3.1. Hydrogen Dispersion with Different Rupture Sizes Induced by Platform Failure

There are safety risks in the long-term operation of FPHP in an offshore environment, especially in areas with high-pressure hydrogen storage devices; more attention should be paid to safety protection measures.

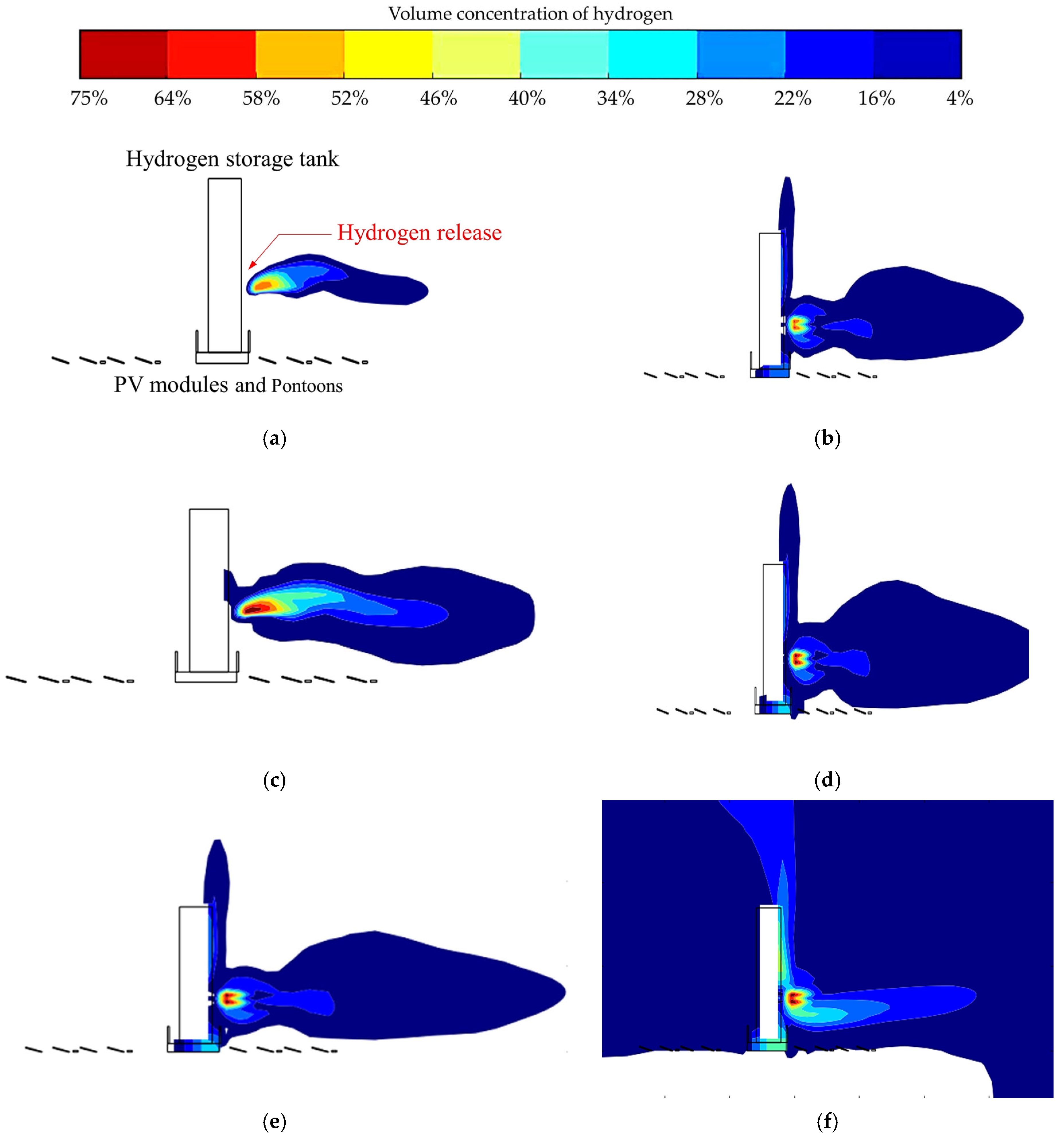

Figure 3 shows the gas concentration distribution when hydrogen leakage occurs horizontally in the hydrogen storage tank of FPHP with a failure rupture of 25 mm. As the leakage time continued to increase, the range of vapor cloud was formed by the hydrogen leakage expanded. The entire dispersion range was roughly divided into two parts. The first part was the dispersion in the horizontal direction along the leakage point. This direction was an unconfined area where hydrogen disperses in open space without obstacles. Within 2.0 s to 8.0 s of leakage duration, the dispersion of combustible vapor cloud was distributed in a willow leaf-like pattern on the horizontal plane. The hydrogen gas reached 10.1 m and 14.2 m, respectively, in the horizontal direction. Between 8.0 s and 14.0 s of hydrogen leakage in FPHP, the vapor cloud formed by hydrogen leakage grew and widened rapidly, further increasing the possibility of HVCE accidents. When the hydrogen leaked for 14.0 s, it reached 18 m along the horizontal direction, and the width expanded from 2.2 m to 8.3 m. The vapor cloud that was formed by hydrogen leakage reached its maximum volume and filled the entire area. Another part spreads vertically upward along the hydrogen storage tank. Due to the low volumetric energy density of hydrogen, it needs to be stored under high pressure during the preparation process. High-pressure hydrogen storage tanks are usually prone to local failure, which leads to the formation of small-sized ruptures. When a compressed medium in a high-pressure hydrogen storage tank communicates with the outside through a small-sized rupture, it disperses to the external environment in the form of a jet release. A small amount of hydrogen vapor cloud then accumulated above the rupture point of storage tank. This part of the gas was not yet within an explosion range. Between 8.0 s and 14.0 s of hydrogen leakage in FPHP, as the leakage duration continued to increase, a large amount of hydrogen accumulated near the rupture point. The blocking effect of the hydrogen storage tank prevented hydrogen from moving horizontally. Due to the momentum conservation, it dispersed in the vertical space. Hydrogen was dispersed in a vertical area with a height of approximately 13.4 m. After some of the hydrogen exceeded the hydrogen storage tank, it began to extend in horizontal space, and the vertical distance was 16.1 m.

Figure 4 demonstrates the hydrogen dispersion process along the horizontal direction with a rupture diameter of 50 mm in the hydrogen storage tank of FPHP. Due to an increase in rupture size, the leakage volume of hydrogen increased. Gas concentrations in the horizontal and vertical directions and the range of vapor cloud formation are significantly larger compared to the 25 mm case. In a scenario where the rupture diameter is 50 mm, more hydrogen disperses along the direction of the leakage outlet. A hydrogen cloud formed by hydrogen spreads horizontally to a distance of 11 m. As the rupture diameter increases, the hydrogen leakage in a high-pressure hydrogen storage tank goes up accordingly. Strong jets form initial momentum, prompting more hydrogen to disperse horizontally. At 8.0 s of hydrogen leakage, a hydrogen vapor cloud with a rupture of 50 mm disperses to 15.7 m. Meanwhile, the width of the hydrogen cloud increases from 2.1 m to 7.3 m. In a scenario where the hydrogen leakage rupture is 50 mm, within 8.0 s of hydrogen leakage occurrence, hydrogen above the leakage outlet has not reached the explosion limit range. This is similar to hydrogen dispersion in an accident scenario with a leakage rupture of 25 mm. When hydrogen leakage occurs in FPHP at 14.0 s, the vertical dispersion height of hydrogen (50 mm rupture case) is approximately 13.3 m. When hydrogen leakage occurs for 25.0 s, there is a risk of HVCE within the hydrogen dispersion range.

Figure 4c shows the concentration distribution of hydrogen dispersion along the horizontal direction when the leakage rupture is 100 mm. Hydrogen is instantly ejected from the leakage point, and the kinetic energy of the fluid in space increases. Due to an increase in leakage rupture, the length and width of the hydrogen vapor cloud are larger than those in the 50 mm rupture case. The horizontal dispersion distance of the hydrogen vapor cloud reaches 15.7 m, and the width of the vapor cloud reaches 3.2 m, both of which are larger than the hydrogen vapor cloud with the rupture case of 50 mm. The hydrogen vapor cloud accumulated above the leakage point (reached explosion limits), which spread upward along the vertical direction. The dispersion concentration of hydrogen in space thus reached the explosive limit range. From 14.0 s of hydrogen leakage occurrence to 23.0 s, in the horizontal direction, the hydrogen concentration increased. In vertical space, the hydrogen dispersion width was greater than in the 50 mm rupture case. Obviously, due to an increase in hydrogen leakage rupture, the amount of hydrogen leakage continued to rise, leading to an enhanced risk of HVCEs in the deep-sea FPHP platform.

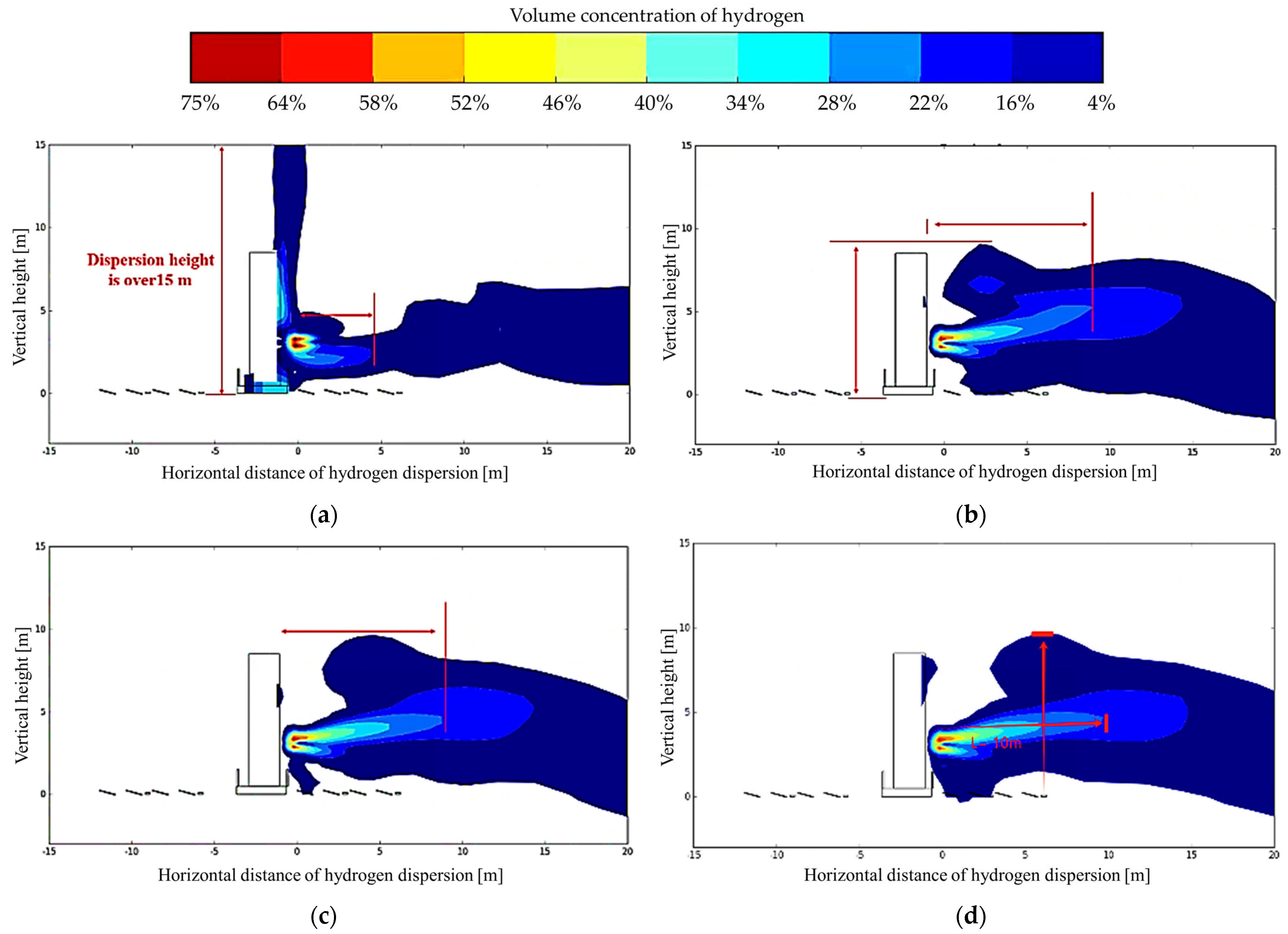

When the sea surface condition approaches a windless state, the hydrogen leakage accident in FPHP is shown in

Figure 5a. Due to different pressure ratios between the leakage source and the marine environment, the hydrogen jet release is in different flow states at the failure location. If the internal pressure of the hydrogen storage tank is close to atmospheric pressure, the pressure ratio is lower than the critical pressure ratio of leaked hydrogen. In this accident scenario, hydrogen is in a fully expanded state at the leakage location, and the leakage form is a subsonic jet. When the hydrogen storage tank in FPHP fails, it is obvious that the pressure ratio at the inner and outer interfaces of the failure rupture is higher than the critical pressure of hydrogen. The velocity at the leakage location is close to the local sound velocity, and hydrogen leakage is in an under-expansion state. Due to the pressure being higher than atmospheric pressure, hydrogen further expands when leaving the rupture point, forming a supersonic flow. When a failure of a high-pressure hydrogen storage tank occurs at 23.0 s, the hydrogen concentration on FPHP is monitored to exceed 52%. When the failure time of the hydrogen storage tank exceeds 50.0 s, high-concentration leakage begins to spread to the photovoltaic modules. Due to the inherent characteristics of hydrogen, it gradually undergoes an upward floating behavior during the process of leaked hydrogen dispersing to the marine surroundings. When the sea surface wind velocity increased to 10 m/s, the wind force effect thus significantly inhibited the ability of hydrogen cloud clusters to draw air in all directions. The dominant role of the wind field prompts hydrogen cloud clusters to break through the original dispersion pattern and instead disperse in a directional manner along the wind direction. Downwind direction becomes the core direction for hydrogen to draw in air, expanding the dispersion distance along the horizontal direction. When the wind velocity from no wind to the sea surface is 10 m/s, the hydrogen dispersion distance along the horizontal direction increases by 5.5 m. The increase in sea surface wind velocity weakens the dispersion distance in vertical space, which expands the vertical dispersion distance to 8.3 m.

Comparisons between

Figure 5b,c show that the hydrogen concentration at the boundary decreases continuously with elevated wind velocity at the sea surface.

Figure 5b indicates that when the hydrogen concentration is 40.7%, the hydrogen disperses horizontally to a position of 10.1 m. While in

Figure 5c, hydrogen disperses horizontally to a position of 8.3 m. The results reveal that in the scenario of downwind leakage, wind force on the sea surface has a dual effect on hydrogen dispersion. On the one hand, wind on the sea surface transports hydrogen to spread further away. On the other hand, high wind velocity significantly reduces the volume of high-concentration hydrogen vapor clouds by rapidly diluting hydrogen. As the sea surface wind velocity continues to increase, the horizontal force of airflow significantly strengthens. This significantly increases the difficulty for hydrogen to draw air upwards, forcing hydrogen to mainly disperse along the ground. From the perspective of hydrogen dispersion characteristics, a high wind velocity can not only drive vapor clouds to migrate to the distal end, but it also reduces the concentration during the dispersion process of hydrogen vapor clouds. By comparing

Figure 5c,d, it indicates that the increase in sea surface wind velocity significantly weakens the ability of hydrogen to draw air around. Specifically, the greater wind velocity at the sea surface, a lower vertical upward dispersion height of hydrogen, and its dispersion pattern gradually flattens. It is worth noting that when the sea surface wind velocity is lower than 10 m/s, the hydrogen dispersion distance is positively correlated with wind velocity. That is, elevated wind force can effectively push a vapor cloud mass to move along the wind direction, promoting the continuous expansion of the hydrogen dispersion range. When the sea surface wind velocity increases to over 15 m/s, the hydrogen dispersion pattern gradually changes under the action of strong winds. These findings suggest the obvious characteristics of near-ground hydrogen dispersion. The strong sea surface wind force has accelerated the dispersion and dilution process of the hydrogen vapor cloud. Meanwhile, due to the directional enhancement effect of gas flow on hydrogen, it is difficult for hydrogen to extend further in the horizontal direction. As a result, the dispersion distance gradually shortens as the wind velocity further increases. Within 25.0 s of hydrogen leakage, hydrogen formed a large-scale mixed vapor cloud near FPHP. The hydrogen vapor cloud is within the explosion limit concentration range of hydrogen/air. Once it encounters a heat source or flame propagation, it causes a large-scale HVCE around FPHP.

In this study, the critical wind velocity at the sea surface is further analyzed. The critical wind velocity and distribution of combustible vapor clouds are discussed by adding different conditions, such as sea surface wind velocities of 15 m/s, 16 m/s, 17 m/s, 18 m/s, 19 m/s, and 20 m/s. The entire hydrogen leakage process is mainly affected by both wind velocity and buoyancy, and the combustible vapor cloud moves in a horizontal direction. The different horizontal dispersion distances of the hydrogen vapor cloud under different sea surface wind velocities. When the sea surface wind velocity is less than 16 m/s, as the sea surface wind velocity increases, the distance that the hydrogen vapor cloud disperses horizontally along the sea surface wind velocity remains above 18.2 m. When the sea surface wind velocity is greater than 16 m/s, with an increase in wind velocity, the distance that the hydrogen vapor cloud disperses horizontally along the wind velocity remains basically unchanged and is maintained at 15.3 m. Analysis suggests that within a certain range of sea surface wind velocity, when hydrogen leaks downwind, the wind force can carry the hydrogen vapor cloud to spread to more distant positions. Based on data-based simulations of hydrogen dispersion changes along the leakage direction under different wind velocity conditions, it is found that wind force has a significant effect on the vertical dispersion process of hydrogen vapor clouds. After hydrogen leakage occurs, when the wind velocity is lower than 16 m/s, while hydrogen leaks horizontally, it also undergoes vertical dispersion in the vertical direction. When the sea surface wind velocity increased to 19 m/s, a strong wind significantly weakened the ability of the hydrogen vapor cloud to draw in surrounding air, forcing the vapor cloud to move horizontally along the wind direction. It significantly compresses the dispersion distance of hydrogen in vertical space. Further observations reveal that when the sea surface wind velocity reaches 19 m/s and 20 m/s, respectively, the dispersion range of hydrogen vapor cloud in both the horizontal and vertical directions shows a gradually shrinking trend. This phenomenon indicates that the increase in sea surface wind velocity can accelerate the dilution process of hydrogen and effectively reduce the spatial proportion of high-concentration hydrogen vapor clouds. As the wind velocity at the sea surface continues to increase, the difficulty for hydrogen to draw air upwards increases sharply, causing its dispersion form to be increasingly close to the ground. High-intensity wind velocity has a dual effect on hydrogen dispersion. On the one hand, strong winds drive hydrogen vapor clouds to spread to more distant areas. On the other hand, elevated wind intensities accelerate the dilution of hydrogen concentration and change the spatial distribution characteristics of vapor clouds. As the wind velocity on the sea surface keeps increasing, the vertical upward dispersion height of hydrogen becomes lower and lower. Under the dominant effect of strong wind force, the dispersion pattern of hydrogen undergoes a significant transformation, showing obvious characteristics of near-ground dispersion. Meanwhile, high-velocity airflow accelerates the mixing process of hydrogen with the surrounding air, greatly enhancing dilution efficiency. Under the influence of these dual factors, the effective dispersion distance of hydrogen does not extend with the increase in wind velocity. Instead, it shows a shrinking trend with increasing wind velocity. With an increase in wind velocity on the sea surface, hydrogen vapor clouds spread close to the ground. Leaked hydrogen accumulates between devices, such as photovoltaic panels and inverters. Impacts of the sea surface wind conditions on these areas are limited, and it takes a relatively long time to dissipate.

3.2. Effect of Ignition Position on Hydrogen Explosion-Driven Thermal Damage

In a deep-sea FPHP platform, flames are most likely to occur near hydrogen storage tanks, electrolyzers, and inverters. This further triggers the risk of HVCEs. In this study, ignition points were set at three different positions, such as the hydrogen storage tank, electrolytic cell, and inverter, to explore the influence of different ignition positions on thermal hazards caused by HVCEs.

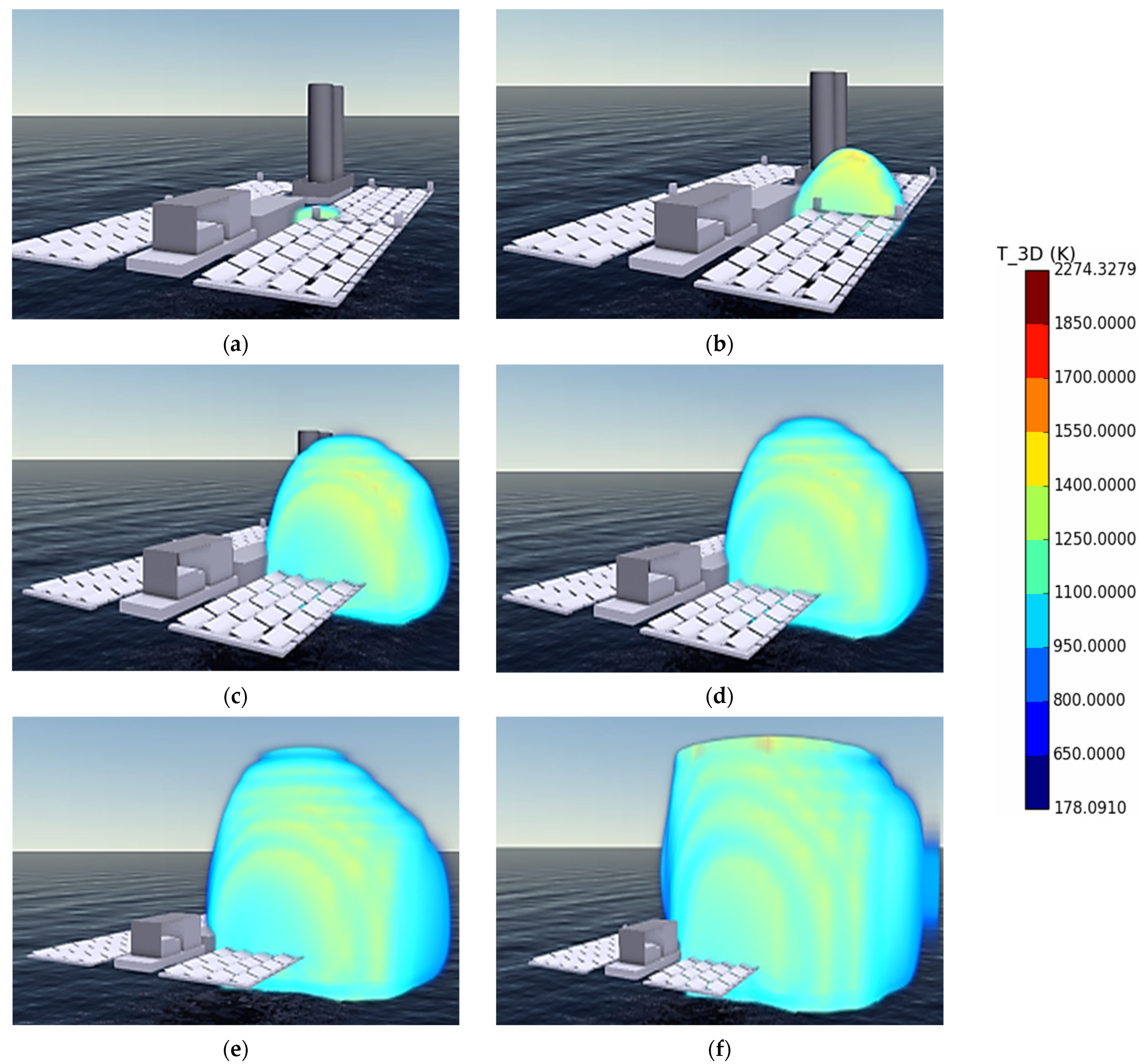

Figure 6 indicates the variation trend of thermal radiation of the ignition source near the hydrogen storage tank over time. At the initial stage of HVCE, the temperature of the explosive fireball is the highest at this time, reaching 1850.1 K. Due to the abundance of combustible materials and high heat released by a HVCE, the affected area at this time is relatively small. When the duration time of a HVCE is 3000 ms, the flame begins to develop into an ellipsoid with a long axis. High-temperature flames completely cover the horizontal photovoltaic panels, and the temperature in the photovoltaic panel area reaches over 1550 K. The temperature remains at a relatively high level, but it is slightly lower than that at approximately 2000 ms. At nearly 4000 s after a HVCE occurs, the flame continued to spread outward. As the flame continues to spread, when the occurrence time of a HVCE is approximately 5000 ms, it has reached the boundary of the entire system platform. Since there are no obstacles blocking the ignition point of the hydrogen storage tank, the spread pattern of flame is completely dominated by the HVCE’s intensity and the form of combustible vapor cloud. The thermal radiation produced by a HVCE reveals a certain geometric regular distribution in its propagation pattern.

Figure 7 shows the variation trend of the thermal radiation of the ignition source near the electrolytic cell over time. Compared with the flame propagation ignited near a hydrogen storage tank, the temperature of the hydrogen cloud ignited near the electrolytic cell is lower, and the time to reach the peak temperature is longer. As shown in

Figure 7, when the HVCE time of the hydrogen/air vapor cloud is 500 ms, the flame temperature reaches 920.2 K. At this time, the maximum temperature of the flame is much lower than that of the vapor cloud near the hydrogen storage tank because the concentration of the hydrogen vapor cloud at this location is relatively low. When a HVCE occurs at nearly 1000 ms, the peak temperature of the flame produced by a HVCE reaches approximately 1040.5 K. The HVCE-driven flames have completely covered the photovoltaic panels in the horizontal direction. When a HVCE occurs at 3000 ms, the area covered by the flame has already exceeded the positions of the hydrogen storage tanks and photovoltaic panels in the horizontal direction. High temperatures formed by a HVCE are spherical, with a diameter of approximately 15.5 m. The peak temperature of the flame generated by a HVCE reaches 1255.5 K. After 4000 ms of a HVCE, the high temperature formed by the combustion flame has reached the regional boundary. The minimum temperature at the boundary at this time is 680.3 K. Compared with the thermal effect formed by igniting near the hydrogen storage tank, the thermal effect formed by igniting in the electrolytic cell is spherical. Analysis suggests that this is because the area near the hydrogen storage tank is less affected by the hydrogen jet.

Hydrogen leakage at the deep-sea FPHP platform causes HVCEs and generates intense thermal damage. The significant hazard of accidents is that high temperatures prompt structural melting and deformation. When there is electrical equipment on the spot, high temperatures and combustion will further cause larger-scale disasters. Due to the strong suddenness of HVCEs, flames and high temperatures generated within the near-ground range near the explosion source spread extremely fast, and the affected area is wide. The degree of thermal damage to structures within a certain range can be determined based on the high temperatures formed by a HVCE.

Figure 8 demonstrates the variation trend of HVCE-driven flames from the ignition source near the inverter over time. As shown in

Figure 8, thermal damage caused by the flames from ignition near the inverter is similar to the effect caused by ignition near the electrolytic cell. When a HVCE occurs for nearly 500 ms, the peak temperature of the flames reaches approximately 1100 K. The high temperature of the flames formed by a HVCE will melt the inverter. At 1000 ms after a HVCE occurred, flames produced by the explosion had completely covered the photovoltaic panel area. The peak temperature of the flames produced by a HVCE goes up to about 1640.2 K, and the minimum temperature at the boundary is approximately 920.7 K. When the explosion of hydrogen gas transportation occurs in 2000 ms, the flames continue to spread outward and horizontally, with a diameter of over 20 m. After 4000 ms of a HVCE, flames spread over the local area boundary of the FPHP platform. Compared with the above conditions, the peak time of the ignition condition in the inverter area is in the middle of the two, and its peak temperature is also in the middle of the two, which corresponds to the concentration of the hydrogen at each point after leakage. The local deflagration and instantaneous high temperature caused by the failure of the hydrogen storage tank both result in local or overall permanent deformation of the structure within a certain range of the sea surface platform. For structural materials in offshore areas far from the explosion source, their performance is damaged and deteriorated due to HVCE-driven high temperatures. Furthermore, the high temperature of the flames reduces the safety of the structures, such as masonry, and shortens their service life. In addition, high-temperature flames generated by HVCEs cause on-site workers to suffer burns of varying degrees, and in severe cases, even direct death.

This study numerically simulated a HVCE that was triggered by two distinct ignition sources within the deep-sea FPHP platform: the static electricity and the hot surface that was induced by equipment overheating. Comparative analysis reveals significant differences between these ignition mechanisms in terms of the triggering processes, energy transfer modes, and consequence profiles. For such offshore FPHP platforms, the hydrogen storage tank area constitutes the primary at-risk zone for electrostatic ignition, where friction-induced static charges may accumulate despite the humid marine environment. Conversely, regions surrounding high-temperature equipment (e.g., electrolyzers and compressors) are susceptible to hot-surface ignition. Notably, seawater cooling proves inadequate to significantly dissipate heat from these surfaces.

In electrostatic ignition scenarios, a spherical flame kernel develops at the spark location, progressing readily to detonation within the turbulence fluctuation of hydrogen/air vapor clouds. The resulting HVCE-driven fireball envelops the entire hydrogen/air vapor cloud with instantaneous thermal radiation. The peak temperatures reach 2200–2800 K, and the time of duration is less than 500 ms. The detonation generates shockwaves propagating at a velocity of 2000 m/s, with the peak overpressure at the epicenter measuring between 8.5 bar and 10.0 bar. In the hot-surface ignition scenarios, the results indicate that the localized combustion effects dominate. The hydrogen adjacent to the hot surface ignites, forming discrete fireballs of HVCEs. The subsequent flame spread and thermal radiation transfer are strongly influenced by buoyancy-driven hydrogen dispersion. It is found that the localized temperatures attain 1500–2000 K, with duration scaling with the hydrogen release time (seconds to tens of seconds). Flame propagates along the hot surface as columnar-shaped jets, exhibiting HVCE-driven deflagration characteristics. In addition, the results indicate that the subsonic flame speeds (3–50 m/s) in deep-sea FPHP platforms generate HVCE peak overpressures of approximately 4.5 bar.

3.3. Shock Wave Propagation of Hydrogen Explosion by Elevated Sea Surface Wind Intensity

When a hydrogen leakage accident occurs in a deep-sea FPHP platform, there is a coupling relationship between the occurrence area and the sea surface wind velocity. The concentration distribution and influence range of leaked gas in a complex layout area show an irregular situation. To explore the influence of sea surface wind velocity on the hydrogen leakage process of the FPHP platform, accidental scenarios with different sea surface wind velocities, such as 0 m/s, 5 m/s, 10 m/s, 15 m/s, and 20 m/s, are conducted, and phased analyses are carried out on the hydrogen dispersion behavior within the platform. The first stage is the change in initial hydrogen leakage and dispersion behavior of the hydrogen storage tank when the sea surface is calm, as shown in

Figure 9. The second stage is a variation in the hydrogen dispersion range under different sea surface wind velocities after a period of time since the hydrogen storage tank failure, as shown in

Figure 10. In the early stage of a hydrogen leakage accident, the sea surface wind velocity mainly acts on the hydrogen concentration distribution near the rupture source. In an accident scenario without the influence of sea surface wind force, hydrogen releases at high velocity will not only move forward rapidly along the centerline of the hydrogen jet but also spread around the leakage point of the hydrogen storage tank.

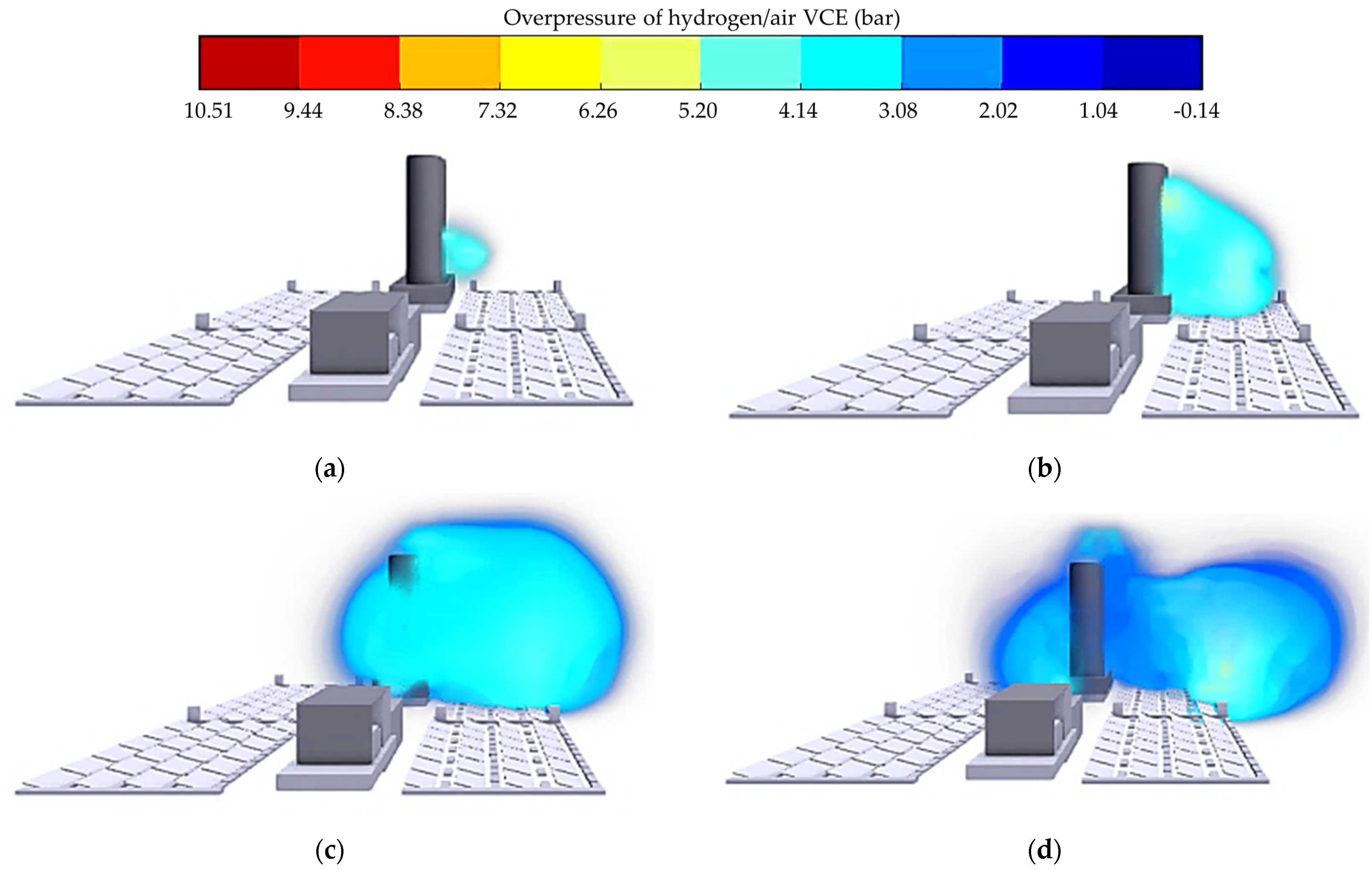

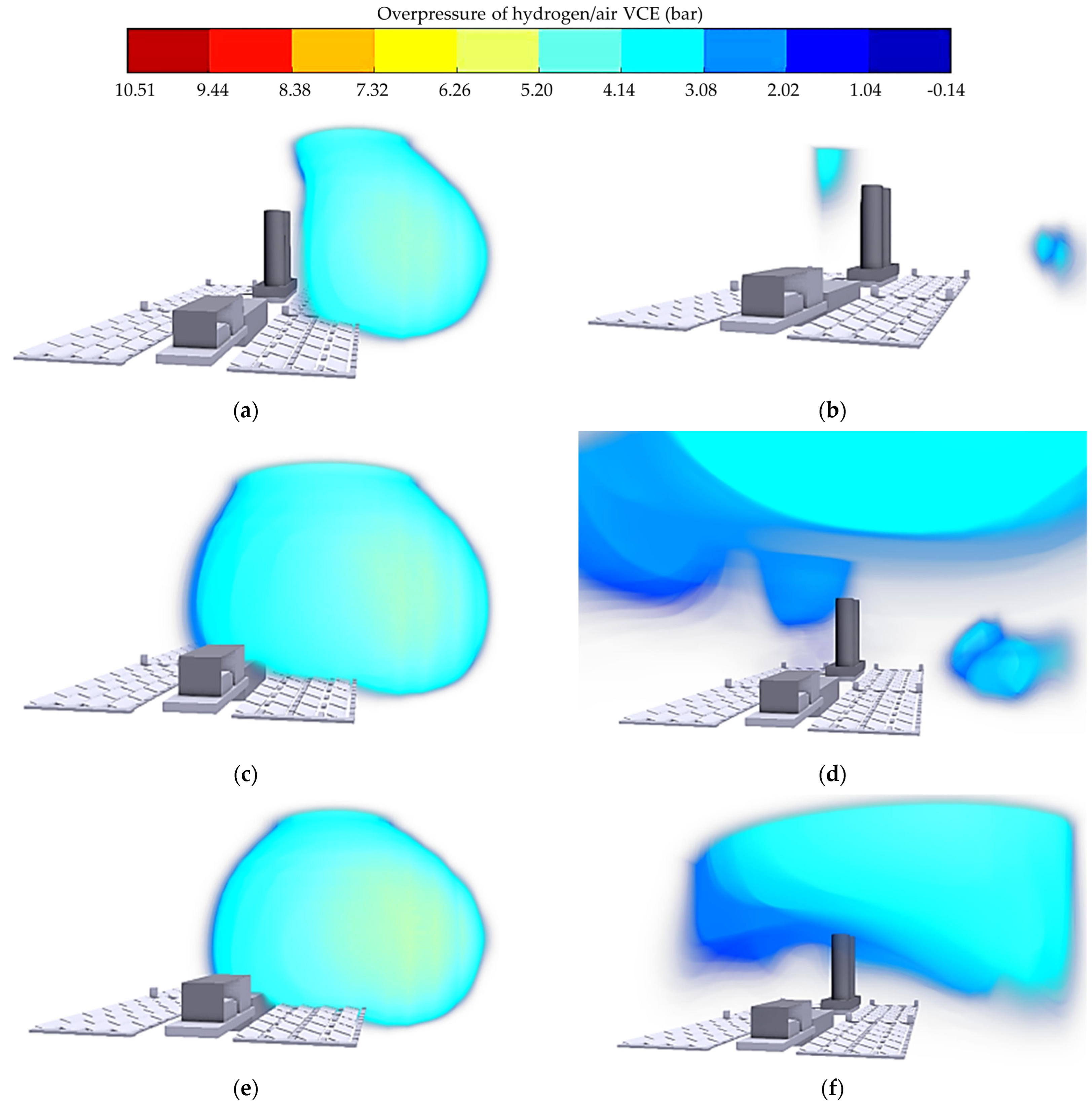

Figure 9 indicates the variation trend of the overpressure of a shock wave generated by a HVCE over time after hydrogen leaked horizontally for 25 s and ignited under a windless force on the sea surface. At 500 ms after the HVCE occurs, overpressure begins to spread outward from the hydrogen storage tank, as shown in

Figure 9. Overpressure near the hydrogen storage tank is high, and the diameter of the explosion range is around 5.4 m, which is relatively small. When a HVCE occurs at 1000 ms, the explosion diameter increases to 10.7 m. The shock wave reaches the vicinity of the photovoltaic panels. The overpressure near the photovoltaic panel is 3.4 bar, and peak overpressure reaches approximately 3.7 bar. When the occurrence time of a HVCE is 1500 ms, the range of the shock wave completely covers the hydrogen storage tank and photovoltaic panel area. The range of the shock wave reaches its maximum and spreads in a spherical pattern. When a HVCE occurs at 2000 ms, the shock wave spreads in all directions, and overpressure gradually decreases as the distance increases.

As the sea surface wind velocity increases to 10 m/s, the hydrogen concentration changes towards the area outside the deep-sea FPHP platform decreases. The movement of the hydrogen vapor cloud is still not significant. As the sea surface wind velocity further increases to 15 m/s and 20 m/s, the area of the hydrogen vapor cloud along the vertical direction gradually shrinks, and the dispersion height in vertical space begins to show a significant downward trend. When the sea surface wind velocity increases to 10 m/s, it reaches a Grade 5 wind standard. Due to the constraints of wind conditions, the hydrogen jet at the rupture point of the hydrogen storage tank mainly spreads along the near-surface after emerging.

Figure 10a,d show the variation trends of the overpressure generated by a HVCE over time after hydrogen leaks horizontally for 25.0 s under a wind velocity of 10 m/s and is ignited. When the occurrence time of a HVCE is 500 ms, the diameter formed by the shock wave is over 10.5 m, which is larger than the range of the shock wave in a windless state, and the maximum hyperpressure reaches 3.8 bar. When the occurrence time extends to 1750 ms, the range of the shock wave further enhances. However, due to the influence of wind force, the shock wave begins to propagate along the wind direction, with peak pressure reaching 3.6 bar and a dispersion diameter being approximately 14.9 m. Compared with a windless situation, the action range of the shock wave is larger, and the shock wave forms an overpressure of 3.4 bar at the photovoltaic panel. Meanwhile, the shock wave propagated horizontally under the influence of the wind force and, instead, moved away from the hydrogen storage tank. After the occurrence time of a HVCE exceeds 1750 ms, the shock wave further spreads along the wind direction under the influence of wind velocity, moves away from the photovoltaic panel and reaches the regional boundary. The dispersion distance extends to the maximum value. With an elevated wind velocity (nearly 10 m/s), it can significantly affect the propagation range of the shock wave. It makes the shock wave propagate along the wind direction, away from the hydrogen storage tank and photovoltaic panels, and to a certain extent, reduces the occurrence of further disasters in this area. In practical design for safety protection, coupling effects between differential hydrogen dispersion characteristics and enhanced wind conditions should be systematically considered. Traditional mist curtain systems exhibit limited efficacy under the above accidental scenarios, necessitating integration with porous energy-absorbent materials. Obstacles inadvertently amplify the shock wave propagation and resultant destruction, which requires identifying critical obstacle locations for retrofitting with inert gas-purging systems to mitigate cascading hazards.

When the sea surface wind velocity increases to 15 m/s, enhanced wind conditions limit the ability of hydrogen vapor clouds to draw air in all directions, prompting hydrogen vapor clouds to move downwind, thus expanding the distance of hydrogen dispersion.

Figure 10b,e show the variation trends of overpressure generated by a HVCE over time when the wind velocity is 15 m/s. With the occurrence time of a HVCE being 500 ms, compared with a wind velocity of 10 m/s, its explosion range is wider. Shock wave propagation can reach 20.1 m horizontally and 15.3 m vertically. When the occurrence time of a HVCE is 1750 ms, the shock wave accumulates above the area after the hydrogen explosion. Compared with the sea surface wind velocity of 10 m/s, the shock wave does not propagate along the wind direction. Instead, a high wind velocity suppresses the flow of hydrogen vapor clouds.

Figure 10c,f demonstrate the variation trends of the overpressure generated by a HVCE over time when the sea surface wind velocity is 20 m/s. The peak overpressure of a HVCE increases to 3.7 bar, and the overpressure near the photovoltaic panel reaches 3.4 bar. The arrival time of the shock wave is earlier than that when the wind velocity is 15 m/s. When the occurrence time of a HVCE is 1750 ms, the explosion range is maximum at this time. The shock wave propagates along the horizontal direction for a distance of 20.1 m and a longitudinal height of 15.2 m. The results indicate that when the sea surface wind velocity goes up to 10 m/s, the influence range of overpressure expands significantly. Meanwhile, the propagation velocity of the shock wave has also significantly accelerated. When the sea surface wind velocity exceeds 15 m/s, the greater sea surface wind velocity limits the range of the shock wave. Due to the enhanced wind conditions, the vertical spatial dispersion of the hydrogen/air vapor cloud is restricted. It leads to confining more vapor clouds to perigee, thereby enhancing the destructive effect of the shock waves on equipment. Upon wind velocities exceeding critical thresholds at sea level, initially, the promotional effect on shock wave propagation transitions to measurable suppression. This phenomenon necessitates dynamic adaptation of monitoring equipment positioning on FPHP platforms, corresponding to the migration of peak destruction epicenters under marine environmental forcing. A synergistic protection strategy is implemented whereby annular water curtains (over 200 L/min·m

2 coverage intensity) automatically engage when wind velocities surpass 15 m/s to obstruct hydrogen dispersion pathways. In addition, the system monitors directional variance rates, triggering immediate nano-aerosol suppressant injection when the fluctuation exceeds 45°/min to achieve flame front-quenching and propagation arrest.

The TNT equivalent method assumes an energy equivalence between flammable material and TNT [

45,

46]. The equivalent mass of TNT is calculated using Equation (7), derived from the total heat of material combustion.

where

η denotes the empirical explosion efficiency,

W is the mass of flammable material,

Qc is the heat of combustion of flammable material,

QTNT is the heat of combustion of TNT, and

WTNT is the mass of TNT (kg).

For gaseous deflagrations,

η typically ranges from 2% to 15%. The explosion effects are assessed using experimental data that are scaled to the equivalent mass of TNT

WTNT. Within this framework, scaled distance

Z is defined by Equation (8), enabling practical computational implementation.

where

R is the distance from the central point of the gas explosion.

The prediction is given as semi-empirical curves on the coordinate system of scaled distance

Z and maximum overpressure

Pm. Henrych [

47] proposed one of the most common attenuation laws for shock wave induced by gas explosion in free-field which is expressed as the following equation.

Mills [

48] investigated the applicability of Sachs’ scaling law to gas explosions in an unconfined environment at overpressures of up to 0.1 MPa. By integrating similarity theory and numerical methodology, he proposed a refinement of established free-field overpressure decay laws through the modification of evaluation distance. This approach yields a modified overpressure–distance decay relationship related to the TNT explosion-driven shock wave, as shown in Equation (10). The theoretical framework established above enables a quantitative assessment of physical explosion in a gas leakage scenario. The accuracy and applicability of the proposed model are empirically validated against full-scale experimental data.

Figure 11 shows the overpressures on the photovoltaic panels and inverters after HVCE occurs in the deep-sea FPHP platform. If the influence of enhanced wind force on the sea surface is not considered, the evolution law of the shock wave generated by the explosion conforms to the overpressure–distance decay relationship proposed by Mills. With an increase in sea surface wind velocity, turbulence induced by high wind velocity enhances the reaction rate of combustion, causing peak overpressure to rise for a period of time. Therefore, the wind velocity on the sea surface will affect the intensity of the shock wave.

Figure 11a presents the overpressure effect of a HVCE-driven shock wave on a photovoltaic panel structure in the FPHP platform under the influence of different sea surface wind velocities. It can be seen from the figure that the enhancement of sea surface wind force has a significant impact on the action time of the shock wave. In an accident scenario where sea surface wind velocity is less than 5 m/s, the effect trend of a HVCE-driven shock wave on a photovoltaic panel structure is relatively consistent. With a low sea surface wind velocity, the time when the first peak overpressure occurs in the photovoltaic panel-laying area is approximately 1084 ms. In an accident scenario of low sea surface wind velocity, peak overpressure shows 2.476 bar. At this point, brick structures are 50% destroyed, and self-restraining steel structures are destroyed in the low sea surface wind velocity case. Under the effect of secondary shock wave propagation, the photovoltaic panel-laying area formed a second peak of overpressure. The overpressure data relatively decreases, with a value of 0.271 bar. When the sea surface wind velocity moved to 10 m/s, the time when the first overpressure peak occurred did not change significantly. In a scenario of high sea surface wind velocity, the peak overpressure data that were monitored in the photovoltaic panel area increased to 2.112 bar. Since an increase in sea surface wind velocity has a significant impact on the dispersion range of a hydrogen vapor cloud, the variation law of overpressure also changes. It can be known from

Figure 11a that when the sea surface wind velocity increases to 15 m/s, the rising rate of pressure was monitored in the area where the photovoltaic panels were laid decreases. The occurrence time of peak overpressure is prolonged compared with the accident scene under weak wind conditions, and the maximum overpressure is approximately 1.461 bar. If the sea surface wind velocity continues to increase to 20 m/s, the findings indicate that the area where the photovoltaic panels are laid is less affected by HVCE-driven shock waves. The peak overpressure of the shock wave is only 0.249 bar.

Figure 11b shows the variation trend of the shock waves generated by a HVCE near the inverter under different sea surface wind velocities. The propagation process of the shock wave near the inverter is affected by wind conditions on the sea surface. Meanwhile, due to a greater number of obstacles around the inverter, overpressure fluctuates to varying degrees over time. Under weak wind conditions on the sea surface, the peak overpressure formed by the shock wave around the inverter is 3.701 bar. Severe displacement of the steel structure is triggered, or serious damage to earthquake-proof structures occurs. When the sea surface wind velocity reaches 10 m/s, a shock wave generates the first peak overpressure at the inverter, and the overpressure is approximately 2.079 bar. Subsequently, overpressure shows a decreasing change until secondary peak overpressure (

Pm = 1.251 bar) occurs at 3871 ms after the explosion. As the sea surface wind velocity increases to 15 m/s, the peak overpressure time formed by the shock wave around the inverter is delayed. However, the duration of peak overpressure relatively increases, and the average overpressure remains at around 1.521 bar. If strong wind conditions occur on the sea surface, the overpressure data monitored around the inverter are relatively small. As shown in

Figure 11a, the maximum overpressure that can be generated in this accident scenario is 0.427 bar. Without concrete, slab-brick structures with a thickness of 0.2–0.3 m are broken, and the building is almost completely destroyed. The results reveal that the enhancement of wind force promotes a shortening of time for the shock wave to reach peak overpressure, and the peak value shows a significant increase. However, this research also finds that with an increase in sea surface wind velocity, the peak overpressure effect generated after a HVCE is weakened somewhat, and the effect time is continuously delayed in the FPHP platform.