccharide | |

|---|---|---|---|---|---|

| Acetone | Hot Water | ||||

| DSRH DS 0.2 | 84.63 | 3.80 | 6.57 | 10.50 | 63.76 |

| DSRH DS 0.3 | 81.49 | 4.36 | 5.67 | 11.23 | 60.23 |

| DSRH DS 0.4 | 78.68 | 5.62 | 4.11 | 12.02 | 56.93 |

| Sample | Galactan | Glucuronic Acid | Arabinan | Cellulose | Xylan | Carboxymethyl |

|---|---|---|---|---|---|---|

| DSRH DS 0.2 | 3.76 | 1.35 | 1.39 | 72.82 | 17.65 | 2.79 |

| DSRH DS 0.3 | 2.86 | 3.45 | 1.38 | 69.40 | 16.28 | 6.24 |

| DSRH DS 0.4 | 1.65 | 6.34 | 1.20 | 66.83 | 15.56 | 8.14 |

| Target DS | Measured DS in DSRH |

|---|---|

| DS 0.2 | 0.17 ± 0.01 |

| DS 0.3 | 0.27 ± 0.01 |

| DS 0.4 | 0.38 ± 0.00 |

| Sample | Grinding | HPH | Width (nm) | Length (nm) |

|---|---|---|---|---|

| DSRH DS 0.2 | 3 | 3 | 890.0 ± 39.5 | 1792.0 ± 28.2 |

| 6 | 220.0 ± 16.1 | 692.9 ± 52.8 | ||

| 9 | 56.3 ± 4.3 | 345.0 ± 47.2 | ||

| 6 | 3 | 138.5 ± 31.1 | 622.6 ± 69.9 | |

| 6 | 92.1 ± 7.3 | 456.2 ± 5.9 | ||

| 9 | 48.0 ±8.0 | 164.3 ± 16.1 | ||

| 9 | 3 | 99.3 ±4.1 | 353.5 ± 41.2 | |

| 6 | 73.1 ± 4.3 | 287.9 ± 8.1 | ||

| 9 | 56.7 ± 4.4 | 246.3 ± 14.9 | ||

| DSRH DS 0.3 | 3 | 3 | 355.7 ± 32.4 | 1523.3 ± 69.0 |

| 6 | 157.7 ± 23.9 | 663.1 ± 27.9 | ||

| 9 | 144.1 ± 29.0 | 317.9 ± 8.8 | ||

| 6 | 3 | 98.0 ± 18.6 | 592.4 ± 24.0 | |

| 6 | 73.0 ± 4.5 | 428.9 ± 22.9 | ||

| 9 | 30.1 ± 10.3 | 151.0 ± 33.4 | ||

| 9 | 3 | 92.6 ± 5.9 | 442.8 ± 29.9 | |

| 6 | 66.4 ± 4.8 | 344.4 ± 28.6 | ||

| 9 | 53.7 ±3.5 | 286.2 ± 8.5 | ||

| DSRH DS 0.4 | 3 | 3 | 125.3 ± 2.6 | 524.0 ± 25.9 |

| 6 | 48.7 ± 5.7 | 327.1 ± 11.4 | ||

| 9 | 37.6 ± 4.3 | 156.3 ± 36.8 | ||

| 6 | 3 | 111.3 ± 9.0 | 518.5 ± 49.8 | |

| 6 | 96.8 ± 15.2 | 393.4 ± 29.3 | ||

| 9 | 40.9 ± 4.7 | 116.6 ± 26.0 | ||

| 9 | 3 | 83.9 ± 3.5 | 408.0 ± 13.6 | |

| 6 | 34.2 ±2.7 | 276.3 ±3.3 | ||

| 9 | 20.0 ± 1.2 | 115 ± 15.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zahra, A.; Lim, S.-K.; Shin, S.-J. Characterization of Lignocellulose Nanofibril from Desilicated Rice Hull with Carboxymethylation Pretreatment. Polysaccharides 2024, 5, 16-27. https://doi.org/10.3390/polysaccharides5010002

Zahra A, Lim S-K, Shin S-J. Characterization of Lignocellulose Nanofibril from Desilicated Rice Hull with Carboxymethylation Pretreatment. Polysaccharides. 2024; 5(1):16-27. https://doi.org/10.3390/polysaccharides5010002

Chicago/Turabian StyleZahra, Audrey, Seo-Kyoung Lim, and Soo-Jeong Shin. 2024. "Characterization of Lignocellulose Nanofibril from Desilicated Rice Hull with Carboxymethylation Pretreatment" Polysaccharides 5, no. 1: 16-27. https://doi.org/10.3390/polysaccharides5010002

APA StyleZahra, A., Lim, S.-K., & Shin, S.-J. (2024). Characterization of Lignocellulose Nanofibril from Desilicated Rice Hull with Carboxymethylation Pretreatment. Polysaccharides, 5(1), 16-27. https://doi.org/10.3390/polysaccharides5010002