1. Introduction

Hydrogen can become a crucial technology in building an independent energy infrastructure for Europe. With a comparably high lower heating value of 119.96 MJ/kg [

1] and no direct harmful emission during use, hydrogen presents a viable alternative for conventional coal and natural gas in the energy sector, for fossil fuels in hydrocarbon-burning internal combustion engines, and through fuel cells, a method for on-board electricity generation for electric vehicles. Furthermore, independently of the final form of usage, hydrogen will play a key role in integrating green electricity into the grid, as according to the state-of-the-art, large-scale, long-term energy storage is only feasible in molecules containing hydrogen [

2].

In September 2022, the European Commission approved “IPCEI Hy2Use”, the second Important Project of Common European Interest in the hydrogen value chain. This unlocked financial resources of 5.2 billion EUR to support the research and development of innovative and scalable hydrogen production technologies and hydrogen-based energetics and mobility solutions [

3]. However, the applicability of hydrogen for specific industries must be analyzed through comprehensive lifecycle methodologies to objectively assess the impact of transitioning to hydrogen—i.e., is hydrogen the techno-economic optimal solution for a specific industry? Moreover, there is a huge shift in the vehicle industry towards electrification and sustainable drivetrains. There are several new countries and regions (e.g., China, ASEAN) that would like to define the future of mobility [

4].

Regarding the contribution of mobility to total greenhouse gas (GHG) emissions, a deviation of up to 10% in the total contribution of the transport sector can be found between sources due to the difference in assessment systems and criteria. The International Energy Agency (IEA) Statistics published by the World Bank show that the contribution of CO

2 emissions of transport to total fuel combustion was between 19% and 22% over the last 50 years (1960–2014) [

5]. It is important to point out that thinking in purely proportional terms can lead to inaccuracies since the exact values are ignored, as in this case. It is important to note that although the proportional share of the transport sector in global CO

2 emissions remained nearly constant, in absolute terms the sector’s emissions increased from approx. 4 Gt in 1990 to more than 7 Gt in 2019, moving in parallel with total global emissions [

6]. Therefore, the CO

2 emissions of the transport sector have grown together with total CO

2 emissions. This value provides the basis for a deeper study on carbon-neutral mobility.

Based on the IEA analysis, it can be concluded that road transport accounts for more than 70% of the total GHG contribution of the transport sector [

7]. The data published by the IEA shows that the closures due to COVID-19 and the reduction in economic trade contributed to a reduction of GHG emissions from the transport sector by approx. 13%. This period ended nearly ten years of massive GHG emission growth, but as anticipated, lifting restrictions and the resurgence of industry and trade have led to a significant increase in emissions again. Therefore, it is worth researching this issue to ensure a sustainable transport sector—especially road transport—while ensuring that industry and everyday life function correctly.

The European Union (EU) has set out several commitments to achieve carbon neutrality, such as recharging and refueling infrastructure for hydrogen, R&I projects for decarbonizing aviation and maritime transport, and revision of the Directive on Alternative Fuels Infrastructure (AFID).

By 2030, the European Commission envisions at least 30 million zero-emission vehicles in operation on European roads, 100 climate-neutral European cities, doubled high-speed rail traffic, carbon-neutral scheduled collective travel of under 500 km within the EU, automated mobility deployed at a large scale, and market-ready zero-emission vessels [

8]. By 2035, zero-emission large aircraft are anticipated to be ready for market introduction. By 2050, the EU has set out the following deliverables: nearly all cars, vans, buses, as well as new heavy-duty vehicles, should be zero-emission, rail freight traffic should double, high-speed rail traffic should triple, and the multimodal Trans-European Transport Network (TEN-T) equipped for sustainable and intelligent transport with high-speed connectivity should be operational for the comprehensive network.

If we consider only mobility, we can realize that hydrogen has multiple pathways to reduce greenhouse gas emissions. Besides its usage in fuel cells, hydrogen can be used to produce synthetic methane and other e-fuels, and it can directly fuel thermal and internal combustion engines. Each of these pathways offers different advantages and disadvantages in conversion losses, storage and transportation challenges, and the practicability of the usage itself. Furthermore, the financial aspects, e.g., investment, depreciation, and running costs, will also impact global warming potential (GWP).

The methodology of Life Cycle Assessment considers the raw material extraction, production, utilization, and end-of-life phases of a product’s life cycle. An LCA has four steps: the goal and scope definition, the inventory analysis, the impact assessment phase, and the interpretation phase [

9,

10]. For the goal and scope definition, we utilize a cradle-to-grave approach that considers all the connecting energy and material flows during the life cycle of the hydrogen-propelled vehicle. Our scope is limited to passenger cars utilizing different hydrogen drivetrain technologies. Currently, there are seven alternatives for using hydrogen in a passenger car: (1) hydrogen fuel cell electric vehicle (H

2FCEV), (2) a hydrogen internal combustion engine vehicle (H

2ICEV), (3) a methanol flexible fuel vehicle (MeOH FFV), (4) an ethanol flexible fuel vehicle (EtOH FFV), (5) a Fischer-Tropsch (FT) diesel internal combustion engine vehicle (FTD ICEV), (6) a Fischer-Tropsch gasoline vehicle (FTG ICEV), and (7) a renewable compressed natural gas vehicle (RNGV). The goal of this LCA is to determine which of these propulsion technologies has the lowest GWP.

Reviewing the scientific literature on the LCA of hydrogen-propelled vehicles, we have found that most articles deal with fuel cell electric vehicles (FCEV) and that the topic of H

2-ICE and e-fuels needs further attention from the scientific community.

Table 1 presents the number of documents in the Scopus database (22 July 2025).

While Life Cycle Assessment (LCA) is increasingly applied to alternative powertrains, the existing literature remains fragmented, often focusing on isolated comparisons or specific segments rather than a comprehensive, unified assessment. For instance, Wong et al. [

11] compares a single FCEV (Toyota Mirai) with a BEV using the GREET model, providing useful insight but only within a narrow, pairwise frame. Similarly, Accardo et al. [

12] applies LCA to hydrogen internal combustion engines in heavy-duty applications, but without extending the analysis across different vehicle technologies. Studies on e-fuels, such as Lindstad et al. [

13], provide valuable insights by examining feasibility, energy utilization, and cost, yet they remain pathway-specific and do not extend to a comprehensive cross-powertrain comparison. Therefore, this paper presents a comparative analysis built primarily on secondary data sourced from established databases, with the aim of addressing this evident research gap. By synthesizing existing data into a unified framework, the study not only underscores the absence of comprehensive cross-powertrain assessments but also provides a foundation for future applied research and methodological refinement in the field.

Examining the scientific literature, Valente et al. [

14] emphasized the importance of the origin of fueled hydrogen. They compared the utilized hydrogen in proton-exchange membrane fuel cells (PEMFC) according to their production technology in an LCA. They found that hydrogen from biomass gasification has the lowest carbon footprint. It can reach better results than green hydrogen produced with wind power electrolysis. The conventional steam methane reforming process from natural gas (NG) is the most environmentally harmful production method. However, the study focuses solely on hydrogen production routes for PEMFCs and does not incorporate full vehicle life cycles or alternative powertrains.

Bicer and Dincer [

15] made a comparative LCA of H

2-ICE, methanol, and battery electric propulsion based on the Greenhouse Gases, Regulated Emissions, and Energy Use in Transportation (GREET) model. They found that internal combustion engine drivetrains have lower GWP than battery electric vehicles (BEV), and hydrogen is the most favorable solution from an environmental aspect. Nevertheless, the analysis is restricted to these few drivetrain options, lacking a cradle-to-grave comparison.

Fernández-Ríos et al. [

16] studied alternative marine hydrogen propulsion technologies, comparing PEMFC and H

2-ICE with LCA methodology. They also showed that the H

2-ICE has a minor advantage compared with PEMFC regarding GWP. It is highlighted that fueled hydrogen must originate from water electrolysis with green electricity. Still, being focused on marine applications, this study only contrasts two hydrogen-based propulsion systems.

Bartolozzi et al. [

17] introduced the comparison of BEV with hydrogen mobility solutions, differentiated by its production via biomass gasification, electrolysis with wind power or Italian electricity grid mix, and utilization in PEMFC or H

2-ICE. They found that regarding BEVs, the one fed with electricity from biomass gasification has the lowest GWP. Meanwhile, from the investigated hydrogen scenarios, the PEMFC with wind power-generated hydrogen has the lowest GWP. Yet, their analysis remains confined to BEVs versus select hydrogen scenarios and does not include other e-fuels.

Candelaresi et al. [

18] investigated the LCA of hydrogen-fueled passenger cars, comparing the technologies of PEMFC, H

2-ICE, and hybrid H

2-ICE (HEV H

2-ICE) with compressed natural gas (CNG) and Hythane. They found that the HEV H

2-ICE has the lowest GWP, while the H

2-ICE and FC ones have only a minor drawback. In contrast, the conventional CNG one has the highest GWP on an LCA basis. Despite covering various hydrogen vehicle configurations, this comparison remains focused on specific technologies and common gaseous fuels, omitting emerging synthetic fuel alternatives, although it provides a valuable basis and inspiration for the present study.

Desantes et al. [

19] compared the GWP and nitrogen oxides (NOX) emissions of conventional, BEV, and hydrogen drivetrains via LCA methodology. According to their study, the FCEV has the lowest GWP, considering hydrogen produced by steam-methane reforming (SMR) technology with CO

2 sequestration. They highlighted that currently, BEVs and water electrolysis powered by the EU grid mix have a significant carbon footprint due to the high CO

2 content of the electricity. This analysis is limited to a few drivetrain cases and to SMR-produced hydrogen; it does not consider other hydrogen production routes or alternatives.

Within our study, the applied cradle-to-grave approach encompasses all relevant energy and material flows throughout the life cycle of a hydrogen-powered vehicle. The analysis is confined to passenger cars employing various hydrogen drivetrain technologies. During this assessment, seven technological alternatives are considered for hydrogen use in passenger vehicles: H

2FCEV, H

2ICEV, MeOH FFV, EtOH FFV, FT, FTD ICEV, FTG ICEV, and RNGV. The objective of this LCA is to identify which of these propulsion technologies results in the lowest global warming potential (GWP). A focus on GWP is particularly relevant, as it remains the most widely applied and policy-relevant impact category in transport-related LCAs as reviewed in Andersen et al. [

20]. Given that climate change mitigation is a primary driver of energy transition policies and technology development. While GWP alone cannot fully capture the environmental trade-offs across vehicle technologies, its holistic assessment provides a robust and meaningful reference point for further investigations that incorporate additional indicators such as particulate matter formation, acidification, or resource depletion. Thus, this study positions GWP assessment as both a crucial standalone evaluation and a foundation for expanding the methodological scope in future research.

This study’s novelty lies in its macroscopic, comprehensive full life cycle assessment, encompassing several vehicle technologies, three distinct pathways for each fuel, and the inclusion of the often-overlooked e-fuels as hydrogen-based products. This unified evaluation of the examined fuels provides an integrated perspective that contributes to the development of sustainable mobility strategies for the future.

2. Hydrogen Production and Utilization

In order to assess the full life-cycle emissions of different vehicle powertrains, it is essential to understand the background of hydrogen production technologies and the pathways of hydrogen utilization as an energy vector. The purpose of this overview is to establish the framework within which the results presented below must be interpreted. It is also intended to demonstrate the potential and the challenge of the complexity of hydrogen technology.

There are numerous studies on hydrogen production technologies and utilization methods. In a related comprehensive analysis, Lubbe et al. [

21] categorized different hydrogen production technologies and assigned a color code to each according to the production method (

Table 2) and feedstock and documented the direct GWP for each technology.

It should be noted that some categories, such as orange, purple, or red hydrogen, are rarely used in mainstream LCA literature and are presented here only for completeness. The comparative analysis in this study focuses exclusively on the widely applied grey, blue, and green hydrogen pathways.

Németh et al. [

22] made a multidimensional comparison of the life cycle footprint of hydrogen production technologies. They pointed out that it is impossible to determine a single hydrogen production technology as the most environmentally friendly option in all situations; instead, it is crucial to evaluate various technologies within the specific context of their use. In the case of water-splitting, particular attention must be given to the source of the electricity, as it significantly impacts the global warming potential (GWP) of hydrogen production. If the electricity used has a high GWP, this method may pose a greater environmental risk than steam methane reforming (SMR).

Based on the available literature, a distinction is made between thermochemical, electrochemical, biological, photochemical, and other combined forms of hydrogen production. There are considerable differences in terms of sustainability and production volume. The interpretation of hydrogen as pure energy depends on the method of production. The use of hydrogen from renewable energy is the most advantageous. Still, other economic rates of return must also be considered in the assessment. The Hydrogen Square (HydS) adequately illustrates the significant post-production challenges outside the utilization, such as storage and safety [

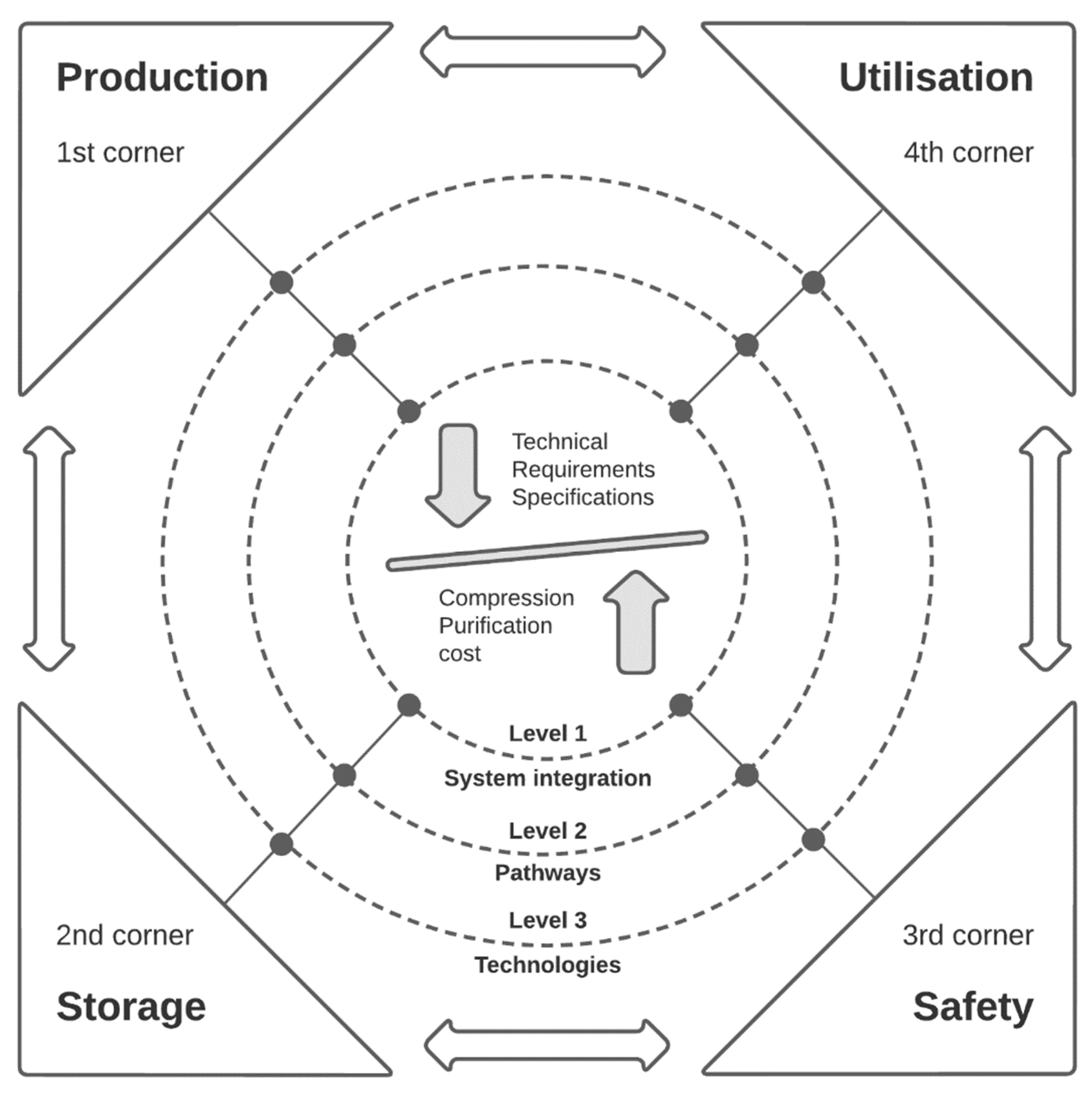

23]. These aspects (

Figure 1) must be addressed together systemically to find the best production-storage-safety-use pathway.

The four-corner model represents hydrogen production, storage, safety, and end-use as interdependent dimensions. Each corner highlights a critical challenge: (i) production methods define the environmental footprint, (ii) storage determines energy density and logistical feasibility, and (iii) safety addresses material durability and handling risks, while (iv) end-use technologies specify efficiency and applicability. Considering these four aspects together allows for a systemic interpretation of hydrogen pathways, which is why the HydS is presented as part of the framework.

2.1. Mobility Usage

2.1.1. Fuel for Fuel Cell Propulsion Technology

Different types of fuel cells could propel most terrestrial and naval vehicles and aeronautical devices up to a limited speed [

24]. Baroutaji et al. highlight the benefits of quiet operation, no emission of pollutants (low-temperature PEMFC), and suitability for the circular economy. On the other hand, high production cost, the requirement of high-purity hydrogen, and slow power modulation must be considered. According to the author, the FC can be a viable alternative to battery electric vehicles for long-haul heavy-duty professional transport applications.

2.1.2. Necessary Component of Syngas and E-Fuels

Billions of ICE-propelled vehicles are and will be in service for the upcoming decades. However, even if future vehicle production is intended to be electric, the 2 °C goal cannot be achieved without providing carbon-neutral fuels [

25], which requires large-scale green hydrogen production as well [

26]. Although commercial aviation could technically use pure hydrogen as the fuel of jet engines, liquid hydrocarbons have significant advantages in terms of safety, payload, range, and profitability.

2.1.3. Direct Fuel for Thermal Engines

Between 2004 and 2007, significant EU funding was allocated to the HYICE project, which aimed to optimize hydrogen propulsion technology for internal combustion engines. Led by BMW, the research was focused on increasing efficiency and power density [

27]. The aforementioned beneficial parameters were achieved through a comprehensive understanding and investigation of the high-pressure injection system, hydrogen combustion process, and mixture formation. In this context, several injectors and different configurations were investigated. Another major area of research has been investigating the concept of cryogenic port injection, where outstanding results have been achieved. Overall, a flexible and high-performance ignition system was developed that provides the high energy transfer and efficiency (23.2–29.0% [

28]) typical of gas without hotspots in the combustion chamber, while achieving markedly lower NO

x emissions compared to conventional diesel engines (63.7 mg kWh

−1 for H

2-ICEV compared to diesel’s 3340 mg/kWh [

29]). In addition to these research results, it was also realized that the development of CFD solvers for a more accurate simulation of mixture formation and combustion processes is essential for optimizing current and future engine concepts. Given their research conclusions, the experts and companies involved in the study have predicted the widespread use of hydrogen-driven reciprocating piston engines in the future, especially in the long turn, in extra-urban traffic [

30].

The future availability of green hydrogen is an opportunity for the climate-neutral usage of combustion engines. The technical development of recent years has shown that the operation of ICE on hydrogen is a cost-effective alternative to the fuel cell, and the exhaust emission can be easily controlled [

31,

32]. Furthermore, the ICE technology does not require high-purity hydrogen. Especially in the case of long-range heavy-duty trucks, the total cost of ownership is the most decisive factor in vehicle choice. Therefore, some truck companies consider hydrogen ICE a bridge technology [

33]. Furthermore, the vehicle architecture of trucks offers suitable space for hydrogen storage devices. The use of hydrogen ICE in lower vehicle classes is under development, but the lower limit will tend toward smaller vehicles in the future [

34].

2.1.4. Direct Fuel for High-Speed Aeronautical and Aerospace Propulsion Devices

Hydrogen is already an established rocket fuel suitable for jet, ramjet, and scramjet engines [

35], although these are not yet implemented in commercial aircraft. In addition, peak performance parameters are critical success factors for military aircraft but not necessarily for commercial applications, where economy and efficiency are the primary decision factors. Hence, hydrogen is expected to be used in critical aeronautical applications [

36].

2.1.5. Techno-Economic Considerations

While this study primarily focuses on environmental life cycle impacts, the economic dimension is undeniably important for policy and technology deployment. A full techno-economic analysis will be carried out in a separate, dedicated research project using a different modeling framework. In order to provide context, we have collected life cycle cost (LCC) data for conventional gasoline, diesel, and electricity, alongside three different hydrogen pathways, renewable natural gas (e-methane), e-methanol, and synthetic diesel. Projections for 2030 and 2050 from multiple sources are included, although fossil fuel values for 2050 remain too speculative to be considered in this simplified comparative overview. This indicates that the prices of hydrogen and other synthetic fuels are interlinked and may become competitive with conventional fuels in the future [

37,

38,

39,

40,

41].

Table 3 presents the projected fuel costs, expressed in €/Liter Diesel Equivalent, for the years 2030 and 2050.

2.2. Non-Mobility Usage

Beyond the scope of this study, hydrogen offers multiple options for decreasing the GWP of industry activities. Hydrogen can be used, e.g., in nearly all areas of power and heat generation, and as a raw material for production processes (e.g., artificial fertilizer production) [

42]. Even though these options might offer attractive opportunities for GWP reduction, they exceed the boundaries of this study and are only included for reference.

2.2.1. Storage of Surplus of Regenerative Electricity

Experience shows that solar and wind power in European countries requires practically 100% dispatchable (conventional) backup. Bothe indicates that the amount of energy to be stored and the duration of the storage both need the storage of molecules instead of electrons [

2]. In this regard, the first inevitable step is hydrogen production via electrolysis. Further steps, i.e., the conversion of hydrogen into syngas or an additional step into liquid fuel via Fischer-Tropsch, could be reasonable, but must be investigated alongside their properties, such as conversion losses, storage options, transportability, and practicability of fueling particular processes or devices.

2.2.2. Raw Material for a Product, e.g., Artificial Fertilizer

Currently, most hydrogen production is related to artificial fertilizer production and is based on steam reforming of fossil natural gas (grey hydrogen) [

43], one of the most polluting industrial processes. The emission of 9+ kg CO

2 burdens the production of 1 kg hydrogen. Since the substitution of grey hydrogen for green one does not require any additional investment in the fertilizer production facilities, it is a favorable leading use case for green hydrogen.

2.2.3. Partial or Complete Substitution of Fossil Fuels in Heat Generation

Industrial or residential heat generation is one of the primary sources of anthropogenic CO

2 emissions [

44]. Since the complete substitution will require modifications in the firing and safety equipment, a partial substitution could be a reasonable mid-term step with affordable costs [

45]. Diluting the natural gas network with hydrogen is the focus of several ongoing research activities. Pure hydrogen can be injected directly into the natural gas infrastructure, but certain physical and chemical limitations must be considered due to material durability, leakage, and safety. The potential for storing hydrogen in the natural gas network depends not only on the concentration but also on the composition of the gas, the structure of the network, and the end-use objectives. To ensure a proper review, the technical and monitoring status of the network needs to be assessed, which in many cases implies R&D, leading to additional costs. Gondal presented a comprehensive analysis of gas transmission, storage, and distribution systems as a function of the concentration of hydrogen [

46]. Based on this, the pipeline infrastructure requires no special modifications up to a mixing ratio of 10%. Still, the addition of hydrogen at this blending ratio already affects the gas quality. In certain areas, the calorific value of the gas in the grid varies or is low. Adding a defined percentage of hydrogen could be practiced without modifying the firing equipment or the grid. Furthermore, a study by Wenguo et al. highlighted that steel production coke could be completely substituted with hydrogen [

47].

4. Results and Discussion

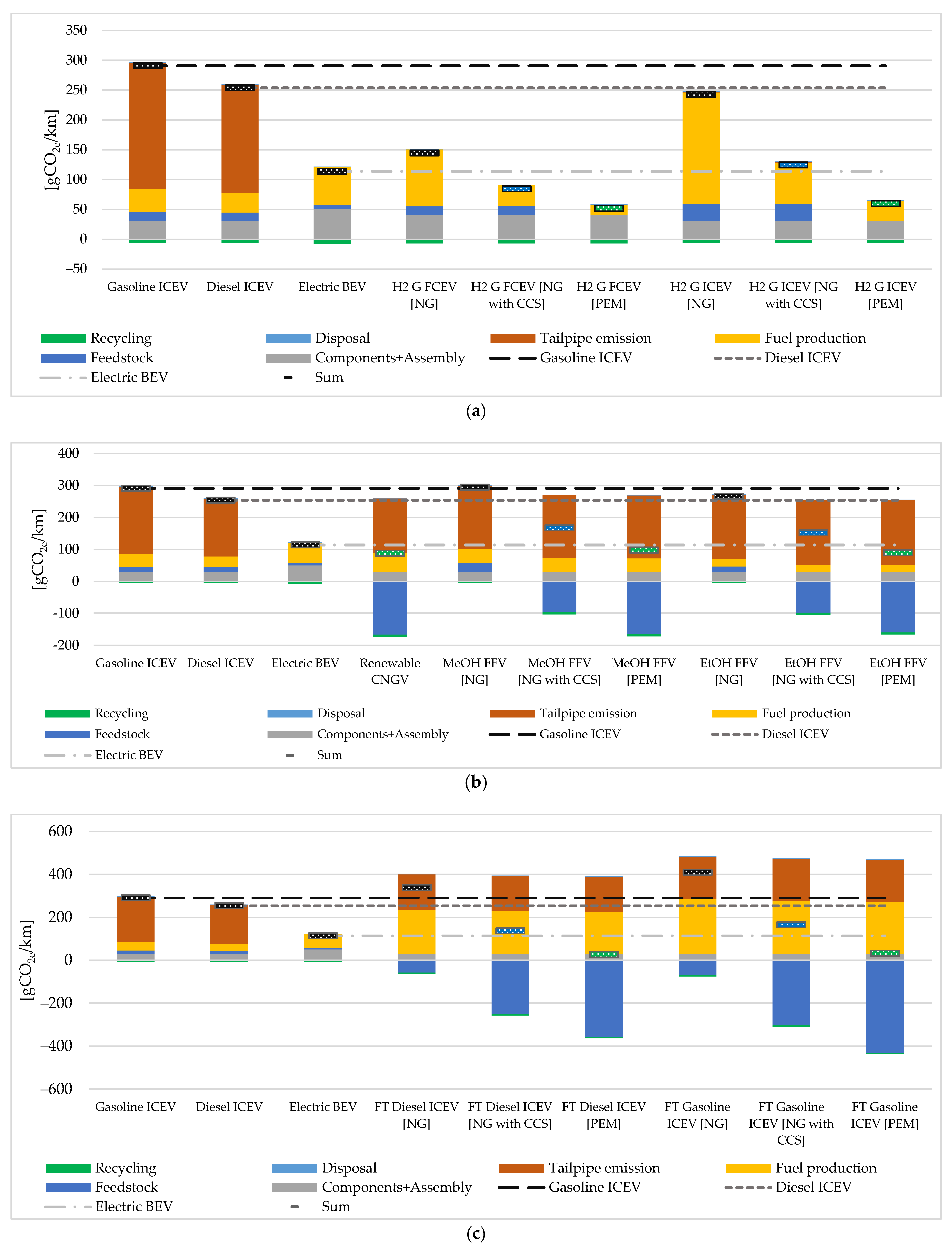

The resulting data outlined represents a key outcome of this article. The figures show (

Figure 2a–c) that in the sequence of fuel types presented, as fuel composition becomes more complex (hydrogen, methanol, ethanol, FT fuel), their sensitivity to the method of hydrogen production increases, indicating a strong correlation in the vehicle’s well-to-tank (WTT) phase (in purely hydrogen-powered vehicles the production technology affects the ‘fuel production’ phase, in e-fuel powered vehicles it affects the ‘feedstock’ phase). The first three figures illustrate a descending stairstep pattern, showcasing the comparative performance of grey, blue, and green hydrogen-based vehicles, with each “Sum” in the figure corresponding in color to its respective pathway. The said sensitivity correlation is also present in these figures. Purely hydrogen powered vehicles (and BEVs) show minimal or no tailpipe emissions, but FCEVs exhibit higher emissions in the components and manufacturing phase due to battery production. CNGVs, FFVs, and alternative ICEVs show tailpipe emissions similar to the traditional benchmarks. In the first two cases, fuel efficiency makes a significant difference. While renewable options like green hydrogen show promising reductions in lifecycle emissions, the differences in emissions among renewable hydrogen-powered vehicles (e.g., FCEVs and ICEVs) suggest that the technology choice also plays a critical role in environmental impact. Although less significant compared to other phases, recycling contributions vary by vehicle type. Technologies reliant on extensive materials, such as BEVs or FCEVs, may benefit more from improved recycling processes. The complete set of numerical sub-results and final results is provided in

Appendix A,

Table A1.

There are two types of optimal results that can be seen as viable. On one hand, we have the least net carbon-intensive vehicle, which emits the lowest amount of CO

2 across its life cycle. On the other hand, there is the least gross carbon-intensive vehicle, which may have higher tailpipe emissions, but offsets significant CO

2 during the fuel production process. The green hydrogen FCEV and ICEV had the least net emissions, while the H

2FCEV’s components (fuel stack, batteries) are less sustainable, and H

2ICEV’s fuel consumption is twice the amount of H

2FCEV’s, so it falls just short of being the best alternative in this standpoint as shown in

Figure 3a.

With these alternatives, there are no tailpipe emissions and although production processes require a great amount of green energy, they are significantly less pollutive than benchmarks. H

2ICEV’s fuel production phase (33.2 g CO

2e/km) is almost equivalent to traditional fueled vehicles (39.26 and 33.08 gCO

2e/km, gasoline and diesel) as seen in

Figure 3b. Electric BEVs’ fuel production (based on EU production mix, 63.36 gCO

2e/km) is almost four times that of H

2FCEV’s (16.95 gCO

2e/km). The FT diesel ICEV has the best results overall and the least gross emissions throughout its lifetime, whose hydrogen feedstock was produced with green electric PEM water electrolysis (electricity made from wind power in the green pathway), although it had around 390 gCO

2e/km results in net emissions, which is 100 gCO

2e/km more than gasoline ICEVs for example (

Figure 4a).

Although gasoline and diesel vehicles, both traditional and synthetic, produce similar tailpipe emissions due to their identical drive trains, the FT fuel synthesis process contributes additional CO

2 emissions. To mitigate this, implementing CO

2 recycling and circulation loops in newer systems is essential. Additionally, using CO

2 as a feedstock for synthetic fuels allows for significant CO

2 sequestration (−357.62 and −431.75 gCO

2e/km, FT diesel and gasoline,

Figure 2c), helping reduce overall lifetime emissions, making both green FT fuel options more than 9 times less pollutant than the traditional fossil fueled vehicles, as shown in

Figure 4b. Aside from FCEVs, all grey hydrogen-powered vehicles appear to have carbon intensity levels comparable to, or even higher than, fossil fuel benchmarks, such as FT- or alcohol-fueled alternatives. This suggests that these environmentally harmful production technologies should be retrofitted with CCS to produce blue H

2. However, concerns about system efficiency, as well as challenges with green electricity-based hydrogen production, make it difficult to initiate adaptations and plan for future projects. BEV and FCEV lifetime emissions are affected by their components, therefore more resource-efficient material to use and recycling should be considered. There is insufficient data regarding the end-of-life (EoL) phase of vehicles with alternative drivetrains; research towards solving problems in this stage should be considered in the future.

The tailpipe emissions of e-fuel vehicles are of the same magnitude as those of fossil fuel benchmark vehicles, H2ICEV’s are negligible and H2FCEV’s are zero. WTT emissions solely depend on the type of hydrogen used throughout the process. Practical and economic information on fuel production chains is also lacking; further data collection, simulations and comparisons in this subject should be considered in the future.

Both Fischer-Tropsch (FT) fuels and hydrogen show long-term, technically viable pathways for decarbonizing the transport and energy sectors, though each faces distinct challenges in terms of integration into the traditional industries. FT fuels, thanks to their chemical similarity to conventional gasoline and diesel, are fully compatible with current internal combustion engine technology and fuel infrastructure, allowing for an easier incorporation into today’s market without the need for major infrastructural overhauls. However, their production processes (especially in terms of energy and carbon efficiency) require further technological optimization to become truly sustainable at scale [

60]. Similarly, hydrogen presents an immense long-term promise not only as a transportation fuel but also as a versatile energy carrier, particularly for storage and sector coupling. Yet, its widespread adoption is hindered by challenges in production efficiency, infrastructure readiness, technological maturity, and social acceptance [

61,

62]. Both fuel forms require efficiency improvements, while ongoing research can help establish their technical viability in the public, institutional, and policy spheres. Looking forward, these findings strongly support the need for intensified applied and techno-economic research, particularly in optimizing fuel synthesis pathways, lifecycle performance modeling, and infrastructure development. Coordinated technical prognostication and future-oriented policy frameworks could pave the way for infrastructure strategies that align with long-term decarbonization goals, making these technologies not just scientifically sound but also economically and socially feasible.