Hydrogen Propulsion Technologies for Aviation: A Review of Fuel Cell and Direct Combustion Systems Towards Decarbonising Medium-Haul Aircraft

Abstract

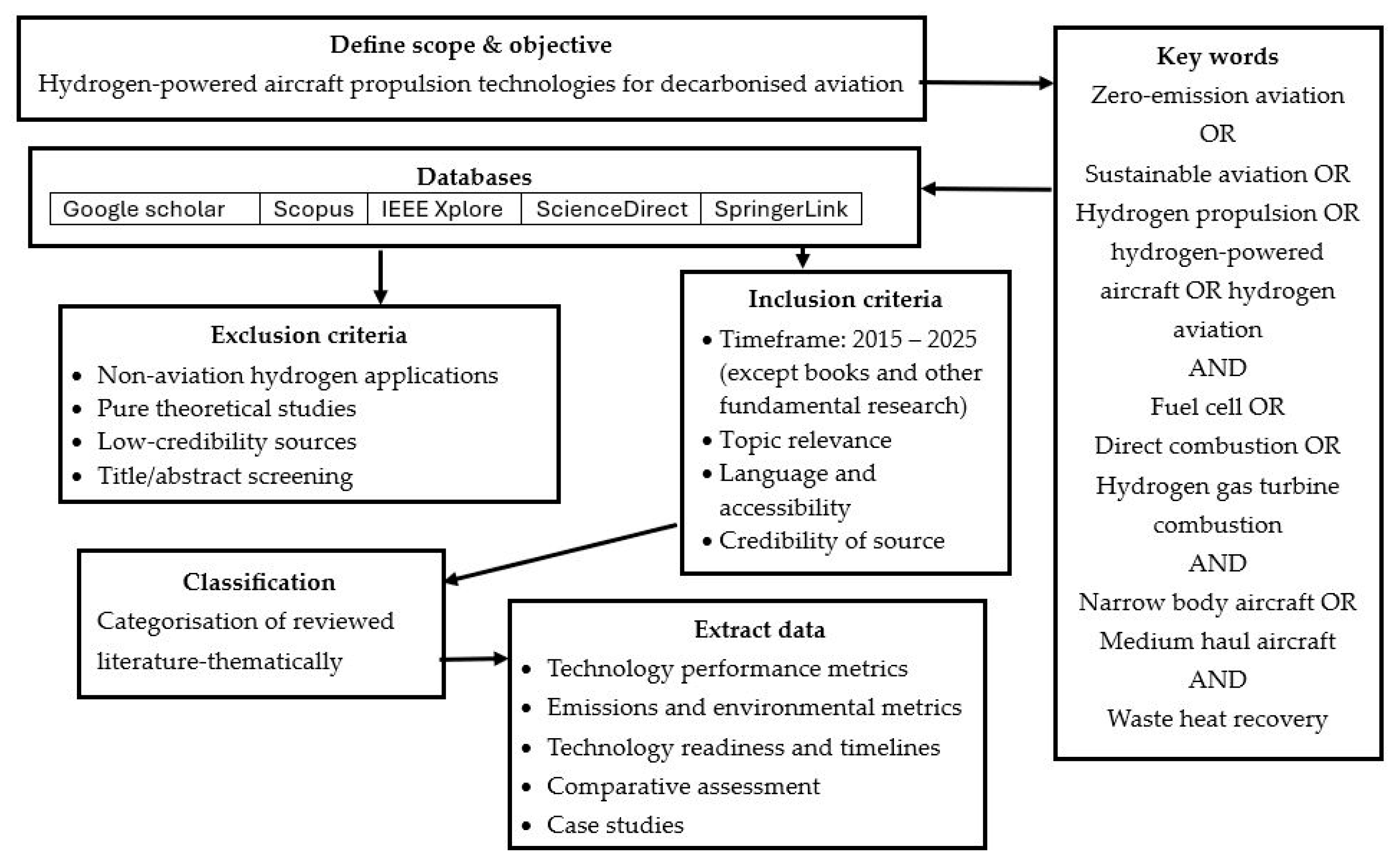

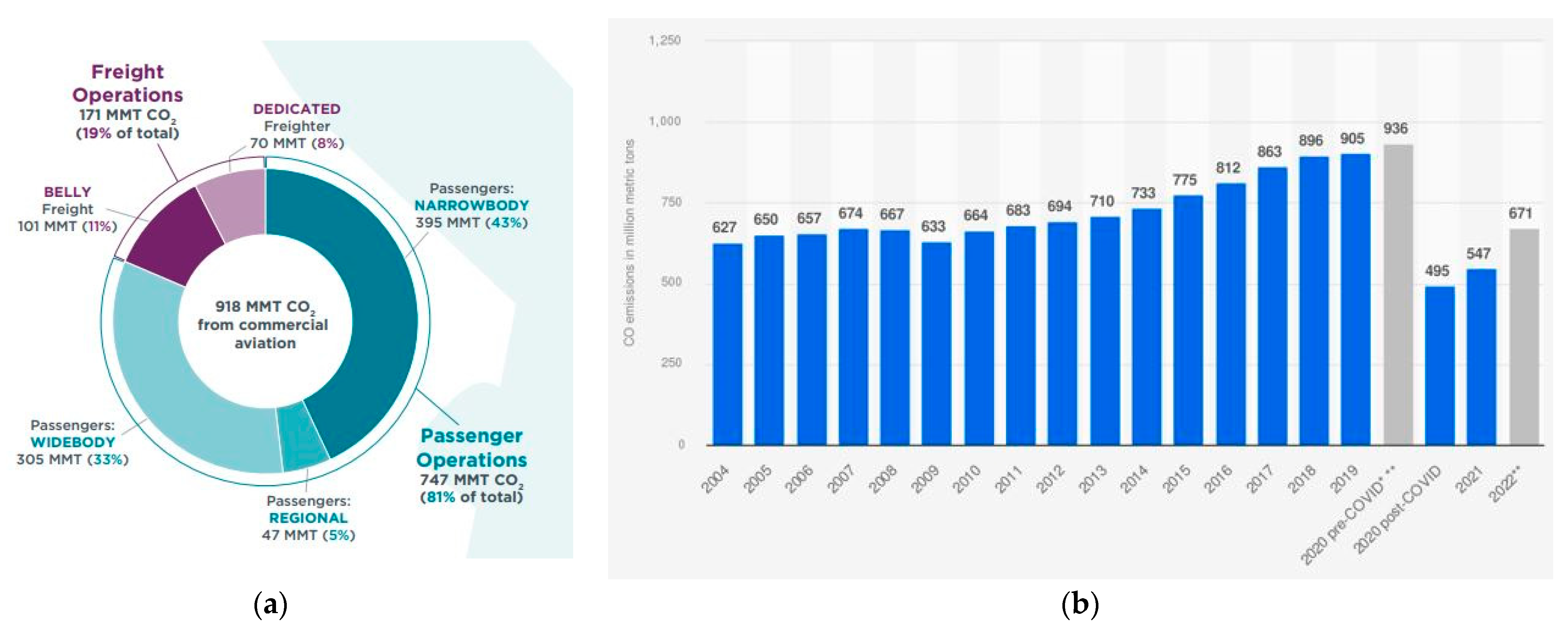

1. Introduction

2. Zero and Low-Emission Fuels Characteristics

| Parameter | Fuel Cells | Hydrogen Combustion | SAF | Battery Hybrid | References |

|---|---|---|---|---|---|

| Specific Energy | 33–40 MJ/kg | 33–40 MJ/kg | ~43 MJ/kg | 0.2–0.4 MJ/kg | [29,30] |

| Energy Efficiency | 45–60% | 35–45% | 38–42% | 80–95% | [31] |

| System Complexity | Very High: Stack, humidifier, compressor, cooling, and inverter | Moderate: Turbine and modified combustor | Low: Drop-in fuel in existing engines | High: Battery packs, inverters, electric motors, and BMS | [32] |

| Fuel/Storage Cost | EUR 6–10/kg LH2 | EUR 6–10/kg LH2 | EUR 1.5–3/kg | EUR 100–200/kWh | [33] |

| GHG Emissions | Zero | Water and NOx | ~80% reduction | Zero | [32,33,34] |

| TRL | Medium | Medium | High | High | [32,33] |

| Constraints | Cooling, durability, and density | Flame stability, NOx control | Supply, feedstock, and LCA | Weight, cooling, and battery aging | [32] |

| Metric | Gray Hydrogen | Blue Hydrogen | Green Hydrogen | References |

|---|---|---|---|---|

| CO2e Intensity (kg CO2e/kg H2) | ~9–11 | ~1.5–5 | ~0.05–1.5 | [38,39] |

| TRL | 9 | 8 | 9 | [40] |

| Cost (USD/kg) | USD 1.00–USD 2.50 | USD 1.50–USD 3.50 | USD 2.50–USD 7.50 | |

| Feedstock | Natural gas | Natural gas + CCS | Renewable electricity + water | [41,42] |

| Water consumption (kg H2O/kg H2) | ~4–7 | ~6–9 | ~9–12 | [43] |

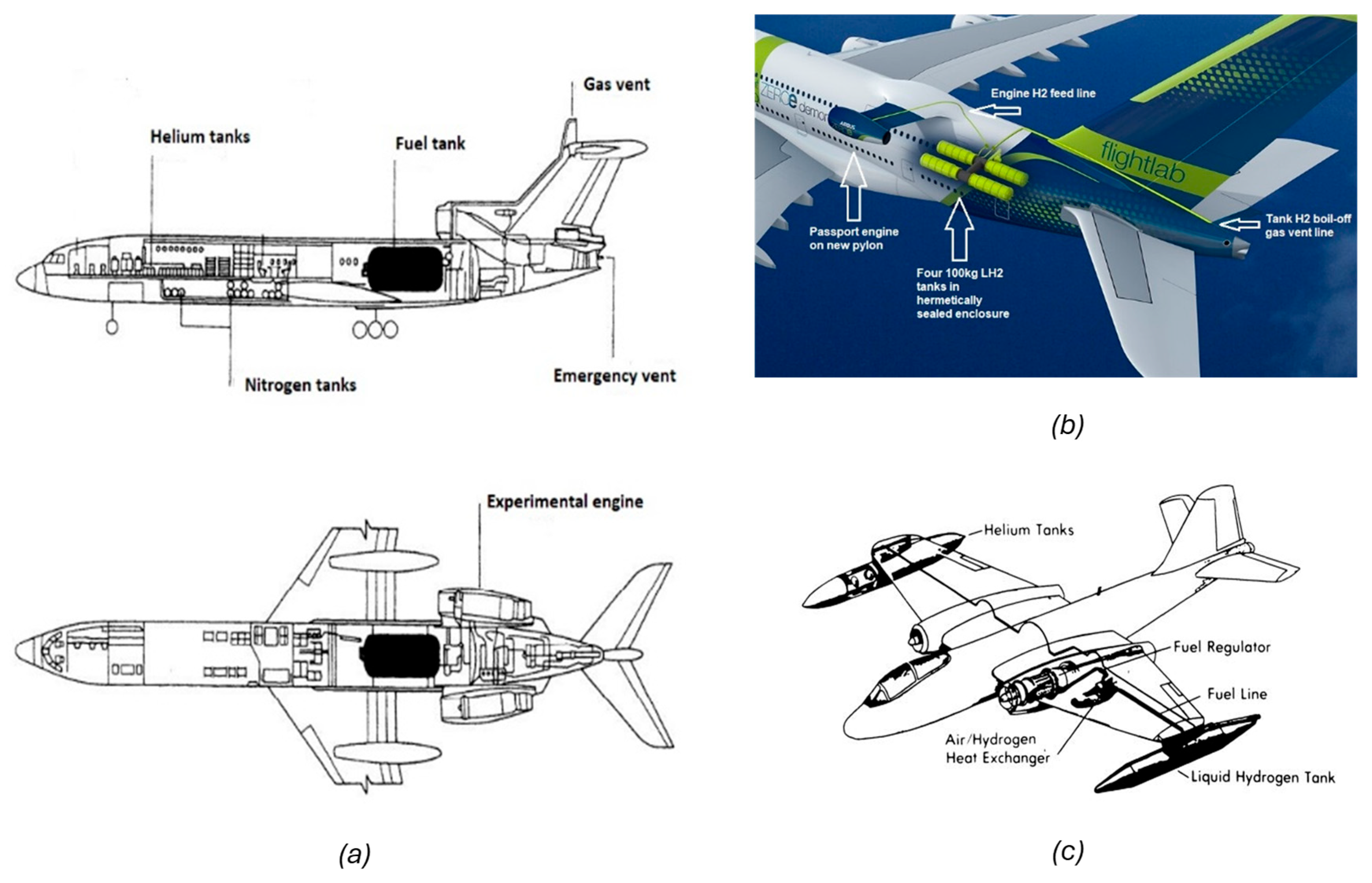

3. Hydrogen-Powered Aircraft

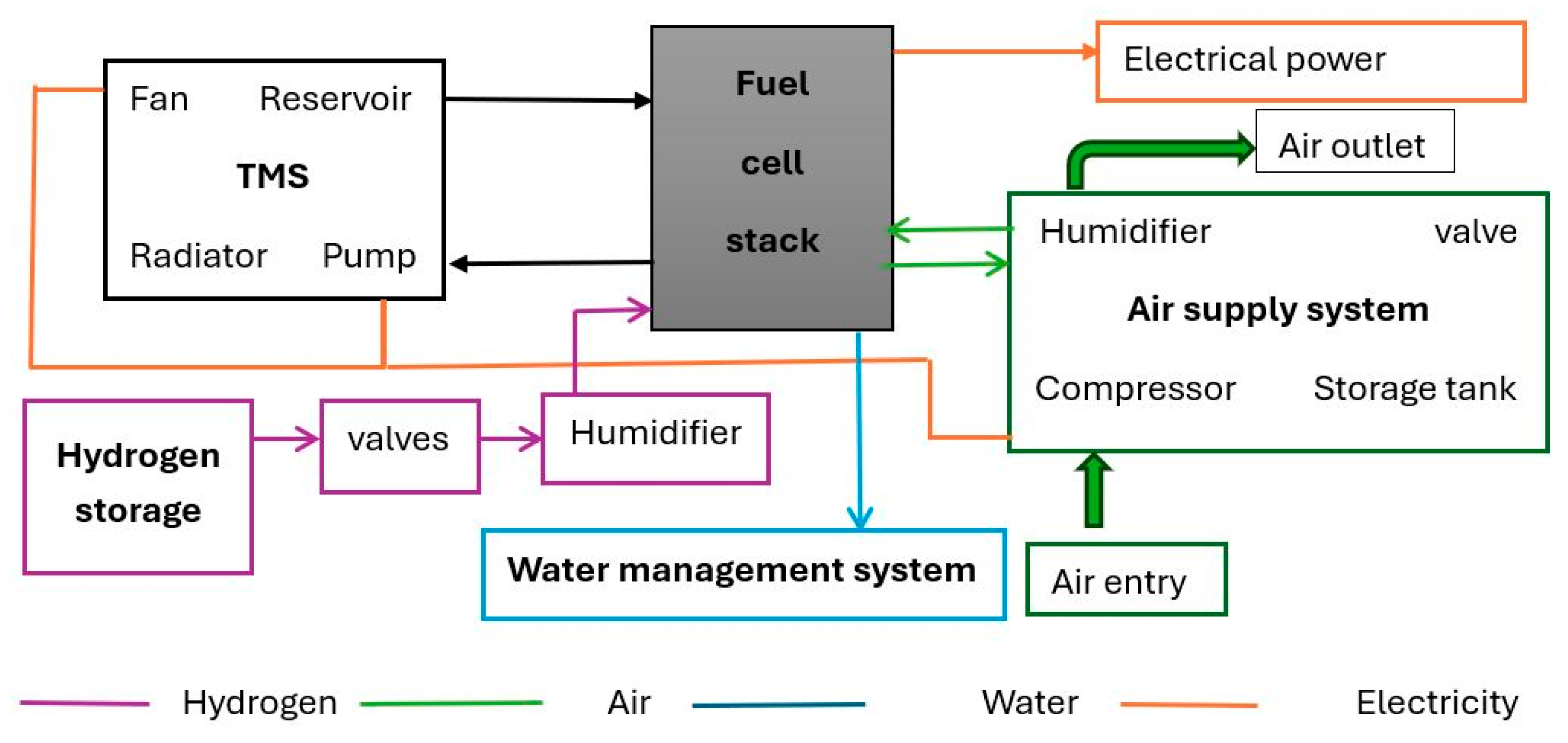

3.1. Fuel Cell Propulsion

3.1.1. Fuel Cell Types

| Industry | Fuel Cell Type | Aircraft Type | Capacity of the Aircraft | Powertrain Capacity | References |

|---|---|---|---|---|---|

| HY4 | LT-PEMFC | Experimental aircraft | 4-seater | 80 kW | [56] |

| ZeroAvia | LT-PEMFC | Piper Malibu M350 | 6-seat aircraft | 250 kW | [57] |

| ZeroAvia | LT-PEMFC | Dornier 228 | 19-seater | 600 kW | [58] |

| Universal Hydrogen | LT-PEMFC | Dash 8-300 | 56-seater | 1–2 MW | [59] |

| Type | Operating Pressure (Bar) | Operating Temperature (Celsius) | Power Density (kW/kg) (Cell Level) | System-Level Efficiency | References |

|---|---|---|---|---|---|

| LT-PEMFC | Up to 3 | 60–80 | Up to 7 | <60% | [50] |

| SOFC | 1–10 | 600–1000 | 0.51 | <65% | [64] |

| HT-PEMFC | Up to 3 | 120–200 | 2.5 | <60% | [58] |

3.1.2. Balance of Plant (BoP)

3.1.3. Power Electronics Systems

3.1.4. Electric Motor

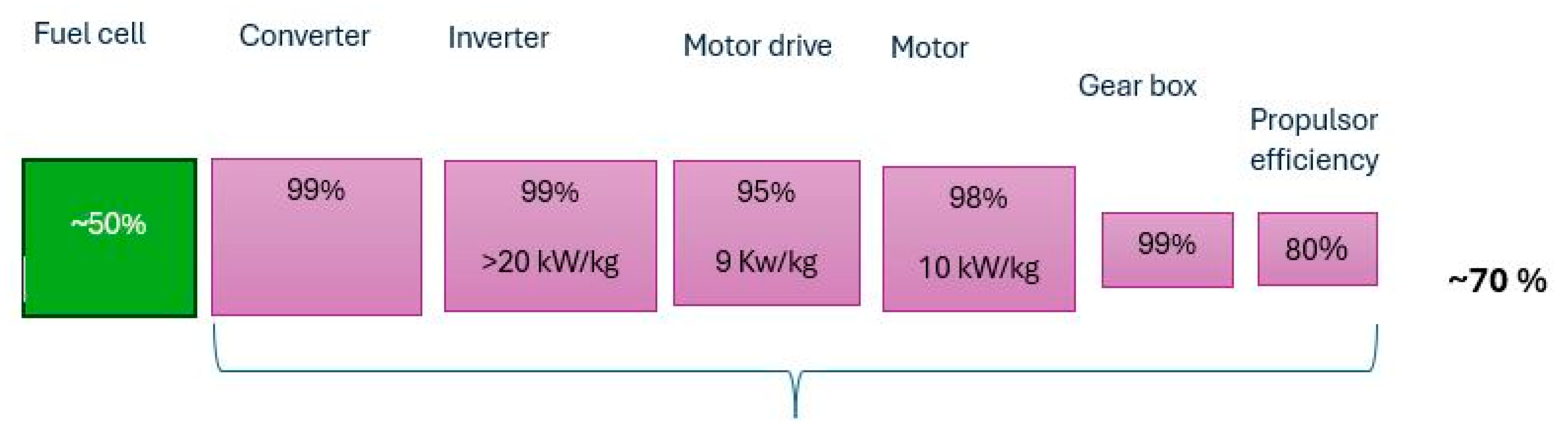

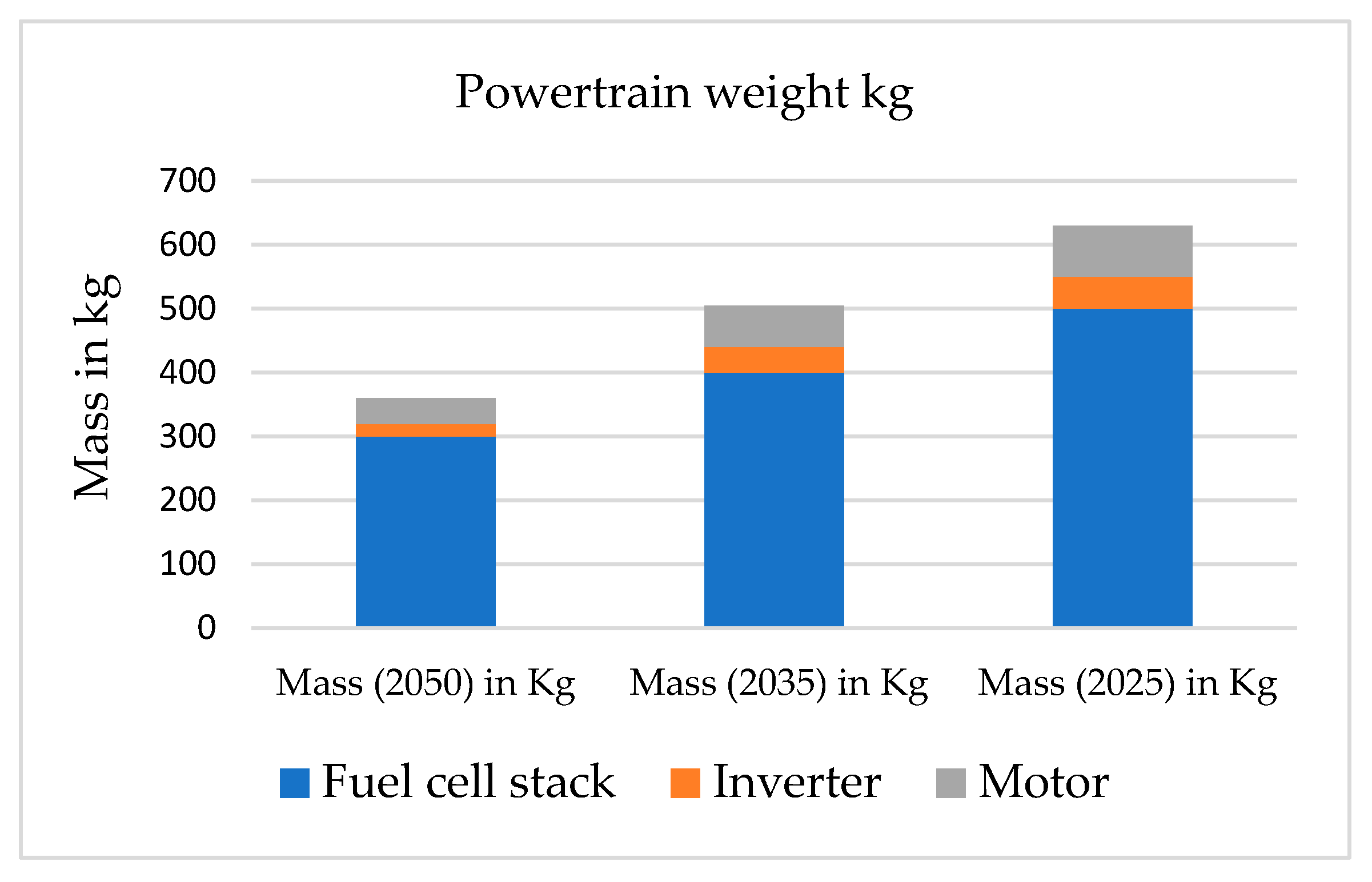

3.2. Hydrogen-Electric Powertrain

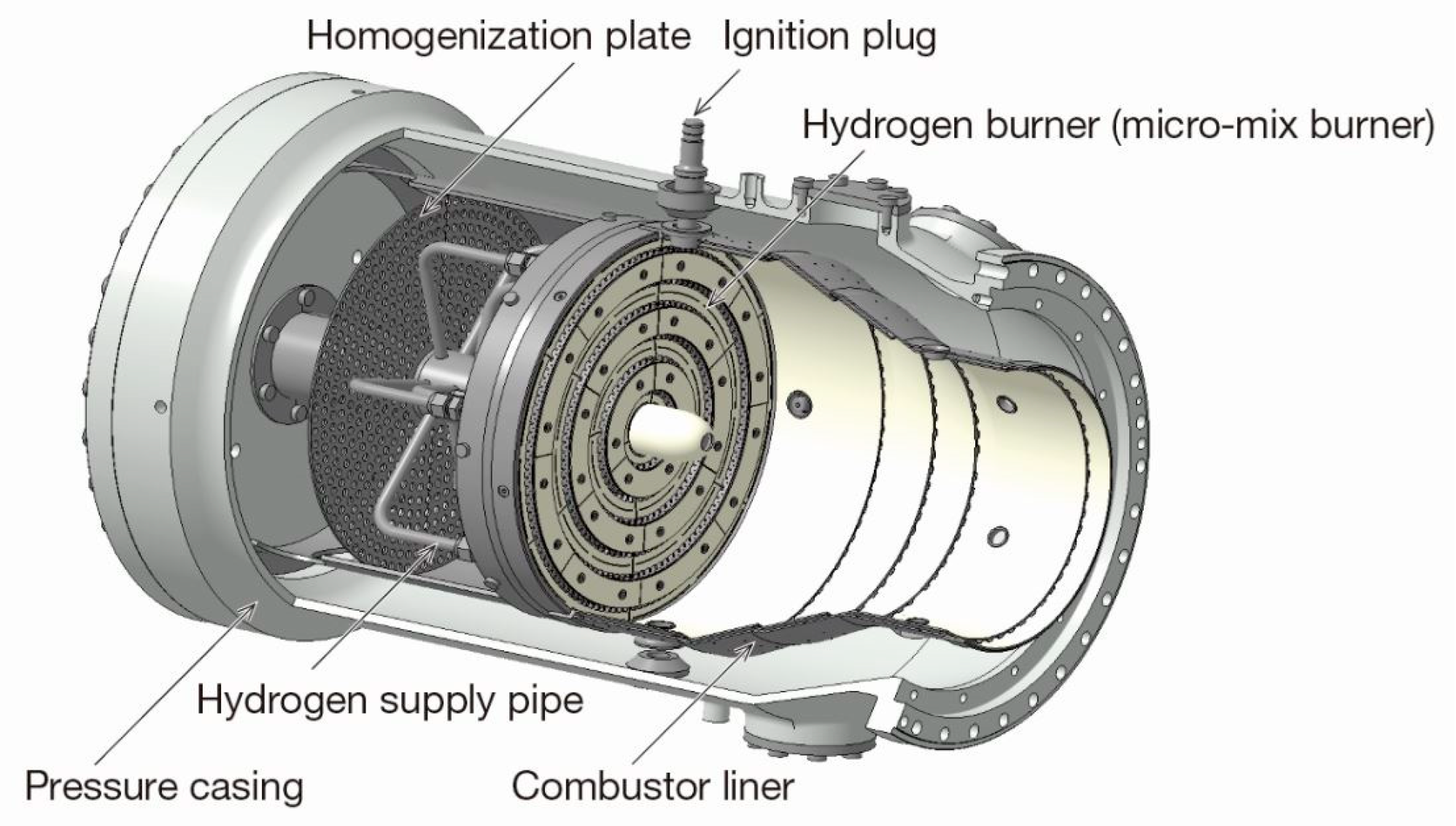

4. Hydrogen Direct Combustion

4.1. Combustion Techniques

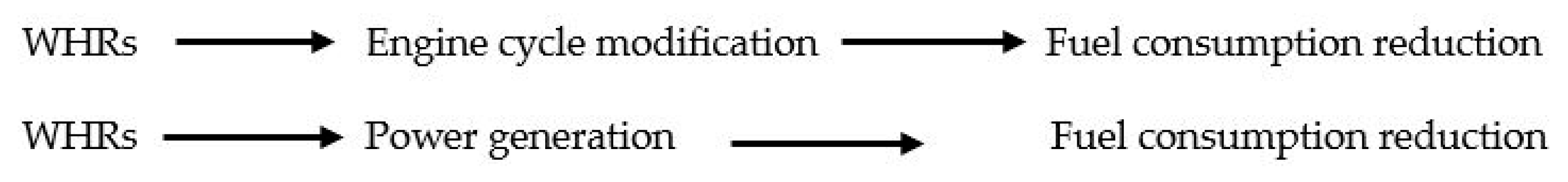

4.2. Waste Heat Recovery Technologies

4.2.1. Organic Rankine Cycle

4.2.2. Supercritical CO2 (sCO2)

4.2.3. Intercooled Recuperated (ICR) Cycles

4.2.4. Thermoelectric Generator (TEG)

| Technology | SFC Reduction/Fuel Saving | Efficiency/Power Density | Key Benefits | Limitations | Research Gaps/Notes | References |

|---|---|---|---|---|---|---|

| Organic Rankine Cycle (ORC) | Up to 4% | Up to ~18%; power density: 1.5 kW/kg | Thermodynamic improvement; utilizes low- to medium-grade waste heat | Heat exchanger size and pressure drop limit performance | Lightweight heat exchangers Optimization of fin design for compact systems | [127,128] |

| Supercritical CO2 (sCO2) | 7–13% | 33% WHR efficiency (system weight increases SFC by 4% due to heat exchanger weight) | High thermodynamic efficiency, potential for compact cycles | High system weight; challenging heat exchanger design | Integration with fuel cell systems remains unexplored Lightweight heat exchangers needed | [130] |

| Intercooled Recuperated (ICR) Cycles | Up to 10% | Increased thermal efficiency by up to 8% | Reduces compressor work and emissions | Increased weight and volume due to complex design | Optimization needed for compact and efficient intercoolers Novel designs showing >9% SFC reduction | [131,140,141] |

| Thermoelectric Generator (TEG) | 0.052–0.1% SFC | Efficiency 3–7%; power density: 1–9 kW/m2 | Compact and low maintenance | Requires large heat exchangers and low overall efficiency | Further work on placement (e.g., de-icing zones), materials, and heat exchanger integration Introduction of low-cost TEG material | [139,142] |

5. Infrastructure and Regulatory Framework Requirements for the Implication of Hydrogen Technology in Aviation

6. Conclusions

- SAFs, hydrogen, and batteries are going to be the future energy mix in aviation.

- Hydrogen-electric powertrain development has gained momentum, as it has the potential to achieve zero CO2 emission flight.

- Hydrogen electric powertrain efficiency is expected to be nearly 55% and half of the weight by 2050, requiring a technology breakthrough to achieve this.

- Hydrogen combustors are expected to reduce NOx and require careful control of the combustion process and properties.

- Gaps in regulatory requirements may delay the entry of hydrogen commercial flights.

- Incorporating a heat recovery system into the powertrain could improve the SFC by up to about 13%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AIA | Aerospace Industries Association |

| AATT | Advanced Air Transport Technology |

| APU | Auxiliary Power Unit |

| ASC | Axially Staged Combustor |

| BoP | Balance of Plant |

| BPR | Bypass Ratio |

| CAEP | Committee on Aviation Environmental Protection |

| CAA UK | Civil Aviation Authority United Kingdom |

| CO2 | Carbon Dioxide |

| CCS | Carbon Capturing system |

| DAC | Double Annular Combustor |

| DC | Direct Current |

| DLR | Deutsches Zentrum für Luft- und Raumfahrt |

| EMI | Electromagnetic Interference |

| GDL | Gas Diffusion Layer |

| GTCP | Gas Turbine Compressor Package |

| HEFA-SPK | Hydroprocessed Esters and Fatty Acids-Synthetic Paraffinic Kerosene |

| IATA | International Air Transport Association |

| ICCT | International Council on Clean Transportation |

| IEA | International Energy Agency |

| IPCC | Intergovernmental Panel on Climate Change |

| LC | Liquid Cooling |

| LH2 | Liquid Hydrogen |

| Li-S | Lithium-Sulphur |

| LHV | Lower Heating Value |

| LPP | Lean Premixed Prevaporized |

| ML | Machine Learning |

| MW | Megawatt |

| NASA | National Aeronautics and Space Administration |

| NEAT | NASA Electric Aircraft Testbed |

| NOx | Nitrogen Oxides |

| PCM | Phase Change Material |

| PMAD | Power Management and Distribution |

| PtL | Power-to-Liquid |

| RQL | Rich-Quench-Lean |

| RPM | Revolutions Per Minute |

| SAF | Sustainable Aviation Fuel |

| SFC | Specific Fuel Consumption |

| SiC | Silicon Carbide |

| SOFC | Solid Oxide Fuel Cell |

| TAPS | Twin Annular Premixing Swirler |

| TMS | Thermal Management System |

| TPC | Two-Phase Cooling |

| TRL | Technology Readiness Level |

| UN | United Nations |

| VGC | Variable Geometry Combustor |

| WHR | Waste Heat Recovery |

References

- IPCC. Global Warming of 1.5 °C.; Cambridge University Press: Cambridge, UK, 2022. [CrossRef]

- Mukhopadhaya, J.; Rutherford, D. Performance Analysis of Evolutionary Hydrogen-Powered Aircraft; International Council on Clean Transportation: Washington, DC, USA, 2022. [Google Scholar]

- Graver, B.; Zheng, S.; Rutherford, D.; Mukhopadhaya, J.; Pronk, E. Vision 2050 Aligning Aviation with the Paris Agreement; International Council on Clean Transportation: Washington, DC, USA, 2022. [Google Scholar]

- Zilliac, G.G.; Bowles, J.V.; Fong, R.K.; Schuh, M.J.; Pham, D.D.V.; Kuptsov, V. Feasibility Study of an All-Electric 150 Passenger Aircraft; AIAA: Reston, VA, USA, 2024. [Google Scholar]

- Tiede, B.; O’meara, C.; Jansen, R. Battery Key Performance Projections based on Historical Trends and Chemistries. In Proceedings of the IEEE Transportation Electrification Conference & Expo (ITEC), Anaheim, CA, USA, 15–17 June 2022. [Google Scholar]

- Barheim, T.; Lamb, J.J.; Noland, J.K.; Burheim, O.S. Potential and Limitations of Battery-Powered All-Electric Regional Flights—A Norwegian Case Study. IEEE Trans. Transp. Electrif. 2023, 9, 1809–1825. [Google Scholar] [CrossRef]

- ZeroAvia. The First Practical Zero-Emission Aviation Powertrain. 2022. Available online: https://www.nordicenergy.org/wp-content/uploads/2019/10/19.Julian-Renz.pdf (accessed on 10 April 2025).

- Brewer, G.D. Hydrogen Aircraft Technology; Routledge: New York, NY, USA, 1991. [Google Scholar] [CrossRef]

- Faass, R. CRYOPLANE: Hydrogen-powered aircraft—Status and challenges. Air Space Eur. 2001, 3, 252–254. [Google Scholar]

- H2FLY. H2FLY Passes First Filling Tests with Integrated Liquid Hydrogen Tank. 2023. Available online: https://www.h2fly.de/2023/04/05/h2fly-accelerates-progress-towards-zero-emission-commercial-flight-3/ (accessed on 15 April 2025).

- ZeroAvia. Together in Electric Dreams—Advancements in Electric Aircraft Propulsion Technology. 2025. Available online: https://zeroavia.com/blogs/together-in-electric-dreams-advancements-in-electric-aircraft-propulsion-technology/ (accessed on 3 September 2025).

- Cranfield Aerospace Solutions. Cranfield Aerospace Solutions is Charting the Flightpath to Cleaner Skies by Delivering Zero Emissions Aircraft and Propulsion Technology. 2024. Available online: https://cranfieldaerospace.com/author/cranfield-aerospace/page/2/ (accessed on 22 July 2025).

- Airbus. Airbus at Paris Air Lab 2025: Discover Tomorrow, Today. 2025. Available online: https://www.airbus.com/en/newsroom/stories/2025-06-airbus-at-paris-air-lab-2025-discover-tomorrow-today (accessed on 22 July 2025).

- United Nations. For a Livable Climate: Net-Zero Commitments Must Be Backed by Credible Action. 2015. Available online: https://www.un.org/en/climatechange/net-zero-coalition (accessed on 26 June 2025).

- IATA. Executive Summary Net Zero CO2 Emissions Roadmap; IATA: Montreal, QC, Canada, 2024. [Google Scholar]

- Bruce, S.; Temminghoff, M.; Hayward, J.; Palfreyman, D.; Burke, N.; Creasey, S. Opportunities for Hydrogen in Commercial Aviation-CSIRO. 2020. Available online: https://www.csiro.au/en/work-with-us/services/consultancy-strategic-advice-services/CSIRO-futures/Energy/hydrogen-commercial-aviation (accessed on 16 April 2025).

- Rakhshani, B.; Stan, A.; Leslie, T. A steady-state model-based evaluation of performance characteristics and feasibility analysis of retrofit hydrogen-powered aircraft configurations. Int. J. Sustain. Aviat. 2024, 10, 99–123. [Google Scholar] [CrossRef]

- Jemioło, W.; Supervisor, M.; Cox, B.; Solvoll, T.G. Life Cycle Assessment of Current and Future Passenger Air Transport in Switzerland. Master’s Thesis, Universitetet i Nordland, Bodø, Norway, 2015. [Google Scholar]

- IATA Sustainable Aviation Fuels in Practice Main milestones so far. 2023. Available online: https://www.iata.org/en/iata-repository/pressroom/fact-sheets/fact-sheet-sustainable-aviation-fuels/ (accessed on 3 May 2025).

- Airbus. What Is Sustainable Aviation Fuel? 2024. Available online: https://www.airbus.com/en/innovation/energy-transition/our-commitment-to-saf/sustainable-aviation-fuels (accessed on 26 June 2025).

- Märkl, R.S.; Voigt, C.; Sauer, D.; Dischl, R.K.; Kaufmann, S.; Harlaß, T.; Hahn, V.; Roiger, A.; Weiß-Rehm, C.; Burkhardt, U.; et al. Powering aircraft with 100% sustainable aviation fuel reduces ice crystals in contrails. Atmos. Chem. Phys. 2024, 24, 3813–3837. [Google Scholar] [CrossRef]

- AIA. Five Years to Chart a New Future for Aviation—The 2030 Sustainable Aviation Goals Report by the AIA; University of Cambridge: Cambridge, UK, 2024. [Google Scholar]

- Brelje, B.J.; Martins, J.R.R.A. Electric, hybrid, and turboelectric fixed-wing aircraft: A review of concepts, models, and design approaches. Prog. Aerosp. Sci. 2019, 104, 1–19. [Google Scholar] [CrossRef]

- National Academies of Sciences, Engineering, and Medicine. Commercial Aircraft Propulsion and Energy Systems Research. Reducing Global Carbon Emissions; National Academies Press: Washington, DC, USA, 2016. [Google Scholar] [CrossRef]

- Grobler, C.; Barrett, S.R.H. Past, Present, and Future Climate Impacts of Aviation. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2016. [Google Scholar]

- Sáez Ortuño, M.Á.; Yin, F.; Gangoli Rao, A.; Vos, R.; Proesmans, P.-J. Climate Assessment of Hydrogen Combustion Aircraft: Towards a Green Aviation Sector; American Institute of Aeronautics and Astronautics (AIAA): Reston, VA, USA, 2023. [Google Scholar] [CrossRef]

- Adler, E.J.; Martins, J.R.R.A. Hydrogen-powered aircraft: Fundamental concepts, key technologies, and environmental impacts. Prog. Aerosp. Sci. 2023, 141, 100922. [Google Scholar] [CrossRef]

- David, H.; Beth, B.; Hodgson, P. Target True Zero Unlocking Sustainable Battery and Hydrogen-Powered Flight. 2022. Available online: https://www3.weforum.org/docs/WEF_Target_True_Zero_Aviation_ROUND_2022.pdf (accessed on 2 May 2025).

- Mertens, J.; Belmans, R.; Webber, M. Why the Carbon-Neutral Energy Transition Will Imply the Use of Lots of Carbon. C 2020, 6, 39. [Google Scholar] [CrossRef]

- Gan, C.; Ma, Q.; Bao, S.; Wang, X.; Qiu, T.; Ding, S. Discussion of the Standards System for Sustainable Aviation Fuels: An Aero-Engine Safety Perspective. Sustainability 2023, 15, 16905. [Google Scholar] [CrossRef]

- ARUP. Hydrogen in Aviation. 2023. Available online: https://www.arup.com/insights/hydrogen-in-aviation/ (accessed on 20 May 2025).

- Alsulaiman, A.; Fellow, O.-A. Navigating Turbulence: Hydrogen’s Role in the Decarbonization of the Aviation Sector; Oxford Institute for Energy Studies: Oxford, UK, 2024. [Google Scholar]

- Detsios, N.; Theodoraki, S.; Maragoudaki, L.; Atsonios, K.; Grammelis, P.; Orfanoudakis, N.G. Recent Advances on Alternative Aviation Fuels/Pathways: A Critical Review. Energies 2023, 16, 1904. [Google Scholar] [CrossRef]

- IATA. Sustainable Aviation Fuel Output Increases, But Volumes Still Low; IATA: Singapore, 2023. [Google Scholar]

- Agarwal, P.; Researcher, P.; Sun, X.; Gauthier, P.Q.; Sethi, V. Injector design space exploration for an ultra-low NOx hydrogen micromix combustion system. In Proceedings of the ASME Turbo Expo 2019: Turbomachinery Technical Conference and Exposition, Phoenix, AZ, USA, 17–21 June 2019. [Google Scholar]

- Eissele, J.; Lafer, S.; Mejía Burbano, C.; Schließus, J.; Wiedmann, T.; Mangold, J.; Strohmayer, A. Hydrogen-Powered Aviation—Design of a Hybrid-Electric Regional Aircraft for Entry into Service in 2040. Aerospace 2023, 10, 277. [Google Scholar] [CrossRef]

- Schnuelle, C.; Wassermann, T.; Stuehrmann, T. Mind the Gap—A Socio-Economic Analysis on Price Developments of Green Hydrogen, Synthetic Fuels, and Conventional Energy Carriers in Germany. Energies 2022, 15, 3541. [Google Scholar] [CrossRef]

- de Kleijne, K.; de Coninck, H.; van Zelm, R.; Huijbregts, M.A.J.; Hanssen, S.V. The many greenhouse gas footprints of green hydrogen. Sustain. Energy Fuels 2022, 6, 4383–4387. [Google Scholar] [CrossRef]

- Webley, P. ‘Green’ Versus ‘blue’ Hydrogen, and the Futility of ‘Colours’; Monash University: Clayton, VIC, Australia, 2022. [Google Scholar]

- Campo Schneider, L.P.; Dhrioua, M.; Ullmer, D.; Egert, F.; Wiggenhauser, H.J.; Ghotia, K.; Kawerau, N.; Grilli, D.; Razmjooei, F.; Ansar, S.A. Advancements in hydrogen production using alkaline electrolysis systems: A short review on experimental and simulation studies. Curr. Opin. Electrochem. 2024, 47, 101552. [Google Scholar] [CrossRef]

- Tong, F.; Michalek, J.; Azevedo, I.L. A review of Hydrogen Production Pathways, Cost and Decarbonization Potential; The International Association for Energy Economics: Cleveland, OH, USA, 2017; pp. 1–2. [Google Scholar]

- Curcio, E. Techno-economic analysis of hydrogen production: Costs, policies, and scalability in the transition to net-zero. Int. J. Hydrogen Energy 2025, 128, 473–487. [Google Scholar] [CrossRef]

- Lin, N.; Arzumanyan, M.; Rodriguez Calzado, E.; Nicot, J.-P. Water Requirements for Hydrogen Production: Assessing Future Demand and Impacts on Texas Water Resources. Sustainability 2025, 17, 385. [Google Scholar] [CrossRef]

- Sharaf, O.Z.; Orhan, M.F. An overview of fuel cell technology: Fundamentals and applications. Renew. Sustain. Energy Rev. 2014, 32, 810–853. [Google Scholar] [CrossRef]

- James, L.; Andrew, D. Fuel Cell Systems Explained, 2nd ed.; J. Wiley: Hoboken, NJ, USA, 2003. [Google Scholar]

- Giorgi, L.; Leccese, F. Fuel Cells: Technologies and Applications; Materials Science & Electrochemistry: Anzio, Italy, 2013. [Google Scholar]

- Bradley, M. Identification and Descriptions of Fuel Cell Architectures for Aircraft Applications. In Proceedings of the IEEE Transportation Electrification Conference and Expo (ITEC), Anaheim, CA, USA, 15–17 June 2022; pp. 1047–1050. [Google Scholar] [CrossRef]

- Toyota. Toyota Mirai Lights Up Festivities in Brussels. 2022. Available online: https://www.toyota-europe.com/news/2022/toyota-mirai-lights-up-festivities-in-brussels (accessed on 26 June 2025).

- Hughes, C.; Gear, C.; Milne, K.; Debney, D. Our Vision for Zero-Carbon Emission Air Travel. 2022. Available online: https://innovair.org/wp-content/uploads/2022/03/FZO-ALL-REP-0004-FlyZero-Our-Vision-for-Zero-Carbon-Emission-Air-Travel.pdf (accessed on 6 June 2025).

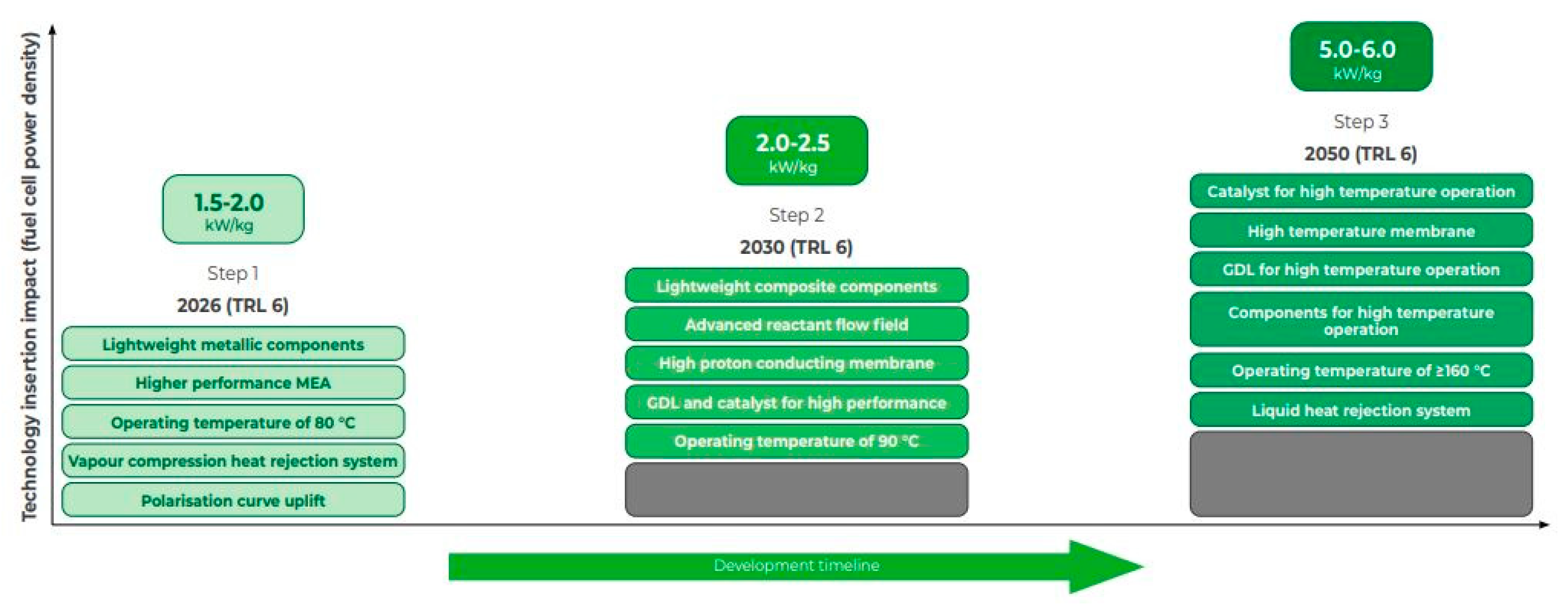

- Bhatti, W.; Wu, W.; Doyle, F.; Llambrich, J.; Webber, H.; Town, N. Fuel Cells Roadmap; Aerospace Technology Institute: Bedford, UK, 2022. [Google Scholar]

- Kazula, S.; de Graaf, S.; Enghardt, L. Review of fuel cell technologies and evaluation of their potential and challenges for electrified propulsion systems in commercial aviation. J. Glob. Power Propuls. Soc. 2023, 7, 43–57. [Google Scholar] [CrossRef]

- Tellez-Cruz, M.M.; Escorihuela, J.; Solorza-Feria, O.; Compañ, V. Proton Exchange Membrane Fuel Cells (PEMFCs): Advances and Challenges. Polymers 2021, 13, 3064. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Chen, K.S.; Mishler, J.; Cho, S.C.; Adroher, X.C. A review of polymer electrolyte membrane fuel cells: Technology, applications, and needs on fundamental research. Appl. Energy 2011, 88, 981–1007. [Google Scholar] [CrossRef]

- Perry, M.L. Durability of Polymer Electrolyte Fuel Cells. PEM Fuel Cells: Theory and Practice; Elsevier: Amsterdam, The Netherlands, 2012; pp. 435–467. [Google Scholar] [CrossRef]

- Borup, R.; Meyers, J.; Pivovar, B.; Kim, Y.S.; Mukundan, R.; Garland, N.; Myers, D.; Wilson, M.; Garzon, F.; Wood, D.; et al. Scientific aspects of polymer electrolyte fuel cell durability and degradation. Chem. Rev. 2007, 107, 3904–3951. [Google Scholar] [CrossRef] [PubMed]

- DLR Zero-Emission Passenger Flights: DLR Presents Project for Hy4 Four-Passenger Fuel Cell Aircraft. 2015. Available online: https://www.dlr.de/en/latest/news/2015/20151012_zero-emission-passenger-flights-dlr-presents-project-for-hy4-four-passenger-fuel-cell-aircraft_15429 (accessed on 26 June 2025).

- Alcock, C. ZeroAvia Makes First Hydrogen Test Flight with Piper Malibu Technology Demonstrator. 2020. Available online: https://www.ainonline.com/news-article/2020-09-25/zeroavia-makes-first-hydrogen-test-flight-piper-malibu-technology (accessed on 26 June 2025).

- ZeroAvia. ZeroAvia High Temperature Fuel Cell Testing Shows Large Aircraft and Rotorcraft Potential for Hydrogen-Electric Propulsion. 2023. Available online: https://zeroavia.com/htpem-fuel-cell-testing/ (accessed on 26 June 2025).

- Powell, L. Universal Hydrogen Flies World’s Largest Hydrogen Fuel Cell-Powered Regional Airliner. 2023. Available online: https://www.laranews.net/universal-hydrogen-flies-worlds-largest-hydrogen-fuel-cell-powered-regional-airliner/ (accessed on 26 June 2025).

- Li, Q.; Jensen, J.O.; Savinell, R.F.; Bjerrum, N.J. High temperature proton exchange membranes based on polybenzimidazoles for fuel cells. Prog. Polym. Sci. 2009, 34, 449–477. [Google Scholar] [CrossRef]

- Tiwari, S.; Pekris, M.J.; Doherty, J.J. A review of liquid hydrogen aircraft and propulsion technologies. Int. J. Hydrog. Energy 2024, 57, 1174–1196. [Google Scholar] [CrossRef]

- Smith, J.R.; Mastorakos, E. An energy systems model of large commercial liquid hydrogen aircraft in a low-carbon future. Int. J. Hydrog. Energy 2024, 52, 633–654. [Google Scholar] [CrossRef]

- Tech Briefs. High-Power-Density Solid Oxide Fuel Cell. 2018. Available online: https://www.techbriefs.com/component/content/article/33394-lew-tops-120 (accessed on 26 June 2025).

- Wehrle, L.; Ashar, A.; Deutschmann, O.; Braun, R.J. Evaluating high power density, direct-ammonia SOFC stacks for decarbonizing heavy-duty transportation applications. Appl. Energy 2024, 372, 123646. [Google Scholar] [CrossRef]

- Kadyk, T.; Winnefeld, C.; Hanke-Rauschenbach, R.; Krewer, U. Analysis and Design of Fuel Cell Systems for Aviation. Energies 2018, 11, 375. [Google Scholar] [CrossRef]

- Filipe, M.; Afonso, F.; Suleman, A. A Study on Thermal Management Systems for Fuel-Cell Powered Regional Aircraft. Energies 2025, 18, 3074. [Google Scholar] [CrossRef]

- Vidović, T.; Tolj, I.; Radica, G.; Bodrožić Ćoko, N. Proton-Exchange Membrane Fuel Cell Balance of Plant and Performance Simulation for Vehicle Applications. Energies 2022, 15, 8110. [Google Scholar] [CrossRef]

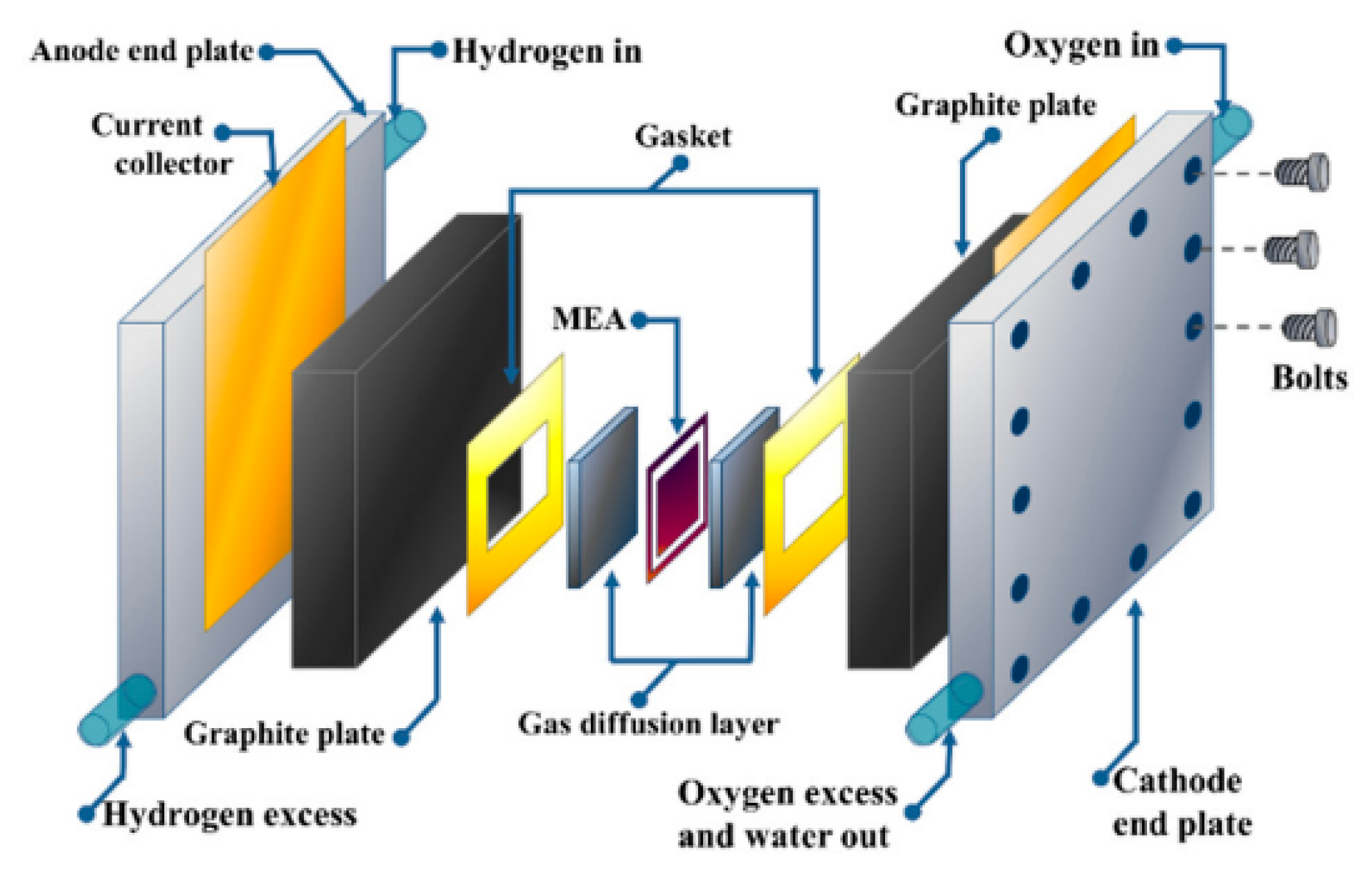

- Barbir, F. Stack Design. In PEM Fuel Cells: Theory and Practice; Elsevier: Amsterdam, The Netherlands, 2012; pp. 159–215. [Google Scholar] [CrossRef]

- Choi, E.J.; Park, J.Y.; Kim, M.S. Two-phase cooling using HFE-7100 for polymer electrolyte membrane fuel cell application. Appl. Therm. Eng. 2019, 148, 868–877. [Google Scholar] [CrossRef]

- Striednig, M.; Cochet, M.; Boillat, P.; Schmidt, T.J.; Büchi, F.N. A model based investigation of evaporative cooling for polymer electrolyte fuel cells—Stack level analysis. J. Power Sources 2022, 517, 230706. [Google Scholar] [CrossRef]

- van Gerner, H.J.; Luten, T.; Resende, W.; Mühlthaler, G.; Buntz, M.B. System Analysis and Comparison Between a 2 MW Conventional Liquid Cooling System and a Novel Two-Phase Cooling System for Fuel Cell-Powered Aircraft. Energies 2025, 18, 849. [Google Scholar] [CrossRef]

- Hemmat Esfe, M.; Afrand, M. A review on fuel cell types and the application of nanofluid in their cooling. J. Therm. Anal. Calorim. 2020, 140, 1633–1654. [Google Scholar] [CrossRef]

- Islam, M.R.; Shabani, B.; Rosengarten, G. Nanofluids to improve the performance of PEM fuel cell cooling systems: A theoretical approach. Appl. Energy 2016, 178, 660–671. [Google Scholar] [CrossRef]

- Fly, A.; Thring, R.H. A comparison of evaporative and liquid cooling methods for fuel cell vehicles. Int. J. Hydrog. Energy 2016, 41, 14217–14229. [Google Scholar] [CrossRef]

- Braumann, L.; Gross, C.; Juen, A.; Amri, H. Achieving Hot-Day Take-Off with Fuel Cells Through Efficient Thermal Management. 2024. Available online: https://exfan-project.eu/sites/default/files/ADT_DLRK2024.pdf (accessed on 19 June 2025).

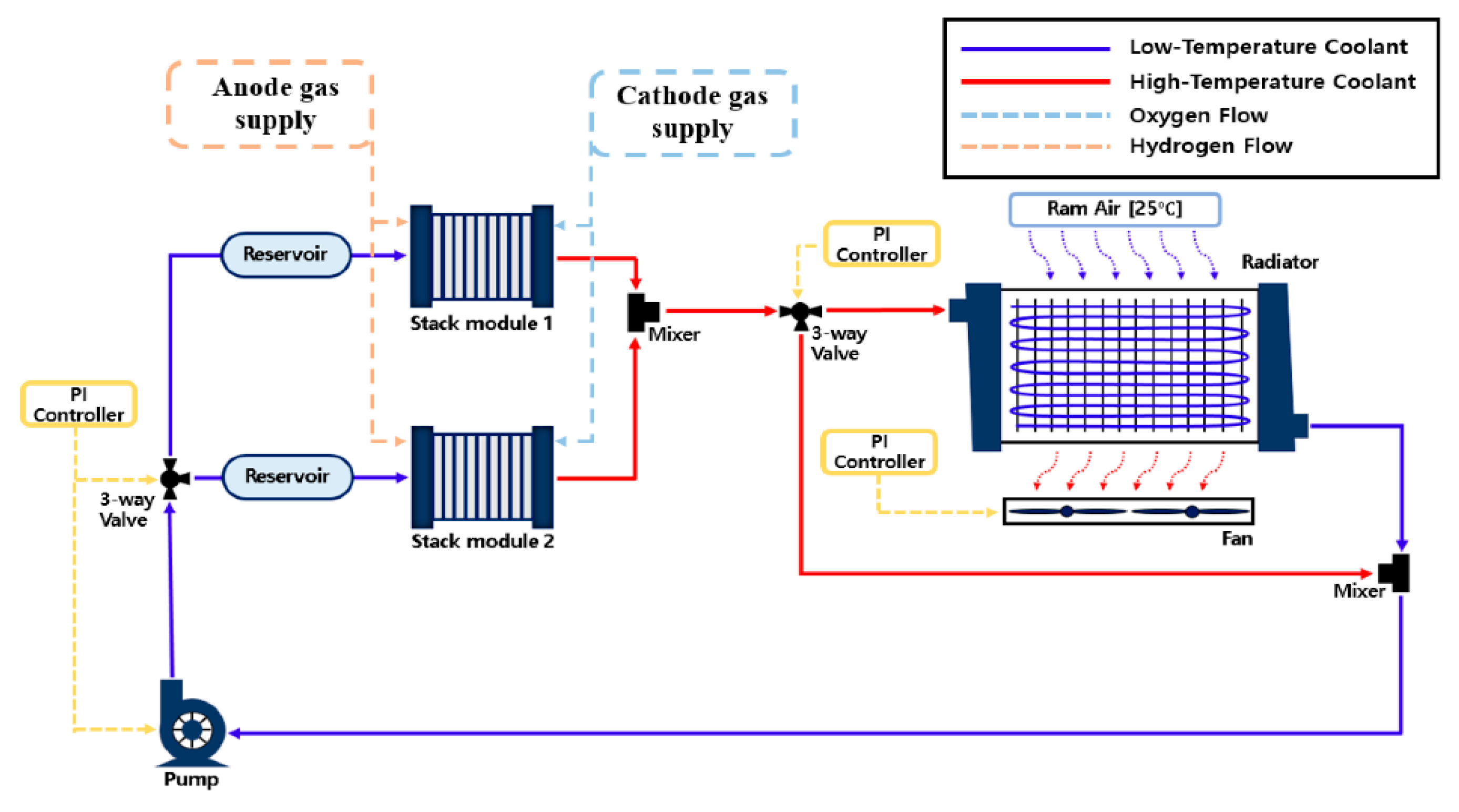

- Woo, J.; Kim, Y.; Yu, S. Cooling-System Configurations of a Dual-Stack Fuel-Cell System for Medium-Duty Trucks. Energies 2023, 16, 2301. [Google Scholar] [CrossRef]

- Pratt, J.W.; Klebanoff, L.E.; Munoz-Ramos, K.; Akhil, A.A.; Curgus, D.B.; Schenkman, B.L. Proton exchange membrane fuel cells for electrical power generation on-board commercial airplanes. Appl. Energy 2013, 101, 776–796. [Google Scholar] [CrossRef]

- Habrard, V.; Hazyuk, I.; Pommier-Budinger, V.; Jezegou, J.; Benard, E. Sensitivity Analysis and Optimization of a Liquid Cooling Thermal Management System for Hybrid Fuel Cell Aircraft. J. Phys. Conf. Ser. 2024, 2716, 012011. [Google Scholar] [CrossRef]

- Baz, F.B.; Elzohary, R.M.; Osman, S.; Marzouk, S.A.; Ahmed, M. A review of water management methods in proton exchange membrane fuel cells. Energy Convers. Manag. 2024, 302, 118150. [Google Scholar] [CrossRef]

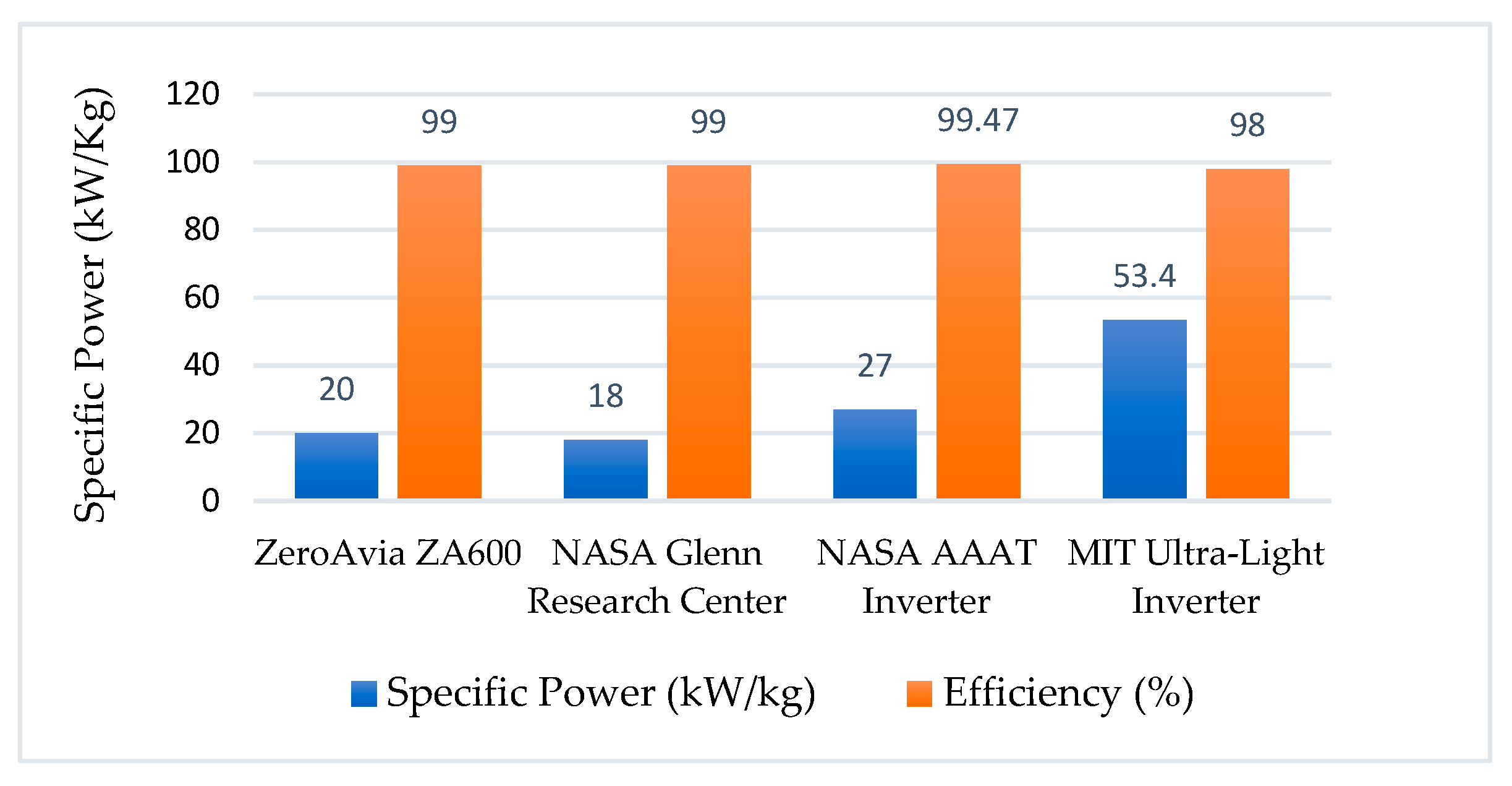

- Wang, F.F.; Chen, R.; Dong, Z. Power Electronics: A critical enabler of future hydrogen-electric systems for aviation. IEEE Electrif. Mag. 2022, 10, 57–68. [Google Scholar] [CrossRef]

- Ren, G.; Qu, Z.; Wang, X.; Zhang, G. Enhancing the performance of proton exchange membrane fuel cell using nanostructure gas diffusion layers with gradient pore structures. Int. J. Hydrog. Energy 2024, 52, 1161–1172. [Google Scholar] [CrossRef]

- Calili-Cankir, F.; Can, E.M.; Ingham, D.B.; Hughes, K.J.; Ma, L.; Pourkashanian, M.; Lyth, S.M.; Ismail, M.S. Patterned hydrophobic gas diffusion layers for enhanced water management in polymer electrolyte fuel cells. Chem. Eng. J. 2024, 484, 149711. [Google Scholar] [CrossRef]

- Ruhkopf, J.; Plachetka, U.; Moeller, M.; Pasdag, O.; Radev, I.; Peinecke, V.; Hepp, M.; Wiktor, C.; Lohe, M.R.; Feng, X.; et al. Graphene Coating of Nafion Membranes for Enhanced Fuel Cell Performance. ACS Appl. Eng. Mater. 2023, 1, 947–954. [Google Scholar] [CrossRef] [PubMed]

- Rosli, R.E.; Sulong, A.B.; Daud, W.R.W.; Zulkifley, M.A.; Husaini, T.; Rosli, M.I.; Majlan, E.H.; Haque, M.A. A review of high-temperature proton exchange membrane fuel cell (HT-PEMFC) system. Int. J. Hydrog. Energy 2017, 42, 9293–9314. [Google Scholar] [CrossRef]

- Frey, A.C.; Bosak, D.; Madrid, E.; Stonham, J.; Sangan, C.M.; Pountney, O.J. Thermal management in high temperature proton exchange membrane fuel cells for aircraft propulsion systems. Prog. Aerosp. Sci. 2025, 153, 101052. [Google Scholar] [CrossRef]

- Wu, Q.; Dong, Z.; Zhang, X.; Zhang, C.; Iqbal, A.; Chen, J. Towards More Efficient PEM Fuel Cells Through Advanced Thermal Management: From Mechanisms to Applications. Sustainability 2025, 17, 943. [Google Scholar] [CrossRef]

- Zhang, D.; He, J.; Pan, D.; Dame, M.; Schutten, M. Development of a high-power density megawatt-scale medium-voltage power converter for aircraft hybrid-electric propulsion systems. In Proceedings of the AIAA Propulsion and Energy Forum and Exposition, Indianapolis, Indiana, 19–22 August 2019; American Institute of Aeronautics and Astronautics Inc., AIAA: Reston, VA, USA, 2019. [Google Scholar] [CrossRef]

- Qasim, M.M.; Otten, D.M.; Spakovszky, Z.S.; Lang, J.H.; Kirtley, J.L.; Perreault, D.J. Design and Optimization of an Inverter for a One-Megawatt Ultra-Light Motor Drive; AIAA: San Diego, CA, USA, 2023. [Google Scholar]

- Wang, J.; Jahns, T.; McCluskey, P.; Kizito, J.; Sarlioglu, B.; Borjas, R.; Swanke, J.A.; Cong, Y.; Yao, Z.; Zeng, H.; et al. 2-kV 1-MW 20,000-RPM Integrated Modular Motor Drive for Electrified Aircraft Propulsion. IEEE J. Emerg. Sel. Top. Power Electron. 2023, 13, 394–407. [Google Scholar] [CrossRef]

- Zhang, H.; Iacchetti, M.F.; Smith, A.C.; Tuohy, P.M.; Manolopoulos, C.D.; Rusu, A.V.; Climente-Alarcon, V. Electromagnetic Characterization of Hyperconducting Aluminum Litz Wires at Cryogenic Temperatures. IEEE Access 2024, 12, 60234–60245. [Google Scholar] [CrossRef]

- Schefer, H.; Canders, W.R.; Hoffmann, J.; Mallwitz, R.; Henke, M. Cryogenically-Cooled Power Electronics for Long-Distance Aircraft. IEEE Access 2022, 10, 133279–133308. [Google Scholar] [CrossRef]

- Fard, M.T.; He, J.; Huang, H.; Cao, Y. Aircraft Distributed Electric Propulsion Technologies—A Review. IEEE Trans. Transp. Electrif. 2022, 8, 4067–4090. [Google Scholar] [CrossRef]

- Sandra, B.S. Cryogenics and Superconductivity for Aircraft, Explained. 2021. Available online: https://www.airbus.com/en/newsroom/stories/2021-03-cryogenics-and-superconductivity-for-aircraft-explained (accessed on 27 June 2025).

- Dyson, R. Aircraft Transportation Electrification Eco-System and Technologies. In Proceedings of the IEEE Transportation Electrification Conference and Expo (ITEC), Washington, DC, USA, 21–25 June 2021. [Google Scholar]

- GKN. GKN Aerospace Launches H2FlyGHT: Pioneering £44M Project for 2 MW Cryogenic Hydrogen-Electric Propulsion. 2024. Available online: www.gknaerospace.com (accessed on 10 June 2025).

- Airbus. Airbus and Toshiba to Partner on Superconductivity Research. 2024. Available online: https://www.airbus.com/en/newsroom/press-releases/2024-10-airbus-and-toshiba-to-partner-on-superconductivity-research (accessed on 21 June 2025).

- Pastra, C.L.; Hall, C.; Cinar, G.; Gladin, J.; Mavris, D.N. Specific Power and Efficiency Projections of Electric Machines and Circuit Protection Exploration for Aircraft Applications. In Proceedings of the IEEE Transportation Electrification Conference and Expo, Anaheim, CA, USA, 15–17 June 2022; pp. 766–771. [Google Scholar] [CrossRef]

- UIUC. Hinetics Unveils Fully Integrated Cryogen-Free Superconducting Motor. Available online: https://grainger.illinois.edu/news/stories/hinetics-unveils-superconducting-motor (accessed on 15 June 2025).

- Balachandran, T.; Salk, N.J.; Xiao, J.; Sirimanna, S.; Bong, U.; Zhao, Y.; Rautela, H.; Bauer, P.; Venkataraaman, R.; Santhanam, S.; et al. Advancements in Superconducting Electric Propulsion: Updates on CHEETA and CRUISE Motors. Available online: https://ieeexplore.ieee.org/stamp/stamp.jsp?arnumber=10870184 (accessed on 10 June 2025).

- El Hajji, T.; Hemeida, A.; Lehikoinen, A.; Martin, F.; Belahcen, A. Optimal Design of High Specific Power Electric Machines for Fully Electric Regional Aircraft: A Case Study of 1MW S-PMSM. Aerospace 2024, 11, 820. [Google Scholar] [CrossRef]

- Vonhoff, G.L.M. Conceptual Design of Hydrogen Fuel Cell Aircraft—Flying on Hydrogen for a More Sustainable Future. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2021. [Google Scholar]

- Kiely, M. The Conceptual Design, Analysis and Optimization of a Hydrogen Combustion and a Hydrogen Fuel-Cell Powered Aircraft. Ph.D. Thesis, McKelvey School of Engineering, St. Louis, MO, USA, 2024. [Google Scholar]

- Hartmann, C.; Noland, J.K.; Nilssen, R.; Mellerud, R. Dual Use of Liquid Hydrogen in a Next-Generation PEMFC-Powered Regional Aircraft with Superconducting Propulsion. IEEE Trans. Transp. Electrif. 2022, 8, 4760–4778. [Google Scholar] [CrossRef]

- GKN. GKN Aerospace Leads New Swedish National Project on Hydrogen Propulsion. 2021. Available online: https://www.gknaerospace.com/news-insights/news/gkn-aerospace-leads-new-swedish-national-project-on-hydrogen-propulsion/ (accessed on 26 June 2025).

- Thomas, M. Hydrogen Combustion, Explained. 2020. Available online: https://www.airbus.com/en/newsroom/stories/2020-11-hydrogen-combustion-explained (accessed on 26 June 2025).

- Safran. Full Throttle on the Hydrogen Turbine for the BeautHyFuel Project! 2024. Available online: https://www.safran-group.com/news/full-throttle-hydrogen-turbine-beauthyfuel-project-2024-04-02#:~:text=A%20promising%20start%20for%20an,Find%20out%20in%20this%20article! (accessed on 26 June 2025).

- Brewer, G.D.; Morris, R.E.; Lange, R.H.; Moore, J.W. Volume I Summary Report: Study of the Application of Hydrogen Fuel to Long-Range Subsonic Transport Aircraft; Divisions of Lockheed Aircraft Corporation: North Bethesda, MA, USA, 1975. [Google Scholar]

- Bicer, Y.; Dincer, I. Life cycle evaluation of hydrogen and other potential fuels for aircrafts. Int. J. Hydrog. Energy 2017, 42, 10722–10738. [Google Scholar] [CrossRef]

- Kawasaki Develops Forty-Percent-Hydrogen Mixed-Fuel Technology in Gas Turbine DLE Combustors. 2021. Available online: https://global.kawasaki.com/en/corp/newsroom/news/detail/?f=20211207_2949 (accessed on 5 May 2025).

- Liu, Y.; Sun, X.; Sethi, V.; Nalianda, D.; Li, Y.G.; Wang, L. Review of modern low emissions combustion technologies for aero gas turbine engines. Prog. Aerosp. Sci. 2017, 94, 12–45. [Google Scholar] [CrossRef]

- Cavaliere, A.; De Joannon, M. Mild combustion. Prog. Energy Combust. Sci. 2004, 30, 329–366. [Google Scholar] [CrossRef]

- de Oliveira, P.M.; Miniero, L.; Pandey, K.; Noiray, N.; Mastorakos, E. A Novel Ultra-Low NOx Hydrogen Combustor Based on the Lean Azimuthal Flame Concept; American Institute of Aeronautics and Astronautics, AIAA SCITECH Forum: Reston, VA, USA, 2023. [Google Scholar] [CrossRef]

- Daggett, D.L.; Fucke, L.; Hendricks, R.C.; Eames, D.J.H. Water Injection on Commercial Aircraft to Reduce Airport Nitrogen Oxides. In Proceedings of the 40th Joint Propulsion Conference and Exhibit, Fort Lauderdale, FL, USA, 11–14 July 2004. [Google Scholar]

- Pratt & Whitney. Pratt & Whitney Awarded Department of Energy Project to Develop Hydrogen Propulsion Technology. 2022. Available online: https://www.prattwhitney.com/en/newsroom/news/2022/02/21/pw-awarded-department-of-energy-project-to-develop-hydrogen-propulsion-technology (accessed on 26 June 2025).

- Zawadzki, N.; Szymański, A.; Igie, U. Effect of Water Injection on Turbofan Engine Compressor Operation and Aerodynamics. In Proceedings of the ASME Turbo Expo 2024: Turbomachinery Technical Conference and Exposition, London, UK, 24–28 June 2024. [Google Scholar]

- Dahl, G.; Suttrop, F. Engine control and low-NOx combustion for hydrogen fuelled aircraft gas turbines. Int. J. Hydrog. Energy 1998, 23, 695–704. [Google Scholar] [CrossRef]

- Ayed, A.H.; Kusterer, K.; Funke, H.H.W.; Keinz, J.; Bohn, D. CFD based exploration of the dry-low-NOx hydrogen micromix combustion technology at increased energy densities. Propuls. Power Res. 2017, 6, 15–24. [Google Scholar] [CrossRef]

- Boretti, A. Towards hydrogen gas turbine engines aviation: A review of production, infrastructure, storage, aircraft design and combustion technologies. Int. J. Hydrog. Energy 2024, 88, 279–288. [Google Scholar] [CrossRef]

- Shankar, A.; Parammasivam, K.M.; Surya Narayanan, S. A review on computational studies on hydrogen combustion for gas turbine applications. Aircr. Eng. Aerosp. Technol. Int. J. 2024, 96, 1225–1233. [Google Scholar] [CrossRef]

- Clemen, C.; Ravikanti, M.; La Bianca, N.; Eggels, R.; Wurm, B.; Young, K. Considerations for hydrogen fueled aerospace gas turbine combustion sub-system design. In Proceedings of the ASME Turbo Expo 2024: Turbomachinery Technical Conference and Exposition, London, UK, 24–28 June 2024. [Google Scholar]

- Foust, M.; Thomsen, D.; Stickles, R.; Cooper, C.; Dodds, W. Development of the GE Aviation Low Emissions TAPS Combustor for Next Generation Aircraft Engines. In Proceedings of the 50th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Nashville, TN, USA, 9–12 January 2012. [Google Scholar] [CrossRef]

- Marek, C.J.; Smith, T.D.; Kundu, K. Low Emission Hydrogen Combustors for Gas Turbines Using Lean Direct Injection. In Proceedings of the 41st AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Tucson, AZ, USA, 10–13 July 2005. [Google Scholar]

- Adolfo, D.; Bertini, D.; Gamannossi, A.; Carcasci, C. Thermodynamic Analysis of an Aircraft Engine to estimate performance and emissions at LTO cycle. Energy Procedia 2017, 126, 915–922. [Google Scholar] [CrossRef]

- De Gouveia Pessanha, A.M. Trends and Limitations of Waste Heat Recovery Technologies in Hybrid Powertrain Architectures. Ph.D. Thesis, University of Bath, Bath, UK, 2023. [Google Scholar]

- Saadon, S.; Talib, A.R.A. An analytical study on the performance of the organic Rankine cycle for turbofan engine exhaust heat recovery. IOP Conf. Ser. Mater. Sci. Eng. 2016, 152, 12011. [Google Scholar] [CrossRef]

- Pateropoulos, G.E.; Efstathiadis, T.G.; Kalfas, A.I. Organic rankine cycle for turboprop engine application. Aeronaut. J. 2021, 125, 1666–1686. [Google Scholar] [CrossRef]

- Krempus, D.; Beltrame, F.; Majer, M.; Maria De Servi, C.; Vos, R.; Colonna, P. ORC Waste Heat Recovery System for the Turboshaft Engines of Turboelectric Aircraft. Delft University of Technology: Delft, The Netherlands, 2023. [Google Scholar] [CrossRef]

- Beltrame, F. Reduced Order Modelling of Optimized Heat Exchangers for Maximum Mass-Specific Performance of Airborne ORC Waste Heat Recovery Units. In Proceedings of the 7th International Seminar on ORC Power System (ORC 2023), Editorial Universidad de Sevilla, Seville, Spain, 4–6 September 2024; pp. 563–573. [Google Scholar] [CrossRef]

- Ken, C.Z.; Saadon, S. Analysis of Recuperation Supercritical Carbon Dioxide Cycle for Heat Recovery of an Aircraft Engine. J. Adv. Res. Fluid. Mech. Therm. Sci. 2022, 96, 1–9. [Google Scholar] [CrossRef]

- Bury, C.-P.; Vesely, L.; Otto, M.; Kapat, J.; Stoia, M. sCO2 Waste Heat Recovery System for Turbofan Engine-System Optimization and Component Design. In Proceedings of the 8th International Supercritical CO2 Power Cycles Symposium, San Antonio, TX, USA, 27–29 February 2024. [Google Scholar]

- Misirlis, D.; Vlahostergios, Z.; Flouros, M.; Salpingidou, C.; Donnerhack, S.; Goulas, A.; Yakinthos, K. Optimization of heat exchangers for intercooled recuperated Aero Engines. Aerospace 2017, 4, 14. [Google Scholar] [CrossRef]

- Xu, Y.; Tang, H.; Chen, M.; Duan, F. Optimization and design of heat recovery system for aviation. Appl. Therm. Eng. 2020, 165, 114581. [Google Scholar] [CrossRef]

- McDonald, C.F.; Massardo, A.F.; Rodgers, C.; Stone, A. Recuperated gas turbine aeroengines. Part III: Engine concepts for reduced emissions, lower fuel consumption, and noise abatement. Aircr. Eng. Aerosp. Technol. 2008, 80, 408–426. [Google Scholar] [CrossRef]

- Zhao, X.; Grönstedt, T.; Kyprianidis, K. Assessment of the Performance Potential for a Two-Pass Cross Flow Intercooler for Aero Engine Applications. In Proceedings of the International Society for Airbreathing Engines, ISABE, Busan, Republic of Korea, 9–13 September 2013. [Google Scholar]

- Petit, O.; Xisto, C.; Zhao, X.; Grönstedt, T. An outlook for radical aero engine intercooler concepts. In Proceedings of the ASME Turbo Expo 2016: Turbomachinery Technical Conference and Exposition, Seoul, Republic of Korea, 13–17 June 2016; Volume 3. [Google Scholar] [CrossRef]

- Ali, A.; Houda, M.; Waqar, A.; Khan, M.B.; Deifalla, A.; Benjeddou, O. A review on application of hydrogen in gas turbines with intercooler adjustments. Results Eng. 2024, 22, 101979. [Google Scholar] [CrossRef]

- Lee, V.D.; Brisson, J.G. Waste Heat Reclamation in Aircraft Engines. Master’s Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2014. [Google Scholar]

- Bode, C.; Friedrichs, J.; Somdalen, R.; Köhler, J.; Büchter, K.-D.; Falter, C.; Kling, U.; Ziolkowski, P.; Zabrocki, K.; Müller, E.; et al. Potential of Future Thermoelectric Energy Recuperation for Aviation. In Proceedings of the ASME 2016 International Mechanical Engineering Congress and Exposition, Phoenix, AZ, USA, 11–17 November 2016. [Google Scholar] [CrossRef]

- Ziolkowski, P.; Zabrocki, K.; Müller, E. TEG design for waste heat recovery at an aviation jet engine nozzle. Appl. Sci. 2018, 8, 2637. [Google Scholar] [CrossRef]

- Saravanamuttoo, H.I.H.; Rogers, G.F.C.; Cohen, H. Gas Turbine Theory, 5th ed.; Pearson Education, Ltd.: London, UK, 2001. [Google Scholar]

- Patrao, A.C.; Jonsson, I.; Xisto, C.; Lundbladh, A.; Grönstedt, T. Compact heat exchangers for hydrogen-fueled aero engine intercooling and recuperation. Appl. Therm. Eng. 2024, 243, 122538. [Google Scholar] [CrossRef]

- Jouhara, H.; Żabnieńska-Góra, A.; Khordehgah, N.; Doraghi, Q.; Ahmad, L.; Norman, L.; Axcell, B.; Wrobel, L.; Dai, S. Thermoelectric generator (TEG) technologies and applications. Int. J. Thermofluids 2021, 9, 100063. [Google Scholar] [CrossRef]

- Jézégou, J.; Almeida-Marino, A.M.; O’Sullivan, G.; Carrasco, B.J.; André, R.; Gourinat, Y. Certification Gap Analysis for Normal-Category and Large Hydrogen-Powered Airplanes. Aerospace 2025, 12, 239. [Google Scholar] [CrossRef]

- Jézégou, J.; André, R.; Gourinat, Y. International Conference on More Electric Aircraft Towards greener aviation Toulouse Hydrogen Aircraft Certification: Determination of Regulatory Gaps. In Proceedings of the International Conference on More Electric Aircraft (MEA2024), Toulouse, France, 7–8 February 2024. [Google Scholar] [CrossRef]

- FAA Hydrogen-Fueled Aircraft Safety and Certification Roadmap. 2024. Available online: https://www.faa.gov/aircraft/air_cert/step/disciplines/propulsion_systems/hydrogen-fueled_aircraft_roadmap (accessed on 9 July 2025).

- EASA Certification Roadmap on H2—International Workshop. 2024. Available online: https://www.easa.europa.eu/en/newsroom-and-events/events/easa-certification-roadmap-h2-international-workshop-2024 (accessed on 2 July 2025).

- ZeroAvia. ZeroAvia Receives FAA G-1 for 600kW Electric Propulsion System. 2025. Available online: https://zeroavia.com/zeroavia-receives-faa-g-1-for-600kw-electric-propulsion-system/ (accessed on 11 July 2025).

- Schmidtchen, U.; Behrend, E.; Pohl, H.-W.; Rostek, N. Hydrogen aircraft and airport safety. Renew. Sustain. Energy Rev. 1997, 1, 239–269. [Google Scholar] [CrossRef]

- Gu, Y.; Wiedemann, M.; Ryley, T.; Johnson, M.E.; Evans, M.J. Hydrogen-Powered Aircraft at Airports: A Review of the Infrastructure Requirements and Planning Challenges. Sustainability 2023, 15, 15539. [Google Scholar] [CrossRef]

- Lu, X.; Krutoff, A.-C.; Wappler, M.; Fischer, A. Key influencing factors on hydrogen storage and transportation costs: A systematic literature review. Int. J. Hydrog. Energy 2025, 105, 308–325. [Google Scholar] [CrossRef]

- Aziz, M. Liquid hydrogen: A review on liquefaction, storage, transportation, and safety. Energies 2021, 14, 5917. [Google Scholar] [CrossRef]

| Component Specific Power kW/kg | ||||

|---|---|---|---|---|

| Year | 2025 | 2035 | 2050 | |

| Components | ||||

| Fuel cell + BOP | 2 | 2.5 | 3.5 | |

| PMAD | >20 | >25 | 25–50 | |

| Motor | 13 | >15 | >25 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gopalasingam, D.; Rakhshani, B.; Rodriguez, C. Hydrogen Propulsion Technologies for Aviation: A Review of Fuel Cell and Direct Combustion Systems Towards Decarbonising Medium-Haul Aircraft. Hydrogen 2025, 6, 92. https://doi.org/10.3390/hydrogen6040092

Gopalasingam D, Rakhshani B, Rodriguez C. Hydrogen Propulsion Technologies for Aviation: A Review of Fuel Cell and Direct Combustion Systems Towards Decarbonising Medium-Haul Aircraft. Hydrogen. 2025; 6(4):92. https://doi.org/10.3390/hydrogen6040092

Chicago/Turabian StyleGopalasingam, Daisan, Bassam Rakhshani, and Cristina Rodriguez. 2025. "Hydrogen Propulsion Technologies for Aviation: A Review of Fuel Cell and Direct Combustion Systems Towards Decarbonising Medium-Haul Aircraft" Hydrogen 6, no. 4: 92. https://doi.org/10.3390/hydrogen6040092

APA StyleGopalasingam, D., Rakhshani, B., & Rodriguez, C. (2025). Hydrogen Propulsion Technologies for Aviation: A Review of Fuel Cell and Direct Combustion Systems Towards Decarbonising Medium-Haul Aircraft. Hydrogen, 6(4), 92. https://doi.org/10.3390/hydrogen6040092