A Modular, Logistics-Centric Digital Twin Framework for Construction: From Concept to Prototype

Abstract

1. Introduction

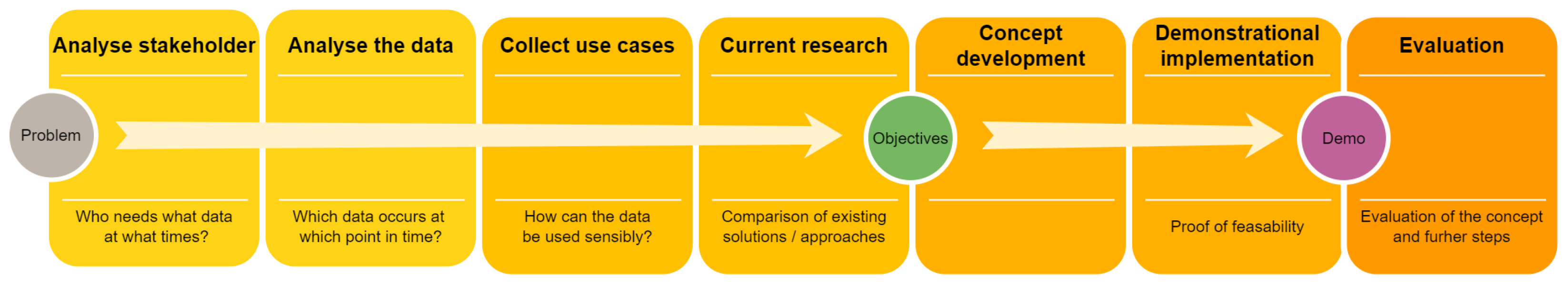

2. Research Design

3. Frame of Reference

3.1. Construction Logistics

3.1.1. Fundamentals

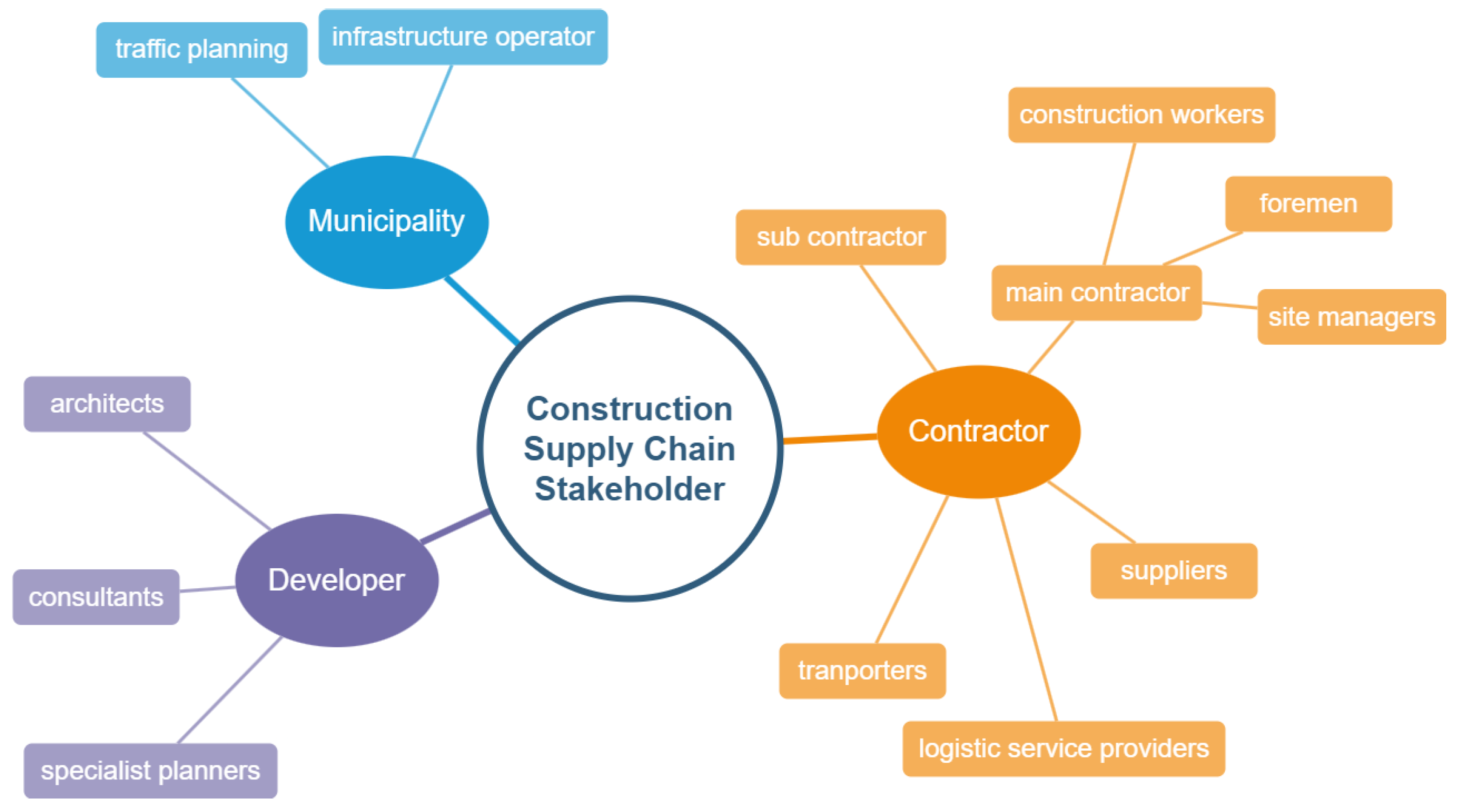

- Conceptual frameGünthner & Borrmann [38] define three conceptual levels for analysing construction logistics. At the first level, construction logistics is described by the elementary logistical activities of ‘transport, handling and storage’. The second level also includes the planning, management and control of logistical flows to maximise the availability of materials. At the third level, the horizon expands and the entire cross-company value creation network is considered as a flow system. This is the so-called Construction Supply Chain (CSC).

- Spatial distributionGirmscheid et al. [7] divide construction logistics spatially into supply, disposal and construction site logistics. Supply logistics deals with the transport of construction materials to the construction site. Disposal logistics covers the removal of materials and waste from the construction site. Construction site logistics manages the transport and storage of materials within a construction site.

- Functional separationThunberg [39] considers two distinct processes. In this context, the actual planning and building of a structure is described as the construction process, which must be coordinated with the production and delivery of materials to the construction site within the supply chain process.

3.1.2. Challenges of the CSC

- Individual production;

- Temporary location;

- Highly fragmented industry structure;

- Production in the open air;

- Limited storage;

- Limited freight splitting;

- Short-term and fragmented customer-supplier relationships;

- Construction during planning.

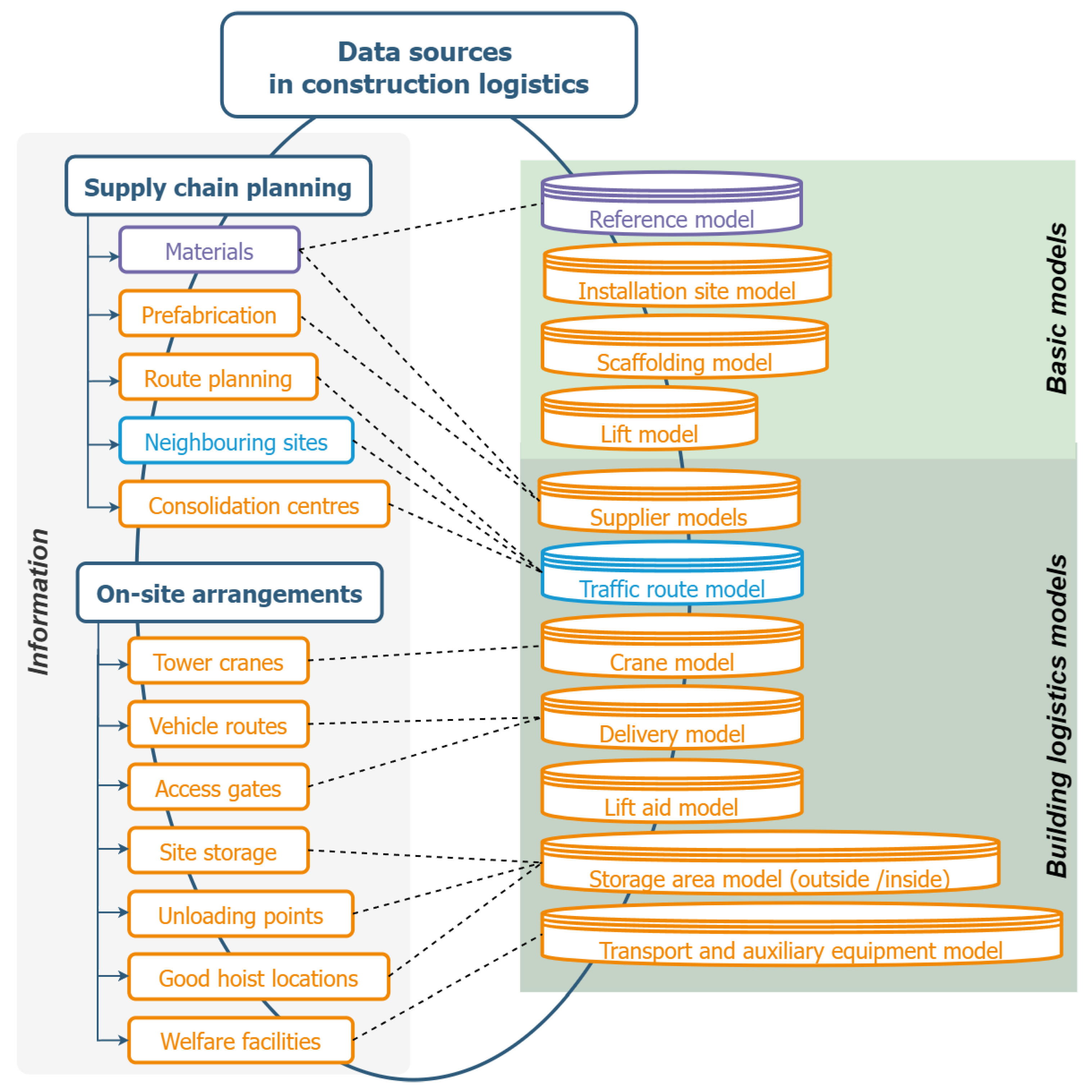

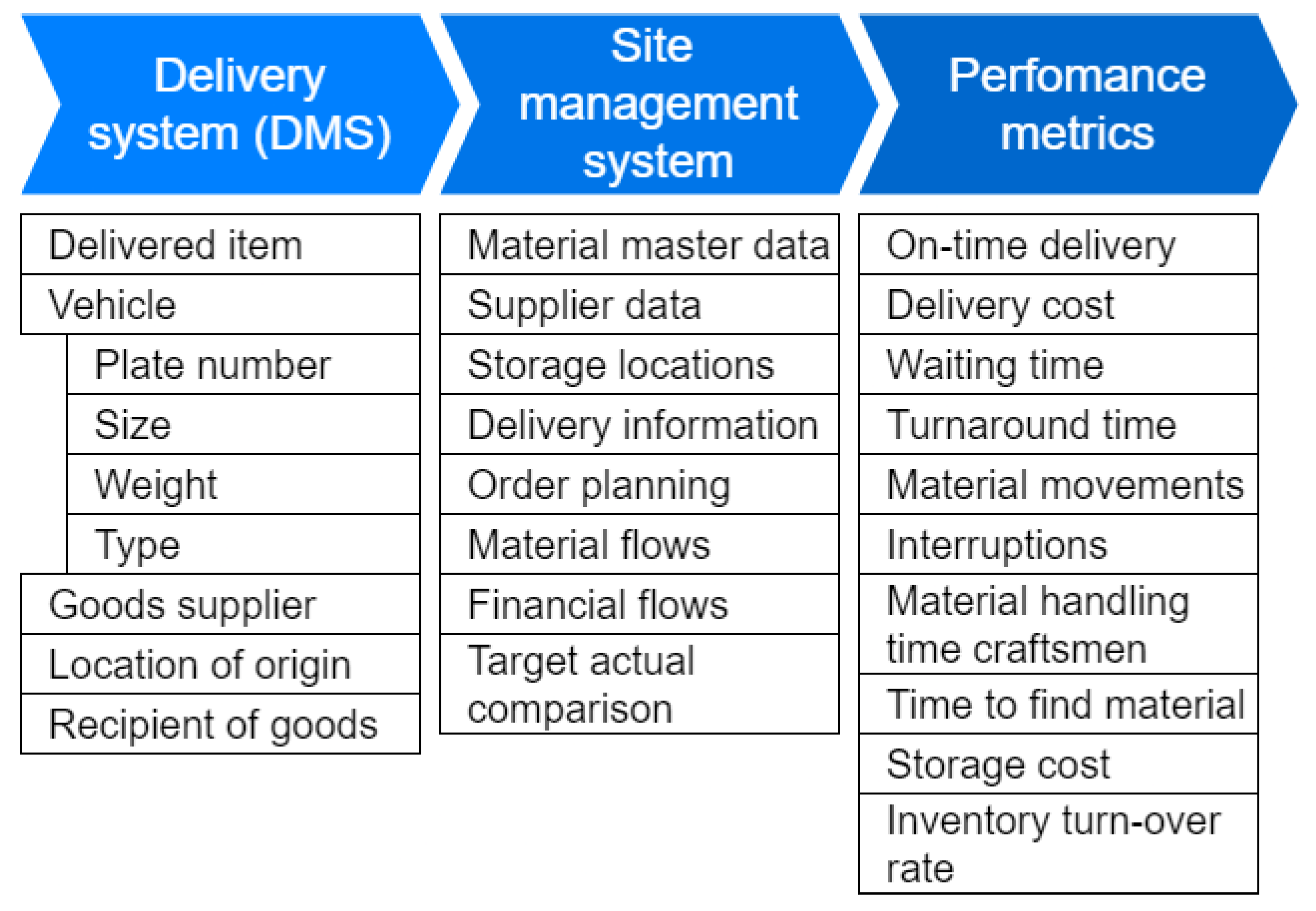

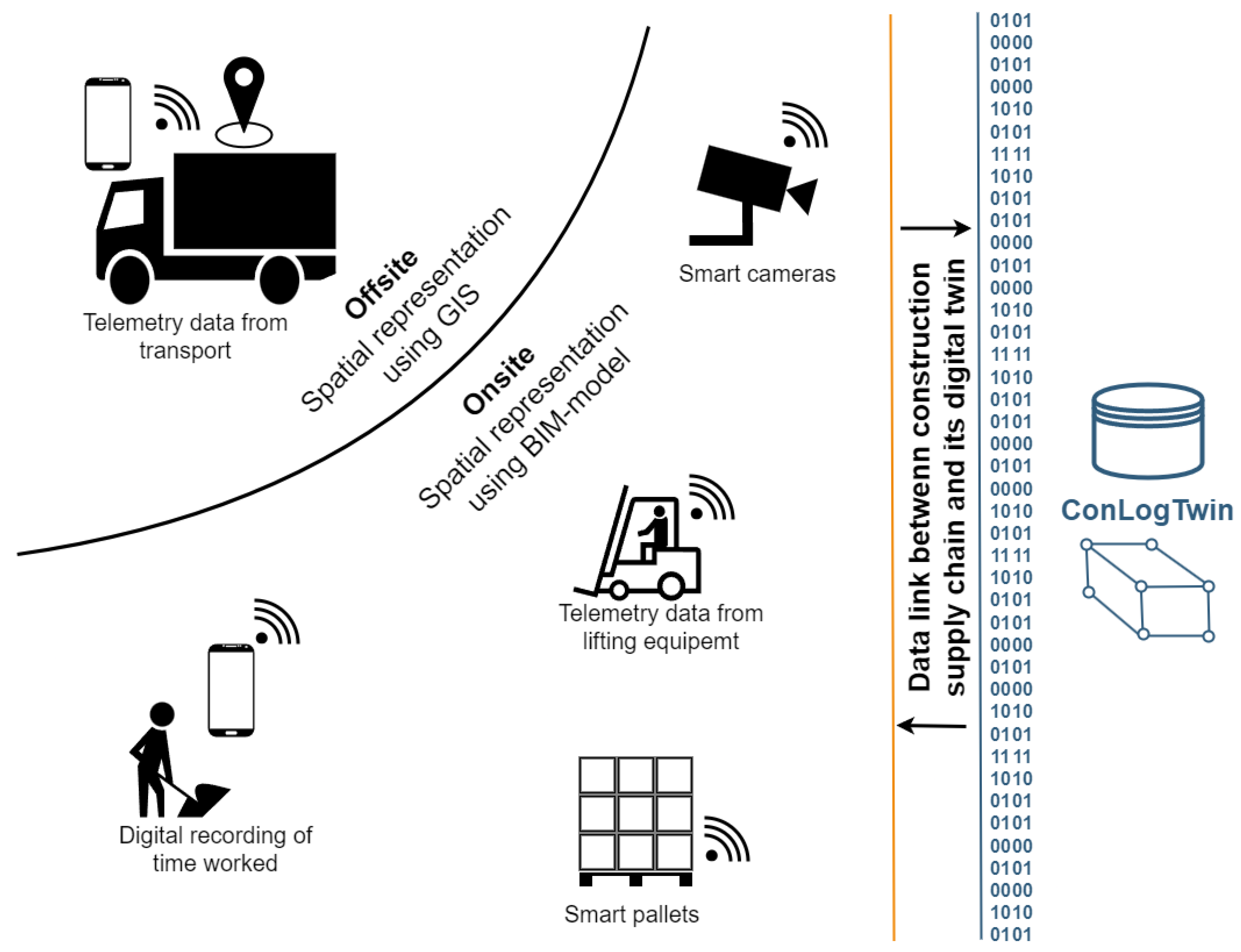

3.1.3. Data Sources in Construction Logistics

3.1.4. Requirements for Construction Logistics Management Software

3.2. Digital Twin

3.2.1. General Definition

- Monitor;

- Simulate;

- Predict;

- Diagnose;

- Control.

3.2.2. Requirements of a DT

3.2.3. Use Cases of Construction Logistics DT

4. Existing Approaches for DTs in Construction Logistics

| Ref. | Description | DT Technology | Architecture |

|---|---|---|---|

| [67,68] | Reference architecture for a semantic DT | Semantic web, ontology | Component-based |

| [69] | Framework for a city-scale, user-centred DT | Web-based | Layered |

| [70] | Framework of building-DT for monitoring applications | Web-based | Component-based |

| [14,71] | Reducing traffic disturbances of construction logistics | Desktop app, simulation | not disclosed |

| [72] | Modular and interoperable DTs of built assets | Web-based, knowledge graph, ontology | Micro Service-based |

| [73,74,75] | Monitoring and prediction of the condition of a building | Web-based, structural analysis, BIM | Service-oriented |

| [76,77,78,79] | Optimisation of transport on- and off-site | Web-based, GPS, robotics, simulation | Service-oriented |

| [80,81] | Construction progress prediction based on machine data | Web-based, machine telemetry, simulation | Not disclosed |

| [82] | Delivery management for mobile silos based on a CSC-DT | Web-based, GPS, refilling sensor | Service-oriented |

| [83] | Safety management of construction processes | Web-based, BIM, simulation | Component-based |

5. The ConLogTwin Framework

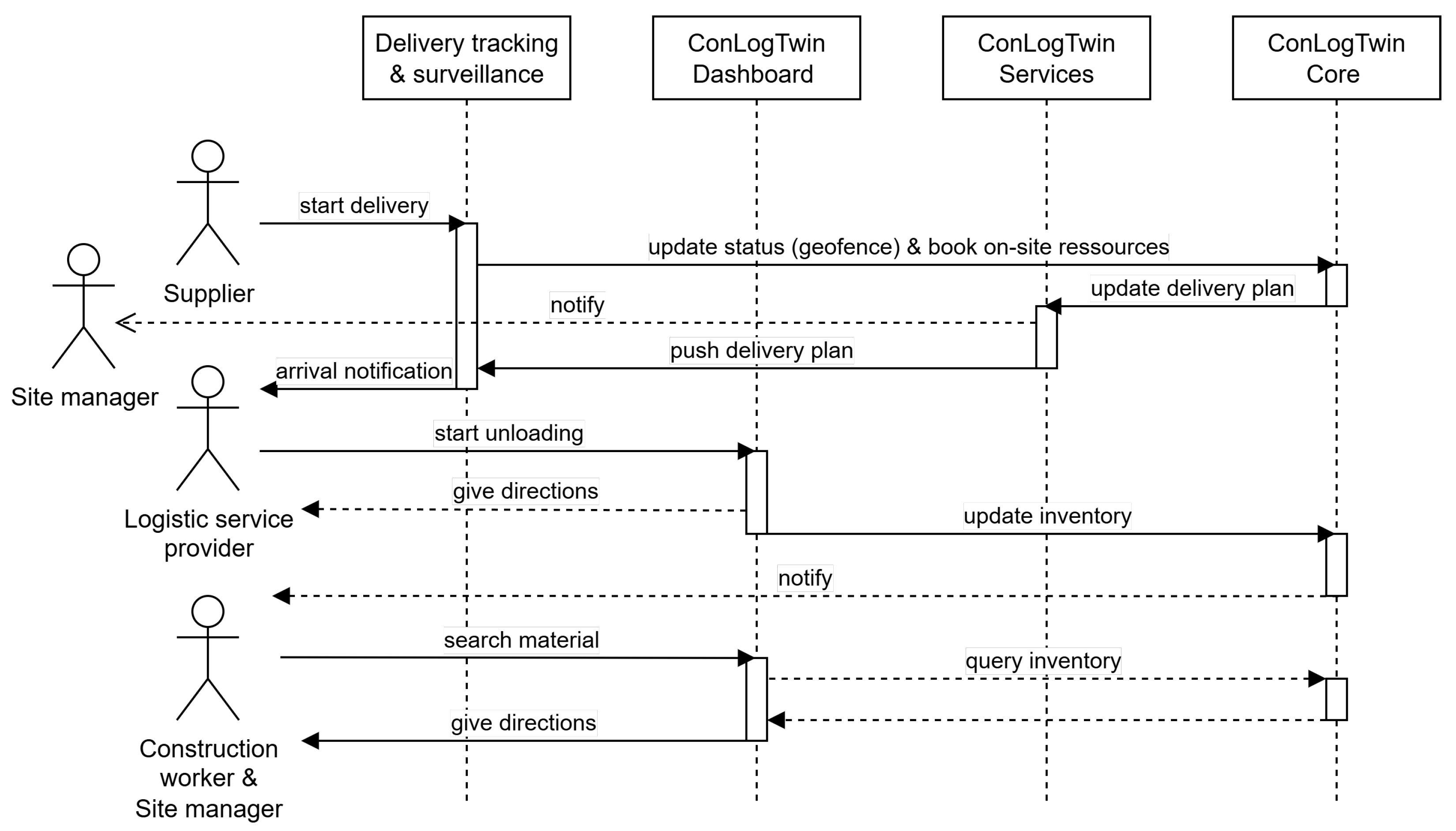

5.1. Concept

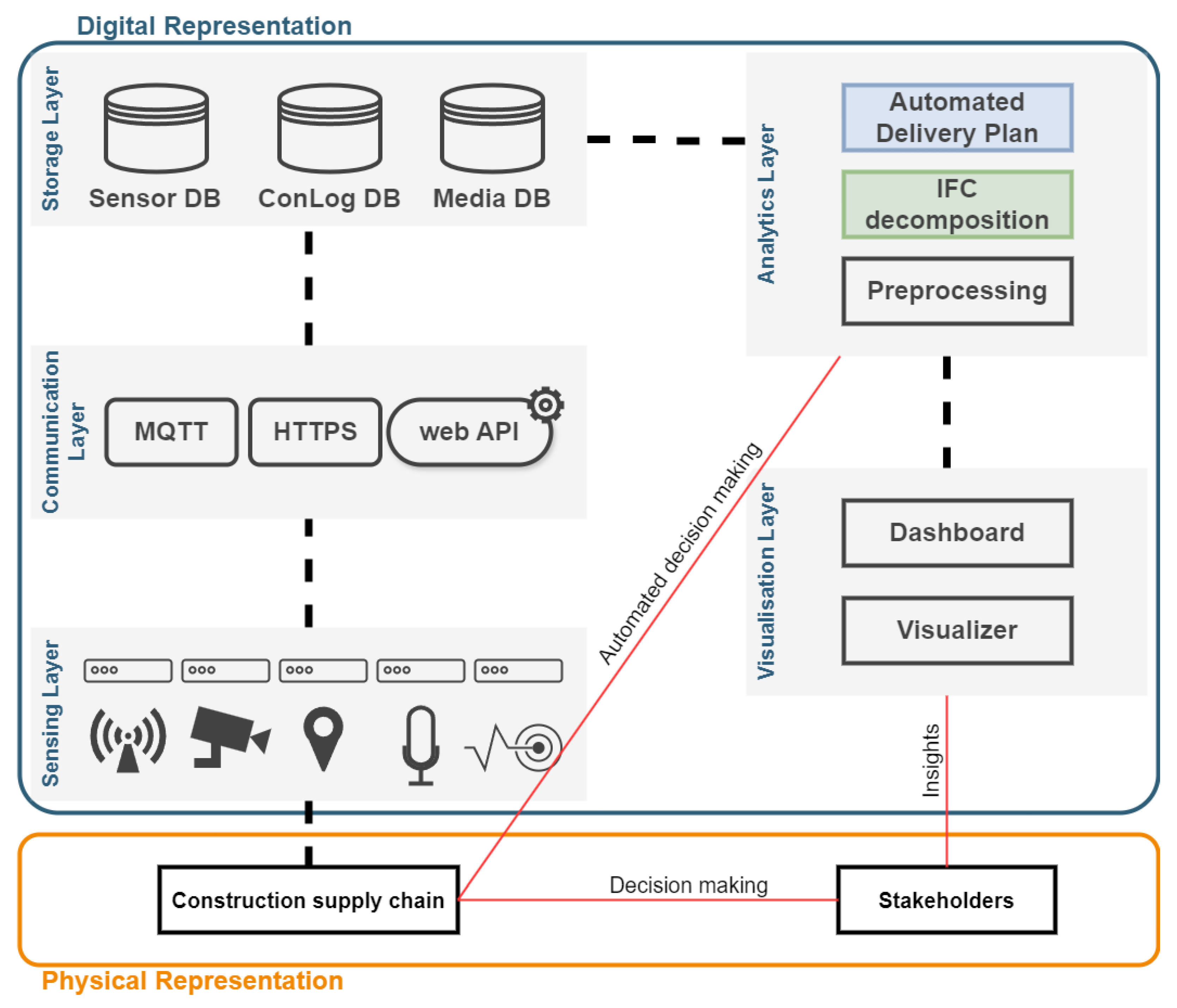

5.2. System Architecture

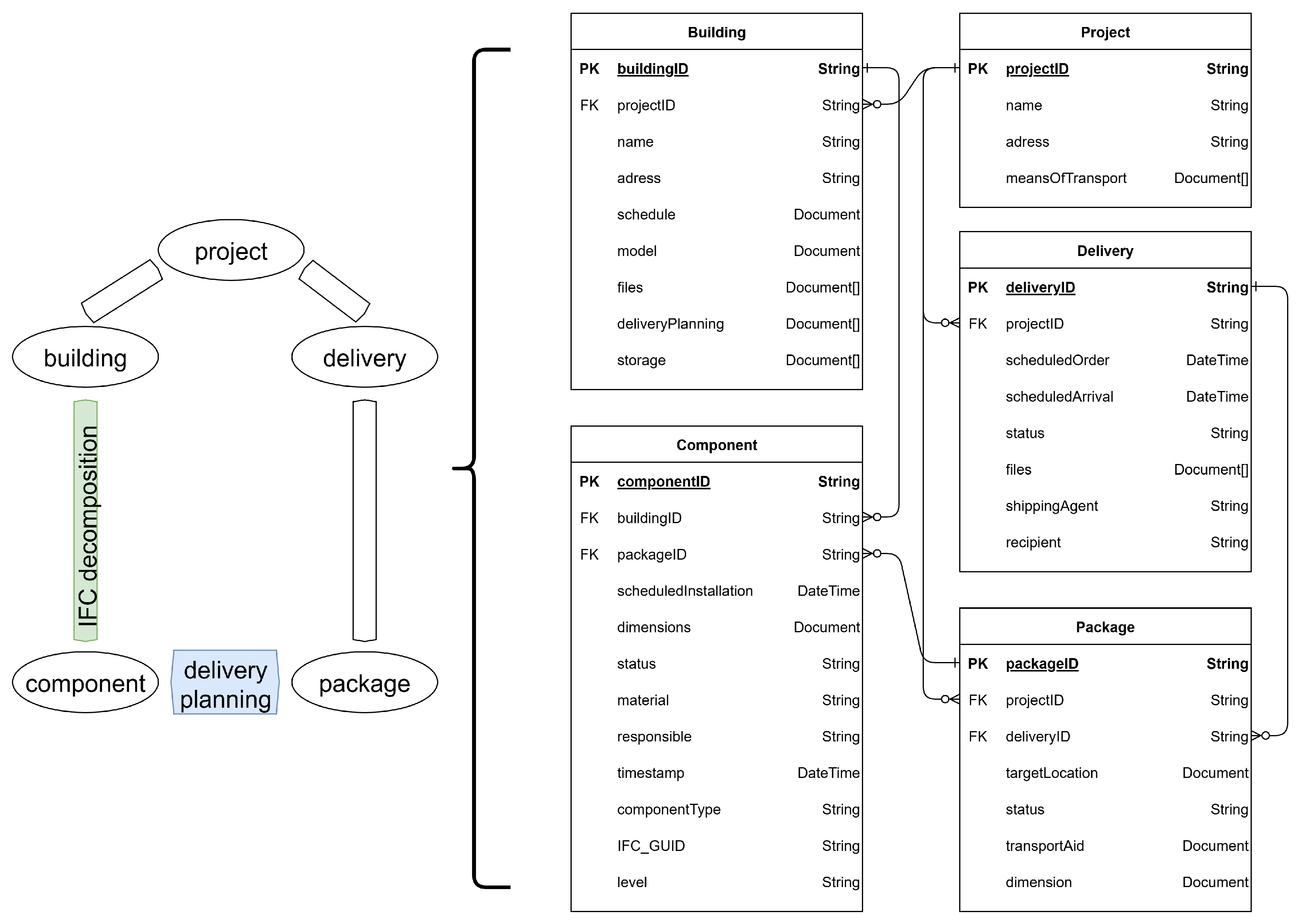

5.2.1. ConLogTwin Core

5.2.2. ConLogTwin Services

- IFC decompositionIn order to be able to use data from the IFC file format from building planning and work preparation with the data structure developed for ConLogTwin, these files must be converted. The transferred files are deserialised for this purpose and then individual sub-objects are extracted from the building as components and saved individually in the data structure. The semantic information is retained and transferred to the ConLogTwin data structure. Geometric information remains in the original IFC file. The extracted component remains linked to the IFC data structure via the IFC GUID, meaning that a geometric shape or spatial arrangement of the component can also be created for visualisations or three-dimensional evaluations.

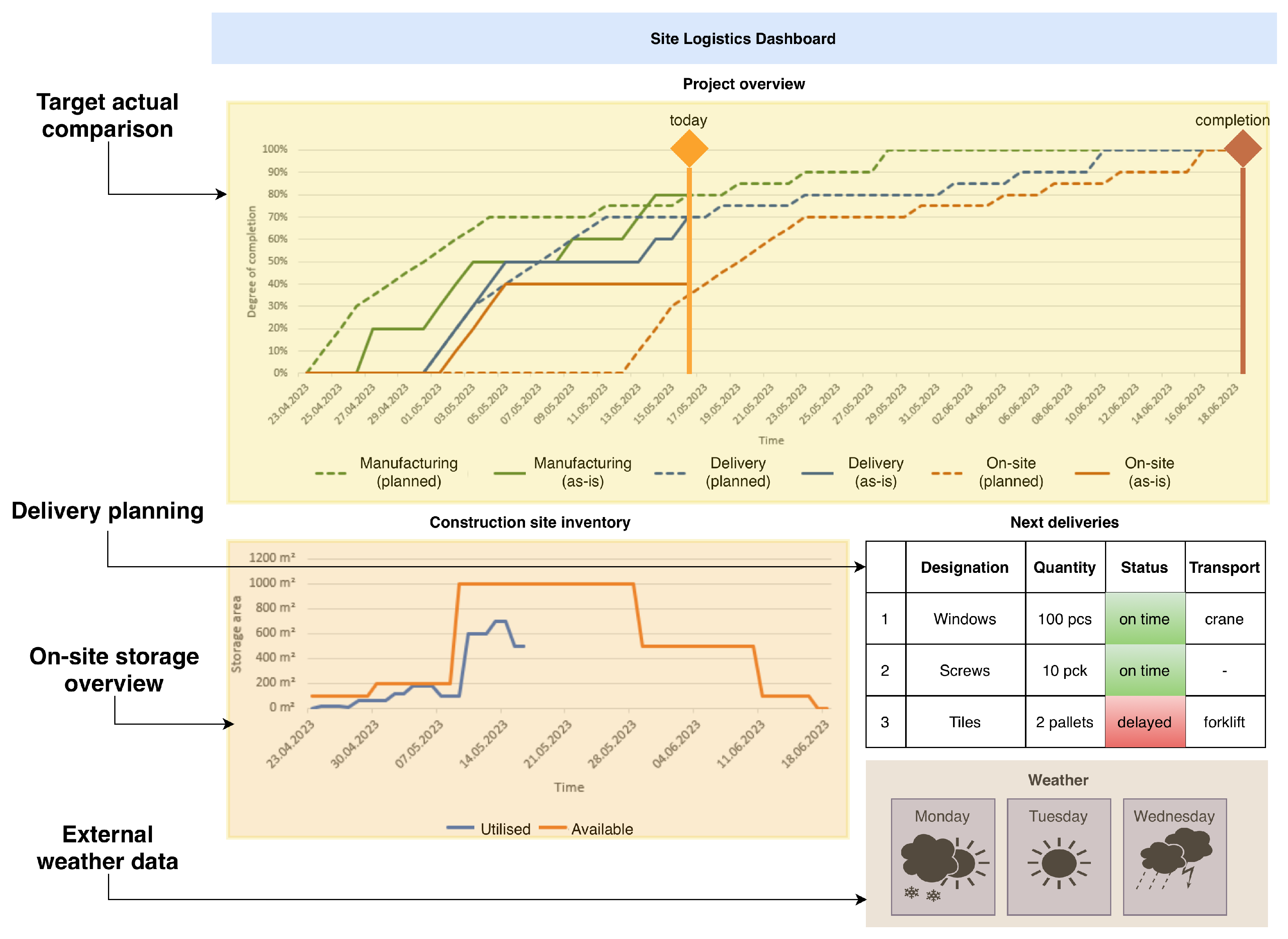

- Automated delivery planAs part of construction logistics planning, delivery quantities, delivery times and storage locations on the construction site are identified and linked to form a comprehensive logistics plan. The detailed planning of each individual delivery is very labour-intensive and is therefore only used for particularly relevant components or very large projects. To simplify and support this process, a service is to be integrated into ConLogTwin for automated delivery planning. This service develops a suitable delivery schedule based on the identified components and quantities from the building models and the scheduling of the work preparation. Such model-based logistics planning has already been demonstrated by Jaster et al. [88] for drywall construction, where production and storage areas are dimensioned and scheduled using the building model. While advanced dependencies between deliveries and work sequences are not directly modelled in ConLogTwin, automated delivery planning modules can accommodate these dependencies where necessary to align with project-specific workflow requirements.

- Analysing and summarising sensor data (delivery surveillance)The process data from the construction site, which is recorded using sensors, must first be processed and aggregated. If this is not already done ‘on the edge’, i.e., by a small computer at the sensor, this must be implemented by a service in ConLogTwin. For example, a service can automate the notification of deliveries using geofencing. By analysing image material from the construction site, the management of storage areas can be supported and the recording of material stocks on the construction site can be automated. A service can also simulate future logistics processes based on the recorded process data and use the results to monitor the schedule.

5.2.3. Data Visualisation

6. Small-Scale Case Study

6.1. Implementation

6.2. Qualitative Assessment of the ConLogTwin

6.2.1. Requirements Coverage Analysis

6.2.2. Scenario-Based Assessment

6.2.3. Risk and Limitation Analysis

6.3. Future Quantitative Assessment

7. Conclusions and Further Development

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AAS | Asset Administration Shell |

| ACID | Atomicity, Consistency, Isolation, Durability |

| API | Application Programming Interface |

| BIM | Building Information Modeling |

| CCC | Construction Consolidation Centre |

| CDE | Common Data Environment |

| CLS | Construction Logistics Setup |

| CSC | Construction Supply Chain |

| DMS | Delivery Management System |

| DSRM-IS | Design Science Research Methodology for Information Systems |

| DT | Digital Twin |

| GIS | Geoinformation System |

| GPS | Global Positioning System |

| GUID | General Unique Identifier |

| HTTPS | Hypertext Transfer Protocoll Secure |

| ICDD | Information Container for linked Document Delivery |

| IFC | Industry Foundation Classes |

| IoT | Internet of Things |

| JIT | Just-in-Time |

| JSON | JavaScript Object Notation |

| LSP | Logistics Service Provider |

| MQTT | Message Queuing Telemetry Transport |

| OLAP | Online Analytical Processing |

| RFID | Radio Frequency Identification |

References

- Leviäkangas, P.; Mok Paik, S.; Moon, S. Keeping up with the pace of digitization: The case of the Australian construction industry. Technol. Soc. 2017, 50, 33–43. [Google Scholar] [CrossRef]

- Construction 4.0—the Benefits of a Digital Twin. 2024. Available online: https://www.bau.fraunhofer.de/en/fieldsofresearch/smartbuilding/digital-twin.html (accessed on 7 September 2025).

- Fuller, A.; Fan, Z.; Day, C.; Barlow, C. Digital Twin: Enabling Technologies, Challenges and Open Research. IEEE Access 2020, 8, 108952–108971. [Google Scholar] [CrossRef]

- Kusiak, A. Smart manufacturing must embrace big data. Nature 2017, 544, 23–25. [Google Scholar] [CrossRef] [PubMed]

- Sullivan, G.; Barthorpe, S.; Robbins, S. Managing Construction Logistics; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Sezer, A.A.; Fredriksson, A. Paving the Path Towards Efficient Construction Logistics by Revealing the Current Practice and Issues. Logistics 2021, 5, 53. [Google Scholar] [CrossRef]

- Girmscheid, G. AVOR—Planung der Ausführung. In Angebots- und Ausführungsmanagement-Prozessorientiert: Erfolgsorientierte Unternehmensführung; Girmscheid, G., Ed.; VDI-Buch; Springer: Berlin/Heidelberg, Germany, 2015; pp. 121–302. [Google Scholar] [CrossRef]

- Auswirkungen des Lieferkettengesetzes auf die Baubranche|DLA Piper. 2023. Available online: https://www.dlapiper.com/de-de/insights/publications/2023/03/auswirkungen-des-lieferkettengesetzes-auf-die-baubranche (accessed on 7 September 2025).

- How To Comply with EU’s CSRD Carbon Accounting Rules. 2024. Available online: https://www.oliverwyman.com/our-expertise/insights/2023/aug/carbon-accounting-europe.html (accessed on 7 September 2025).

- Sundquist, V.; Gadde, L.E.; Hulthén, K. Reorganizing construction logistics for improved performance. Constr. Manag. Econ. 2017, 36, 49–65. [Google Scholar] [CrossRef]

- Janné, M.; Rudberg, M.; Sezer, A. Construction logistics performance metrics: A Delphi study. In Construction Logistics in a City Development Setting; Linköping University: Norrköping, Sweden, 2020. [Google Scholar]

- Whitlock, K.; Abanda, H.; Manjia, M.; Pettang, C.; Nkeng, G. BIM for Construction Site Logistics Management. J. Eng. Proj. Prod. Manag. 2018, 8, 47–55. [Google Scholar] [CrossRef]

- Gupta, A.; Priya, T.S.; Ramani, P.V. Android application prototype for construction logistics tracking. Innov. Infrastruct. Solut. 2022, 7, 360. [Google Scholar] [CrossRef]

- Brusselaers, N.; Fredriksson, A.; Gundlegård, D.; Zernis, R. Decision support for improved construction traffic management and planning. Sustain. Cities Soc. 2024, 104, 105305. [Google Scholar] [CrossRef]

- Placzek, G.; Barking, L.; Schwerdtner, P.; Troitzsch, H.; Kassoumeh, B.; Niggemann, J. Frühzeitige Erstellung von Baulogistikkonzepten—Chancen und Herausforderungen einer BIM-basierten Baulogistikplanung. In Proceedings of the Internationaler BBB-Kongress 2021, Weimar, Germany, 16 September 2021. [Google Scholar]

- Weber, J. Simulation von Logistikprozessen auf Baustellen auf Basis von 3D-CAD Daten. Ph.D. Thesis, Universität Dortmund, Dortmund, Germany, 2007. [Google Scholar]

- Voigtmann, J.; Bargstädt, H.J. Construction logistics planning by simulation. In Proceedings of the 2010 Winter Simulation Conference, Baltimore, MD, USA, 5–8 December 2010; pp. 3201–3211, ISSN 1558-4305. [Google Scholar] [CrossRef]

- Alvanchi, A.; Baniassadi, F.; Shahsavari, M.; Kashani, H. Improving materials logistics plan in road construction projects using discrete event simulation. Eng. Constr. Archit. Manag. 2021, 28, 3144–3163. [Google Scholar] [CrossRef]

- Autodesk Tandem, v3.2; Autodesk: San Francisco, CA, USA, March 2024.

- Bosch IoT Suite—A Toolbox in the Cloud for IoT Developers. Available online: https://bosch-iot-suite.com/ (accessed on 7 September 2025).

- Irizarry, J.; Karan, E.P.; Jalaei, F. Integrating BIM and GIS to improve the visual monitoring of construction supply chain management. Autom. Constr. 2013, 31, 241–254. [Google Scholar] [CrossRef]

- Li, C.Z.; Xue, F.; Li, X.; Hong, J.; Shen, G.Q. An Internet of Things-enabled BIM platform for on-site assembly services in prefabricated construction. Autom. Constr. 2018, 89, 146–161. [Google Scholar] [CrossRef]

- Xiong, W.; Xu, X.; Chen, L.; Yang, J. Sound-Based Construction Activity Monitoring with Deep Learning. Buildings 2022, 12, 1947. [Google Scholar] [CrossRef]

- Ergen, E.; Akinci, B.; Sacks, R. Tracking and locating components in a precast storage yard utilizing radio frequency identification technology and GPS. Autom. Constr. 2007, 16, 354–367. [Google Scholar] [CrossRef]

- Helbig, S.; Hildebrandt, S.; Bonitz, F.; Wagner, R.; Haase, D.; Adler, J.; Lizarazu, J.; Damaschke, A.; Schulz, T.; Ulanov, A.; et al. Entwicklung von Porenkeramik-Sensorelementen für ein Monitoring des Trocknungsverlaufs von Calciumsulfat-Estrichen. ce/papers 2023, 6, 1483–1492. [Google Scholar] [CrossRef]

- Grieves, M. Digital twins: Past, present, and future. In The Digital Twin; Crespi, N., Drobot, A.T., Minerva, R., Eds.; Springer: Cham, Switzerland, 2023; pp. 97–121. [Google Scholar] [CrossRef]

- Opoku, D.G.J.; Perera, S.; Osei-Kyei, R.; Rashidi, M. Digital twin application in the construction industry: A literature review. J. Build. Eng. 2021, 40, 102726. [Google Scholar] [CrossRef]

- Naz, F.; Fredriksson, A. Clarifying the Interface Between Construction Supply Chain and Site—A Key to Improved Delivery Efficiency. In Advances in Production Management Systems. Production Management Systems for Responsible Manufacturing, Service, and Logistics Futures; Alfnes, E., Romsdal, A., Strandhagen, J.O., von Cieminski, G., Romero, D., Eds.; Springer: Cham, Switzerland, 2023; pp. 140–153. [Google Scholar] [CrossRef]

- Boje, C.; Guerriero, A.; Kubicki, S.; Rezgui, Y. Towards a semantic Construction Digital Twin: Directions for future research. Autom. Constr. 2020, 114, 103179. [Google Scholar] [CrossRef]

- Ammar, A.; Nassereddine, H.; AbdulBaky, N.; AbouKansour, A.; Tannoury, J.; Urban, H.; Schranz, C. Digital Twins in the Construction Industry: A Perspective of Practitioners and Building Authority. Front. Built Environ. 2022, 8, 834671. [Google Scholar] [CrossRef]

- Sacks, R.; Brilakis, I.; Pikas, E.; Xie, H.S.; Girolami, M. Construction with digital twin information systems. Data-Centric Eng. 2020, 1, e14. [Google Scholar] [CrossRef]

- Gilson, L.L.; Goldberg, C.B. Editors’ Comment: So, What Is a Conceptual Paper? Group Organ. Manag. 2015, 40, 127–130. [Google Scholar] [CrossRef]

- Peffers, K.; Tuunanen, T.; Rothenberger, M.A.; Chatterjee, S. A Design Science Research Methodology for Information Systems Research. J. Manag. Inf. Syst. 2007, 24, 45–77. [Google Scholar] [CrossRef]

- Gregor, S. Design theory in information systems. Australas. J. Inf. Syst. 2002, 10, 14–22. [Google Scholar] [CrossRef]

- Segovia, M.; Garcia-Alfaro, J. Design, Modeling and Implementation of Digital Twins. Sensors 2022, 22, 5396. [Google Scholar] [CrossRef] [PubMed]

- Motzko, C.; Petzschmann, E.; Kesting, H.; Helmus, M.; Böttcher, P.; Einhaus, M.E.; Rahming, H.; Leitzbach, O.; Stein, D.; Stein, R. Baubetrieb und Bauverfahrenstechnik. In Handbuch für Bauingenieure: Technik, Organisation und Wirtschaftlichkeit; Zilch, K., Diederichs, C.J., Beckmann, K.J., Gertz, C., Malkwitz, A., Moormann, C., Urban, W., Valentin, F., Eds.; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2020; pp. 1–126. [Google Scholar] [CrossRef]

- Pfohl, H.C. Grundlagen der betriebswirtschaftlichen Logistik. In Logistiksysteme: Betriebswirtschaftliche Grundlagen; Pfohl, H.C., Ed.; Springer: Berlin/Heidelberg, Germany, 2010; pp. 2–65. [Google Scholar] [CrossRef]

- Günthner, W.; Borrmann, A. (Eds.) Digitale Baustelle-Innovativer Planen, Effizienter Ausführen: Werkzeuge und Methoden für das Bauen im 21. Jahrhundert; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar] [CrossRef]

- Thunberg, M. Developing a Framework for Supply Chain Planning in Construction; Linköping University Electronic Press: Linköping, Sweden, 2016; Volume 1782. [Google Scholar]

- Vrijhoef, R. Extended roles of construction supply chain management for improved logistics and environmental performance. In Lean Construction; Routledge: Oxfordshire, UK, 2020; p. 23. [Google Scholar]

- Dubois, A.; Gadde, L.E. The construction industry as a loosely coupled system: Implications for productivity and innovation. Constr. Manag. Econ. 2002, 20, 621–631. [Google Scholar] [CrossRef]

- Fredriksson, A.; Janné, M.; Rudberg, M. Characterizing third-party logistics setups in the context of construction. Int. J. Phys. Distrib. Logist. Manag. 2021, 51, 325–349. [Google Scholar] [CrossRef]

- Janné, M.; Fredriksson, A. Construction logistics governing guidelines in urban development projects. Constr. Innov. 2019, 19, 89–109. [Google Scholar] [CrossRef]

- Ruhl, F.; Motzko, C.; Lutz, P. Baulogistikplanung: Schnelleinstieg für Bauherren, Architekten und Fachplaner; Essentials; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2018. [Google Scholar] [CrossRef]

- Vrijhoef, R.; Koskela, L. The four roles of supply chain management in construction. Eur. J. Purch. Supply Manag. 2000, 6, 169–178. [Google Scholar] [CrossRef]

- Fredriksson, A.; Huge-Brodin, M. Green construction logistics—A multi-actor challenge. Res. Transp. Bus. Manag. 2022, 45, 100830. [Google Scholar] [CrossRef]

- Eriksson, V.; Hulthén, K.; Sundquist, V.; Fredriksson, A.; Janné, M. The role of public actors in construction logistics: Effects on and of relational interfaces. Constr. Manag. Econ. 2021, 39, 791–806. [Google Scholar] [CrossRef]

- Körperschonender Lastentransport Dank Optimaler Baulogistik—Leitfaden für die Projektabwicklung; Technical Report; SUVA: Luzern, Switzerland, 2025.

- Construction Logistics Plans|London Borough of Waltham Forest; London Borough of Waltham Forest: London, UK, 2024.

- Placzek, G.; Barking, L.; Schwerdtner, P. Entwicklung eines Level-of-Logistics-Konzepts zur Beschreibung des Fachmodells “Baulogistik”. Bauwirtschaft 2022, 7, 1–11. [Google Scholar]

- Industry Foundation Classes (IFC)—buildingSMART International. 2019. Available online: https://www.buildingsmart.org/standards/bsi-standards/industry-foundation-classes/ (accessed on 7 September 2025).

- Hasenclever, T.; Horenburg, T.; Höppner, G.; Klaubert, C.; Krupp, M.; Popp, K.H.; Schneider, O.; Schürkmann, W.; Uhl, S.; Weidner, J. Logistikmanagement in der Bauwirtschaft. In Digitale Baustelle-Innovativer Planen, Effizienter Ausführen: Werkzeuge und Methoden für das Bauen im 21. Jahrhundert; Günthner, W., Borrmann, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; pp. 205–290. [Google Scholar] [CrossRef]

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital Twin in manufacturing: A categorical literature review and classification. IFAC-PapersOnLine 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- Broy, M. Cyber-Physical Systems: Innovation Durch Softwareintensive Eingebettete Systeme; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital Twin in Industry: State-of-the-Art. IEEE Trans. Ind. Inform. 2019, 15, 2405–2415. [Google Scholar] [CrossRef]

- Tuhaise, V.V.; Tah, J.H.M.; Abanda, F.H. Technologies for digital twin applications in construction. Autom. Constr. 2023, 152, 104931. [Google Scholar] [CrossRef]

- Saif, W.; RazaviAlavi, S.; Rogage, K.; Xie, X.; Kassem, M. Inductive Theorization of Construction Digital Twins: Deriving A Taxonomy of Applications and Enabling Technologies. In Proceedings of the European Council on Computing in Construction, Crete, Greece, 14–17 July 2024; Volume 5. [Google Scholar] [CrossRef]

- Zheng, Y.; Yang, S.; Cheng, H. An application framework of digital twin and its case study. J. Ambient Intell. Humaniz. Comput. 2019, 10, 1141–1153. [Google Scholar] [CrossRef]

- Klar, R.; Fredriksson, A.; Angelakis, V. Digital Twins for Ports: Derived From Smart City and Supply Chain Twinning Experience. IEEE Access 2023, 11, 71777–71799. [Google Scholar] [CrossRef]

- Moyne, J.; Qamsane, Y.; Balta, E.C.; Kovalenko, I.; Faris, J.; Barton, K.; Tilbury, D.M. A Requirements Driven Digital Twin Framework: Specification and Opportunities. IEEE Access 2020, 8, 107781–107801. [Google Scholar] [CrossRef]

- Schwerdtner, P.; Barking, L.; Placzek, G. Solving the Last Mile Delivery Challenge—Modellbasierte Baulogistikplanung nach LEAN-Prinzipien. Available online: https://www.tu-braunschweig.de/ibb/forschung/lmdc (accessed on 7 September 2025).

- Pauwels, P.; de Koning, R.; Hendrikx, B.; Torta, E. Live semantic data from building digital twins for robot navigation: Overview of data transfer methods. Adv. Eng. Inform. 2023, 56, 101959. [Google Scholar] [CrossRef]

- Gremyr, I.; Bäckstrand, J.; Fredriksson, A.; Gatenholm, G.; Halldorsson, A. Blueprinting construction logistics services for quality improvement. Constr. Manag. Econ. 2023, 41, 60–78. [Google Scholar] [CrossRef]

- Farnood Ahmadi, P.; Arashpour, M. An analysis of 4D-BIM Construction Planning: Advantages, Risks and Challenges. In Proceedings of the 37th International Symposium on Automation and Robotics in Construction (ISARC), Kitakyushu, Japan, 27–29 October 2020; pp. 163–170. [Google Scholar] [CrossRef]

- Speckle—The Platform For 3D Data. 2024. Available online: https://speckle.systems (accessed on 7 September 2025).

- Stolipin, J.; Jessen, U.; Wenzel, S.; Weber, J.; König, M. Schlussbericht zum Projekt BIMLog—BIM-Basierte Logistikplanung und -Steuerung im Großanlagenbau; Universität Kassel: Kassel, Germany, 2020. [Google Scholar] [CrossRef]

- Schlenger, J.; Pluta, K.; Mathew, A.; Yeung, T.; Sacks, R.; Borrmann, A. Reference architecture and ontology framework for digital twin construction. Autom. Constr. 2025, 174, 106111. [Google Scholar] [CrossRef]

- Kosse, S.; Hagedorn, P.; König, M. Semantic Digital Twins in Construction: Developing a modular System Reference Architecture based on Information Containers. Adv. Eng. Inform. 2025, 67, 103483. [Google Scholar] [CrossRef]

- Osama, Z. The digital twin framework: A roadmap to the development of user- centred digital twin in the built environment. J. Build. Eng. 2024, 98, 111081. [Google Scholar] [CrossRef]

- Kang, T.W.; Mo, Y. A comprehensive digital twin framework for building environment monitoring with emphasis on real-time data connectivity and predictability. Dev. Built Environ. 2024, 17, 100309. [Google Scholar] [CrossRef]

- Fredriksson, A.; Eriksson, L.; Löwgren, J.; Lemon, N.; Eriksson, D. An Interactive Visualization Tool for Collaborative Construction Logistics Planning—Creating a Sustainable Project Vicinity. Sustainability 2022, 14, 17032. [Google Scholar] [CrossRef]

- Ramonell, C.; Chacón, R.; Posada, H. Knowledge graph-based data integration system for digital twins of built assets. Autom. Constr. 2023, 156, 105109. [Google Scholar] [CrossRef]

- Thiele, C.D.; Brötzmann, J.; Huyeng, T.J.; Rüppel, U.; Lorenzen, S.R.; Berthold, H.; Schneider, J. A Digital Twin as a framework for a machine learning based predictive maintenance system. In ECPPM 2021—eWork and eBusiness in Architecture, Engineering and Construction; CRC Press: Boca Raton, FL, USA, 2021; p. 7. [Google Scholar]

- Brötzmann, J.; Thiele, C.D.; Rüppel, U.; Lorenzen, S.; Berthold, H.; Schneider, J. A review of the digital twin in the AEC sector in the context of application. In Proceedings of the Bridge Safety, Maintenance, Management, Life-Cycle, Resilience and Sustainability, Barcelona, Spain, 11–15 July 2022; pp. 855–862. [Google Scholar] [CrossRef]

- Brötzmann, J.; Grunert, G.; Thiele, C.D.; Rüppel, U.; Lorenzen, S.R. BIM-Integration von Sensordaten aus dem Monitoring von Eisenbahnbrücken im Betrieb. Bautechnik 2024, 101, 166–173. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, M.; Li, M.; Liu, X.; Zhong, R.Y.; Pan, W.; Huang, G.Q. Digital twin-enabled real-time synchronization for planning, scheduling, and execution in precast on-site assembly. Autom. Constr. 2022, 141, 104397. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, M.; Guo, D.; Wu, W.; Zhong, R.Y.; Huang, G.Q. Digital twin-enabled smart modular integrated construction system for on-site assembly. Comput. Ind. 2022, 136, 103594. [Google Scholar] [CrossRef]

- Lee, D.; Lee, S. Digital Twin for Supply Chain Coordination in Modular Construction. Appl. Sci. 2021, 11, 5909. [Google Scholar] [CrossRef]

- Liu, Z.; Shi, G.; Qin, J.; Wang, X.; Sun, J. Prestressed Steel Material-Allocation Path and Construction Using Intelligent Digital Twins. Metals 2022, 12, 631. [Google Scholar] [CrossRef]

- Kargul, A.; Günthner, W.A.; Bügler, M.; Borrmann, A. Web based field data analysis and data-driven simulation application for construction performance prediction. J. Inf. Technol. Constr. 2015, 20, 479–494. [Google Scholar]

- Saini, G.S.; Fallah, A.; Ashok, P.; van Oort, E. Digital Twins for Real-Time Scenario Analysis during Well Construction Operations. Energies 2022, 15, 6584. [Google Scholar] [CrossRef]

- Greif, T.; Stein, N.; Flath, C.M. Peeking into the void: Digital twins for construction site logistics. Comput. Ind. 2020, 121, 103264. [Google Scholar] [CrossRef]

- Jiang, W.; Ding, L.; Zhou, C. Cyber physical system for safety management in smart construction site. Eng. Constr. Archit. Manag. 2020, 28, 788–808. [Google Scholar] [CrossRef]

- Lee, J.; Lapira, E.; Bagheri, B.; Kao, H.a. Recent advances and trends in predictive manufacturing systems in big data environment. Manuf. Lett. 2013, 1, 38–41. [Google Scholar] [CrossRef]

- Rodriguez Garzon, S.; Deva, B. Geofencing 2.0: Taking location-based notifications to the next level. In Proceedings of the 2014 ACM International Joint Conference on Pervasive and Ubiquitous Computing, UbiComp’14, New York, NY, USA, 13–17 September 2014; pp. 921–932. [Google Scholar] [CrossRef]

- Emery, D.; Hilliard, R. Every architecture description needs a framework: Expressing architecture frameworks using ISO/IEC 42010. In Proceedings of the 2009 Joint Working IEEE/IFIP Conference on Software Architecture & European Conference on Software Architecture, Cambridge, UK, 14–17 September 2009; pp. 31–40. [Google Scholar] [CrossRef]

- Lee, G.; Jeong, J.; Won, J.; Cho, C.Y.; You, S.j.; Ham, S.; Kang, H. Query Performance of the IFC Model Server Using an Object-Relational Database Approach and a Traditional Relational Database Approach. J. Comput. Civ. Eng. 2014, 28, 210–222. [Google Scholar] [CrossRef]

- Jaster, I.; Placzek, G.; Schwerdtner, P. Modellbasierte Etagenlogistikplanung für die Ausbauphase im Hochbau—Teil 1: Erarbeitung des Konzepts. Bautechnik 2023, 100, 742–750. [Google Scholar] [CrossRef]

- Chaudhuri, S.; Dayal, U. An overview of data warehousing and OLAP technology. ACM SIGMOD Rec. 1997, 26, 65–74. [Google Scholar] [CrossRef]

- Gehring, M.; Wala, J.; Rüppel, U. IoT-altimeter in smart pallets for material tracking on multi-storey construction sites. Smart Constr. 2025, 2, 0023. [Google Scholar] [CrossRef]

- Gehring, M.; Mosler, P. Indoor Navigation with Augmented Reality and BIM: A Marker-Based Approach for Locating Logistics Areas on Construction Sites. In Proceedings of the 33. Forum Bauinformatik, Munich, Germany, 7–9 September 2022; pp. 199–206. [Google Scholar] [CrossRef]

- Docker: Accelerated Container Application Development. 2022. Available online: https://www.docker.com/ (accessed on 7 September 2025).

- FastAPI Framework, High Performance, Easy to Learn, Fast to Code, Ready for Production. Available online: https://fastapi.tiangolo.com (accessed on 7 September 2025).

- Ravoof, S. MongoDB vs PostgreSQL: 15 Critical Differences. 2022. Available online: https://kinsta.com/blog/mongodb-vs-postgresql/ (accessed on 7 September 2025).

- Dhanagari, M.R. MongoDB and data consistency: Bridging the gap between performance and reliability. J. Comput. Sci. Technol. Stud. 2024, 6, 183–198. [Google Scholar] [CrossRef]

- Xu, X.; He, Y. Blockchain application in modern logistics information sharing: A review and case study analysis. Prod. Plan. Control 2024, 35, 886–900. [Google Scholar] [CrossRef]

- Zheng, Y.; Tetik, M.; Törmä, S.; Peltokorpi, A.; Seppänen, O. A Shared Ontology for Logistics Information Management in the Construction Industry. In Proceedings of the 37th International Symposium on Automation and Robotics in Construction (ISARC 2020), Kitakyushu, Japan, 27–28 October 2020. [Google Scholar] [CrossRef]

- MongoDB: The Database for Dynamic, Demanding Software. Available online: https://www.mongodb.com (accessed on 7 September 2025).

- MinIO|S3 & Kubernetes Native Object Storage for AI. Available online: https://www.min.io (accessed on 7 September 2025).

- MQTT—The Standard for IoT Messaging. Available online: https://mqtt.org/ (accessed on 7 September 2025).

- IfcOpenShell—The Open Source IFC Toolkit and Geometry Engine. Available online: https://ifcopenshell.org/ (accessed on 7 September 2025).

- Babar, M.A.; Gorton, I. Comparison of scenario-based software architecture evaluation methods. In Proceedings of the 11th Asia-Pacific Software Engineering Conference, Busan, Republic of Korea, 30 November–3 December 2004; IEEE: New York, NY, USA, 2004; pp. 600–607. [Google Scholar]

- Sutcliffe, A. Scenario-based requirements analysis. Requir. Eng. 1998, 3, 48–65. [Google Scholar] [CrossRef]

- Singh, S. Security analysis of mongodb. Int. J. Digit. Soc. IJDS 2019, 10, 1556–1561. [Google Scholar] [CrossRef]

- Whitepaper der buildingSMART-Fachgruppe BIM-Basierte Baulogistik; buildingSMART Deutschland e.V.: Berlin, Germany, 2022.

- Janné, M.; Fredriksson, A. Construction logistics in urban development projects—Learning from, or repeating, past mistakes of city logistics? Int. J. Logist. Manag. 2022, 33, 49–68. [Google Scholar] [CrossRef]

- Stojanovic, N.; Milenovic, D. Data-driven Digital Twin approach for process optimization: An industry use case. In Proceedings of the 2018 IEEE International Conference on Big Data (Big Data), Seattle, WA, USA, 10–13 December 2018; pp. 4202–4211. [Google Scholar] [CrossRef]

- El Mokhtari, K.; Panushev, I.; McArthur, J.J. Development of a Cognitive Digital Twin for Building Management and Operations. Front. Built Environ. 2022, 8, 856873. [Google Scholar] [CrossRef]

| Aspect | MongoDB | PostgreSQL |

|---|---|---|

| Transactions | Eventual consistency | Full ACID compliance |

| Scalability | Native horizontal scaling | Vertical scaling |

| Geospatial | Indexes for point/area queries | Geospatial joins |

| Time-series | Native time-series collections | TimescaleDB extension |

| Analytics | Weak for complex aggregations | Mature OLAP ecosystem |

| Schema | Flexible JSON-like documents | Rigid relational schema |

| ConLogTwin alignment | High adaptability for evolving project-specific requirements, lightweight IoT integration | Strong transactional and analytical capabilities but less adaptable for dynamic heterogeneous data |

| Requirement | ConLogTwin Feature | |

|---|---|---|

| CSC | Heterogenous data sources | Web-API + flexible data model |

| Delivery tracking | IoT-integration + dashboard | |

| Storage space monitoring | Dashboard + data model entities | |

| Stakeholder involvement | Web-based dashboard + visualizer | |

| Work preparation and order planning | ConLogTwin Service ‘Automated Delivery Plan’ | |

| DT | Data Capacities | Horizontal scalability of database |

| Extensibility | Flexible data model + containerized services (e.g., Automated Delivery Plan) | |

| Reusability and Interoperability | Web API + flexible data model (MongoDB, IFC link) | |

| Valuable Insights | ConLogTwin dashboard | |

| Risk Category | Limitation | Potential Mitigation |

|---|---|---|

| Technical | Lack of real-world performance validation | Pilot deployment with controlled data streams |

| Organizational | Data sovereignty concerns | Role-based access control, contractual data agreements |

| Economic | Cost of maintaining containers and APIs | Cloud-hosted shared infrastructure, shared development in trade association |

| Integration | Compatibility with legacy tools | AAS and ICDD interface implementation, IFC-linked data model |

| Aspect | DMS/CDE | Existing DT Architectures | ConLogTwin |

|---|---|---|---|

| Primary focus | Delivery scheduling and document management | Lifecycle asset management, abstract DT reference models | Construction logistics integration and real-time site operations |

| Architecture | Centralized system, often vendor-specific | High-level reference frameworks, often conceptual | Modular, container-based, open-source reference architecture |

| Data model | Project-centric, mainly delivery slots and documents | Broad domain ontologies, often complex and abstract | Lightweight five-entity model (project, building, component, package, delivery) tailored for logistics with extensibility |

| Real-time data | Limited (manual updates, some GPS integration) | Conceptualized but rarely implemented in practice | IoT and sensor integration (MQTT, geofencing, IFC decomposition) |

| Flexibility/Extensibility | Fixed workflows, limited customisation | Flexible in theory but complex and heavy in practice | Service-oriented, easily extendable via containerised services |

| Interoperability | Vendor lock-in, limited APIs | Focus on standards (e.g., AAS, ICDD) but low adoption | Open API, IFC-based integration, extendable towards AAS/ICDD |

| Evaluation maturity | Widely used in practice but fragmented | Conceptual, little practical adoption in construction | Demonstrative prototype, qualitative requirement-based evaluation |

| Strengths | Proven for delivery slot booking and transparency | Conceptual completeness, cross-domain alignment | Pragmatic, implementable with open technologies, tailored to logistics |

| Weaknesses | No semantic integration, poor flexibility | Lack of construction logistics perspective, no field validation | Not yet field-tested, qualitative evaluation only |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gehring, M.; Brötzmann, J.; Rüppel, U. A Modular, Logistics-Centric Digital Twin Framework for Construction: From Concept to Prototype. CivilEng 2025, 6, 59. https://doi.org/10.3390/civileng6040059

Gehring M, Brötzmann J, Rüppel U. A Modular, Logistics-Centric Digital Twin Framework for Construction: From Concept to Prototype. CivilEng. 2025; 6(4):59. https://doi.org/10.3390/civileng6040059

Chicago/Turabian StyleGehring, Maximilian, Jascha Brötzmann, and Uwe Rüppel. 2025. "A Modular, Logistics-Centric Digital Twin Framework for Construction: From Concept to Prototype" CivilEng 6, no. 4: 59. https://doi.org/10.3390/civileng6040059

APA StyleGehring, M., Brötzmann, J., & Rüppel, U. (2025). A Modular, Logistics-Centric Digital Twin Framework for Construction: From Concept to Prototype. CivilEng, 6(4), 59. https://doi.org/10.3390/civileng6040059