Hydrogen-Induced Intergranular Fracture Behavior Accelerated by Needle-like MC Carbide in IN740H Superalloy

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

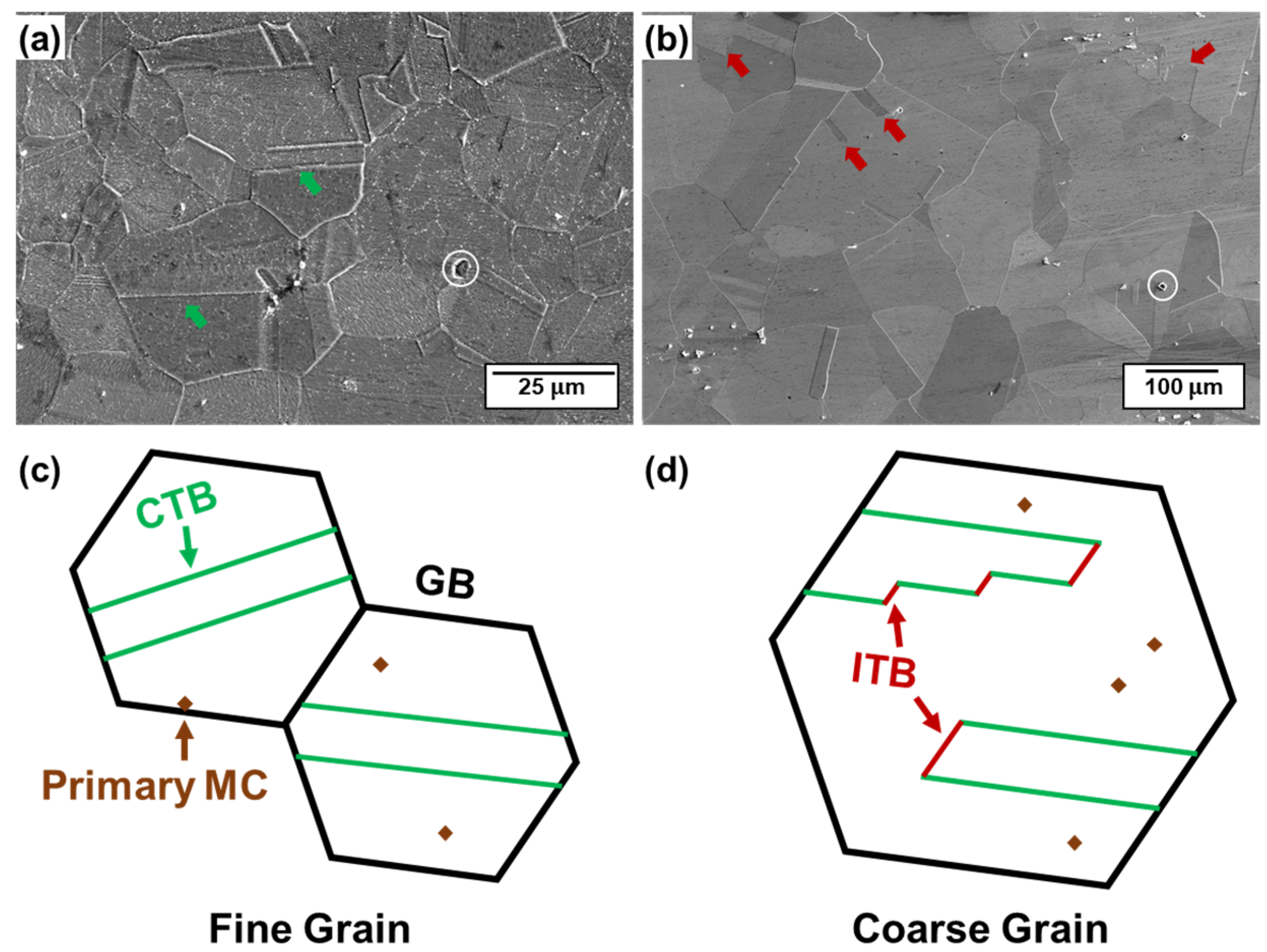

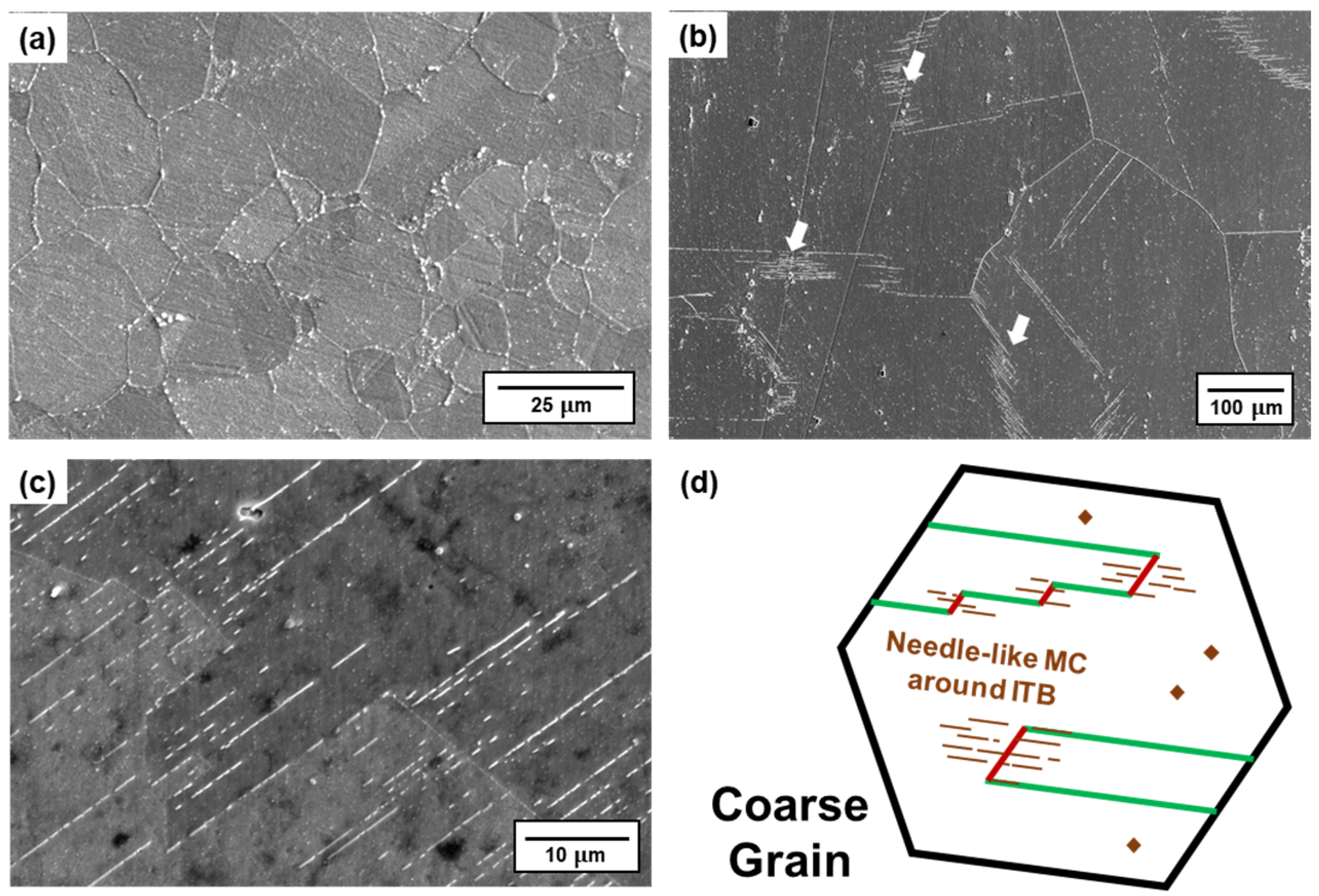

3.1. Initial Microstructure

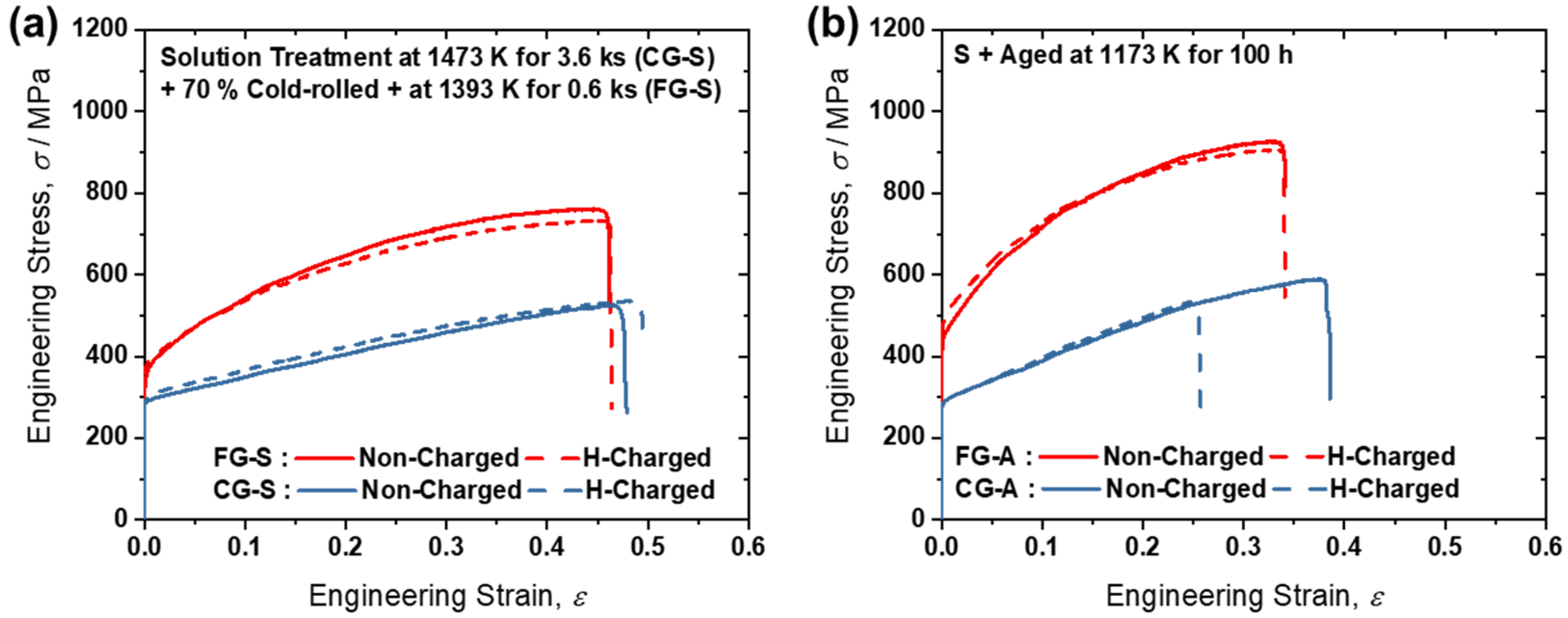

3.2. Tensile Property with and without Hydrogen

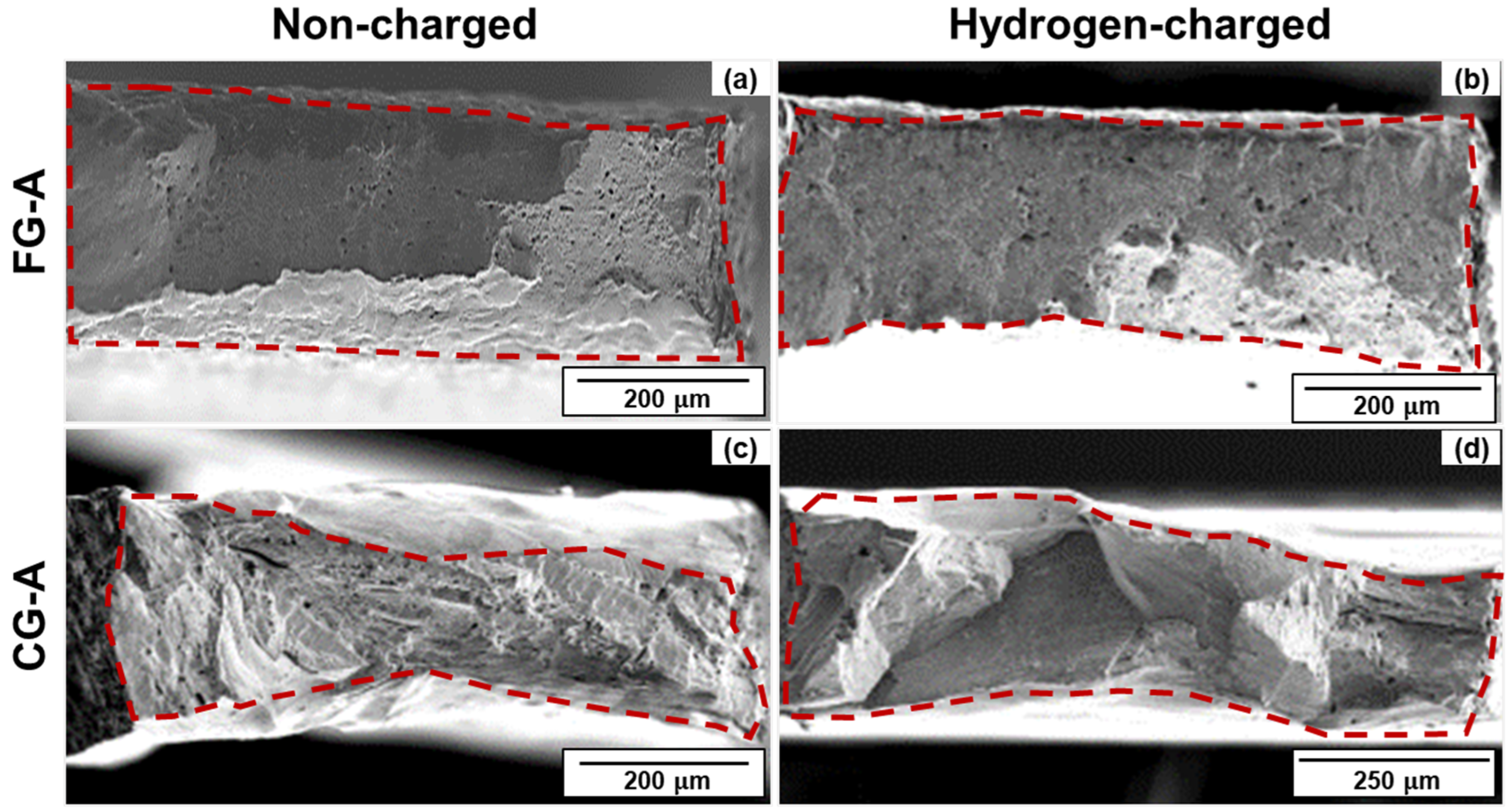

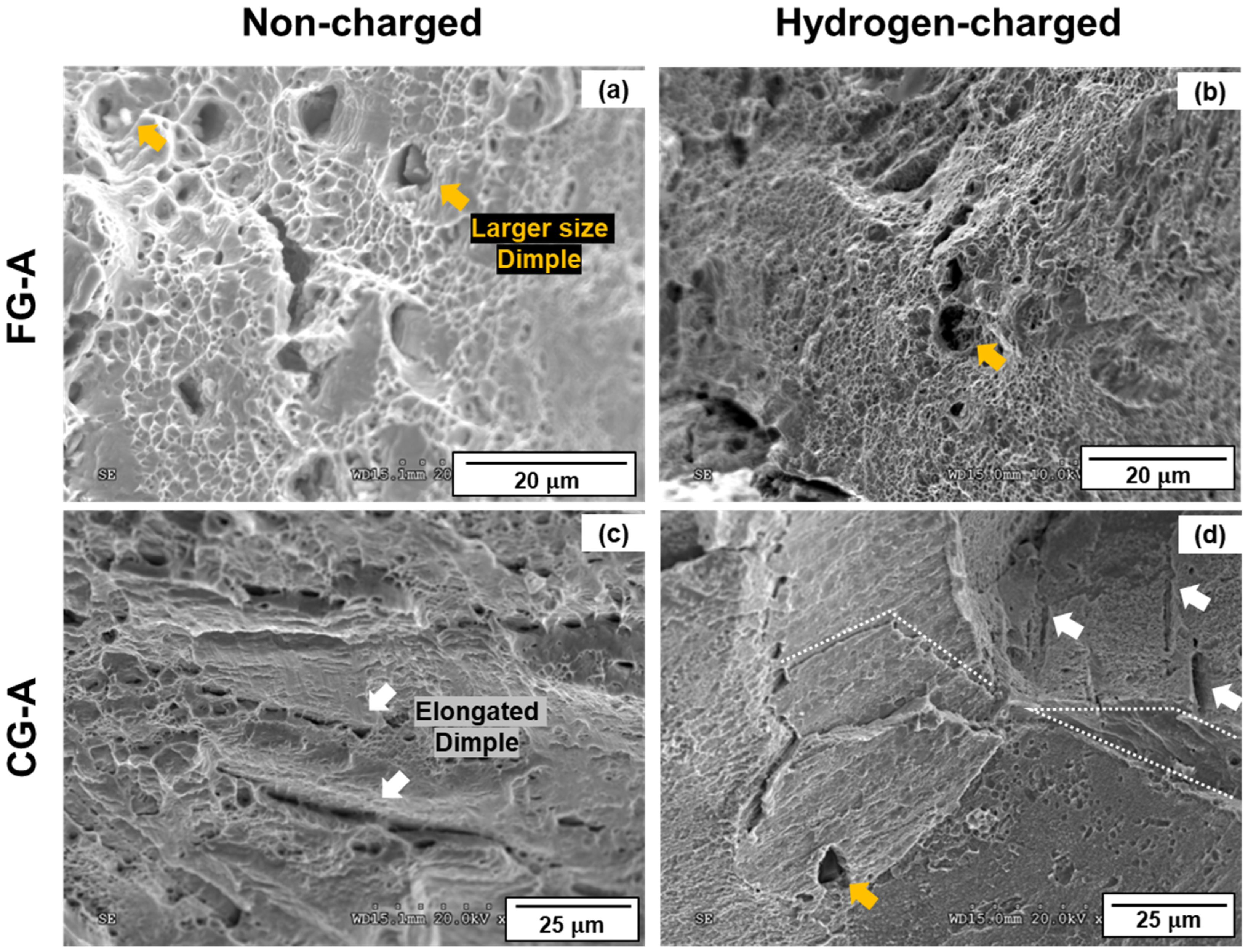

3.3. Fracture Behavior

4. Discussion

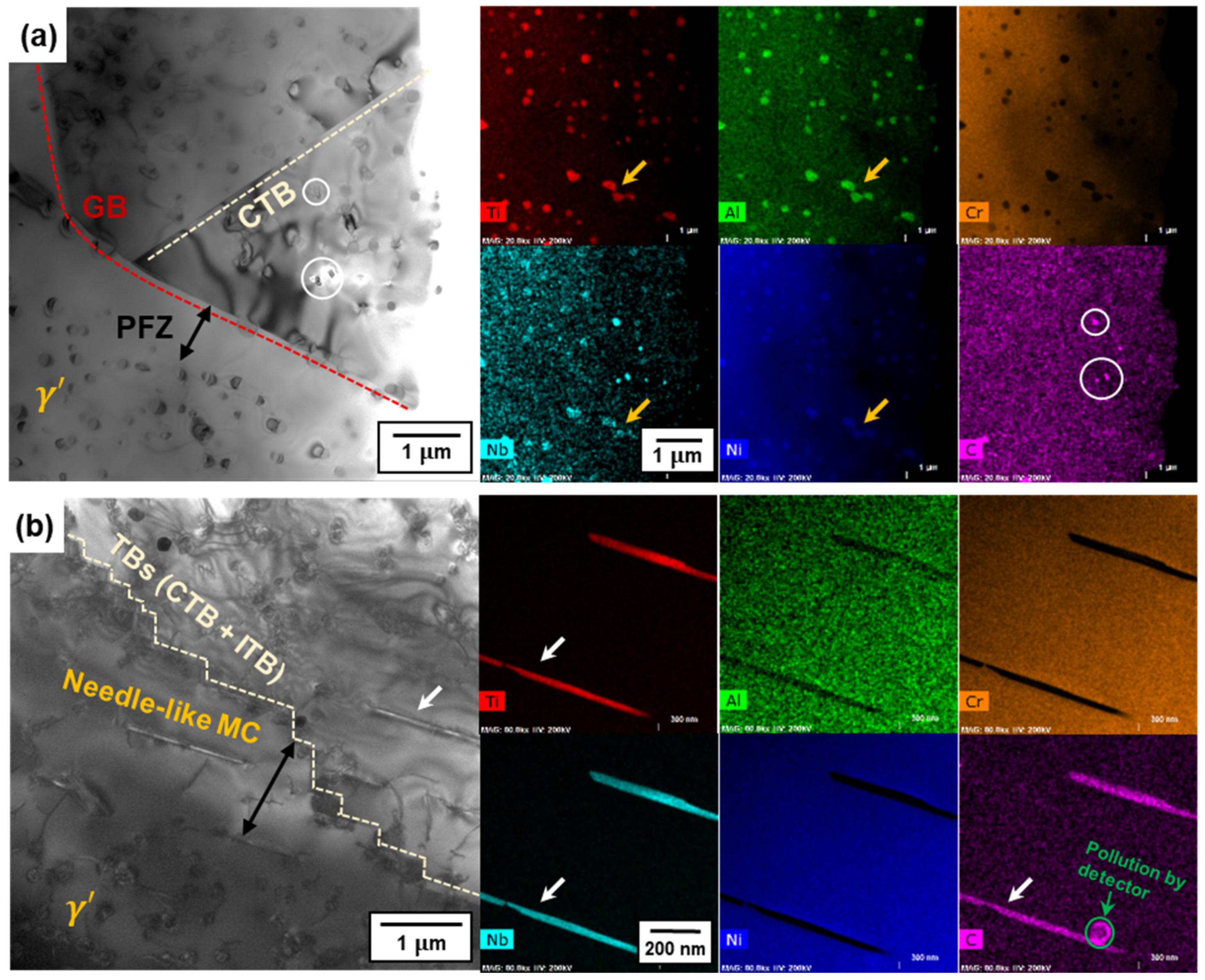

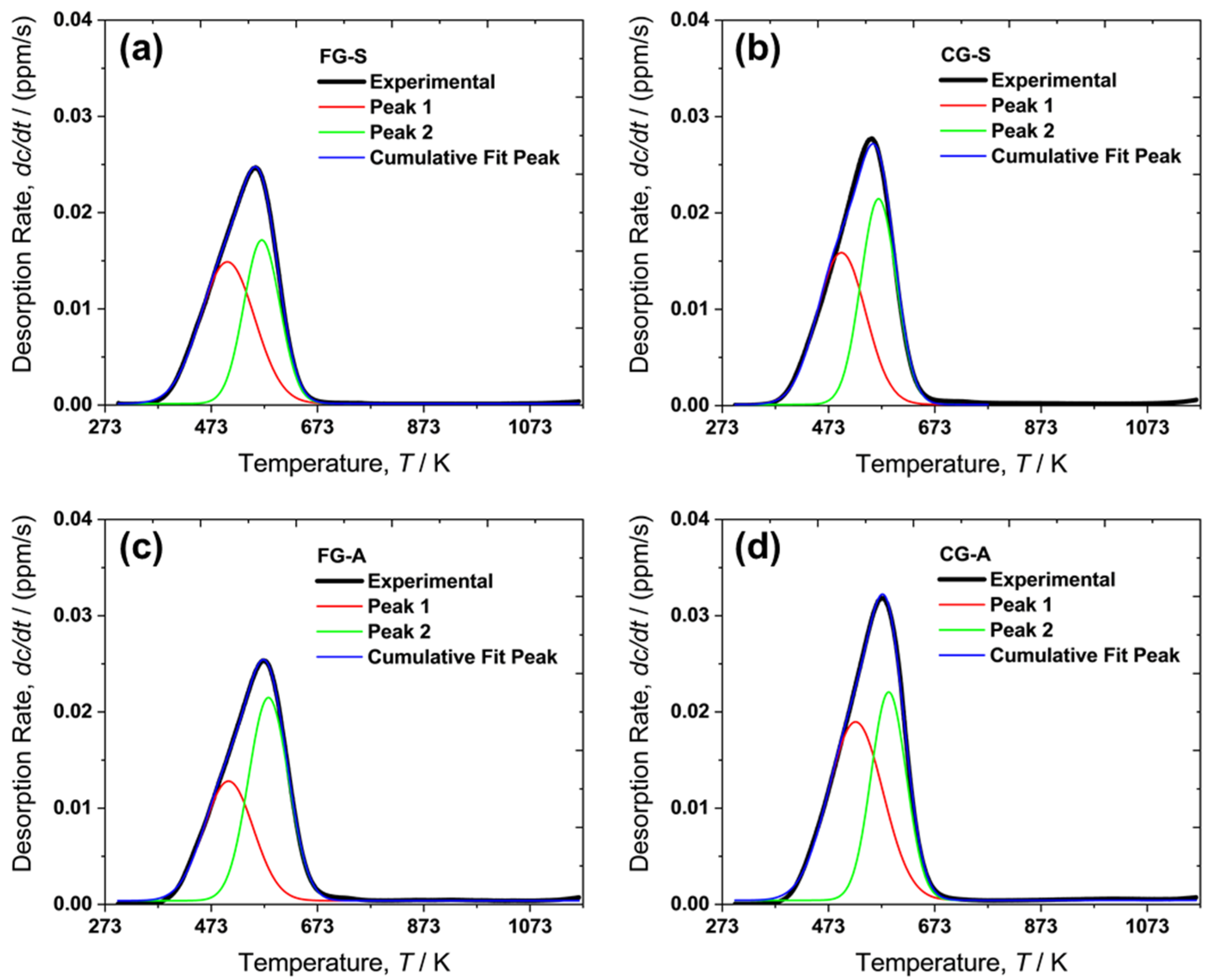

4.1. Hydrogen Trapping Behavior

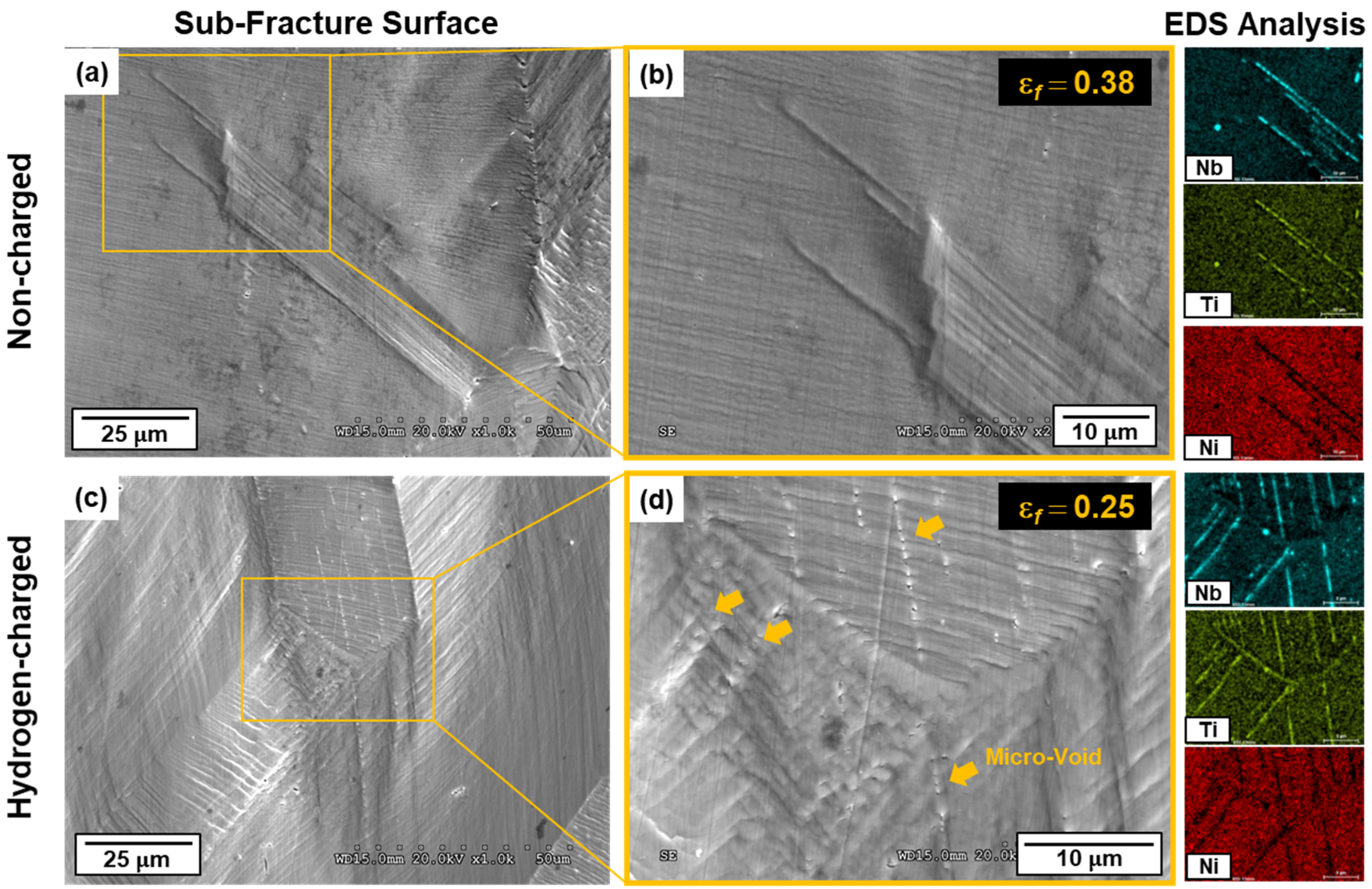

4.2. Hydrogen-Induced Intergranular Fracture

5. Conclusions

- For the FG-S specimen, the annealing twin boundaries developed well as the typical appearance of CTB. For the CG-S specimen, however, a larger portion of twin boundaries appeared, but their appearance was imperfect: most of the twin boundaries did not completely cross the grain and stopped along the way, which led to a large portion of ITB in the microstructure. After the aging process, needle-like MC carbides formed around ITBs only in the CG-A specimen.

- After hydrogen charging, only the elongation of CG-A specimens noticeably decreased: The ductility loss was estimated to be 32% for the CG-A specimen, while the other specimens did not decrease. In the fractography result, the fracture behavior strikingly changed in the CG-A specimen by hydrogen absorption: the fracture mode transits from the MVC process to intergranular fracture. Additionally, elongated dimples appeared, adjoining with the interface between intergranular fracture surfaces.

- TDS curves indicated that annealing with the coarse-grained condition (CG-A) resulted in the highest amount of hydrogen absorption, implying that the only characteristic difference of the CG-A, needle-like MC carbide, could be the dominant factor increasing the hydrogen absorption. Additionally, decomposition of the experimentally obtained TDS curves based on the assumption of two different trapping sites having Gaussian distribution showed that the peak area of the lower trapping energy (C1) increased more than that for higher trapping energy (C2) for CG-A compared to CG-S, which suggests that the interface between the needle-like MC carbide and the matrix could work as a weak hydrogen trapping site.

- In the presence of hydrogen in the CG-A specimen, deformation was more localized around ITBs and dislocations were promptly piled-up at the interface between the needle-like MC carbide and the matrix. This accelerated micro-void/crack formation and coalescence process at the interface. It imposed much higher load on the neighboring region, and finally led to hydrogen-induced intergranular fracture at ITBs at earlier strain.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tarzimoghadam, Z.; Rohwerder, M.; Merzlikin, S.V.; Bashir, A.; Yedra, L.; Eswara, S.; Ponge, D.; Raabe, D. Multi-scale and spatially resolved hydrogen mapping in a Ni–Nb model alloy reveals the role of the δ phase in hydrogen embrittlement of alloy 718. Acta Mater. 2016, 109, 69–81. [Google Scholar] [CrossRef]

- Tarzimoghadam, Z.; Ponge, D.; Klöwer, J.; Raabe, D. Hydrogen-assisted failure in Ni-based superalloy 718 studied under in situ hydrogen charging: The role of localized deformation in crack propagation. Acta Mater. 2017, 128, 365–374. [Google Scholar] [CrossRef]

- Xiong, J.; Zhu, Y.; Li, Z.; Huang, M. Hydrogen-enhanced interfacial damage in Ni-based single crystal superalloy. Scr. Mater. 2018, 143, 30–34. [Google Scholar] [CrossRef]

- Zhang, Z.; Obasi, G.; Morana, R.; Preuss, M. Hydrogen assisted crack initiation and propagation in a nickel-based superalloy. Acta Mater. 2016, 113, 272–283. [Google Scholar] [CrossRef]

- Rezende, M.C.; Araujo, L.S.; Gabriel, S.B.; dos Santos, D.S.; de Almeida, L.H. Hydrogen embrittlement in nickel-based superalloy 718: Relationship between γ′+ γ″ precipitation and the fracture mode. Int. J. Hydrog. Energy 2015, 40, 17075–17083. [Google Scholar] [CrossRef]

- Seita, M.; Hanson, H.P.; Gradecak, S.; Demkowicz, M.J. The dual role of coherent twin boundaries in hydrogen embrittlement. Nat. Commun. 2015, 6, 6164. [Google Scholar] [CrossRef] [PubMed]

- Bang, H.R.; Park, J.; Seong, H.G.; Kim, S.J. Effect of Minor Alloying Elements (C, Ni, Cr, Mo) on the Long-Term Corrosion Behaviors of Ultrahigh-Strength Automotive Steel Sheet in Neutral Aqueous Environment. Korean J. Met. Mater. 2022, 60, 35–45. [Google Scholar] [CrossRef]

- Hwang, A.I.; Lee, D.G.; Jung, Y.; Koo, J.M.; Cho, J.D.; Lee, J.S.; Suh, D.W. Influence of Microstructure Constituents on the Hydrogen-Induced Mechanical Degradation in Ultra-High Strength Sheet Steels. Met. Mater. Int. 2021, 27, 3959–3967. [Google Scholar] [CrossRef]

- Kobayashi, N.; Koyama, M.; Kobayashi, K.; Hojo, T.; Akiyama, E. Hydrogen Embrittlement Behavior of Pure Ni and Ni–20Cr Alloy with Different Grain Sizes. Mater. Trans. 2022, 63, 247–256. [Google Scholar] [CrossRef]

- Harte, A.; Atkinson, M.; Smith, A.; Drouven, C.; Zaefferer, S.; da Fonseca, J.Q.; Preuss, M. The effect of solid solution and gamma prime on the deformation modes in Ni-based superalloys. Acta Mater. 2020, 194, 257–275. [Google Scholar] [CrossRef]

- Maciejewski, K.; Ghonem, H. Isotropic and kinematic hardening as functions of gamma prime precipitates in a nickel-based superalloy. Int. J. Fatigue 2014, 68, 123–135. [Google Scholar] [CrossRef]

- Goodfellow, A.J. Strengthening mechanisms in polycrystalline nickel-based superalloys. Mater. Sci. Tech. 2018, 34, 1793–1808. [Google Scholar] [CrossRef]

- Sinha, N.K. Short strain relaxation/recovery tests for evaluating creep response of nickel-base superalloys like IN-738LC. J. Mater. Sci. Lett. 2001, 20, 951–953. [Google Scholar] [CrossRef]

- Shenoy, M.; Tjiptowidjojo, M.; McDowell, D. Microstructure-sensitive modeling of polycrystalline IN 100. Int. J. Plast. 2008, 24, 1694–1730. [Google Scholar] [CrossRef]

- Araujo, L.S.; Guimaraes, A.V.; Siqueira, M.C.; Mendes, M.C.; Mallet, L.; dos Santos, D.S.; de Almeida, L.H. The influence of the processing route on the fragmentation of (Nb,Ti)C stringers and its role on mechanical properties and hydrogen embrittlement of nickel based alloy 718. Int. J. Hydrog. Energy 2021, 46, 16164–16178. [Google Scholar] [CrossRef]

- Young, G.A.; Scully, J.R. Evidence that carbide precipitation produces hydrogen traps in Ni-17Cr-8Fe alloys. Scr. Mater. 1997, 36, 713–719. [Google Scholar] [CrossRef]

- Symons, D.M. The effect of carbide precipitation on the hydrogen-enhanced fracture behavior of alloy 690. Metall. Mater. Trans. A 1998, 29A, 1265–1277. [Google Scholar] [CrossRef]

- Lee, J.; Lee, T.; Kwon, Y.J.; Mun, D.J.; Yoo, J.Y.; Lee, C.S. Effects of vanadium carbides on hydrogen embrittlement of tempered martensitic steel. Met. Mater. Int. 2016, 22, 364–372. [Google Scholar] [CrossRef]

- Depover, T.; Verbeken, K. The detrimental effect of hydrogen at dislocations on the hydrogen embrittlement susceptibility of Fe-C-X alloys: An experimental proof of the HELP mechanism. Int. J. Hydrog. Energy 2018, 43, 3050–3061. [Google Scholar] [CrossRef]

- Lee, S.Y.; Kim, B.K.; Lee, S.H.; Kim, D.I.; Shim, J.H.; Jung, W.S.; Suh, J.Y. Formation of needle-like MC carbide at or near incoherent twin boundary in IN740H Ni-based superalloy. J. Alloy. Compd. 2020, 813, 152222. [Google Scholar] [CrossRef]

- Lee, J.; Park, H.; Kim, M.; Kim, H.J.; Suh, J.Y.; Kang, N. Role of Hydrogen and Temperature in Hydrogen Embrittlement of Equimolar CoCrFeMnNi High-entropy Alloy. Met. Mater. Int. 2021, 27, 166–174. [Google Scholar] [CrossRef]

- Kim, H.J.; Cho, M.K.; Kim, G.; Lee, S.Y.; Jo, M.G.; Kim, H.; Suh, J.Y.; Lee, J. Influence of Hydrogen Absorption on Stacking Fault of Energy of a Face-Centered Cubic High Entropy Alloy. Met. Mater. Int. 2022, 28, 2637–2645. [Google Scholar] [CrossRef]

- Zhao, Y.; Lee, D.H.; Seok, M.Y.; Lee, J.A.; Phaniraj, M.P.; Suh, J.Y.; Ha, H.Y.; Kim, J.Y.; Ramamurty, U.; Jang, J.I. Resistance of CoCrFeMnNi high-entropy alloy to gaseous hydrogen embrittlement. Scr. Mater. 2017, 135, 54–58. [Google Scholar] [CrossRef]

- Phaniraj, M.P.; Kim, H.J.; Suh, J.Y.; Shim, J.H.; Park, S.J.; Lee, T.H. Hydrogen embrittlement in high interstitial alloyed 18Cr10Mn austenitic stainless steels. Int. J. Hydrog. Energy 2015, 40, 13635–13642. [Google Scholar] [CrossRef]

- Kim, H.J.; Phaniraj, M.P.; Kim, J.H.; Lee, Y.S.; Kim, D.I.; Suh, J.Y.; Lee, J.; Shim, J.H.; Park, S.J. Effect of thermal charging of hydrogen on the microstructure of metastable austenitic stainless steel. Steel Res. Int. 2017, 88, 1600063. [Google Scholar] [CrossRef]

- Brown, J.A.; Ghoniem, N.M. Structure and motion of junctions between coherent and incoherent twin boundaries in copper. Acta Mater. 2009, 57, 4454–4462. [Google Scholar] [CrossRef]

- Romero, R.J.; Murr, L.E. Torque-related lamellar carbide growth associated with annealing twins in 304 stainless steel. Acta Metall. Mater. 1995, 43, 461–469. [Google Scholar] [CrossRef]

- Zaika, Y.V.; Kostikova, E.K.; Nechaev, Y.S. Peaks of Hydrogen Thermal Desorption: Simulation and Interpretation. Tech. Phys. 2021, 66, 210–220. [Google Scholar] [CrossRef]

- Lu, X.; Ma, Y.; Wang, D. On the hydrogen embrittlement behavior of nickel-based alloys: Alloys 718 and 725. Mater. Sci. Eng. A 2020, 792, 139785. [Google Scholar] [CrossRef]

- Ai, J.H.; Ha, H.M.; Gangloff, R.P.; Scully, J.R. Hydrogen diffusion and trapping in a precipitation-hardened nickel–copper–aluminum alloy Monel K-500 (UNS N05500). Acta Mater. 2013, 61, 3186–3199. [Google Scholar] [CrossRef]

- Liu, L.; Zhai, C.; Lu, C.; Ding, W.; Hirose, A.; Kobayashi, K.F. Study of the effect of δ phase on hydrogen embrittlement of Inconel 718 by notch tensile tests. Corros. Sci. 2005, 47, 355–367. [Google Scholar] [CrossRef]

- Wei, F.G.; Hara, T.; Tsuzaki, K. Precise determination of the activation energy for desorption of hydrogen in two Ti-added steels by a single thermal-desorption spectrum. Metall. Mater. Trans. B 2004, 35, 587–597. [Google Scholar] [CrossRef]

- Wei, F.G.; Tsuzaki, K. Quantitative analysis on hydrogen trapping of TiC particles in steel. Metall. Mater. Trans. A 2006, 37, 331–353. [Google Scholar] [CrossRef]

- Krol, T.; Baither, D.; Nembach, E. The formation of precipitate free zones along grain boundaries in a superalloy and the ensuing effects on its plastic deformation. Acta Mater. 2004, 52, 2095–2108. [Google Scholar] [CrossRef]

- Wang, C.; Li, R. Effect of double aging treatment on structure in Inconel 718 alloy. J. Mater. Sci. 2004, 39, 2593–2595. [Google Scholar] [CrossRef]

- Troiano, A.R. The role of hydrogen and other interstitials in the mechanical behavior of metals. Trans. Am. Soc. Met. 1960, 52, 54–80. [Google Scholar] [CrossRef]

- Beachem, C.D. A new model for hydrogen-assisted cracking (hydrogen “embrittlement”). Metall. Trans. A 1972, 3A, 437–451. [Google Scholar] [CrossRef]

- Guedes, D.; Malheiros, L.C.; Oudriss, A.; Cohendoz, S.; Bouhattate, J.; Creus, J.; Thebault, F.; Piette, M.; Feaugas, X. The role of plasticity and hydrogen flux in the fracture of a tempered martensitic steel: A new design of mechanical test until fracture to separate the influence of mobile from deeply trapped hydrogen. Acta Mater. 2020, 186, 133–148. [Google Scholar] [CrossRef]

| Specimen | without H (El.N) | with H (El.H) | Ductility Loss (%) | Specimen | without H (El.N) | with H (El.H) | Ductility Loss (%) |

|---|---|---|---|---|---|---|---|

| FG-S | 0.46 | 0.46 | 0 | CG-S | 0.48 | 0.49 | −0.02 |

| FG-A | 0.34 | 0.34 | 0 | CG-A | 0.38 | 0.26 | 0.32 |

| Fitted Curves | Experimental Curve | |||||

|---|---|---|---|---|---|---|

| Peak 1 | Peak 2 | |||||

| Specimen | Peak Temperature (K) | Hydrogen Content, C1 (wppm) | Peak Temperature (K) | Hydrogen Content, C2 (wppm) | Peak Temperature (K) | Total Hydrogen Content (wppm) |

| FG-S | 503 | 19.7 | 568 | 22.1 | 555 | 41.8 |

| CG-S | 496 | 19.3 | 567 | 26.2 | 552 | 45.5 |

| FG-A | 505 | 15.5 | 580 | 30.0 | 571 | 45.5 |

| CG-A | 524 | 26.3 | 587 | 28.9 | 573 | 55.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.-Y.; Kim, H.-J.; Ahn, C.-H.; Baek, S.-W.; Shim, J.-H.; Suh, J.-Y. Hydrogen-Induced Intergranular Fracture Behavior Accelerated by Needle-like MC Carbide in IN740H Superalloy. Hydrogen 2022, 3, 474-487. https://doi.org/10.3390/hydrogen3040030

Lee S-Y, Kim H-J, Ahn C-H, Baek S-W, Shim J-H, Suh J-Y. Hydrogen-Induced Intergranular Fracture Behavior Accelerated by Needle-like MC Carbide in IN740H Superalloy. Hydrogen. 2022; 3(4):474-487. https://doi.org/10.3390/hydrogen3040030

Chicago/Turabian StyleLee, Seung-Yong, Han-Jin Kim, Chang-Ho Ahn, Seung-Wook Baek, Jae-Hyeok Shim, and Jin-Yoo Suh. 2022. "Hydrogen-Induced Intergranular Fracture Behavior Accelerated by Needle-like MC Carbide in IN740H Superalloy" Hydrogen 3, no. 4: 474-487. https://doi.org/10.3390/hydrogen3040030

APA StyleLee, S.-Y., Kim, H.-J., Ahn, C.-H., Baek, S.-W., Shim, J.-H., & Suh, J.-Y. (2022). Hydrogen-Induced Intergranular Fracture Behavior Accelerated by Needle-like MC Carbide in IN740H Superalloy. Hydrogen, 3(4), 474-487. https://doi.org/10.3390/hydrogen3040030