1. Introduction

Climate change, which describes the long-term changes in weather patterns and global temperature, is one of the biggest threats to modern civilization [

1]. While some schools of thought have argued that climate change is natural, scientific evidence has also shown that since the 1800s, human actions have been a significant precipitator of climate change due to the increased use of conventional fuels like gas, oil, and coal, which causes greenhouse gas (GHG) emissions [

2]. When fossil fuels are burnt for energy production, they produce greenhouse gases, which act as a blanket, absorbing heat from the sun and causing global temperatures to rise [

3,

4]. The major constituents of GHG are carbon dioxide (CO

2) and Methane (CH

4), most of which come from the burning of gasoline used for powering the transportation sector and the burning of coal and gas for electricity generation and heating [

5]. Deforestation is also a major source that releases CO

2 into the Earth’s atmosphere while using gas, oil, and agricultural activities (especially poultry) are identified as the primary source of Methane [

6]. As such, the release of GHGs can be attributed to land use, farming activities, building, transportation, and the energy sector.

The consequences of climate change are not distant threats but harsh realities the world is already grappling with. These include extreme weather conditions, flooding, drought, and severe air, land, and water pollution [

3]. The impacts extend to famine, hunger, malnutrition, mental health issues, forced displacements, and increased sickness and disease. A 2023 World Health Organization (WHO) report estimates that 3.6 billion people occupy regions highly susceptible to climate change, and the world could see 250,000 additional deaths between 2030 and 2050 [

7]. These figures are not mere statistics but a stark reminder of the urgent need to mitigate climate change.

Various initiatives have been taken to reduce climate change, including adopting climate education, climate-friendly policies, forest protection [

8], recycling and reuse [

9], green transportation [

10], sustainable agriculture [

11], energy efficiency [

12], and the transition to green energy [

13]. The transition to green energy, primarily through adopting renewable energy, holds significant promise in mitigating climate change. Many countries have pledged to adopt renewable energy on various global platforms; this has thus increased the adoption of green energy in various sectors of the economy. The adoption of renewable energy has also gained momentum recently due to increased efficiency (especially biomass, wind, and solar photovoltaics), improved modularity, and technological breakthroughs in materials engineering—all photovoltaic (PV)—which have resulted in cost competitiveness [

14,

15]. Data published by The International Renewable Energy Agency (IRENA) between 2010 and 2022 indicate that both wind and solar were cost-competitive with conventional energy sources, even without subsidies [

16]. More specifically, it was noted that the global weighted average cost of electricity from solar PV fell to USD 0.049/kWh (89% decrease), almost 33.33% less than the cheapest conventional fuel globally.

Despite the negative effect of COVID-19 on the global renewable energy supply chain, it has been reported that between 2021 and 2022, solar PV has been responsible for more than 50% of new power plant installations globally [

17]. In 2022 alone, solar PV capacity increased by 25%, making it the fastest-growing generation technology. Furthermore, global PV power production increased from 3.6% in 2021 to 4.5% in 2022 [

17]. Solar PV and wind power have been the main drivers of the new addition of renewable energy to the power-plant mix, accounting for nearly 75% of the capacity increase between 2021 and 2022. Although the contribution of both wind and PV to the generation mix in the last three years is impressive, there are also various challenges associated with them.

Solar radiation and wind are intermittent in nature and are thus unreliable without backup [

18]. To make solar PV and wind electricity generation more reliable, it is common to integrate them with conventional sources of energy generation or energy storage systems like battery and hydrogen storage [

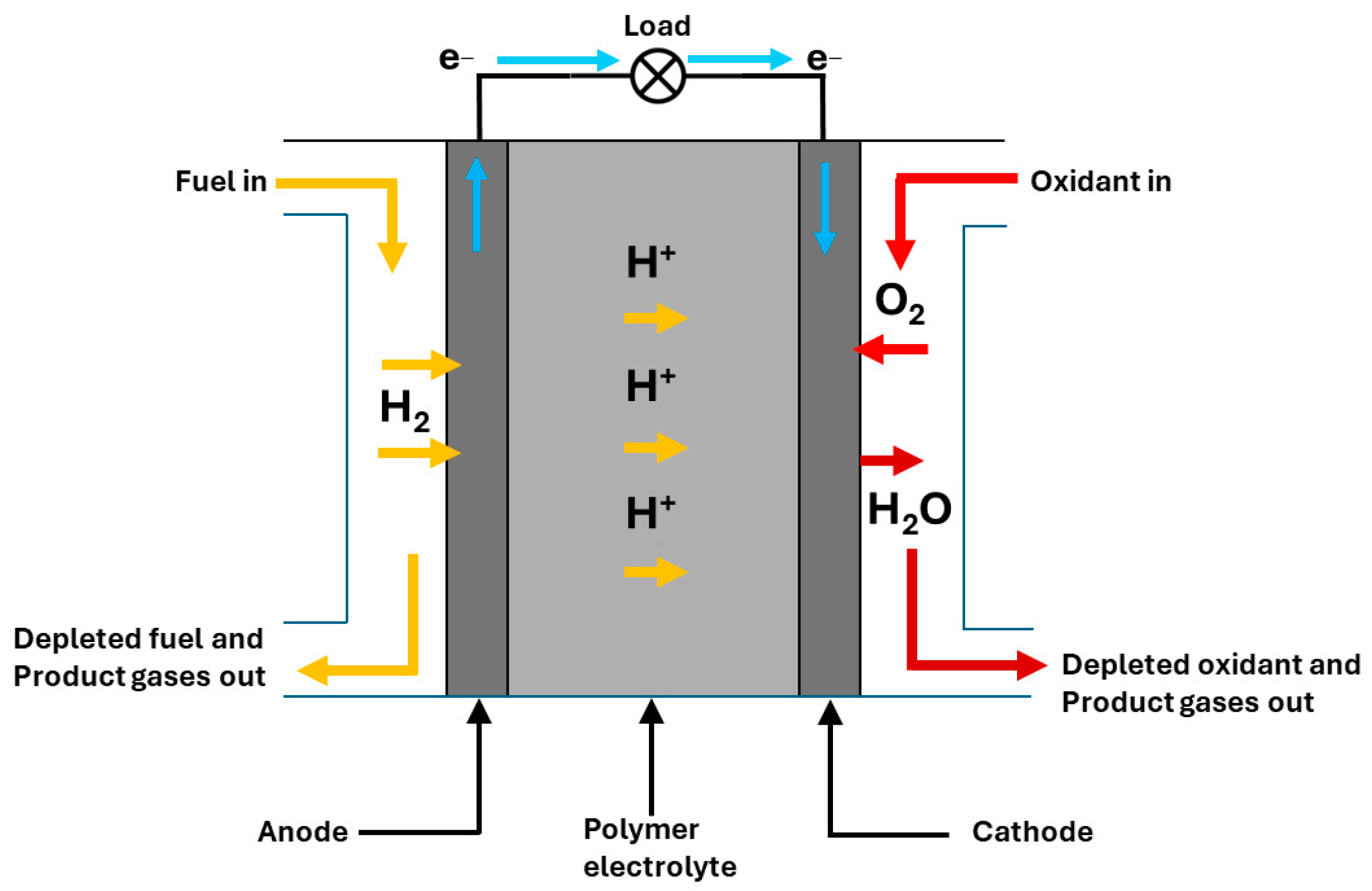

19]. Of these two storage technologies, battery storage has gained more attention. However, more research endeavors are currently being dedicated to hydrogen energy storage. The hydrogen energy storage consists of the electrolyzer, hydrogen tank, power conditioning units, control and monitoring system, and fuel cell (FC) [

20]. Like the operation of the battery, the FC uses an electrochemical reaction with oxygen to convert the chemical energy of the hydrogen to electricity. This makes the FC an essential component of the hydrogen storage system [

21,

22]. As FC technologies become more efficient and economical, they find applications in various carbon-intensive sectors, including telecommunications, aerospace, industrial applications, portable power supply, backup power, and transportation (electric vehicles, ships, rail) [

21]. Proton-exchange membrane (PEM) and solid oxide fuel cells (SOFC) are the most prevalent forms of FC for hydrogen energy storage systems.

Hydrogen energy storage is a clean energy source that only releases water as the primary byproduct during its operational life span [

21,

23]. While the FC does not release emissions during its operations, it consists of membranes, catalysts (e.g., platinum), and bipolar plates [

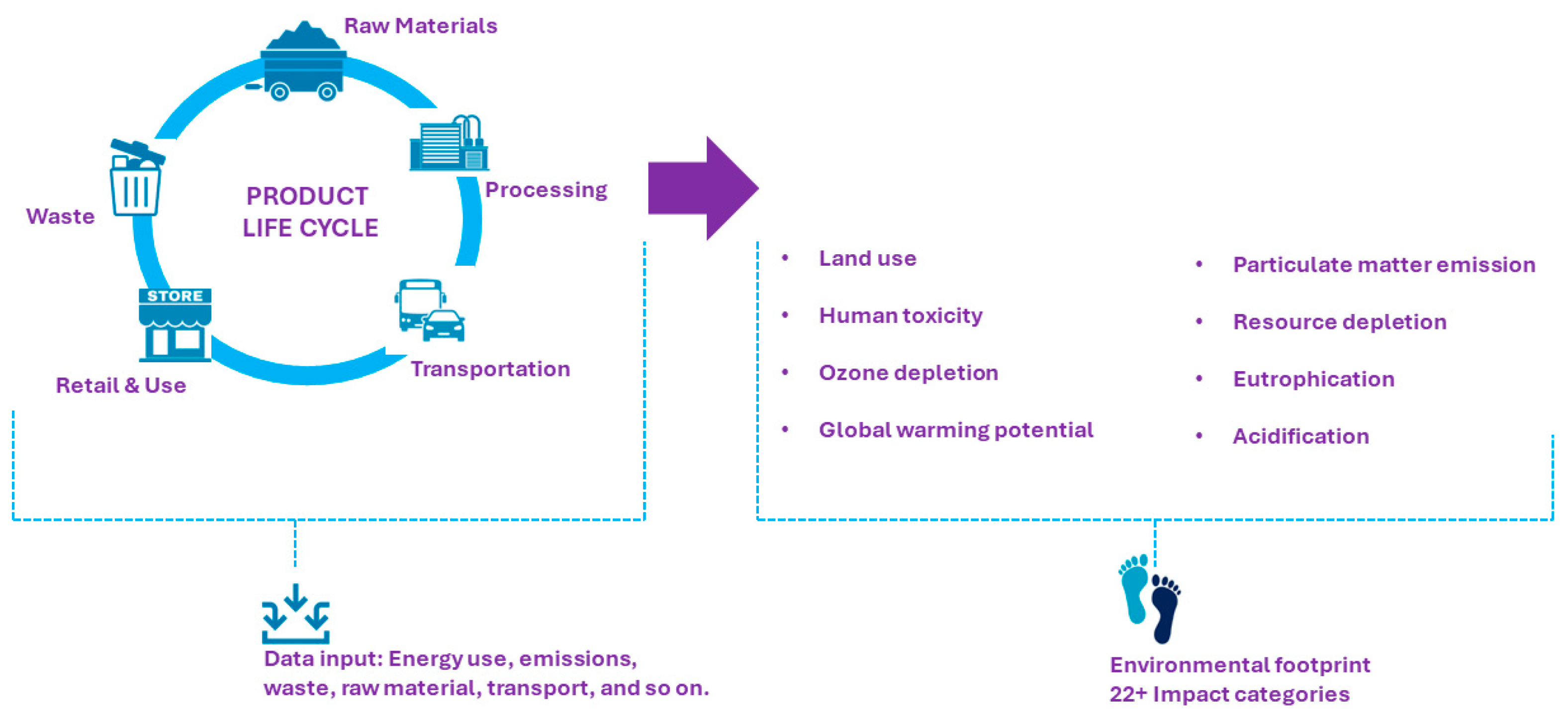

24]. The materials used for these components pass through the extraction and production stages, which are resource and energy-intensive and may have an environmental impact. It is, therefore, essential to consider the FC’s life cycle assessment (LCA) to quantify its overall ecological impact. Various articles have considered the LCA of FCs [

25,

26,

27]. Gulotta et al. [

28] presented a state-of-the-art systematic review of the various aspects of life cycle costing (LCC) and the LCA for Unitized Regenerative FCs using PEM devices. The authors selected and reviewed scientific articles from ScienceDirect, Scopus, and Web of Science (WoS) databases. The results indicate a gap in knowledge on the LCA and LCC of URFC, with only one article on the LCA of the PEM-URFC system and none on the LCC. This means more studies are needed in this domain to give insights into the technology’s environmental impact and damage categories. Furthermore, Pehnt’s [

25] study was dedicated to analyzing the LCA of FC stacks, emphasizing the environmental impact of its production process. Also, using LCA, Evangelisti et al. [

26] compared the environmental impact of a proton-exchange membrane fuel cell (PEMFC) for passenger automobiles with conventional fossil-powered internal combustion engines. Staffell et al. [

27] investigated the energy and carbon payback timeframes for SOFC-based home combined heat and power systems. However, research studies that extensively combine mid- and end-point methodologies within PEMFC systems are sparse. By conducting a comprehensive LCA of a 1 kW PEMFC system using both mid-point and end-point methods, this paper attempts to bridge this gap.

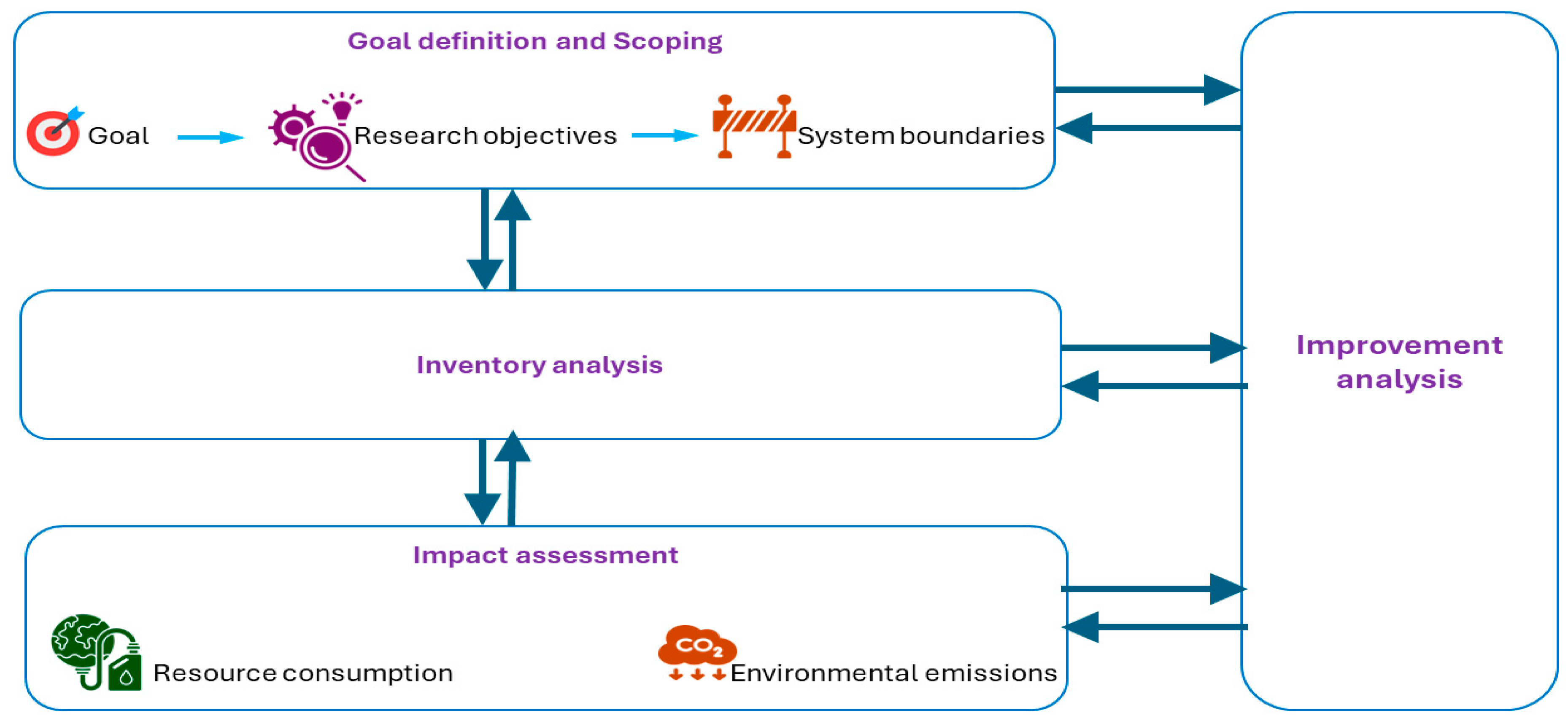

Therefore, this paper aims to implement a comprehensive LCA for a kW PEMFC system to identify the significant environmental impacts. The study uses mid- and end-point approaches to evaluate the environmental effects of producing the 1 kW PEMFC system. The rest of this article is arranged as follows: the relevant literature on the subject is presented in

Section 2, the materials and methods are presented in

Section 3, and

Section 4 covers the results of the mid-point and end-point assessment. The work is concluded in

Section 5, where significant contributions, limitations, and future research areas are highlighted.

2. The Literature Review

This section discusses the relevant papers that have been dedicated to the environmental assessment of FC. Pehnt’s study used an LCA to compare the environmental impact of PEFC stack generation to vehicle utilization [

25]. It highlighted platinum group metals as the principal contributors to ecological damage and advocated for their recycling to offset the consequences. Despite stack production emissions, FC automobiles have near-zero local emissions, which is critical for metropolitan settings. Considering recycling and better energy sources, according to the study, stack production emits 10% of automobile emissions for hydrogen and methanol, implying significant environmental advantages over gasoline vehicles. In another study, Dhanushkodi et al. [

29] reviewed studies related to the life cycle analysis of FC technology. The study identified various tools researchers have deployed in conducting LCAs of FCs; these include GREET and Simapro. The review covers studies related to fuel cycle stages and vehicle cycle of FC technology. The result shows that material extraction used to produce FCs leads to environmental impact. Although the study emphasized the significance of recycling, it did not consider the comprehensive LCA of FC technology. Similarly, using LCA, Usai et al. [

30] assessed the environmental impact of an FC-powered light-duty electric vehicle. The study results show that 5-ton CO

2-eq is released to the environment when an FC with a net power output of 80 kW is manufactured. Furthermore, the study identified that the production of the FC auxiliaries, together with the catalyst and tanks, performed below expectations regarding environmental impact across all impact categories considered. The study also noted that the transition to renewable energy technology, the use of secondary platinum, and technical improvements would yield between 25% and 70% reduction in carbon footprint across the impact categories. Baratto and Diwekar [

31] evaluated and compared the environmental impact of FC-based auxiliary power units (APUs) with that of idling diesel engines. The analysis shows that the quantity of emissions related to the use of APUs is considerably less than that of the idling of diesel engines; furthermore, the authors concluded that SOFC shows superiority to other FC technologies concerning environmental impacts and human health with a short payback period of approximately two years.

Yang et al. [

32] conducted a state-of-the-art and in-depth LCA to compare the environmental impact of internal combustion vehicles, electric vehicles, and FC-powered vehicles using China as a case study. The study compared these transport alternatives based on the hydrogen production approach and driving mileage to ascertain their sustainability. The study concluded that based on the vehicle life cycle, GHG emissions and energy consumption attributed to electric vehicles are considerably higher than that of the other two vehicles. The higher GHG emissions and energy consumption values are due to the high energy used during battery production. The results of the entire life cycle of the vehicles show that as they approach 75,000 km, fuel-cell vehicles powered by hydrogen—obtained by electrolysis using coke oven gas—and the abandoned hydropower provided the best performance compared to other scenarios. Granovskii, Dincer, and Rosen [

33] examined the environmental impact of using FCs (hydrogen as fuel) and internal combustion engines (gasoline as fuel) vehicles, comparing their fuel production and utilization. The study also compared the efficiencies of the FC and the internal combustion engines and their environmental impacts. Specifically, the authors considered the efficiencies and quantity of emissions from natural gas and crude oil transportation, a distillation of crude oil, reformation of natural gas, solar, and wind electricity production, hydrogen production through water electrolysis, and gasoline and hydrogen distribution and utilization. Based on the study’s findings, for the FC vehicle employing hydrogen to be competitive regarding GHG emission and energy consumption, its efficiency must be higher than gasoline by 25–30%. In another study, Evtimov et al. [

34] used an LCA to evaluate fuel-cell electric vehicle (FCEV) efficiency using various hydrogen production technologies. The study compared the fuel consumption and GHG emissions over the entire life of conventional gasoline vehicles and FCEVs. The impact of the energy generation mix and hydrogen production technology on the energy consumed and emissions shows that the most effective option for producing hydrogen in countries with CO

2 emissions over 447 g per 1 kWh of energy is by using natural gas as fuel.

Ally and Pryor [

35] present a discourse on a Western Australian government initiative on a Sustainable Transport Energy Programme that explores replacing natural gas and diesel public transit infrastructure in Perth with hydrogen FC alternatives. The study conducted an LCA for the hydrogen infrastructure implementation, bus production, operation, and end-of-life disposal of the FC bus to estimate the total energy demand and its associated environmental footprint. The results reveal that the FC bus alternative is competitive with the diesel and natural gas bus systems regarding eutrophication and global warming potential; furthermore, it was reported that the emissions attributed to photochemical and acidification ozone are higher in FC buses. Hwang et al. [

36] used MATLAB/Simulink and the GREET model to examine the FC vehicle’s life cycle performance. They compared greenhouse gas (GHG) emissions and energy usage for three hydrogen generation pathways: steam reforming of natural gas, grid electricity electrolysis, and PV electricity electrolysis. FCV system efficiency was highest at 25% of maximum net power, with PV electrolysis hydrogen reducing energy usage and GHG emissions the most compared to conventional gasoline vehicles. Grid-electrolysis FCVs showed higher lifespan energy consumption and GHG emissions than GVs but reforming hydrogen FCVs had fewer impacts than grid-based BEVs.

Evangelisti et al. [

26] reported the outcome of a detailed LCA of an FC vehicle with an emphasis on its production phase. The authors also compared the results from the manufacturing FCV with that of conventional internal combustion engine vehicles (ICEVs) and battery electric vehicles (BEVs). The study implemented a sensitivity analysis on the hydrogen tank and balance-of-plant to account for uncertainties in the input variables (inventory models and materials). The results indicate that the FC vehicle’s manufacturing phase displays a higher environmental impact than the BEV and the ICEV, which can be traced to the FC stack and hydrogen tank. Further analysis revealed that it is possible to achieve a 25% reduction in the climate change impact category for the FCV compared to a baseline FCV scenario. Further analysis shows that ICEVs generally have the highest global warming potential (GWP), mainly because of the release of fossil carbon emissions during their operation. Minimizing the ecological footprint in the production of FCVs continues to be a significant obstacle. Bareiß et al. [

37] conducted a life cycle evaluation to examine the environmental impact of proton-exchange membrane water electrolysis and steam methane reforming. The findings indicate that proton-exchange membrane water electrolysis is a highly promising technology for mitigating CO

2 emissions in the hydrogen industry. This technology has the potential to reduce emissions by up to 75% when the electrolysis system operates only on electricity derived from renewable energy sources. Jiangyi et al. [

38] proposed a PEMFC-based distributed energy system that includes input energy, a PEMFC-based combined cooling, heating, and power system, and building loads. The proposed system’s energy, environmental, and economic performance is examined through an LCA of various hydrogen–electricity contribution rates (

), hydrogen production methods, and hydrogen gas prices. The findings indicate that the hydrogen production method has a more significant effect on greenhouse gas emissions and primary energy consumption.

Krishnan et al. [

39] conducted an LCA to examine the environmental effects of alkaline electrolyzer (AE) and proton-exchange membrane (PEM) electrolyzer systems to produce green hydrogen, with a specific emphasis on the stack components’ baseline and near-future advanced designs, taking into consideration the cycle from the extraction to the operating phase. The primary sources of electricity, along with the emissions from the stacks, are recognized as significant factors that contribute to environmental impact. The study was not able to establish the preferred method between AE and PEM with regard to environmental impact. Through a comparative life cycle assessment between a stand-alone gas condensing boiler and electricity sourced from a grid mix, Slotyuk et al. [

40] examined the emission-reduction potential of a PEMFC whose application is in housing with a standard system. The findings indicate that, while the operational stage of the PEMFC had notable benefits in most of the environmental impact categories over the existing energy supply system, the manufacturing phase of the FC had drawbacks. Xu et al. [

41] designed an integrated system that combines coalbed methane recovery with a PEMFC. The sustainability of the proposed system was analyzed using an LCA and an emergy analysis model. A parametric analysis was conducted to evaluate the impact of the reforming temperature, steam carbon ratio, and current density on the emergy performance. According to the LCA results, the production phase has the highest impact on system sustainability, representing 51.65%.

In summary, the research examined in this section offers important perspectives on the LCA and other approaches for evaluating the environmental effect and sustainability of PEMFCs and associated systems. Emphasizing the significance of the production phase and the possibility for emissions reduction, Evangelisti et al. [

26] and Slotyuk et al. [

40] examined the environmental impact of PEMFCs in transportation and residential applications, respectively. In their studies on the impact of hydrogen production techniques on PEMFC environmental performance, Bareiß et al. [

37] and Jiangyi et al. [

38] highlighted the need for renewable energy sources. To produce green hydrogen, Krishnan et al. [

39] analyzed the environmental impacts of alkaline and PEM electrolyzers, while Xu et al. [

41] evaluated the sustainability of an integrated system that included coalbed methane recovery and a PEMFC. The current work contributes significantly to the LCA of FC systems by extensively examining the life cycle of a 1 kW PEMFC system utilizing both mid-point and end-point techniques from cradle to gate.

Contribution of the Present Study

The present work provides a unique way for evaluating the environmental effect of PEMFCs by integrating end-point and mid-point LCA techniques in a comprehensive cradle-to-gate analysis of a 1 kW PEMFC system. This method offers an in-depth overview of the long-term effects on human health, ecosystems, and resources as well as the immediate impacts on certain impact categories related to PEMFC manufacturing. This work differs from other studies in focusing on a 1 kW PEMFC system and comprehensively examining the upstream processes that contribute to the total environmental effect. This study analyzes the environmental impact of a 1 kW PEMFC system because it is widely used in small-scale PEMFC applications like backup power, portable power, and small stationary systems [

42,

43]. Additionally, studying the effects of a 1 kW system allows for extrapolation to larger multi-kW systems that combine multiple 1 kW stacks, as the 1 kW size forms a modular building block. This work fills a vacuum in the literature by illuminating environmental hotspots and possible areas for improvement and offers insightful information on the environmental performance of PEMFC technology. The findings complement previous research while offering new perspectives on optimizing the environmental sustainability of PEMFCs, making a significant contribution to the field. A comparison of various studies on the LCA of FCs and this present study is given in

Table 1.

4. Results

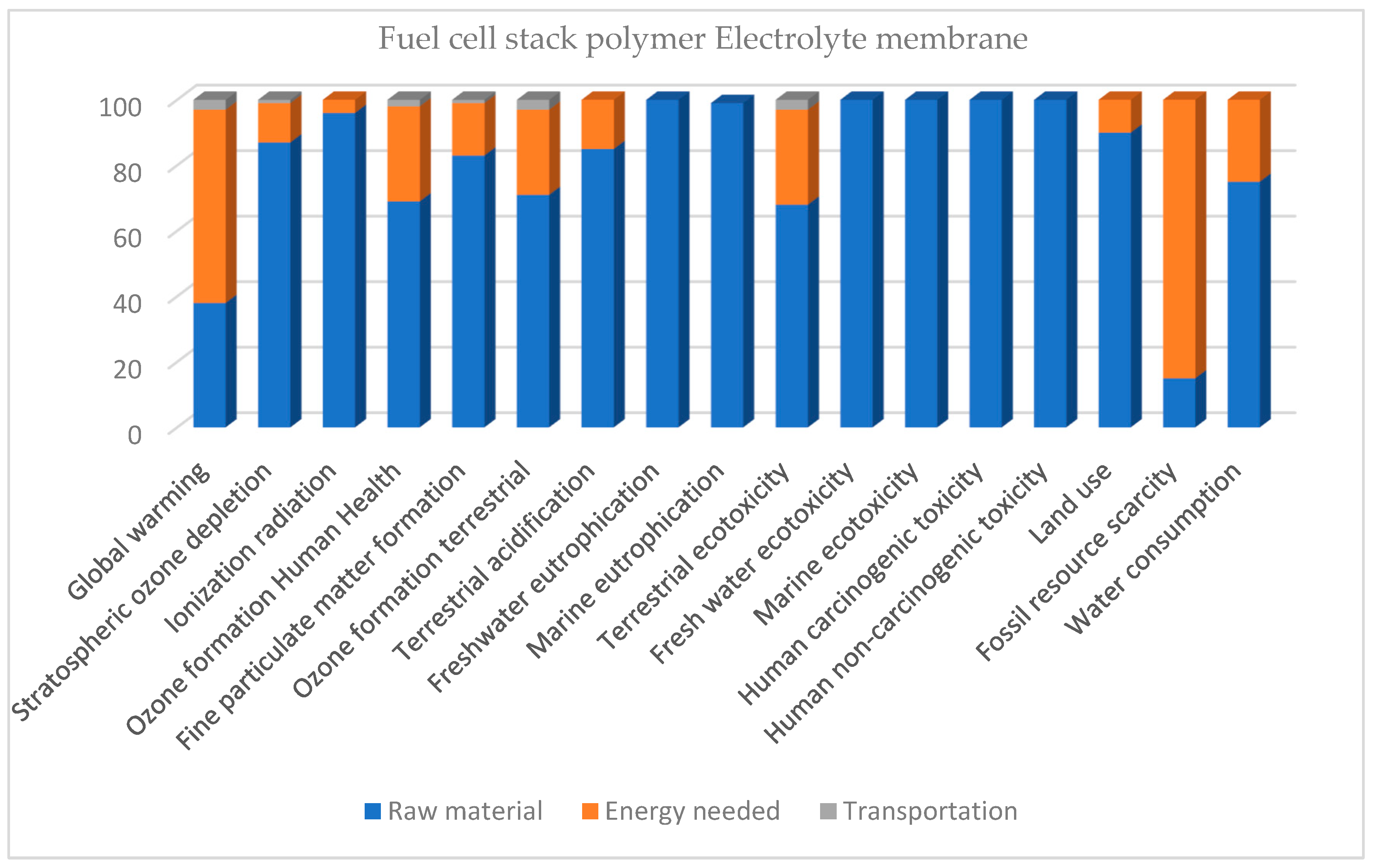

4.1. Mid-Point Analysis (Process-Oriented Approach)

When designing and implementing energy systems like FCs, it is essential to consider how the production processes will affect the environment. Finding ways to improve and making decisions that reduce adverse ecological impacts can be aided by understanding the influence of each stage on different impact categories. This section presents the characterization results of the 1 kW FC system and discusses how the three production processes of the 1 kW FC system—raw material, the energy needed, and transportation—contribute to the environmental impact categories. The characterization results are shown in

Table 3, with 18 impact categories and their values. A further analysis with respect to the production stages is presented in

Figure 4.

4.2. Raw Material Process

For the 1 kW FC system, the raw material process has the most influence on several environmental impact categories. Its contribution to freshwater eutrophication, marine eutrophication, human carcinogenic toxicity, marine ecotoxicity, and human non-carcinogenic toxicity is the highest (100%). Furthermore, it contributes substantially to the production of fine particulate matter (83%), ionization radiation (96%), land use (90%), stratospheric ozone depletion (87%), and terrestrial acidification (85%). Based on these findings, it can be deduced that the extraction and processing of raw materials for the FC system have a significant influence on the environment in a variety of different areas.

4.3. Energy Needed

The energy associated with the production of the 1 kW FC system is a major factor in the depletion of fossil resources (85%) and the acceleration of global warming (59%). It has significant impacts on ozone formation—human health (29%), ozone formation—terrestrial ecosystems (26%), fine particulate matter formation (16%), and terrestrial acidification (15%). These findings indicate that the energy usage during FC system manufacturing has a notable effect on the depletion of fossil resources and the release of greenhouse gases, in addition to its contribution to other environmental impact categories.

4.4. Transportation

The transportation process has relatively lower environmental impacts than the raw material and the energy-intensive processes of producing the 1 kW FC. Its most notable impacts are on terrestrial ecotoxicity, global warming, and ozone formation on land. These findings suggest that transporting materials and components for the 1 kW FC system has a significantly lower environmental footprint than the other two procedures. Various strategies can be implemented to reduce the environmental impact of transportation. These include optimizing logistics and transportation routes to minimize distance and trips and adopting eco-friendly transportation methods. Some examples of these approaches include deploying electric or hybrid vehicles with low-emission fuels, enforcing strict emission control measures, regularly maintaining vehicles to minimize pollutant release, and promoting local suppliers and materials to reduce the need for long-distance transportation.

Human non-carcinogenic toxicity, terrestrial ecotoxicity, freshwater toxicity, human carcinogenic toxicity, and marine ecotoxicity were grouped and captioned ‘toxicity’. Toxicity, alongside the two top environmental impacts, global warming and fossil resource scarcity, was further analyzed to understand the exact substance contributing to these impact categories.

4.5. Toxicity

The toxicity impact values indicate the potential environmental and human health risks associated with the 1 kW FC energy system, underlining the significance of an in-depth understanding and suitable risk mitigation techniques. These categories cover marine ecotoxicity, freshwater toxicity, terrestrial ecotoxicity, human carcinogenic toxicity, and human non-carcinogenic toxicity. Toxicants, either carcinogenic or non-carcinogenic, can be highly hazardous to humans.

The characterization results of the 1 kW FC system are shown in

Table 3. The toxicity results correspond to the levels of harm caused to marine ecosystems (44.82992 kg 1,4-DCB eq), freshwater ecosystems (35.13203 kg 1,4-DCB eq), terrestrial ecosystems (129.5218 kg 1,4-DCB eq), and the human cancer-causing potential (10.88584 kg 1,4-DCB eq) and human non-cancer-causing potential (1109.935 kg 1,4-DCB eq). This indicates that approximately 1330.305 kg of 1,4-DCB eq is generated for every 1 kW of power generated by the FC system. These figures illustrate the potentially hazardous impacts of the 1 kW FC energy system on various environmental sectors and human health. Toxic substances released during the life cycle of an FC system can harm marine organisms and disrupt aquatic ecosystems, negatively impact aquatic life and water quality in freshwater bodies, contaminate soil and harm terrestrial flora and fauna, and endanger human health, including the development of cancers and other adverse health effects such as respiratory issues, neurological disorders, and organ toxicity.

It is critical to identify the specific substances contributing to each toxicity category and devise strategies to reduce their release, such as utilizing alternative materials, enhancing production processes, and ensuring appropriate disposal and recycling procedures to mitigate these toxic effects. In addition, performing site-specific risk assessments can assist in quantifying the actual toxicity effects based on the specific environmental conditions and population exposure.

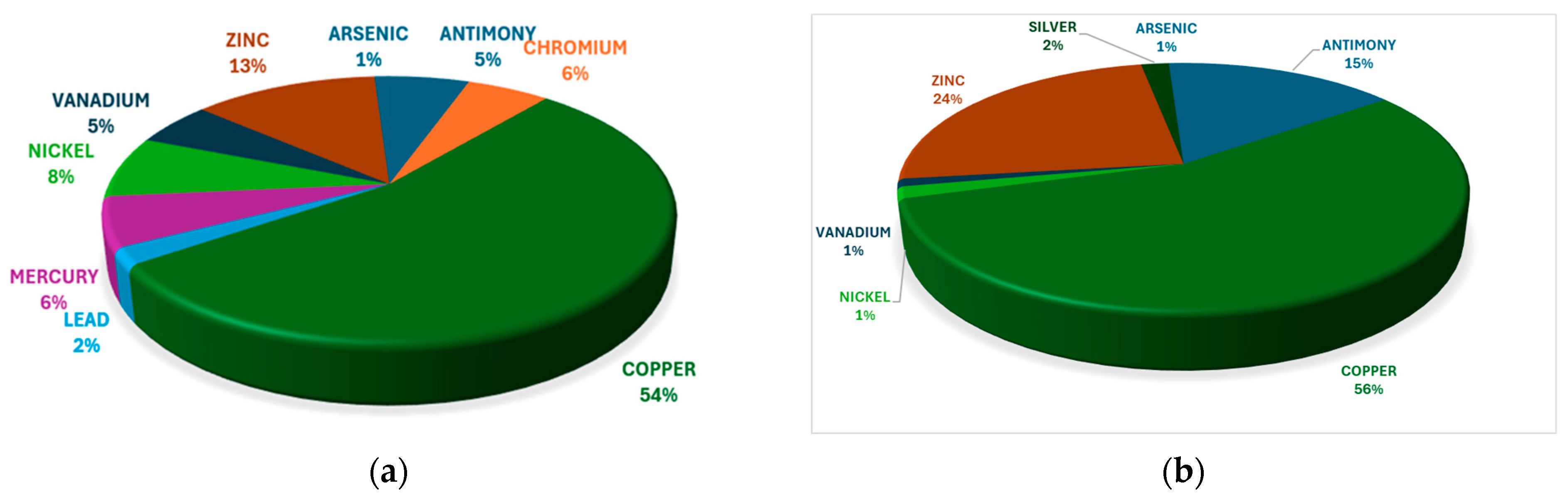

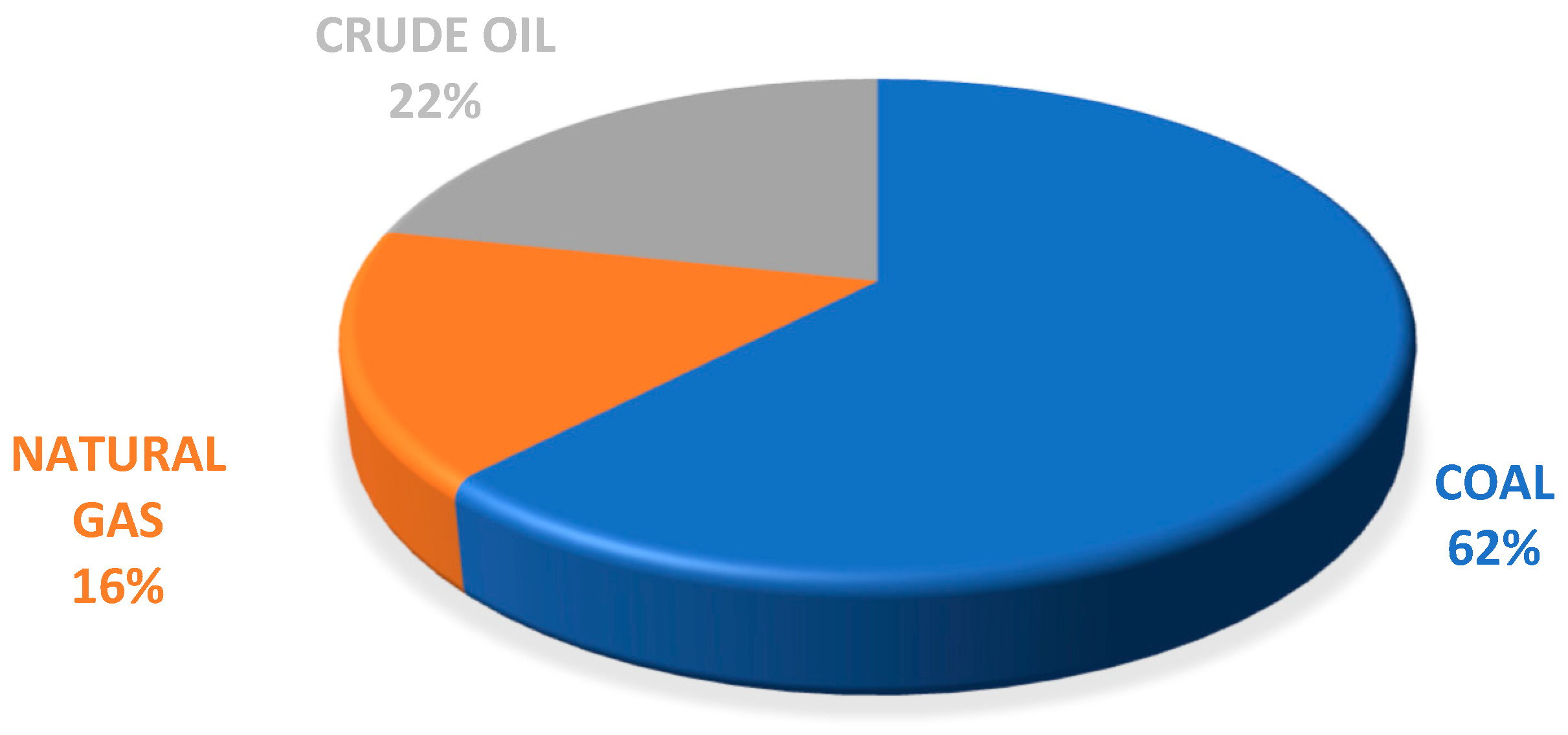

Further analysis of the elemental contribution of the FC to terrestrial ecotoxicity is depicted in

Figure 5. The results show that copper contributed the most (53.7%) to terrestrial ecotoxicity, followed by Zinc (12.5%), Nickel (7.4%), Mercury (6%), Chromium (5.6%), Antimony (5.4%), Vanadium (5.3%), Lead (2%), and Arsenic (1%). An analysis of the toxicity caused to the freshwater bodies shows that the element with the greatest impact on the freshwater is also Copper with 55.6%, followed by Zinc (24%), and Antimony (14.8%). Silver, Nickel, Arsenic, and Vanadium also contributed 1.89%, 1.5%, 1%, and 1%, respectively, to freshwater contamination. With regard to marine water contamination, Copper had the highest concentration (51.8%), while Vanadium contributed the least at 1%. Other elements that contributed to marine water contamination include Zinc (26.5%), Antimony (15.8%), Silver (1.6%), and Nickel (1%).

4.6. Global Warming

The concept of global warming and its relationship to climatic changes has received global attention, which is the result of human activities such as burning fossil fuels, deforestation, and industrial processes. Gases in the atmosphere, like carbon dioxide (CO2), methane (CH4), water vapor, and others, trap heat from the sun and keep it from going back into space. The Earth’s surface stays warm enough for life as we know it because of this process.

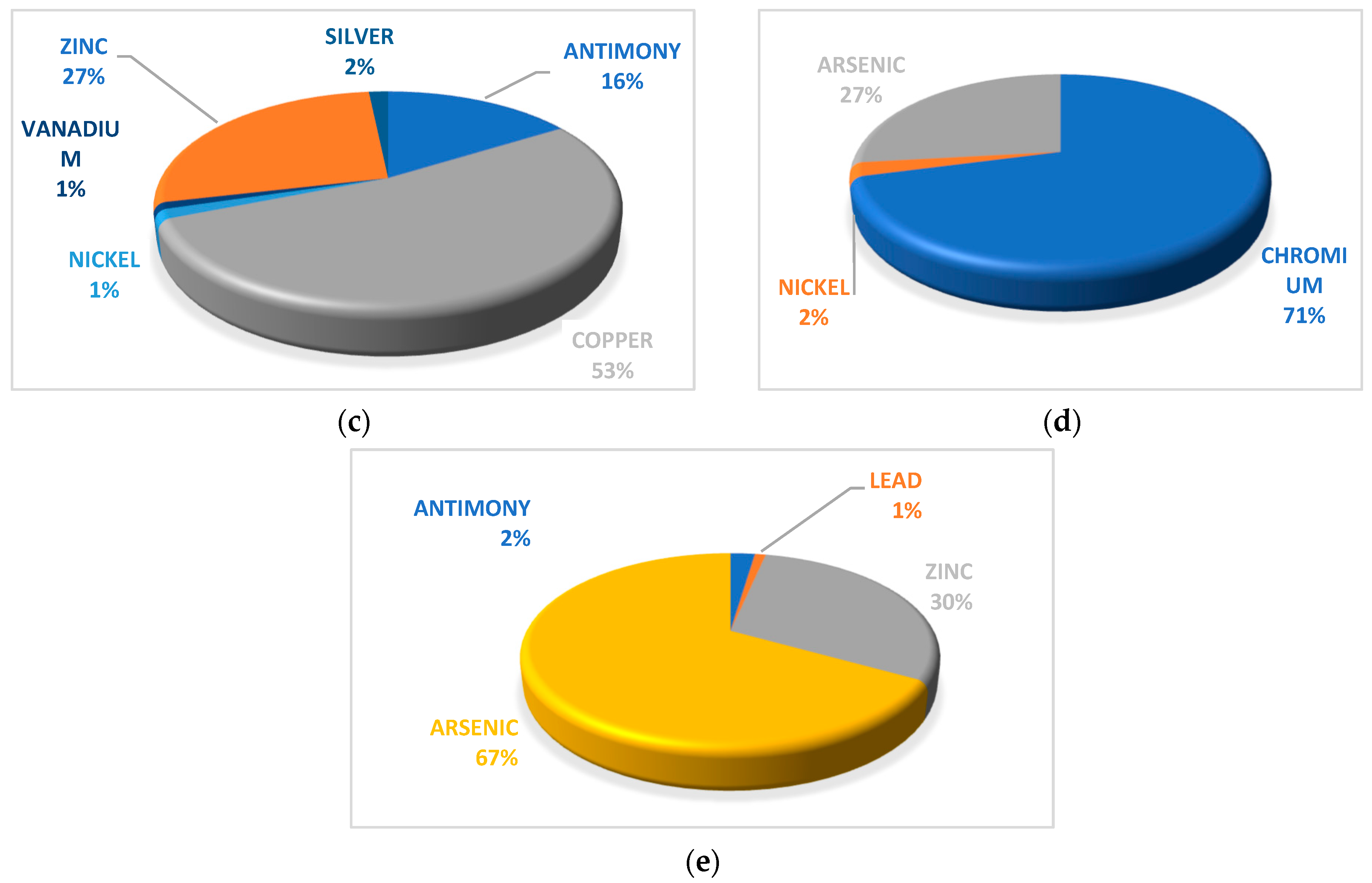

According to the characterization results presented in

Table 3, it is apparent that for every 1 kW of energy produced by the FC energy system, about 193.16 kg of carbon dioxide equivalent (CO

2 eq) emissions are discharged into the environment. This signifies a substantial ecological impact linked to the functioning of FC technology. Further analysis reveals that CO

2 is responsible for a significant portion of the total CO

2 equivalent emissions. Specifically, CO

2 contributes 82.77 kg, which represents 85.7% of the total emissions (

Figure 6). In addition, CH

4 and nitrous oxide (NO

2) account for 11% and 3.3% of the total emissions, respectively. These findings highlight the need to understand the composition of greenhouse gas emissions originating from the FC system, with a particular emphasis on the substantial contribution of CO

2. These insights are essential for developing successful methods to reduce the impact and improve the environmental sustainability of FC energy systems.

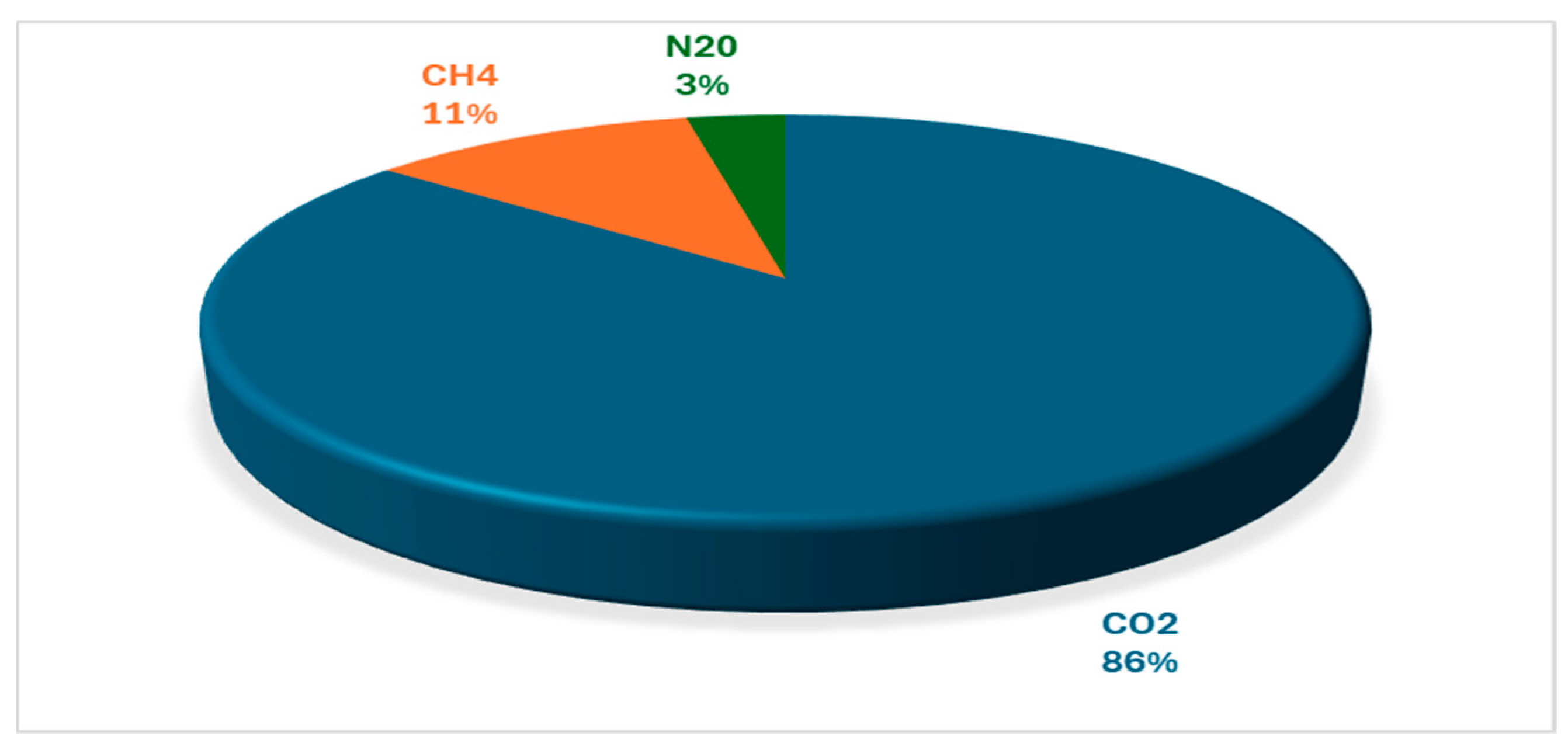

4.7. Fossil Resource Scarcity

The fossil fuel resources for a 1 kW FC energy system, as provided, are significantly reliant on non-renewable sources, with coal, natural gas, and crude oil accounting for 100% of the fuel mix; this mix raises serious questions about the system’s environmental impact and long-term viability. Coal, accounting for the majority of the fuel mix at 62.2%, as seen in

Figure 7, is renowned for its significant environmental impact. Coal combustion emits significant quantities of greenhouse gases, including carbon dioxide, which contribute to the phenomenon of climate change. Furthermore, coal mining operations frequently result in the destruction of habitats, polluting of water sources, and worsening of air quality. The use of coal in this FC device worsens these environmental concerns. Moreover, coal is a finite resource with limited availability. With the increasing global energy demands, the depletion of coal supplies is becoming an urgent concern. The significant reliance on coal in this FC system raises concerns over its long-term sustainability and the possibility of future supply disruptions.

Natural gas and crude oil, which make up 16.2% and 21.6% of the fuel mix, respectively, provide comparatively cleaner options in comparison to coal. Specifically, natural gas exhibits higher combustion efficiency and generates lower quantities of greenhouse gas emissions. Nevertheless, these fossil fuels remain non-renewable and prone to depletion. The production and transportation of natural gas and crude oil precipitates environmental hazards, including methane emissions and oil spills, which can have significant ecological implications.

The finite nature of these fossil fuel resources emphasizes the necessity for a shift towards renewable energy sources. Renewable alternatives, such as solar, wind, and hydropower, provide a more sustainable and eco-friendly energy generation method. To reduce the environmental impact of the FC system and tackle the issues of limited fossil resources, it is necessary to vary the fuel mix and increase the proportion of renewable energy sources. Furthermore, investment in renewable energy technology can spur innovation, generate new economic possibilities, and help to build a more resilient and sustainable energy infrastructure. Governments, corporations, and individuals must prioritize the transition to cleaner energy sources to address climate change and assure a sustainable future.

4.8. End-point Analysis (Damage-Oriented Approach)

The environmental impact characterization results for a 1 kW FC stack offer useful insights into the various impact categories impacted by its production. The findings (

Table 4)—presented in various units such as DALY for human health impacts, species per year for ecosystem impacts, and US dollars for resource scarcity—indicate the most pressing areas of concern.

The effects of acidification and climate change on freshwater ecosystems are less severe than those on terrestrial ecosystems. An examination of resource scarcity indicates a greater dependence on fossil resources in comparison to mineral resources. Other impact categories, such as ozone formation, affect both human health and terrestrial ecosystems to varying degrees. Reducing emissions that cause human toxicity, particulate matter formation, and terrestrial acidification should be the primary focus of efforts to mitigate these environmental impacts. Improvements in energy efficiency and increased use of renewable energy sources should also be prioritized. Optimizing resources and reducing the overall environmental imprint should be the top priorities of ongoing FC technology research and development.

4.9. Damage Assessment

Table 5 displays the results of the overall environmental effects resulting from the manufacturing of a 1 kW FC stack. The assessment is divided into three main categories: human health, ecosystems, and resources. The overall impact on human health is 0.000866 DALY, which designates it as the most affected area. This discovery implies that the manufacturing procedure leads to a substantial decrease in the duration of disease-free years due to factors such as the formation of particulate matter, global warming, and non-carcinogenic toxicity.

The damage to environments is measured by the number of species that die each year, which adds up to 1.04 × 10−6 species/yr. This shows that, in comparison to the effect on human health, the production of FC stacks has a negligible impact on ecosystem degradation and biodiversity loss. The impact related to the depletion of resources is measured in terms of United States dollars (2013) and amounts to USD2013 6.16844. This is an indication of the economic cost that is linked with the consumption of both mineral and fossil resources during the production process. To reduce these negative impacts, manufacturers should prioritize more environmentally friendly production processes, improve the efficiency of resource usage, and encourage the adoption of renewable resources. To decrease the overall environmental impact of the FC stack, it is important to focus on minimizing toxic emissions and mitigating the potential for global warming. Furthermore, the implementation of green practices and the use of circular economy principles can effectively mitigate the strain on ecosystems and limited resources.

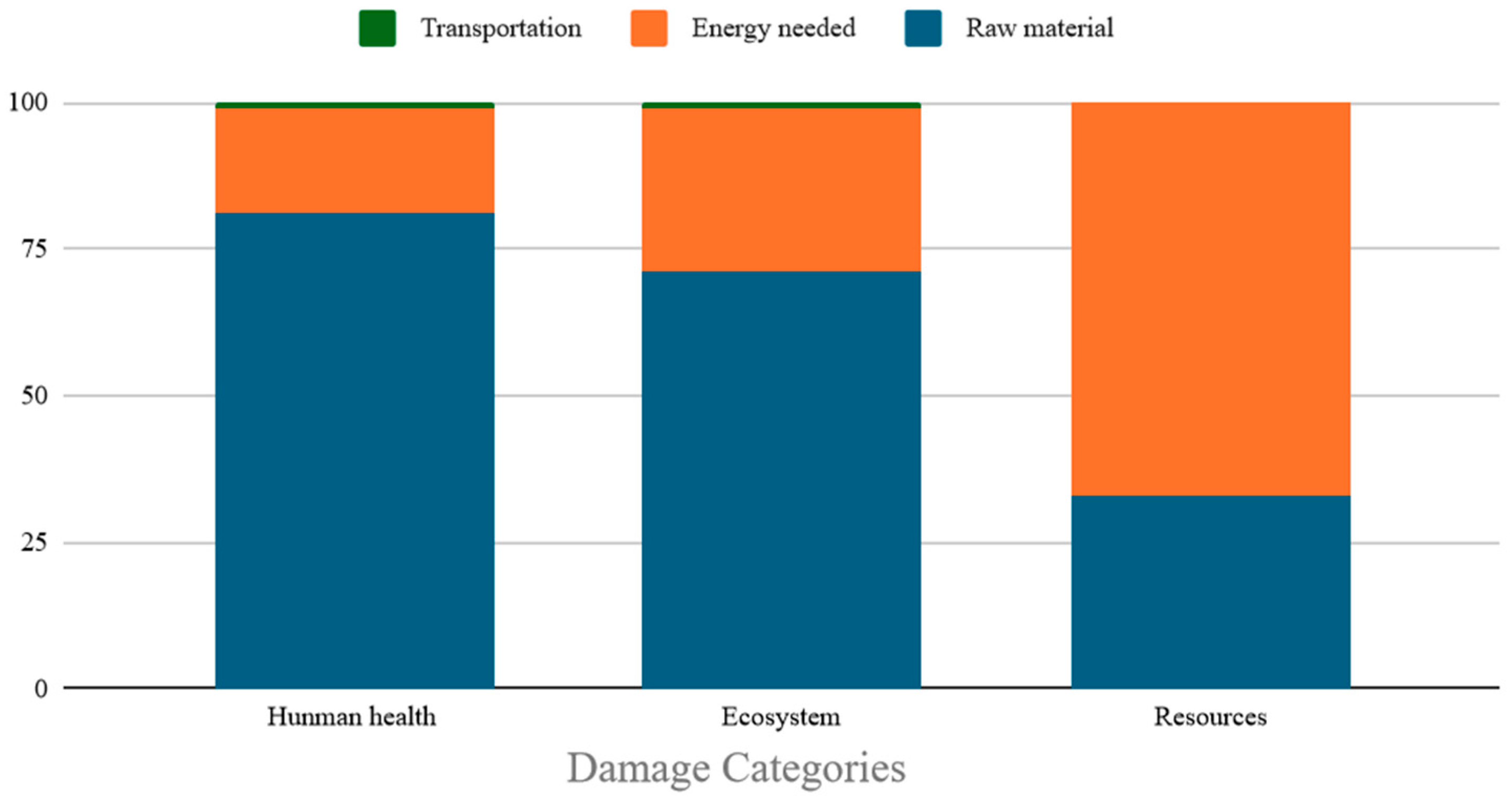

Figure 8 illustrates the corresponding impact of various stages of the 1 kW FC stack production on three primary categories of damage: human health, ecosystems, and resources. The raw material extraction and processing phase is the leading cause of human health damage (81%), damage to ecosystems (71%), and damage to resources (33%). The energy required to produce FC stacks is the second-largest contributor to the human health damage category (18%), the primary driver of resource depletion (67%), and accounts for 28% of ecosystem damage. Transportation contributes very little to all three categories of damage, accounting for 1% of the total impact on human health and environmental damage and making no contribution to resource depletion. To lower the overall environmental impact of 1 kW FC stack production, efforts should be directed at optimizing the raw material stage and increasing energy efficiency throughout the manufacturing process.

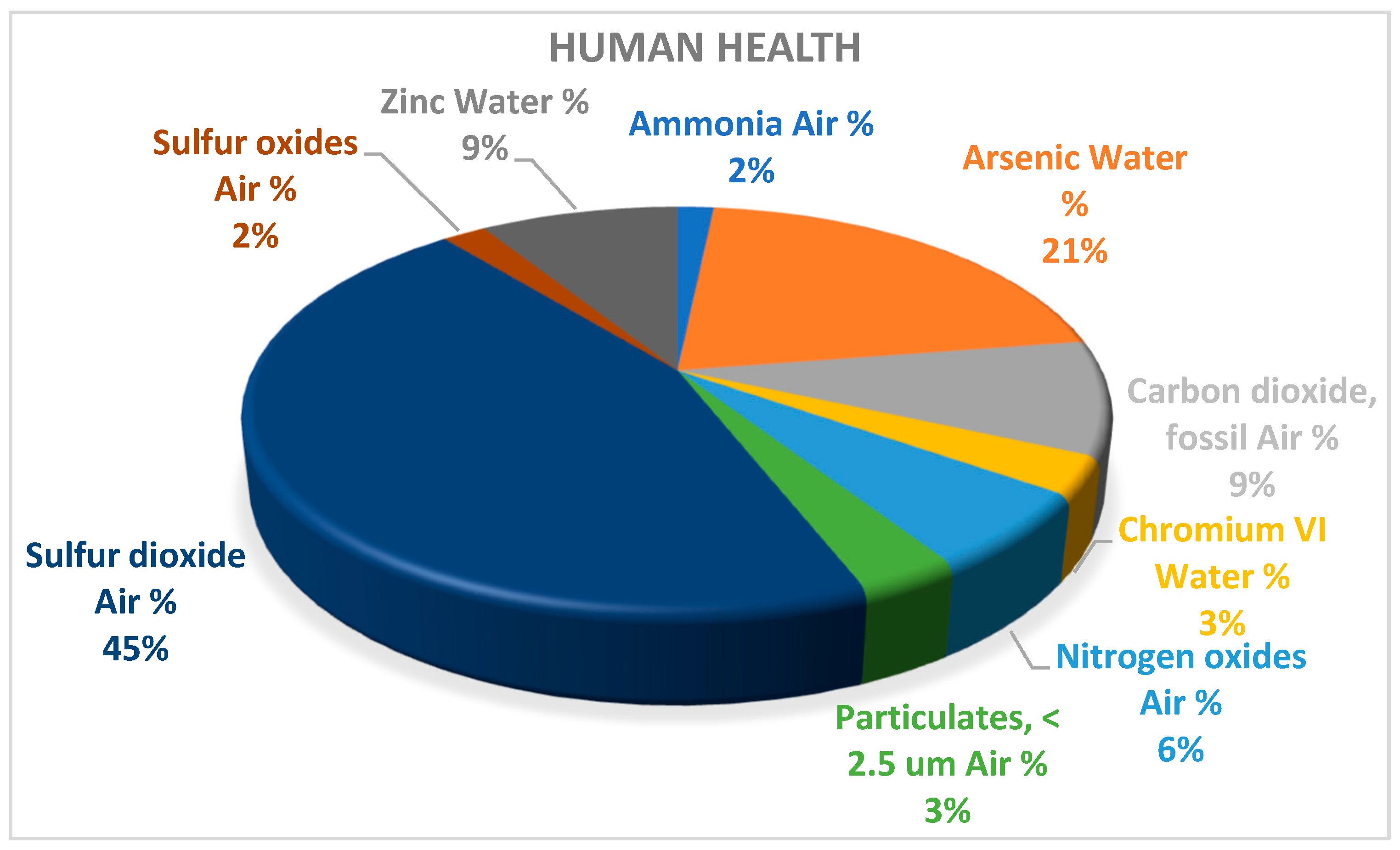

Figure 9 represents further analysis carried out on the human health damage category of substances that cause these damages and the mediums in which they were expressed. The results showed that 45% of Sulphur dioxide, 2% of Sulphur oxides, 2% of ammonia, 6% of Nitrogen oxides, less than 2.5 μm of particulate matter, and, 9% of Carbon dioxide were emitted into the air, while 21% of arsenic, 7% of zinc, and 3% of chromium IV were emitted into water bodies. The consequence of all these emissions, as explained earlier in the mid-point assessment, is damage to human health.

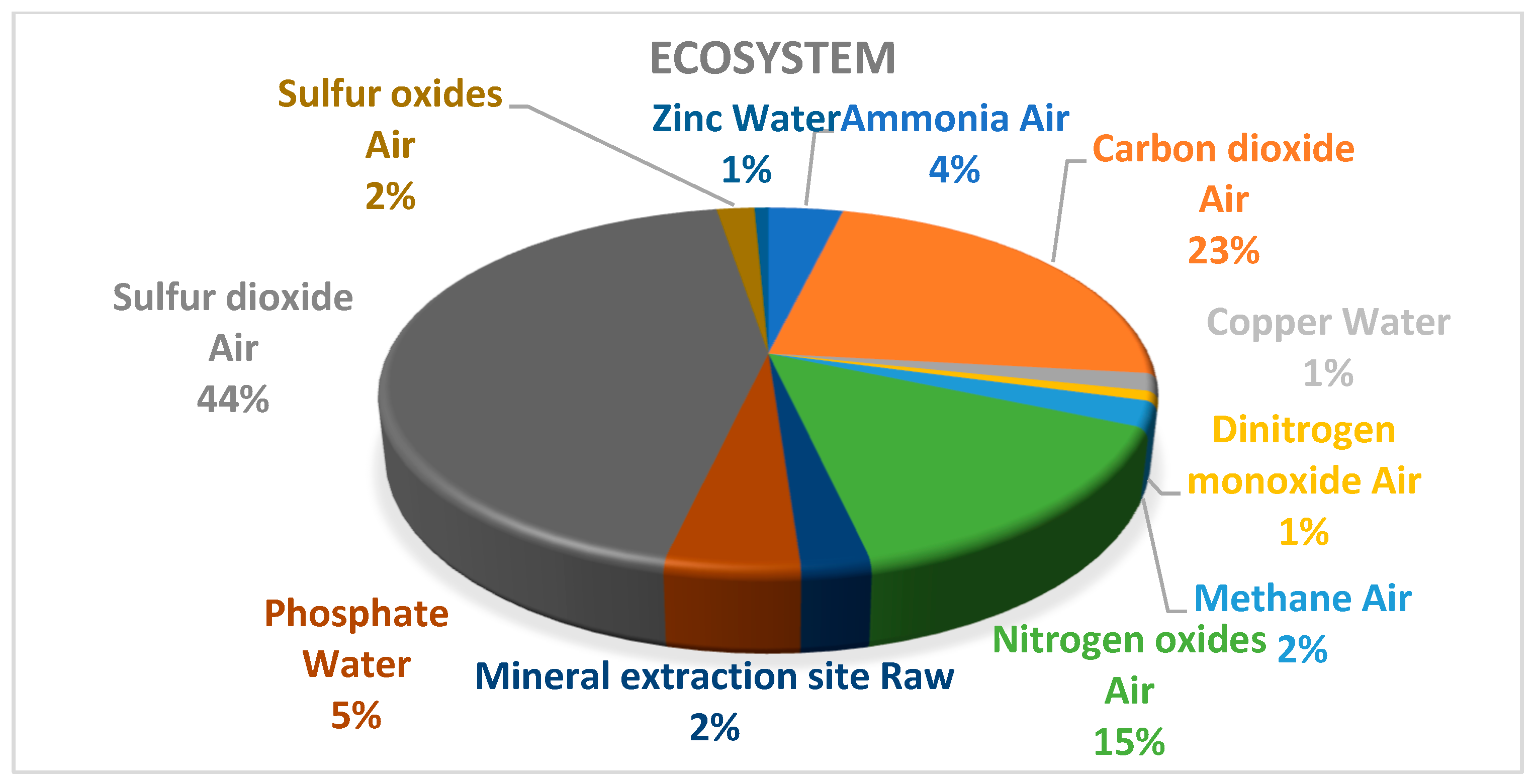

Figure 10 depicts a more detailed analysis conducted on the damage to ecosystems, focusing on the substances responsible for this damage and the channels through which it is manifested. The findings indicated that 44% of Sulphur dioxide, 2% of Sulphur oxides, 15% of Nitrogen oxides, 1% dinitrogen monoxide, 23% of CO

2, 4% of ammonia, and 1% of methane were emitted into the air, while 5% of phosphate, 1% of zinc, and 1% or copper were discharged into water bodies, and 2% of minerals extracted from the soil also contributed to the impact on ecosystems. The emissions, discussed previously in the midpoint analysis, have a detrimental impact on the ecosystem.

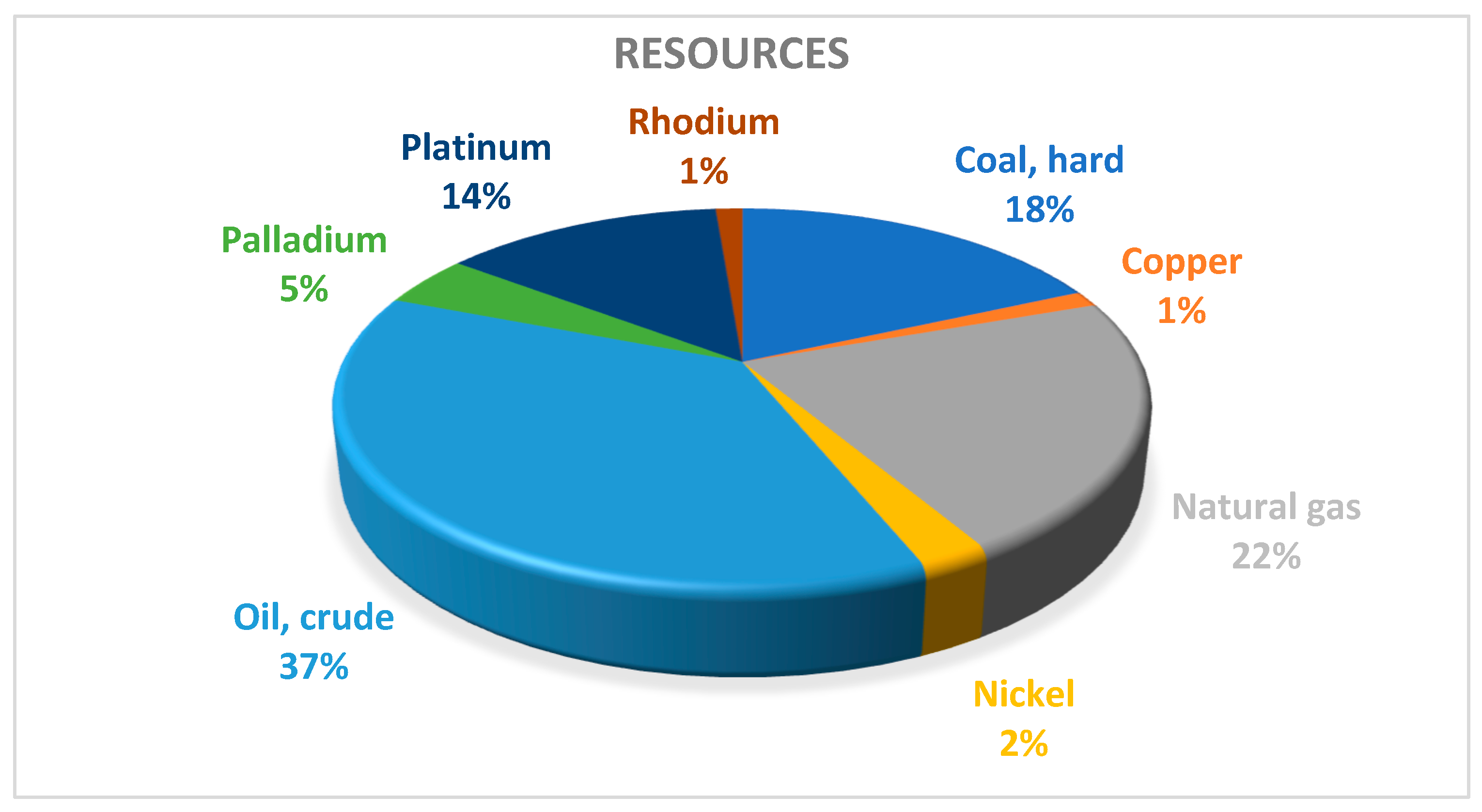

Figure 11 depicts an additional study conducted on the category of resource degradation. The analysis revealed that 37% of the resources in question were from crude oil, 22% were from natural gas, 18% were from hard coal, 14% from vanadium, 2% from nickel, and 1% from both Rhodium and copper.

4.10. Normalization Results

The normalization results from the mid-point assessment are presented in

Table 6. The major impact categories were observed to be freshwater ecotoxicity, marine toxicity, and human carcinogenic toxicity.

Table 7 represents the normalization results from the damage assessment showing that human health experiences the most significant damage during the production of a 1 kW FC stack.

4.11. Uncertainty Analysis

Uncertainty analysis is a systematic procedure that quantifies the uncertainty introduced in the results of a life cycle inventory analysis caused by model imprecision, input uncertainty, and data variability. The Monte Carlo simulation, which is very prevalent, is a stochastic model that has been incorporated into commercial LCA software (version 9.2). The uncertainty analysis was conducted using 1000 iterations and a 95% confidence interval on the SimaPro software. The results are available in the

Supplementary Materials, where

Tables S2–S4 represent the uncertainty analysis of the mid-point analysis, end-point analysis, and damage assessment. Considering the coefficient of variation (CV) in both approaches, the degree of uncertainty is high for water consumption, human non-carcinogenic toxicity, human carcinogenic toxicity, ionizing radiation, and freshwater eutrophication. On the other hand, freshwater ecotoxicity, marine eutrophication, marine ecotoxicity, land use, and terrestrial ecotoxicity have a relatively high degree of uncertainty. The impacts in all other categories in the approaches were comparatively minimal; additionally, the damage categories have a low degree of uncertainty.