A Bibliometric Review of Lightweight Aggregate Geopolymer Concrete

Abstract

1. Introduction

2. Methodology

3. Bibliometric Analysis

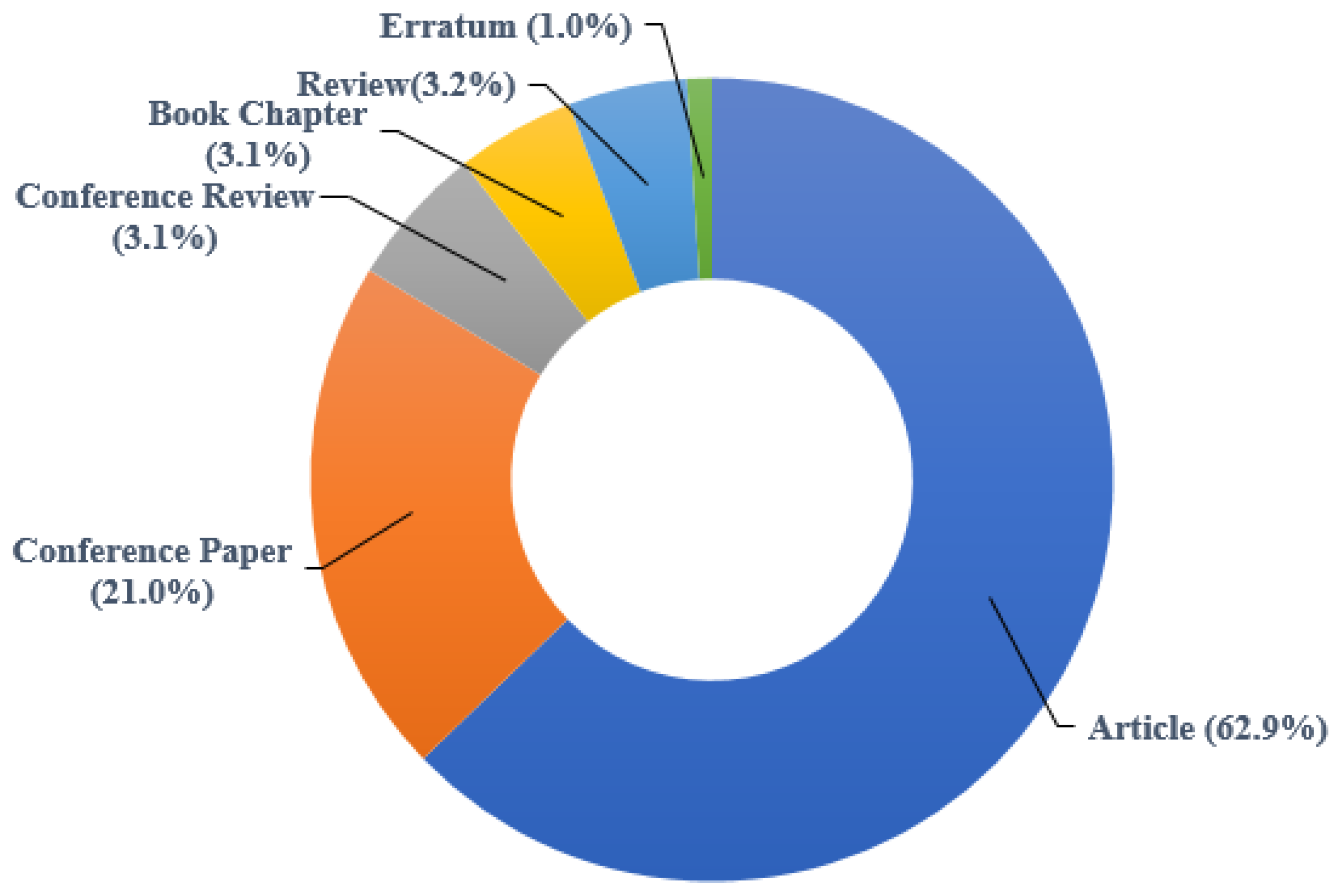

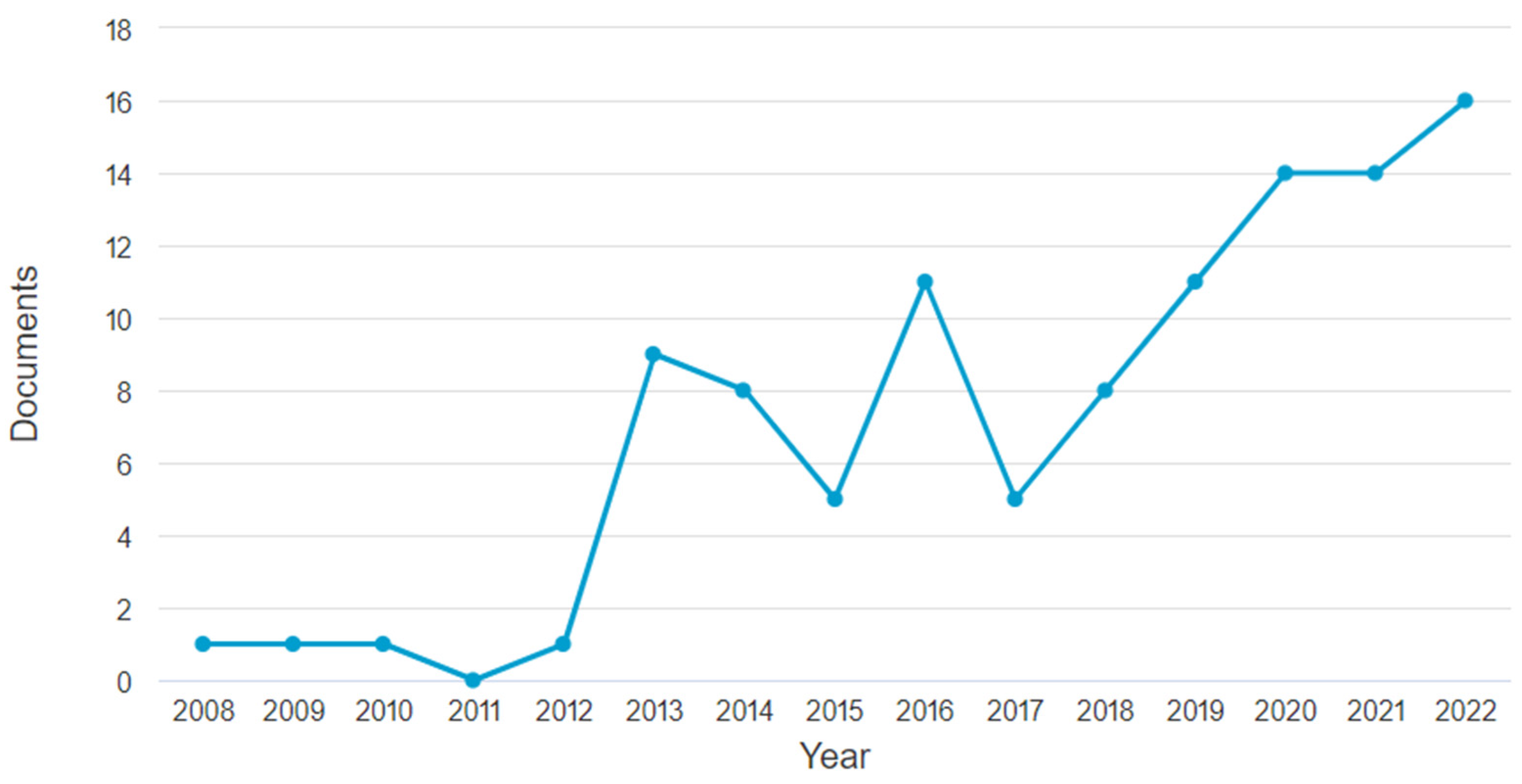

3.1. Literature Samples

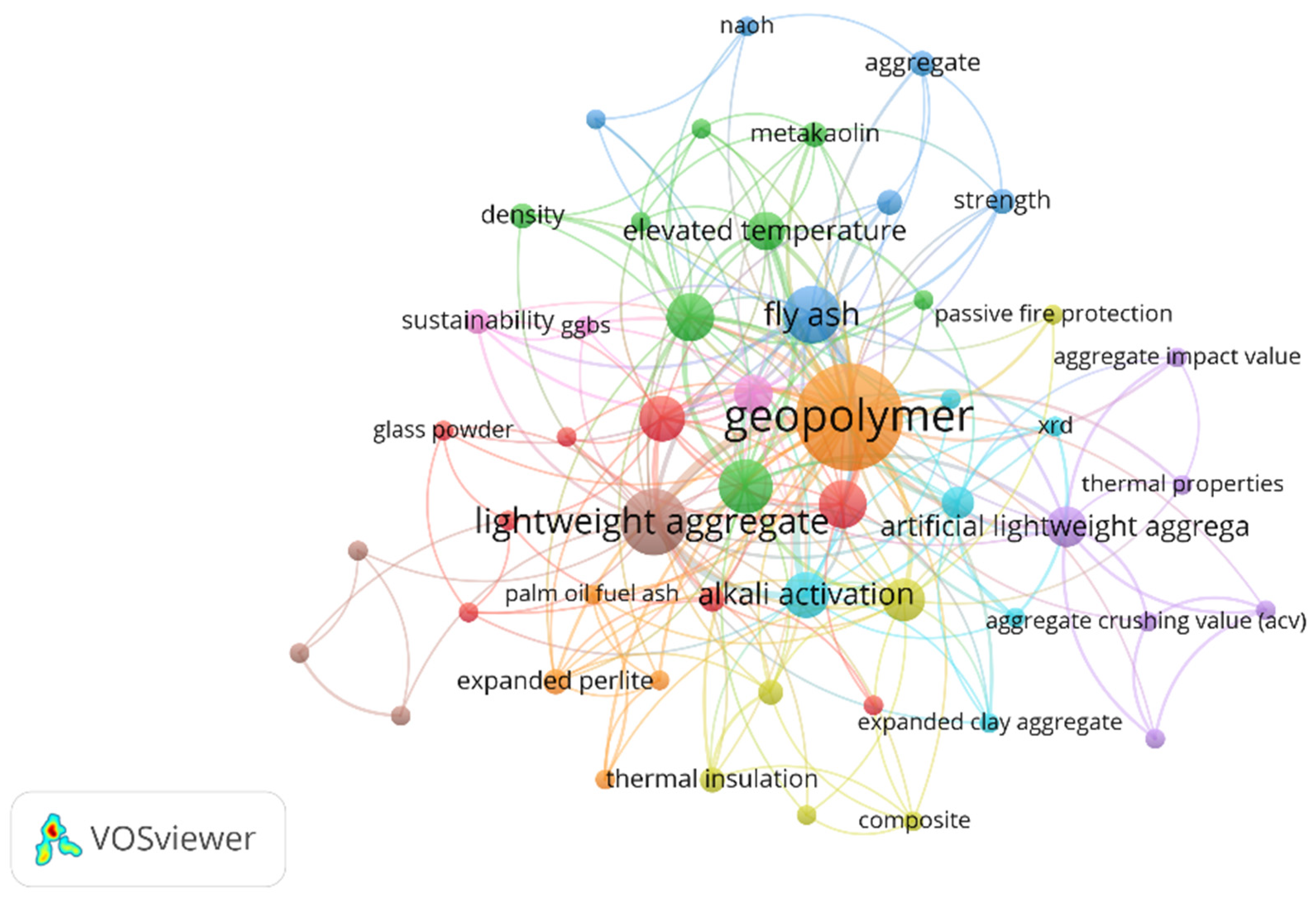

3.2. Research Keywords

3.3. Sources of Documents

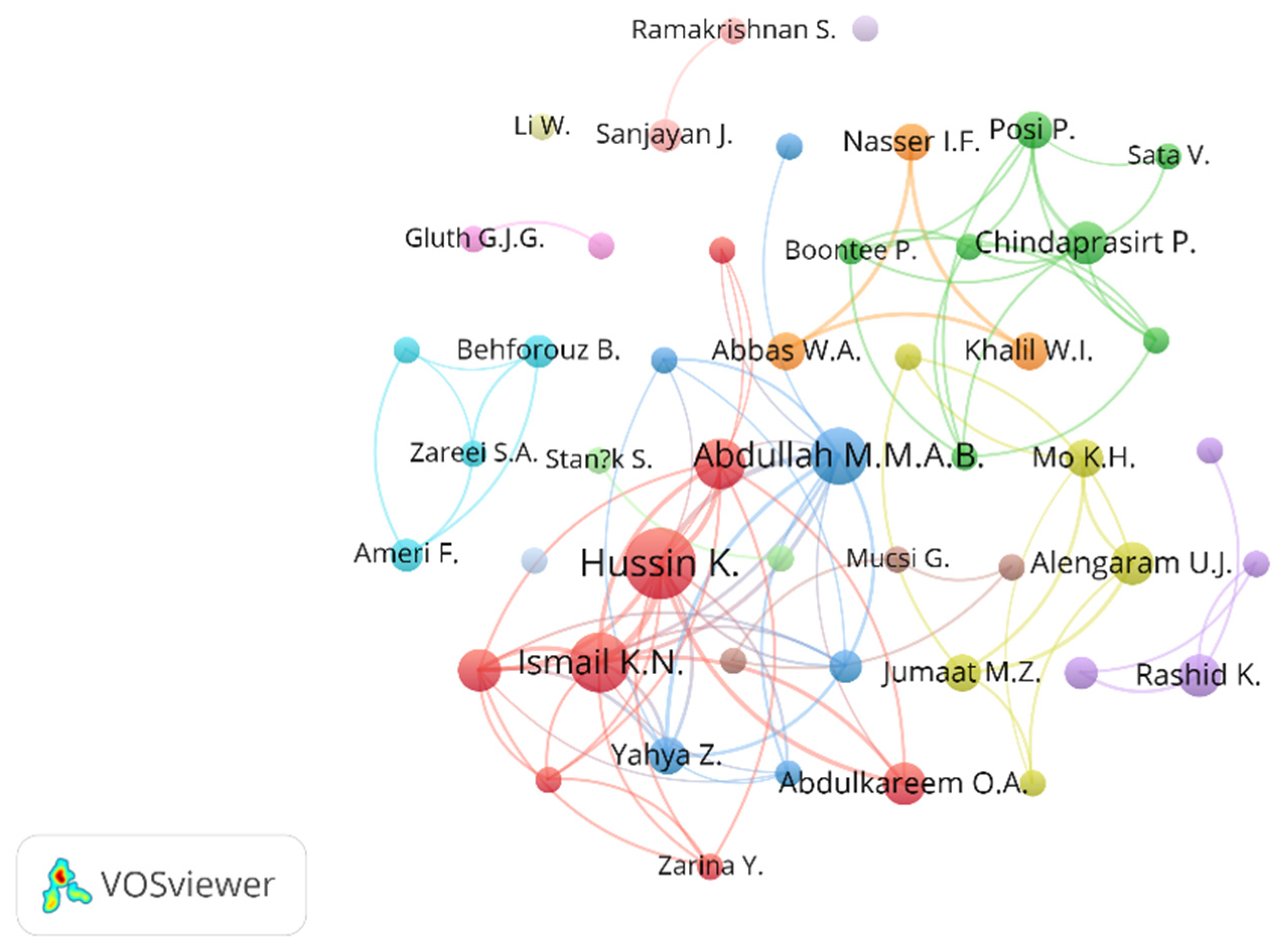

3.4. Publications by Author

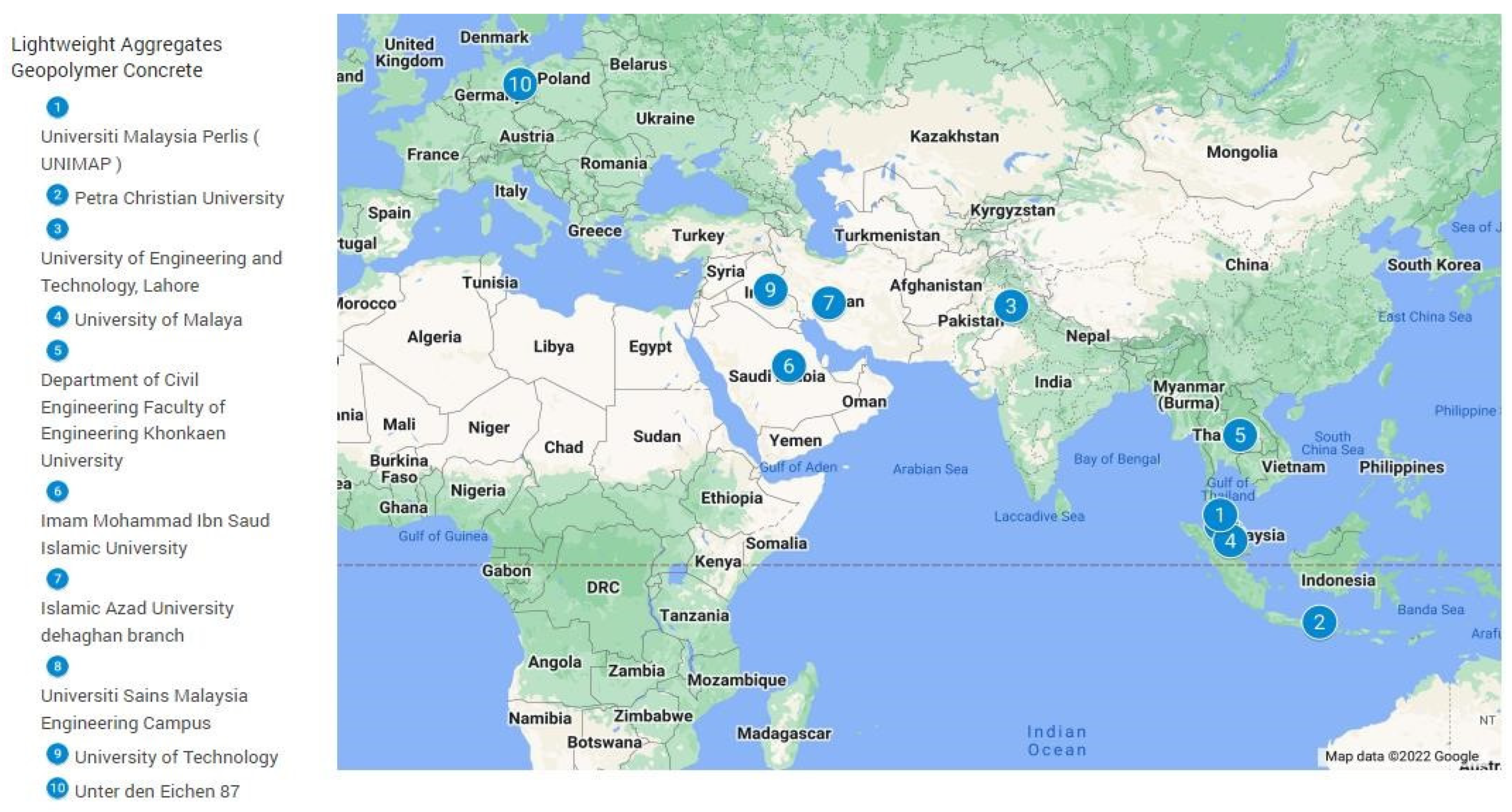

3.5. Research Institutions

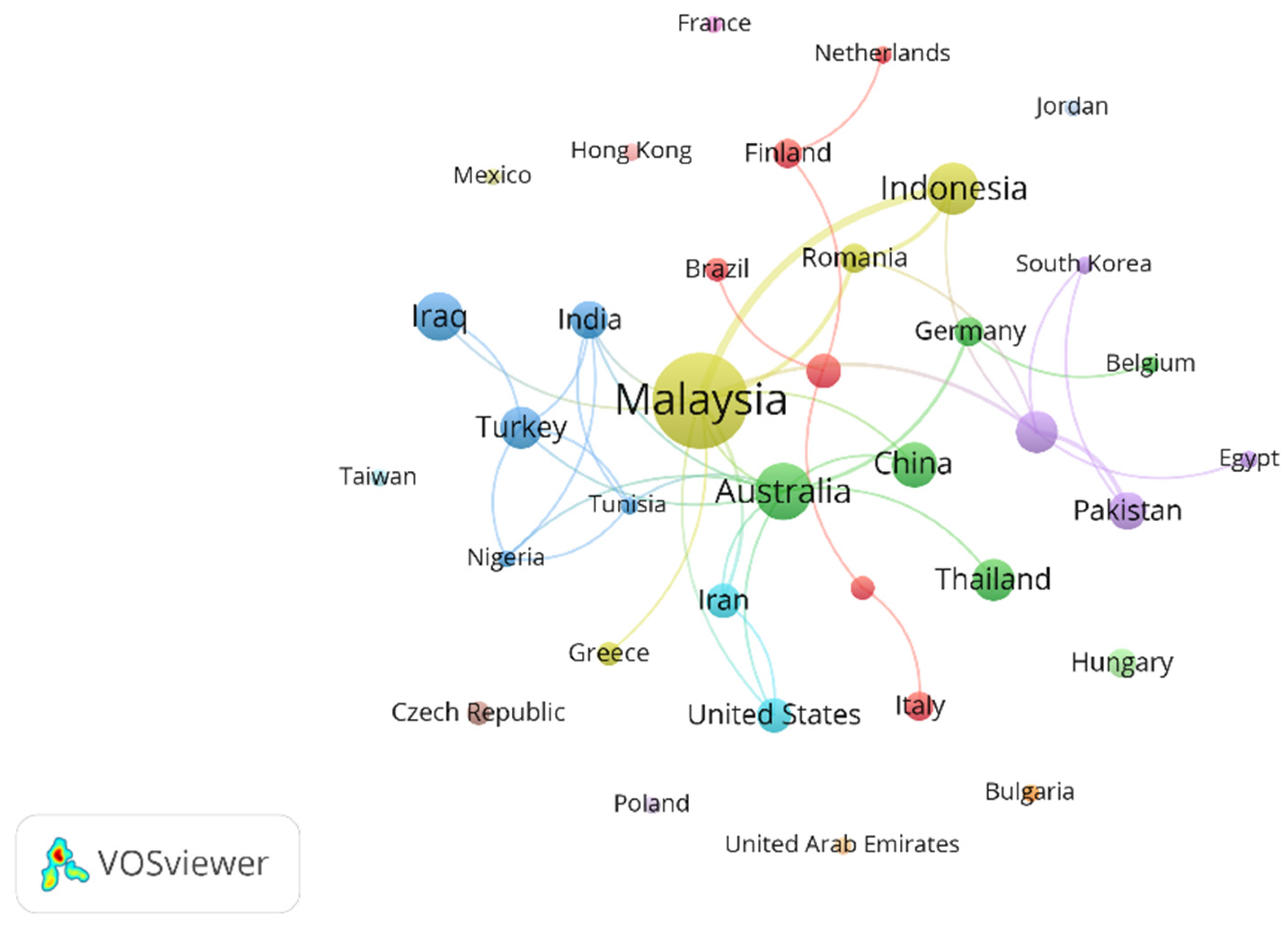

3.6. Countries

4. Findings and Discussion

4.1. Geopolymer Concrete

4.2. Lightweight Concrete

4.3. Binding Materials

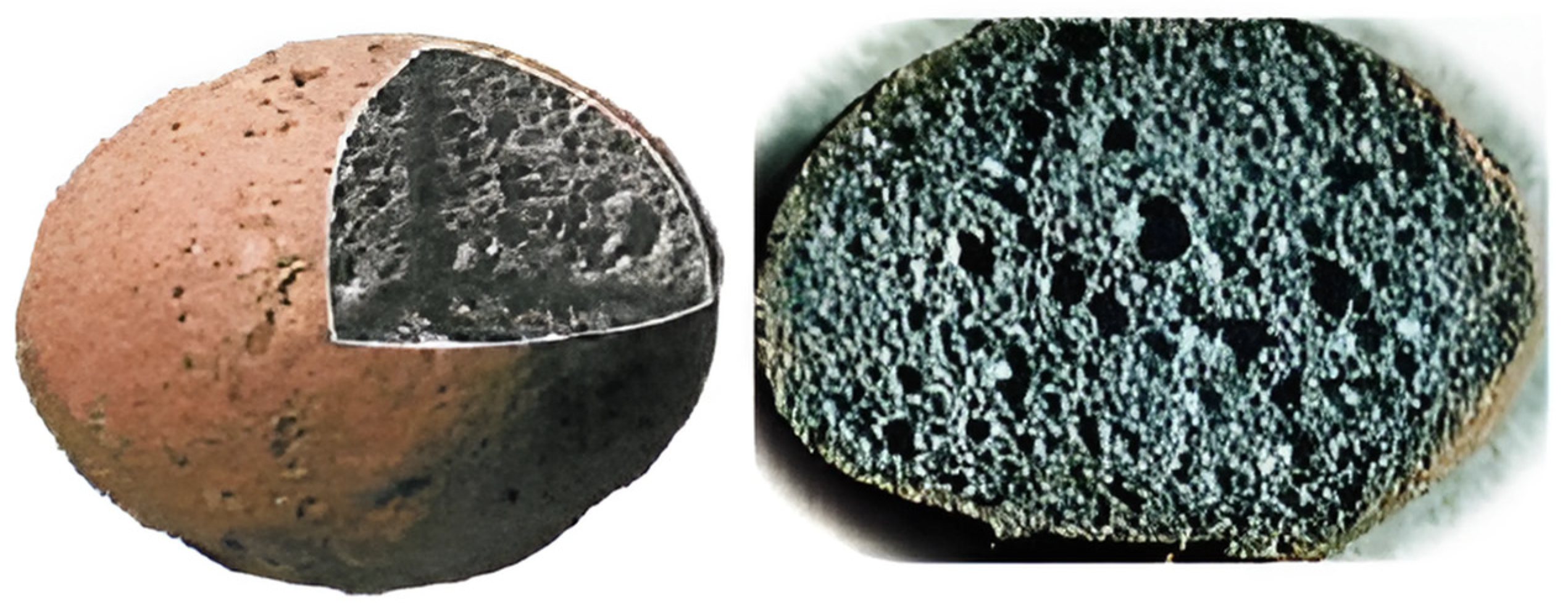

4.4. Lightweight Aggregates

4.5. Alkaline Solution

4.6. Alkaline-to-Binder Ratio

4.7. Sodium Silicate to Sodium Hydroxide Ratio

4.8. Superplasticizer

4.9. Setting Time

4.10. Workability

4.11. Compressive Strength

4.12. Splitting Tensile Strength

4.13. Modulus of Elasticity

4.14. Flexural Strength

4.15. Elevated Temperature

5. Conclusions

Author Contributions

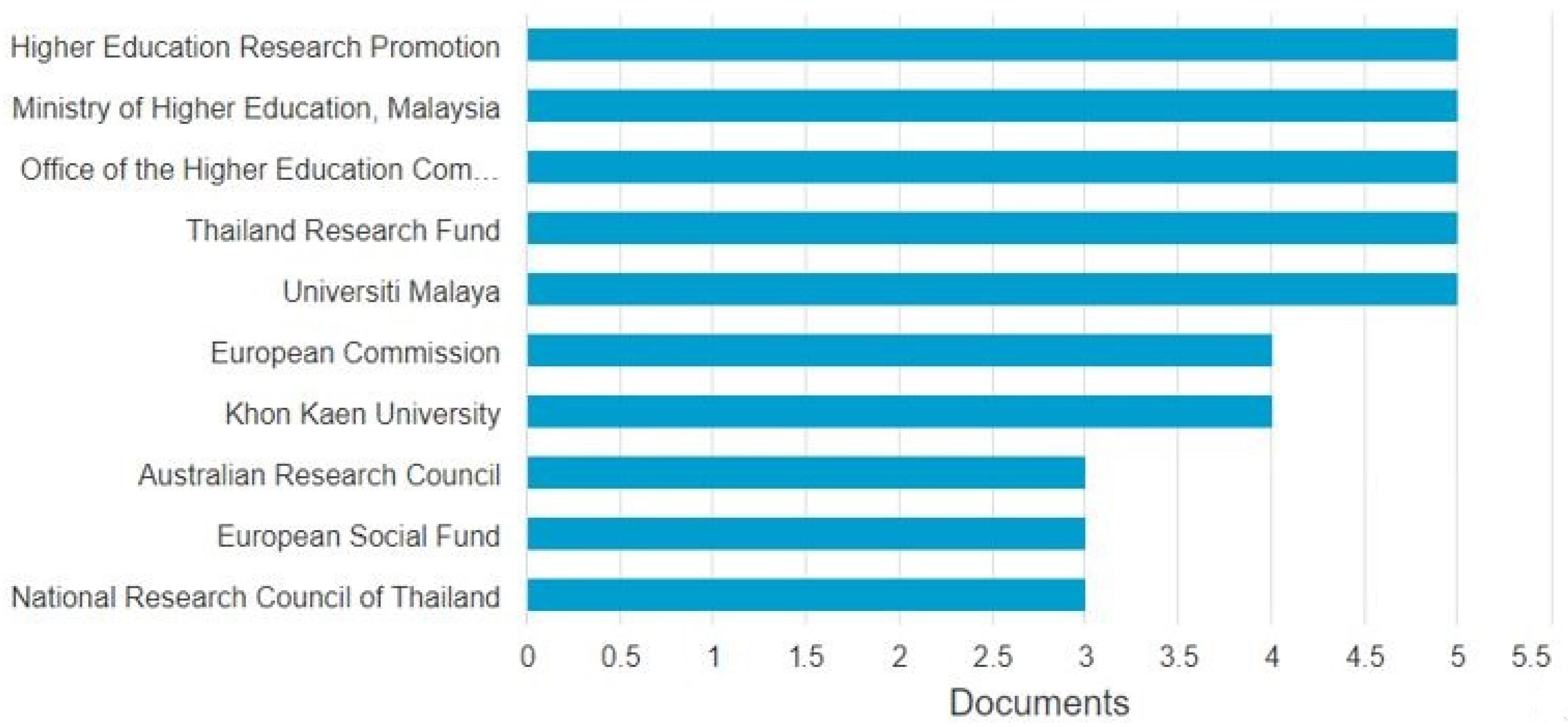

Funding

Conflicts of Interest

References

- Davidovits, J. Geopolymer Chemistry and Applications, 5th ed.; The Geopolymer Institute: Saint-Quentin, France, 2020. [Google Scholar]

- Miltiadis, S.K.; Giannopoulou, I.; Tahir, M.F.M.; Abu Hashim, M.F.; Panias, D. Upgrading Copper Slags to Added Value Fire Resistant Geopolymers. Waste Biomass Valorization 2019, 11, 3811–3820. [Google Scholar] [CrossRef]

- Shafigh, P.; Jumaat, M.Z.; Mahmud, H. Mix design and mechanical properties of oil palm shell lightweight aggregate concrete: A review. Int. J. Phys. Sci. 2010, 5, 2127–2134. [Google Scholar]

- Sajedi, F.; Shafigh, P. High-Strength Lightweight Concrete Using Leca, Silica Fume, and Limestone. Arab. J. Sci. Eng. 2012, 37, 1885–1893. [Google Scholar]

- Polat, R.; Demirboğa, R.; Karakoç, M.B.; Türkmen, I. The influence of lightweight aggregate on the physico-mechanical properties of concrete exposed to freeze–thaw cycles. Cold Reg. Sci. Technol. 2010, 60, 51–56. [Google Scholar] [CrossRef]

- Bin Othman, M.L.; Alsarayreh AI, M.; Bin Abdullah, R.; Sarbini, N.N.B.; Bin Yassin, M.S.; Ahmad, H.B. Experimental study on lightweight concrete using lightweight expanded clay aggregate (LECA) and expanded perlite aggregate (EPA). J. Eng. Sci. Technol. 2020, 15, 1186–1201. [Google Scholar]

- van Eck, N.J.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. VOSviewer Manual: Manual for VOSviewer Version 1.6.7; Univeristeit Leiden: Leiden, The Netherlands, 2018; p. 51. [Google Scholar]

- Guo, Y.M.; Huang, Z.L.; Guo, J.; Li, H.; Guo, X.R.; Nkeli, M.J. Bibliometric analysis on smart cities research. Sustainability 2019, 11, 3606. [Google Scholar] [CrossRef]

- Abdulkareem, O.A.; Mustafa Al Bakri, A.M.; Kamarudin, H.; Khairul Nizar, I.; Saif, A.A. Effects of elevated temperatures on the thermal behavior and mechanical performance of fly ash geopolymer paste, mortar and lightweight concrete. Constr. Build. Mater. 2014, 50, 377–387. [Google Scholar] [CrossRef]

- Abdulkareem, O.A.; Al Bakri AM, M.; Kamarudin, H.; Nizar, I.K. Fire resistance evaluation of lightweight geo-polymer concrete system exposed to elevated temperatures of 100–800 °C. Key Eng. Mater. 2014, 594, 427–432. [Google Scholar]

- Abdulkareem, A.O.; Al Bakri AM, M.; Kamarudin, H.; Nizar, I.K. Lightweight fly ash-based geopolymer concrete. Adv. Mater. Res. 2013, 626, 781–785. [Google Scholar]

- Mermerdaş, K.; Algın, Z.; Ekmen, Ş. Experimental assessment and optimization of mix parameters of fly ash-based lightweight geopolymer mortar with respect to shrinkage and strength. J. Build. Eng. 2020, 31, 101351. [Google Scholar] [CrossRef]

- Colangelo, F.; Roviello, G.; Ricciotti, L.; Ferrándiz-Mas, V.; Messina, F.; Ferone, C.; Tarallo, O.; Cioffi, R.; Cheeseman, C.R. Mechanical and thermal properties of lightweight geopolymer composites. Cem. Concr. Compos. 2018, 86, 266–272. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Geng, G.; Lin, A.; Biolzi, L.; Ostertag, C.P.; Monteiro, P.J.M. The influence of expansive cement on the mechanical, physical, and microstructural properties of hybrid-fiber-reinforced concrete. Cem. Concr. Compos. 2019, 96, 21–32. [Google Scholar] [CrossRef]

- Arora, S.; Singh, S. Probability of failure of RCA concrete with ternary blended cements. Constr. Build. Mater. 2019, 225, 401–414. [Google Scholar] [CrossRef]

- Zhang, Z.; Provis, J.L.; Reid, A.; Wang, H. Geopolymer foam concrete: An emerging material for sustainable construction. Constr. Build. Mater. 2014, 56, 113–127. [Google Scholar]

- McLellan, B.C.; Williams, R.P.; Lay, J.; van Riessen, A.; Corder, G.D. Costs and carbon emissions for geopolymer pastes in comparison to ordinary portland cement. J. Clean. Prod. 2011, 19, 1080–1090. [Google Scholar] [CrossRef]

- Aleem, M.A.; Arumairaj, P.D. Optimum mix for the geopolymer concrete. Indian J. Sci. Technol. 2012, 5, 2299–2301. [Google Scholar]

- Gordon, L.E.; Provis, J.L.; Van Deventer, J.S.J. Non-traditional (“geopolymer”) cements and concretes for construc-tion of large CCS equipment. Energy Procedia 2011, 4, 2058–2065. [Google Scholar]

- Davidovits, J. Geopolymers. J. Therm. Anal. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Davidovits, J. Properties of Geopolymer Cements. In Proceedings of the First International Conference on Alkaline Cements and Concretes, Kiev, Ukraine, 11–14 October 1994; pp. 131–149. [Google Scholar]

- Hardjito, D.; Wallah, S.E.; Sumajouw, D.M.J.; Rangan, B.V. Factors influencing the compressive strength of fly ash-based geopolymer concrete. Civ. Eng. 2004, 6, 88–93. [Google Scholar]

- Shinde, B.P.; Suryawanshi, B.S.; Chougule, D.A. A Characteristic Study of Light Weight Geopolymer Concrete. Int. Res. J. Eng. Technol. 2016, 3, 1555–1558. [Google Scholar]

- Singh, B.; Ishwarya, G.; Gupta, M.; Bhattacharyya, S. Geopolymer concrete: A review of some recent developments. Constr. Build. Mater. 2015, 85, 78–90. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers and geopolymeric materials. J. Therm. Anal. 1989, 35, 429–441. [Google Scholar]

- Mohseni, E.; Kazemi, M.J.; Koushkbaghi, M.; Zehtab, B.; Behforouz, B. Evaluation of mechanical and durability properties of fiber-reinforced lightweight geopolymer composites based on rice husk ash and nano-alumina. Constr. Build. Mater. 2019, 209, 532–540. [Google Scholar] [CrossRef]

- Pasupathy, K.; Ramakrishnan, S.; Sanjayan, J. Enhancing the mechanical and thermal properties of aerated geopolymer concrete using porous lightweight aggregates. Constr. Build. Mater. 2020, 264, 120713. [Google Scholar] [CrossRef]

- Khalil, W.I.; Abbas, W.A.; Nasser, I.F. Mechanical properties and thermal conductivity of lightweight geopolymer concrete. In Proceedings of the 1st International Scientific Conference of Engineering Sciences—3rd Scientific Conference of Engineering Science, ISCES 2018, Diyala, Iraq, 10–11 January 2018; pp. 175–180. [Google Scholar]

- Diaz-Loya, E.I.; Allouche, E.N.; Vaidya, S. Mechanical properties of fly-ash-based geopolymer concrete. ACI Mater. J. 2011, 108, 300–306. [Google Scholar]

- Khale, D.; Chaudhary, R. Mechanism of geopolymerization and factors influencing its development: A review. J. Mater. Sci. 2007, 42, 729–746. [Google Scholar] [CrossRef]

- Zhang, S.; Gong, K.; Lu, J. Novel modification method for inorganic geopolymer by using water soluble organic polymers. Mater. Lett. 2003, 58, 1292–1296. [Google Scholar] [CrossRef]

- Alonso, S.; Palomo, A. Calorimetric study of alkaline activation of calcium hydroxidemetakaolin solid mixtures. Cem. Concr. Res. 2001, 31, 25–30. [Google Scholar]

- Dimas, D.; Giannopoulou, I.; Panias, D. Polymerization in sodium silicate solutions: A fundamental process in geo-polymerization technology. J. Mater. Sci. 2009, 44, 3719–3730. [Google Scholar]

- Zhang, Y.J.; Wang, Y.C.; Xu, D.L.; Li, S. Mechanical performance and hydration mechanism of geopolymer composite reinforced by resin. Mater. Sci. Eng. A 2010, 527, 6574–6580. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Rattanasak, U.; Taebuanhuad, S. Resistance to acid and sulfate solutions of microwave-assisted high calcium fly ash geopolymer. Mater. Struct. 2013, 46, 375–381. [Google Scholar] [CrossRef]

- Kumaravel, S.; Girija, K. Acid and salt resistance of geopolymer concrete with varying concentration NaOH. J. Eng. Res. Stud. 2013, 4, 3–5. [Google Scholar]

- Nasvi, M.; Ranjith, P.; Sanjayan, J.; Bui, H. Effect of temperature on permeability of geopolymer: A primary well sealant for carbon capture and storage wells. Fuel 2014, 117, 354–363. [Google Scholar] [CrossRef]

- Mohseni, E. Assessment of Na2SiO3 to NaOH ratio impact on the performance of polypropylene fiber-reinforced geo-polymer composites. Constr. Build. Mater. 2018, 186, 904–911. [Google Scholar]

- Bakharev, T. Resistance of geopolymer materials to acid attack. Cem. Concr. Res. 2005, 35, 658–670. [Google Scholar]

- Kong, D.L.; Sanjayan, J.G. Damage behavior of geopolymer composites exposed to elevated temperatures. Cem. Concr. Compos. 2008, 30, 986–991. [Google Scholar] [CrossRef]

- van Jaarsveld, J.; van Deventer, J. The effect of metal contaminants on the formation and properties of waste-based geopolymers. Cem. Concr. Res. 1999, 29, 1189–1200. [Google Scholar] [CrossRef]

- Xu, H.; Van Deventer, J.S.J. The geopolymerisation of alumino-silicate minerals. Int. J. Miner. Process. 2000, 59, 247–266. [Google Scholar] [CrossRef]

- van Deventer, J.; Provis, J.; Duxson, P.; Lukey, G. Reaction mechanisms in the geopolymeric conversion of inorganic waste to useful products. J. Hazard. Mater. 2007, 139, 506–513. [Google Scholar] [CrossRef]

- He, J.; Jie, Y.; Zhang, J.; Yu, Y.; Zhang, G. Synthesis and characterization of red mud and rice husk ash-based geo-polymer composites. Cem. Concr. Compos. 2013, 37, 108–118. [Google Scholar] [CrossRef]

- Zhang, J.; He, Y.; Wang, Y.-P.; Mao, J.; Cui, X.-M. Synthesis of a self-supporting faujasite zeolite membrane using geopolymer gel for separation of alcohol/water mixture. Mater. Lett. 2014, 116, 167–170. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Kodur, V.; Qi, S.L.; Wu, B. Characterizing the bond strength of geopolymers at ambient and elevated temperatures. Cem. Concr. Compos. 2015, 58, 40–49. [Google Scholar] [CrossRef]

- Lyon, R.E.; Balaguru, P.N.; Foden, A.; Sorathia, U.; Davidovits, J.; Davidovics, M. Fire-resistant aluminosilicate composites. Fire Mater. 1997, 21, 67–73. [Google Scholar] [CrossRef]

- Abdel-Ghani, N.T.; Elsayed, H.A.; AbdelMoied, S. Geopolymer synthesis by the alkali-activation of blastfurnace steel slag and its fire-resistance. HBRC J. 2018, 14, 159–164. [Google Scholar] [CrossRef]

- Cheng, Y.; Hongqiang, M.; Hongyu, C.; Jiaxin, W.; Jing, S.; Zonghui, L.; Mingkai, Y. Preparation and characterization of coal gangue geopolymers. Constr. Build. Mater. 2018, 187, 318–326. [Google Scholar] [CrossRef]

- Zhang, P.; Zheng, Y.; Wang, K.; Zhang, J. A review on properties of fresh and hardened geopolymer mortar. Compos. Part B Eng. 2018, 152, 79–95. [Google Scholar] [CrossRef]

- Priyanka, M.; Karthikeyan, M.; Chand, M.S.R. Development of mix proportions of geopolymer lightweight aggregate concrete with LECA. In Proceedings of the 1st International Conference on Advanced Light-Weight Materials and Structures (ICALMS 2020), Hyderabad, India, 6 March 2020; pp. 958–962. [Google Scholar] [CrossRef]

- EN 1992-1-1; EC2. Eurocode 2: Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings. CEN: Brussels, Belgium, 2004.

- BS EN 206:2013; BSI Standards Publication Concrete—Specification, Performance, Production and Conformity. British Standard: London, UK, 2013.

- Chen, B.; Liu, J. Contribution of hybrid fibers on the properties of the high-strength lightweight concrete having good workability. Cem. Concr. Res. 2005, 35, 913–917. [Google Scholar] [CrossRef]

- Owens, P.L.; Newman, J.B. Lightweight aggregate manufacture. Adv. Concr. Technol. 2003, 1-12, 1–12. [Google Scholar] [CrossRef]

- Arioz, O.; Kilinc, K.; Karasu, B.; Kaya, G.; Arslan, G.; Tuncan, M.; Tuncan, A.; Korkut, M.; Kivrak, S. A preliminary research on the properties of lightweight expanded clay aggregate. J. Aust. Ceram. Soc. 2008, 44, 23–30. [Google Scholar]

- ACI 116R-90; Cement and Concrete Terminology. American Concrete Institute: Farmington Hills, MI, USA, 2000; pp. 1–58.

- Rafieizonooz, M.; Mirza, J.; Salim, M.R.; Hussin, M.W.; Khankhaje, E. Investigation of coal bottom ash and fly ash in concrete as replacement for sand and cement. Constr. Build. Mater. 2016, 116, 15–24. [Google Scholar] [CrossRef]

- Ghazali, N.; Muthusamy, K.; Wan Ahmad, S. Utilization of Fly Ash in Construction. IOP Conf. Ser. Mater. Sci. Eng. 2019, 601, 012023. [Google Scholar] [CrossRef]

- Terzano, R.; Spagnuolo, M.; Medici, L.; Tateo, F.; Ruggiero, P. Characterization of different coal fly ashes for their application in the synthesis of Zeolite X as cation exchange for soil remediation. Fresenius Environ. Bull. 2005, 14, 263–267. [Google Scholar]

- ASTM Standards C618; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use. Annual Book of ASTM Standards; American Concrete Institute: Farmington Hills, MI, USA, 2015; pp. 3–6.

- Oner, A.; Akyuz, S.; Yildiz, R. An experimental study on strength development of concrete containing fly ash and optimum usage of fly ash in concrete. Cem. Concr. Res. 2005, 35, 1165–1171. [Google Scholar] [CrossRef]

- Widianto, A.K.; Wiranegara, J.L.; Hardjito, D. Consistency of fly ash quality for making high volume fly ash concrete. J. Teknol. 2017, 79, 13–20. [Google Scholar]

- Aponte, D.F.; Barra, M.; Vàzquez, E. Durability and cementing efficiency of fly ash in concretes. Constr. Build. Mater. 2012, 30, 537–546. [Google Scholar] [CrossRef]

- Yildirim, H.; Sümer, M.; Akyüncü, V.; Gürbüz, E. Comparison on efficiency factors of F and C types of fly ashes. Constr. Build. Mater. 2011, 25, 2939–2947. [Google Scholar] [CrossRef]

- Ahari, R.S.; Erdem, T.K.; Ramyar, K. Effect of various supplementary cementitious materials on rheological properties of self-consolidating concrete. Constr. Build. Mater. 2015, 75, 89–98. [Google Scholar] [CrossRef]

- Sumer, M. Compressive strength and sulfate resistance properties of concretes containing Class F and Class C fly ashes. Constr. Build. Mater. 2012, 34, 531–536. [Google Scholar] [CrossRef]

- Sinsiri, T.; Teeramit, P.; Jaturapitakkul, C.; Kiattikomol, K. Effect of finenesses of fly ash on expansion of mortars in magnesium sulfate. Sci. Asia 2006, 32, 63–69. [Google Scholar] [CrossRef]

- Posi, P.; Thongjapo, P.; Thamultree, N.; Boontee, P.; Kasemsiri, P.; Chindaprasirt, P. Pressed lightweight fly ash-OPC geopolymer concrete containing recycled lightweight concrete aggregate. Constr. Build. Mater. 2016, 127, 450–456. [Google Scholar] [CrossRef]

- Wongsa, A.; Zaetang, Y.; Sata, V.; Chindaprasirt, P. Properties of lightweight fly ash geopolymer concrete containing bottom ash as aggregates. Constr. Build. Mater. 2016, 111, 637–643. [Google Scholar] [CrossRef]

- Lloyd, N.A.; Rangan, B.V. Geopolymer concrete with fly ash. In Proceedings of the 2nd International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, 28 June 2010; pp. 1493–1504. [Google Scholar]

- Abbas, W.; Khalil, W.; Nasser, I. Production of lightweight Geopolymer concrete using artificial local lightweight aggregate. MATEC Web Conf. 2018, 162, 1–8. [Google Scholar] [CrossRef]

- Abdullah, A.; Abdullah, M.M.; Hussin, K.; Tahir, M.F. Effect of different sintering temperature on fly ash based geopolymer artificial aggregate. AIP Conf. Proc. 2017, 183, 020050. [Google Scholar]

- Abdullah, S.F.A.; Liew, Y.M.; Abdullah, M.M.A.B.; Heah, C.Y.; Zulkifly, K. The effect of aggregate content on the expanded lightweight aggregate geopolymer concretes. AIP Conf. Proc. 2018, 2045, 020097. [Google Scholar]

- Bagheri, A.; Nazari, A. Compressive strength of high strength class C fly ash-based geopolymers with reactive granulated blast furnace slag aggregates designed by Taguchi method. Mater. Des. 2014, 54, 483–490. [Google Scholar] [CrossRef]

- Chanh N van Bùi, D.T.; Đặng, D.T. Recent research geopolymer concrete. In Proceedings of the 3rd ACF International Conference-ACF/VCA, Ho Chi Minh City, Vietnam, 11–13 November 2008; Volume 18, pp. 235–241. [Google Scholar]

- Chindaprasirt, P.; Chalee, W. Effect of sodium hydroxide concentration on chloride penetration and steel corrosion of fly ash-based geopolymer concrete under marine site. Constr. Build. Mater. 2014, 63, 303–310. [Google Scholar] [CrossRef]

- Darvish, P.; Alengaram, U.J.; Poh, Y.S.; Ibrahim, S.; Yusoff, S. Performance evaluation of palm oil clinker sand as replacement for conventional sand in geopolymer mortar. Constr. Build. Mater. 2020, 258, 120352. [Google Scholar] [CrossRef]

- Deb, P.S.; Nath, P.; Sarker, P.K. The effects of ground granulated blast-furnace slag blending with fly ash and activator content on the workability and strength properties of geopolymer concrete cured at ambient temperature. Mater. Des. 2014, 62, 32–39. [Google Scholar] [CrossRef]

- Esparham, A.; Moradikhou, A.B. A novel type of alkaline activator for geopolymer concrete based on class C fly ash. Adv. Res. Civ. Eng. 2021, 3, 1–13. [Google Scholar]

- Gomaa, E.; Sargon, S.; Kashosi, C.; Gheni, A.; ElGawady, M.A. Mechanical Properties of High Early Strength Class C Fly Ash-Based Alkali Activated Concrete. Transp. Res. Rec. J. Transp. Res. Board 2020, 2674, 430–443. [Google Scholar] [CrossRef]

- Hadi, M.N.; Zhang, H.; Parkinson, S. Optimum mix design of geopolymer pastes and concretes cured in ambient condition based on compressive strength, setting time and workability. J. Build. Eng. 2019, 23, 301–313. [Google Scholar] [CrossRef]

- Hardjito, D.; Rangan, B.V. Development and properties of low-calcium fly ash-based geopolymer concrete. In Research Report GC; Curtin University: Perth, Australia, 2005; pp. 1–104. [Google Scholar]

- Hardjito, D.; Wallah, S.E.; Sumajouw, D.M.J.; Rangan, B.V. Fly Ash-Based Geopolymer Concrete. Aust. J. Struct. Eng. 2005, 6, 77–86. [Google Scholar] [CrossRef]

- Huiskes, D.M.A.; Keulen, A.; Yu, Q.L.; Brouwers, H.J.H. Design and performance evaluation of ultra-lightweight geopolymer concrete. Mater. Des. 2016, 89, 516–526. [Google Scholar] [CrossRef]

- Khalil, W.I.; Abbas, W.A.; Nasser, I.F. Some properties and microstructure of fibre reinforced lightweight geopolymer concrete. In Proceedings of the International Conference on Advances in Sustainable Engineering and Applications, ICASEA, Wasit-Kut, Iraq, 14–15 March 2018; pp. 147–152. [Google Scholar]

- Khalil, W.I.; Abbas, W.A.; Nasser, I.F. Dynamic modulus of elasticity of geopolymer lightweight aggregate concrete. IOP Conf. Ser. Mater. Sci. Eng. 2019, 518, 022023. [Google Scholar] [CrossRef]

- Kong, D.L.; Sanjayan, J.G. Effect of elevated temperatures on geopolymer paste, mortar and concrete. Cem. Concr. Res. 2010, 40, 334–339. [Google Scholar] [CrossRef]

- Liu, M.Y.J.; Alengaram, U.J.; Santhanam, M.; Jumaat, M.Z.; Mo, K.H. Microstructural investigations of palm oil fuel ash and fly ash based binders in lightweight aggregate foamed geopolymer concrete. Constr. Build. Mater. 2016, 120, 112–122. [Google Scholar] [CrossRef]

- Madheswaran, C.K.; Gnanasundar, G.; Gopalakrishnan, N. Effect of molarity in geopolymer concrete. Int. J. Civ. Struct. Eng. 2013, 4, 106. [Google Scholar]

- Ming, L.Y.U.N.; Sandu, A.V.; Yong, H.C.; Tajunnisa, Y.; Azzahran, S.F.; Bayuji, R.; Abdullah, M.M.A.B.; Vizureanu, P.; Hussin, K.; Jin, T.S.; et al. Compressive strength and thermal conductivity of fly ash geopolymer concrete incorporated with lightweight aggregate, expanded clay aggregate and foaming agent. Rev. Chim. 2019, 70, 4021–4028. [Google Scholar] [CrossRef]

- Muthadhi, A.; Vanjinathan, J.; Durai, D. Experimental Investigations on Geo Polymer Concrete based on Class C Fly Ash. Indian J. Sci. Technol. 2016, 9, 87270. [Google Scholar] [CrossRef][Green Version]

- Nasser, I.F.; Khalil, W.I.; Abbas, W. Strength and thermal conductivity of geopolymer pervious concrete made from artificial lightweight aggregate. IOP Conf. Ser. Mater. Sci. Eng. 2020, 737, 012074. [Google Scholar] [CrossRef]

- Olivia, M.; Nikraz, H. Properties of fly ash geopolymer concrete designed by Taguchi method. Mater. Des. 2011, 36, 191–198. [Google Scholar] [CrossRef]

- Rangan, B.V.; Rangan, B.V.; Fieaust, P.; Faci, C. Fly Ash-Based Geopolymer Concrete; Engineering Faculty Curtin University of Technology: Perth, Australia, 2008; pp. 3124–3130. [Google Scholar]

- Rehman, M.U.; Rashid, K.; Haq, E.U.; Hussain, M.; Shehzad, N. Physico-mechanical performance and durability of artificial lightweight aggregates synthesized by cementing and geopolymerization. Constr. Build. Mater. 2020, 232, 117290. [Google Scholar] [CrossRef]

- Ryu, G.S.; Lee, Y.B.; Koh, K.T.; Chung, Y.S. The mechanical properties of fly ash-based geopolymer concrete with alkaline activators. Constr. Build. Mater. 2013, 47, 409–418. [Google Scholar] [CrossRef]

- Top, S.; Vapur, H.; Altiner, M.; Kaya, D.; Ekicibil, A. Properties of fly ash-based lightweight geopolymer concrete prepared using pumice and expanded perlite as aggregates. J. Mol. Struct. 2020, 1202, 127236. [Google Scholar] [CrossRef]

- Younis, K.H.; Salihi, K.; Mohammedameen, A.; Sherwani, A.F.H.; Alzeebaree, R. Factors affecting the Characteristics of Self-Compacting Geopolymer Concrete. IOP Conf. Ser. Earth Environ. Sci. 2021, 856, 012028. [Google Scholar] [CrossRef]

- Ameri, F.; Zareei, S.A.; Behforouz, B. Zero-cement vs. cementitious mortars: An experimental comparative study on engineering and environmental properties. J. Build. Eng. 2020, 32, 101620. [Google Scholar] [CrossRef]

- Malkawi, A.B.; Habib, M.; Aladwan, J.; Alzubi, Y. Engineering properties of fibre reinforced lightweight geopolymer concrete using palm oil biowastes. Aust. J. Civ. Eng. 2020, 18, 82–92. [Google Scholar] [CrossRef]

- Medri, V.; Papa, E.; Mazzocchi, M.; Laghi, L.; Morganti, M.; Francisconi, J.; Landi, E. Production and characterization of lightweight vermiculite/geopolymer-based panels. Mater. Des. 2015, 85, 266–274. [Google Scholar] [CrossRef]

- Rashad, A.M. Lightweight expanded clay aggregate as a building material—An overview. Constr. Build. Mater. 2018, 170, 757–775. [Google Scholar] [CrossRef]

- Nkansah, M.A.; Christy, A.A.; Barth, T.; Francis, G.W. The use of lightweight expanded clay aggregate (LECA) as sorbent for PAHs removal from water. J. Hazard. Mater. 2012, 217–218, 360–365. [Google Scholar] [CrossRef] [PubMed]

- Shafigh, P.; Hassanpour, M.H.; Razavi, S.V.; Kobraei, M. An investigation of the flexural behaviour of reinforced lightweight concrete beams. Int. J. Phys. Sci. 2011, 6, 2414–2421. [Google Scholar]

- Baker, M.D.; Simkins, S.; Spokas, L.; Veneman, P.; Xing, B. Comparison of Phosphorus Sorption by Light-Weight Aggregates Produced in the United States. Pedosphere 2014, 24, 808–816. [Google Scholar] [CrossRef]

- Sepehr, M.N.; Kazemian, H.; Ghahramani, E.; Amrane, A.; Sivasankar, V.; Zarrabi, M. Defluoridation of water via Light Weight Expanded Clay Aggregate (LECA): Adsorbent characterization, competing ions, chemical regeneration, equilibrium and kinetic modeling. J. Taiwan Inst. Chem. Eng. Taiwan Inst. Chem. Eng. 2014, 45, 1821–1834. [Google Scholar] [CrossRef]

- Sagirul Islam, M.; Sharmin, N.; Moniruzzaman, M.; Sarmeen Akhtar, U. Effect of Soda lime Silica Glass waste on the basic properties of Clay Aggregate. Int. J. Sci. Eng. Res. 2016, 7, 149–153. [Google Scholar]

- Sarkar, S.L.; Satish, C.; Leif, B. Interdependence of microstructure and strength of structural lightweight aggregate concrete. Cem. Concr. Compos. 1992, 14, 239–248. [Google Scholar] [CrossRef]

- Zhang, M.H.; Gjørv, O.E. Penetration of cement paste into lightweight aggregate. Cem. Concr. Res. 1992, 22, 47–55. [Google Scholar] [CrossRef]

- Zendehzaban, M.; Sharifnia, S.; Hosseini, S.N. Photocatalytic degradation of ammonia by light expanded clay aggregate (LECA)-coating of TiO2 nanoparticles. Korean J. Chem. Eng. 2013, 30, 574–579. [Google Scholar]

- Ardakani, A.; Yazdani, M. The relation between particle density and static elastic moduli of lightweight expanded clay aggregates. Appl. Clay Sci. 2014, 93–94, 28–34. [Google Scholar] [CrossRef]

- Shendy, M. A comparative study of LECA concrete sandwich beams with and without core reinforcement. Cem. Concr. Compos. 1991, 13, 143–149. [Google Scholar] [CrossRef]

- Real, S.; Bogas, J.A.; Pontes, J. Chloride migration in structural lightweight aggregate concrete produced with different binders. Constr. Build. Mater. 2015, 98, 425–436. [Google Scholar] [CrossRef]

- Bogas, J.A.; Gomes, A. Compressive behavior and failure modes of structural lightweight aggregate concrete—Characterization and strength prediction. Mater. Des. 2013, 46, 832–841. [Google Scholar]

- Bogas, J.A.; Gomes, A.; Gomes, M.G. Estimation of water absorbed by expanding clay aggregates during structural lightweight concrete production. Mater. Struct. 2012, 45, 1565–1576. [Google Scholar] [CrossRef]

- Muñoz-Ruiperez, C.; Rodríguez, A.; Gutiérrez-González, S.; Calderón, V. Lightweight masonry mortars made with expanded clay and recycled aggregates. Constr. Build. Mater. 2016, 118, 139–145. [Google Scholar] [CrossRef]

- Bogas, J.A.; de Brito, J.; Cabaço, J. Long-term behaviour of concrete produced with recycled lightweight expanded clay aggregate concrete. Constr. Build. Mater. 2014, 65, 470–479. [Google Scholar] [CrossRef]

- Bogas, J.A.; Gomes, A. Non-steady-state accelerated chloride penetration resistance of structural lightweight aggregate concrete. Cem. Concr. Compos. 2015, 60, 111–122. [Google Scholar] [CrossRef]

- JNTUA College of Engineering; Ramanjaneyulu, N.; Srigiri, K.; CVR College of Engineering; Rao, N.S. Strength and Durability Studies on Light Weight Self-Compacting Concrete with LECA as Partial Replacement of Coarse Aggregate. CVR J. Sci. Technol. 2018, 15, 1–9. [Google Scholar] [CrossRef]

- Sonia, T.; Subashini, R. Experimental Investigation on Mechanical Properties of Lightweight Concrete using LECA and Steel Scraps. SSRG Int. J. Civ. Eng. 2017, 5, 594–598. [Google Scholar]

- Shafigh, P.; Chai, L.J.; Bin Mahmud, H.; Nomeli, M.A. A comparison study of the fresh and hardened properties of normal weight and lightweight aggregate concretes. J. Build. Eng. 2018, 15, 252–260. [Google Scholar] [CrossRef]

- Zaharaki, D.; Komnitsas, K.; Perdikatsis, V. Use of analytical techniques for identification of inorganic polymer gel composition. J. Mater. Sci. 2010, 45, 2715–2724. [Google Scholar] [CrossRef]

- Mohammadinia, A.; Arulrajah, A.; Horpibulsuk, S.; Shourijeh, P.T. Impact of potassium cations on the light chemical stabilization of construction and demolition wastes. Constr. Build. Mater. 2019, 203, 69–74. [Google Scholar] [CrossRef]

- Ameri, F.; Shoaei, P.; Zareei, S.A.; Behforouz, B. Geopolymers vs. alkali-activated materials (AAMs): A comparative study on durability, microstructure, and resistance to elevated temperatures of lightweight mortars. Constr. Build. Mater. 2019, 222, 49–63. [Google Scholar] [CrossRef]

- Novais, R.M.; Senff, L.; Carvalheiras, J.; Seabra, M.P.; Pullar, R.C.; Labrincha, J.A. Sustainable and efficient cork—Inorganic polymer composites: An innovative and eco-friendly approach to produce ultra-lightweight and low thermal conductivity materials. Cem. Concr. Compos. 2018, 97, 107–117. [Google Scholar] [CrossRef]

- Rehman, M.U.; Rashid, K.; Zafar, I.; Alqahtani, F.K.; Khan, M.I. Formulation and characterization of geopolymer and conventional lightweight green concrete by incorporating synthetic lightweight aggregate. J. Build. Eng. 2020, 31, 101363. [Google Scholar] [CrossRef]

- Swaminathan, N.; Elangovan, N.S.; Anandan, J. Experimental study on the strength of lightweight geopolymer concrete with eco-friendly material. Gradjevinar 2020, 72, 523–532. [Google Scholar]

- Udvardi, B.; Hamza, A.; Kurovics, E.; Kocserha, I.; Géber, R.; Simon, A. Production of lightweight geopolymer concrete. J. Phys. Conf. Ser. 2020, 1527, 012045. [Google Scholar] [CrossRef]

- Ariffin, M.A.M.; Hussin, M.W.; Bhutta, M.A.R. Mix Design and Compressive Strength of Geopolymer Concrete Containing Blended Ash from Agro-Industrial Wastes. Adv. Mater. Res. 2011, 339, 452–457. [Google Scholar] [CrossRef]

- Mustafa Al Bakria, A.M.; Kamarudin, H.; Bin Hussain, M.; Khairul Nizar, I.; Zarina, Y.; Rafiza, A.R. The effect of curing temperature on physical and chemical properties of geopolymers. Phys. Procedia 2011, 22, 286–291. [Google Scholar] [CrossRef]

- Malkawi, A.B.; Nuruddin, M.F.; Fauzi, A.; Almattarneh, H.; Mohammed, B.S. Effects of Alkaline Solution on Properties of the HCFA Geopolymer Mortars. Procedia Eng. 2016, 148, 710–717. [Google Scholar]

- Posi, P.; Teerachanwit, C.; Tanutong, C.; Limkamoltip, S.; Lertnimoolchai, S.; Sata, V.; Chindaprasirt, P. Lightweight geopolymer concrete containing aggregate from recycle lightweight block. Mater. Des. 2013, 52, 580–586. [Google Scholar] [CrossRef]

- Nematollahi, B.; Sanjayan, J. Effect of different superplasticizers and activator combinations on workability and strength of fly ash based geopolymer. Mater. Des. 2014, 57, 667–672. [Google Scholar] [CrossRef]

- Parthiban, K.; Saravanarajamohan, K.; Shobana, S.; Anchal Bhaskar, A. Effect of replacement of Slag on the mechanical properties of flyash based Geopolymer Concrete. Int. J. Eng. Technol. 2013, 5, 2555–2559. [Google Scholar]

- Pacheco-Torgal, F.; Moura, D.; Ding, Y.; Jalali, S. Composition, strength and workability of alkali-activated metakaolin based mortars. Constr. Build. Mater. 2011, 25, 3732–3745. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Chareerat, T.; Sirivivatnanon, V. Workability and strength of coarse high calcium fly ash geopolymer. Cem. Concr. Compos. 2007, 29, 224–229. [Google Scholar]

- Ghosh, K.; Ghosh, P. Effect of Na2O/Al2O3, SiO2/Al2O3 and w/b ratio on setting time and workability of fly ash based geopolymer. Int. J. Eng. Res. Appl. 2012, 2, 2142–2147. [Google Scholar]

- Cheng, T.-W.; Chiu, J.P. Fire-resistant geopolymer produced by granulated blast furnace slag. Miner. Eng. 2003, 16, 205–210. [Google Scholar] [CrossRef]

- Phoo-Ngernkham, T.; Sata, V.; Hanjitsuwan, S.; Ridtirud, C.; Hatanaka, S.; Chindaprasirt, P. Compressive strength, Bending and Fracture Characteristics of High Calcium Fly Ash Geopolymer Mortar Containing Portland Cement Cured at Ambient Temperature. Arab. J. Sci. Eng. 2016, 41, 1263–1271. [Google Scholar] [CrossRef]

- Saggaff, A.; Mawarni, A. Geopolymer mortar with fly ash. MATEC Web Conf. 2016, 78, 01026. [Google Scholar]

- Rattanasak, U.; Chindaprasirt, P. Influence of NaOH solution on the synthesis of fly ash geopolymer. Miner. Eng. 2009, 22, 1073–1078. [Google Scholar] [CrossRef]

- Huseien, G.F.; Mirza, J.; Ismail, M.; Hussin, M.W. Influence of different curing temperatures and alkali activators on properties of GBFS geopolymer mortars containing fly ash and palm-oil fuel ash. Constr. Build. Mater. 2016, 125, 1229–1240. [Google Scholar] [CrossRef]

- Huseien, G.F.; Mirza, J.; Ismail, M.; Ghoshal, S.; Ariffin, M.A.M. Effect of metakaolin replaced granulated blast furnace slag on fresh and early strength properties of geopolymer mortar. Ain Shams Eng. J. 2018, 9, 1557–1566. [Google Scholar] [CrossRef]

- Hardjito, D.; Cheak, C.C.; Ing, C.H.L. Strength and Setting Times of Low Calcium Fly Ash-based Geopolymer Mortar. Mod. Appl. Sci. 2008, 2, p3. [Google Scholar] [CrossRef]

- Minnu, S.; Bahurudeen, A.; Athira, G. Comparison of sugarcane bagasse ash with fly ash and slag: An approach towards industrial acceptance of sugar industry waste in cleaner production of cement. J. Clean. Prod. 2020, 285, 124836. [Google Scholar] [CrossRef]

- Shi, C.; Day, R.L. Acceleration of strength gain of lime-pozzolan cements by thermal activation. Cem. Concr. Res. 1993, 23, 824–832. [Google Scholar] [CrossRef]

- Somna, K.; Jaturapitakkul, C.; Kajitvichyanukul, P.; Chindaprasirt, P. NaOH-activated ground fly ash geopolymer cured at ambient temperature. Fuel 2011, 90, 2118–2124. [Google Scholar]

- Sindhunata; van Deventer, J.S.J.; Lukey, G.C.; Xu, H. Effect of Curing Temperature and Silicate Concentration on Fly-Ash-Based Geopolymerization. Ind. Eng. Chem. Res. 2006, 45, 3559–3568. [Google Scholar] [CrossRef]

- Huseien, G.F.; Tang, W.; Yu, Y.; Wong, L.S.; Mirza, J.; Dong, K.; Gu, X. Evaluation of high-volume fly-ash cementitious binders incorporating nanosilica as eco-friendly sustainable concrete repair materials. Constr. Build. Mater. 2024, 447, 138022. [Google Scholar]

- Liew, Y.-M.; Heah, C.-Y.; Mohd Mustafa, A.B.; Kamarudin, H. Structure and properties of clay-based geopolymer cements: A review. Prog. Mater. Sci. 2016, 83, 595–629. [Google Scholar] [CrossRef]

- Lee, W.; van Deventer, J. The effect of ionic contaminants on the early-age properties of alkali-activated fly ash-based cements. Cem. Concr. Res. 2002, 32, 577–584. [Google Scholar] [CrossRef]

- Ramachandran, K.S.; Feldman, R. Concrete Admixtures Handbook: Properties, Science, and Technology, 2nd ed.; William Andrew: Norwich, NY, USA, 1996; pp. 1–66. [Google Scholar]

- Kwasny, J.; Sonebi, M.; Plasse, J.; Amziane, S. Influence of rheology on the quality of surface finish of cement-based mortars. Constr. Build. Mater. 2015, 89, 102–109. [Google Scholar] [CrossRef]

- Alonso, M.; Gismera, S.; Blanco, M.; Lanzón, M.; Puertas, F. Alkali-activated mortars: Workability and rheological behaviour. Constr. Build. Mater. 2017, 145, 576–587. [Google Scholar] [CrossRef]

- Thokchom, S.; Mandal, K.K.; Ghosh, S. Effect of Si/Al Ratio on Performance of Fly Ash Geopolymers at Elevated Temperature. Arab. J. Sci. Eng. 2012, 37, 977–989. [Google Scholar] [CrossRef]

- Nuruddin, M.F.; Demie, S.; Shafiq, N. Effect of mix composition on workability and compressive strength of self-compacting geopolymer concrete. Can. J. Civ. Eng. 2011, 38, 1196–1203. [Google Scholar] [CrossRef]

- Huseien, G.F.; Ismail, M.; Khalid, N.H.; Hussin, M.W.; Mirza, J. Compressive strength and micro-structure of assorted wastes incorporated geopolymer mortars: Effect of solution molarity. Alex. Eng. Journal. Fac. Eng. 2018, 57, 3375–3386. [Google Scholar] [CrossRef]

- Koutnik, P.; Soukup, A.; Bezucha, P.; Šafář, J.; Kohout, J. Low viscosity metakaolinite based geopolymer binders. Constr. Build. Mater. 2020, 230, 116978. [Google Scholar] [CrossRef]

- Lee, H.; Kim, H.; Hwang, E. Utilization of power plant bottom ash as aggregates in fiber-reinforced cellular concrete. Waste Manag. 2009, 30, 274–284. [Google Scholar] [CrossRef]

- Singh, M.; Siddique, R. Effect of coal bottom ash as partial replacement of sand on properties of concrete. Resour. Conserv. Recycl. 2013, 72, 20–32. [Google Scholar] [CrossRef]

- Kim, H.; Lee, H. Use of power plant bottom ash as fine and coarse aggregates in high-strength concrete. Constr. Build. Mater. 2011, 25, 1115–1122. [Google Scholar] [CrossRef]

- Hossain, K.; Ahmed, S.; Lachemi, M. Lightweight concrete incorporating pumice based blended cement and aggregate: Mechanical and durability characteristics. Constr. Build. Mater. 2010, 25, 1186–1195. [Google Scholar] [CrossRef]

- Rashad, A.M. A short manual on natural pumice as a lightweight aggregate. J. Build. Eng. 2019, 25, 100802. [Google Scholar] [CrossRef]

- Karami, H.; Teymouri, E.; Mousavi, S.-F.; Farzin, S. Experimental Investigation of the Effect of Adding LECA and Pumice on Some Physical Properties of Porous Concrete. Eng. J. 2018, 22, 205–213. [Google Scholar] [CrossRef]

- Ali, M.; Kumar, A.; Yvaz, A.; Salah, B. Central composite design application in the optimization of the effect of pumice stone on lightweight concrete properties using RSM. Case Stud. Constr. Mater. 2023, 18, e01958. [Google Scholar] [CrossRef]

- Raj, D.M.; Raju, J.N.; Suneel, M. An experimental study on effect of partial replacement of normal weight aggregates with lightweight aggregates in fly ash based geopolymer concrete. Int. Res. J. Eng. Technol. 2018, 5, 1090–1096. [Google Scholar]

- Zhang, H.Y.; Kodur, V.; Wu, B.; Cao, L.; Wang, F. Thermal behavior and mechanical properties of geopolymer mortar after exposure to elevated temperatures. Constr. Build. Mater. 2016, 109, 17–24. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.M.; Palomo, A.; López-Hombrados, C. Engineering properties of alkaliactivated fly ash concrete. ACI Mater. J. 2006, 103, 106–112. [Google Scholar]

- Kabir, S.A.; Alengaram, U.J.; Jumaat, M.Z.; Yusoff, S.; Sharmin, A.; Bashar, I.I. Performance evaluation and some durability characteristics of environmental friendly palm oil clinker based geopolymer concrete. J. Clean. Prod. 2017, 161, 477–492. [Google Scholar] [CrossRef]

- Wongsa, A.; Sata, V.; Nuaklong, P.; Chindaprasirt, P. Use of crushed clay brick and pumice aggregates in lightweight geopolymer concrete. Constr. Build. Mater. 2018, 188, 1025–1034. [Google Scholar] [CrossRef]

- Peng, H.; Cui, C.; Liu, Z.; Cai, C.S.; Liu, Y. Synthesis and Reaction Mechanism of an Alkali-Activated Metakaolin-Slag Composite System at Room Temperature. J. Mater. Civ. Eng. 2019, 31, 04018345. [Google Scholar] [CrossRef]

- Bakharev, T. Geopolymeric materials prepared using Class F fly ash and elevated temperature curing. Cem. Concr. Res. 2005, 35, 1224–1232. [Google Scholar] [CrossRef]

- Pan, Z.; Sanjayan, J.G.; Rangan, B.V. An investigation of the mechanisms for strength gain or loss of geopolymer mortar after exposure to elevated temperature. J. Mater. Sci. 2009, 44, 1873–1880. [Google Scholar] [CrossRef]

- Kuenzel, C.; Grover, L.M.; Vandeperre, L.; Boccaccini, A.R.; Cheeseman, C.R. Production of nepheline/quartz ceramics from geopolymer mortars. J. Eur. Ceram. Soc. 2013, 33, 251–258. [Google Scholar] [CrossRef]

- Ranjbar, N.; Mehrali, M.; Alengaram, U.J.; Metselaar, H.S.C.; Jumaat, M.Z. Compressive strength and microstructural analysis of fly ash/palm oil fuel ash based geopolymer mortar under elevated temperatures. Constr. Build. Mater. 2014, 65, 114–121. [Google Scholar] [CrossRef]

- Hussin, M.W.; Bhutta, M.A.R.; Azreen, M.; Ramadhansyah, P.J.; Mirza, J. Performance of blended ash geopolymer concrete at elevated temperatures. Mater. Struct. 2015, 48, 709–720. [Google Scholar] [CrossRef]

| S/N | Keyword | Occurrences | Total Link Strength |

|---|---|---|---|

| 1 | Geopolymer | 55 | 130 |

| 2 | Lightweight aggregate | 21 | 56 |

| 3 | Fly ash | 16 | 48 |

| 4 | Lightweight geopolymer | 14 | 37 |

| 5 | Compressive strength | 11 | 29 |

| 6 | Lightweight concrete | 11 | 27 |

| 7 | Alkali activation | 10 | 33 |

| 8 | Mechanical properties | 10 | 25 |

| 9 | Thermal conductivity | 9 | 28 |

| 10 | Artificial lightweight aggregate | 8 | 22 |

| 11 | Elevated temperature | 7 | 22 |

| 12 | Microstructure | 7 | 25 |

| 13 | SEM | 5 | 20 |

| 14 | Aggregate | 3 | 6 |

| 15 | Density | 3 | 7 |

| 16 | Durability | 3 | 9 |

| 17 | Expanded perlite | 3 | 10 |

| 18 | Expanded polystyrene | 3 | 11 |

| 19 | Lightweight | 3 | 7 |

| 20 | Metakaolin | 3 | 11 |

| 21 | Strength | 3 | 7 |

| 22 | Sustainability | 3 | 9 |

| 23 | Thermal insulation | 3 | 8 |

| 24 | Aggregate crushing value (acv) | 2 | 7 |

| 25 | Aggregate impact value | 2 | 6 |

| 26 | Composite | 2 | 6 |

| 27 | Construction materials | 2 | 4 |

| 28 | Expanded clay aggregate | 2 | 7 |

| 29 | Foamed concrete | 2 | 6 |

| 30 | Geopolymerization | 2 | 4 |

| 31 | GGBS | 2 | 7 |

| 32 | Glass powder | 2 | 5 |

| 33 | Granulation | 2 | 4 |

| 34 | Inorganic polymer | 2 | 4 |

| 35 | Lightweight mortar | 2 | 7 |

| 36 | Microwave irradiation | 2 | 3 |

| 37 | NaOH | 2 | 4 |

| 38 | Oil palm shell | 2 | 6 |

| 39 | Palletizing | 2 | 7 |

| 40 | Palm oil clinker | 2 | 4 |

| 41 | Palm oil fuel ash | 2 | 6 |

| 42 | Passive fire protection | 2 | 4 |

| 43 | Physical and mechanical properties | 2 | 2 |

| 44 | Physico-mechanical performance | 2 | 4 |

| 45 | Recycled lightweight aggregate | 2 | 4 |

| 46 | Recycling | 2 | 5 |

| 47 | Thermal properties | 2 | 5 |

| 48 | Thermal shrinkage | 2 | 8 |

| 49 | Volcanic ash | 2 | 7 |

| 50 | Water absorption | 2 | 7 |

| 51 | XRD | 2 | 8 |

| 52 | XRF | 2 | 8 |

| Rank | Journal | No. of Publications | No. of Citations | CiteScore (2022) | The Most Cited Article | Times Cited | Publisher |

|---|---|---|---|---|---|---|---|

| 1 | Construction and Building Materials | 22 (21.0%) | 868 | 12.3 | [10] | 162 | Elsevier |

| 2 | Key Engineering Materials | 7 (6.7%) | 6 | 0.9 | [11] | 3 | Trans Tech Publications Ltd. |

| 3 | Advanced Materials Research | 6 (5.7%) | 7 | 45.6 | [12] | 5 | Trans Tech Publications Ltd. |

| 4 | Journal of Building Engineering | 5 (4.8%) | 68 | 8.2 | [13] | 28 | Elsevier |

| 5 | Cement and Concrete Composites | 4 (3.8%) | 164 | 15.4 | [14] | 104 | Elsevier |

| Rank | Author | Scopus Author ID | Year of 1st Publication | Total Publication | h-Index | Total Citation | Current Affiliation and Country |

|---|---|---|---|---|---|---|---|

| 1 | Abdullah, Mohd Mustafa Al Bakri | 53164519100 | 2008 | 8 | 41 | 62 | Universiti Malaysia Perlis, Arau, Malaysia |

| 2 | Hussin, Kamarudin | 16642513600 | 1994 | 7 | 41 | 62 | Universiti Malaysia Perlis, Arau, Malaysia |

| 3 | Abdulkareem, O. A. | 54393305300 | 2011 | 5 | 7 | 184 | Louisiana Tech University, Ruston, LA, USA |

| 4 | Alengaram, U. J. | 26533874300 | 2008 | 5 | 51 | 313 | Universiti Malaya, Kuala Lumpur, Malaysia |

| 5 | Chindaprasirt, Prinya | 8302542200 | 1980 | 5 | 70 | 192 | Khon Kaen University, Khon Kaen, Thailand |

| 6 | Hardjito, Djwantoro | 6508089898 | 1994 | 5 | 14 | 30 | Universitas Kristen Petra, Surabaya, East Java, Indonesia |

| 7 | Ismail, Khairul Nizar | 51161627800 | 2006 | 5 | 24 | 48 | Universiti Malaysia Perlis, Arau, Malaysia |

| 8 | Rashid, Khuram | 56725212400 | 2015 | 5 | 17 | 64 | University of Engineering and Technology, Lahore, Lahore, Pakistan |

| S/N | Organization | Documents | Citations | Total Link Strength |

|---|---|---|---|---|

| 1 | Universiti Malaysia Perlis | 19 | 380 | 8 |

| 2 | University of Malaya | 7 | 602 | 3 |

| 3 | Khon Kaen University | 5 | 301 | 3 |

| 4 | Petra Christian University | 5 | 47 | 6 |

| 5 | University of Engineering and Technology | 5 | 73 | 5 |

| 6 | University of Technology | 5 | 25 | 4 |

| 7 | Curtin University | 4 | 130 | 3 |

| 8 | Islamic Azad University | 4 | 160 | 5 |

| 9 | Middle Technical University | 4 | 23 | 4 |

| 10 | Al Imam Mohammad Ibn Saud Islamic University | 3 | 32 | 5 |

| 11 | Rajamangala University of Technology Isan | 3 | 82 | 3 |

| 12 | Swinburne University of Technology | 3 | 101 | 0 |

| 13 | Universiti Sains Malaysia | 3 | 34 | 4 |

| 14 | University of Aveiro | 3 | 78 | 1 |

| 15 | University of Miskolc | 3 | 30 | 0 |

| 16 | Gaziantep University | 2 | 21 | 0 |

| 17 | Hunan University | 2 | 133 | 1 |

| 18 | Indian Institute of Technology Madras | 2 | 131 | 1 |

| 19 | King Saud University | 2 | 27 | 4 |

| 20 | Gheorghe Asachi Technical University | 2 | 17 | 3 |

| 21 | National Technical University of Athens | 2 | 10 | 1 |

| 22 | Sharif University of Technology | 2 | 79 | 4 |

| 23 | Texas State University | 2 | 44 | 3 |

| 24 | University Of Oulu | 2 | 86 | 1 |

| 25 | Bundesanstalt für Materialforschung | 2 | 35 | 2 |

| S/N | Country | Documents | Citations | Total Link Strength |

|---|---|---|---|---|

| 1 | Malaysia | 31 | 1016 | 22 |

| 2 | Australia | 11 | 412 | 11 |

| 3 | Indonesia | 9 | 61 | 13 |

| 4 | Iraq | 8 | 40 | 2 |

| 5 | China | 7 | 311 | 2 |

| 6 | Saudi Arabia | 6 | 79 | 9 |

| 7 | Thailand | 6 | 301 | 1 |

| 8 | Turkey | 6 | 114 | 5 |

| 9 | India | 5 | 164 | 5 |

| 10 | Pakistan | 5 | 73 | 4 |

| 11 | Iran | 4 | 160 | 4 |

| 12 | Portugal | 4 | 145 | 3 |

| 13 | United States | 4 | 114 | 3 |

| 14 | Finland | 3 | 86 | 2 |

| 15 | Germany | 3 | 35 | 3 |

| 16 | Hungary | 3 | 30 | 0 |

| 17 | Italy | 3 | 227 | 1 |

| 18 | Romania | 3 | 20 | 7 |

| 19 | Brazil | 2 | 29 | 1 |

| 20 | Czech Republic | 2 | 3 | 0 |

| 21 | Greece | 2 | 10 | 1 |

| 22 | United Kingdom | 2 | 185 | 2 |

| 23 | Belgium | 1 | 0 | 1 |

| 24 | Bulgaria | 1 | 0 | 0 |

| 25 | Egypt | 1 | 8 | 1 |

| 26 | France | 1 | 25 | 0 |

| 27 | Hong Kong | 1 | 32 | 0 |

| 28 | Jordan | 1 | 11 | 0 |

| 29 | Mexico | 1 | 158 | 0 |

| 30 | Netherlands | 1 | 39 | 1 |

| 31 | Nigeria | 1 | 18 | 4 |

| 32 | Poland | 1 | 4 | 0 |

| 33 | South Korea | 1 | 5 | 2 |

| 34 | Taiwan | 1 | 21 | 0 |

| 35 | Tunisia | 1 | 18 | 4 |

| 36 | United Arab Emirates | 1 | 53 | 0 |

| Binding Materials | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | K2O | Na2O | SO3 | LOI |

|---|---|---|---|---|---|---|---|---|---|

| GGBFS [28] | 43.23 | 32.19 | 12.53 | 0.43 | 5.69 | 0.29 | 0.26 | 4.02 | 0.39 |

| MK [14] | 0.17 | 52.90 | 41.90 | 1.60 | 0.19 | 0.77 | - | - | - |

| RHA [27] | 0.41 | 91.15 | 0.41 | 0.21 | 0.45 | 6.25 | 0.05 | 0.62 | 0.45 |

| Chemical Composition | Class C | Class F |

|---|---|---|

| SiO2 + Al2O3 + Fe2O3 (minimum %) | 50.00 | 70.00 |

| SO3 (maximum %) | 5.00 | 5.00 |

| LOI (maximum %) | 6.00 | 6.00 |

| Moisture content (maximum %) | 3.00 | 3.00 |

| Oxides (%) | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | K2O | Na2O | SO3 | LOI |

|---|---|---|---|---|---|---|---|---|---|

| [64] | 20.42 | 32.47 | 14.92 | 16.50 | 7.95 | 1.32 | 2.92 | 1.88 | 0.43 |

| [65] | 27.39 | 38.71 | 16.46 | 6.21 | 1.34 | 1.55 | 0.22 | 3.30 | 10.17 |

| [66] | 15.10 | 46.38 | 13.90 | 8.26 | 6.68 | 2.78 | 2.13 | 4.26 | 0.22 |

| [67] | 36.56 | 31.94 | 13.50 | 4.09 | 1.42 | 0.94 | 1.10 | 3.86 | 2.99 |

| [68] | 15.10 | 46.38 | 13.90 | 8.26 | 6.68 | 2.78 | 2.13 | 4.26 | 0.22 |

| [69] | 12.15 | 45.69 | 24.59 | 11.26 | 2.87 | 2.66 | 0.07 | 1.57 | 1.23 |

| [70] | 15.50 | 45.23 | 19.95 | 13.15 | 2.02 | 2.15 | 0.52 | 0.30 | 0.88 |

| [71] | 14.50 | 39.4 | 20.80 | 11.50 | 2.20 | 2.40 | - | 4.20 | 1.50 |

| Refs. | Class C | Class F | SiO2 | Al2O3 | Fe2O3 |

|---|---|---|---|---|---|

| [73] | ✔ | 59.56 | 29.33 | 3.36 | |

| [74] | ✔ | 35.70 | 15.40 | 19.91 | |

| [75] | ✔ | 52.30 | 25.90 | 10.52 | |

| [19] | ✔ | - | - | - | |

| [76] | ✔ | 34.60 | 10.30 | 0.73 | |

| [77] | ✔ | - | - | - | |

| [78] | ✔ | 32.10 | 19.90 | 16.91 | |

| [79] | ✔ | 58.30 | 22.50 | 8.00 | |

| [80] | ✔ | 53.71 | 27.20 | 11.17 | |

| [81] | ✔ | - | - | - | |

| [82] | ✔ | - | - | - | |

| [83] | ✔ | 62.20 | 27.50 | 3.92 | |

| [84] | ✔ | 53.36 | 26.49 | 10.86 | |

| [85] | ✔ | - | - | - | |

| [86] | ✔ | 45.23 | 19.95 | 13.15 | |

| [87] | ✔ | 59.56 | 29.33 | 3.36 | |

| [88] | ✔ | 59.56 | 29.33 | 3.36 | |

| [89] | ✔ | 48.80 | 27.00 | 10.20 | |

| [90] | ✔ | 57.60 | 28.90 | 5.80 | |

| [72] | ✔ | - | - | - | |

| [91] | ✔ | - | - | - | |

| [92] | ✔ | 52.30 | 25.90 | 10.52 | |

| [93] | ✔ | 32.62 | 31.23 | 8.48 | |

| [94] | ✔ | - | - | - | |

| [95] | ✔ | 50.50 | 26.57 | 13.77 | |

| [28] | ✔ | 56.74 | 24.89 | 6.87 | |

| [70] | ✔ | 45.23 | 19.94 | 13.15 | |

| [52] | ✔ | 58.25 | 25.10 | 4.60 | |

| [96] | ✔ | - | - | - | |

| [97] | ✔ | 56.34 | 23.08 | 1.70 | |

| [98] | ✔ | 55.30 | 25.80 | 5.50 | |

| [99] | ✔ | 55.20 | 24.10 | 5.50 | |

| [71] | ✔ | 39.40 | 20.80 | 11.50 | |

| [100] | ✔ | 62.34 | 21.13 | 7.16 |

| Chemical Composition | SiO2 | Al2O3 | Fe2O3 | K2O | MgO | CaO | Na2O | P2O5 | SO3 | SrO | TiO2 | MnO | LOI |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Acidic pumice [99] | 69.70 | 13.64 | 2.34 | 4.07 | - | 3.15 | 0.40 | - | 0.07 | 0.03 | 0.15 | - | 3.65 |

| Expanded perlite [99] | 75.16 | 14.50 | 1.04 | 5.98 | - | 1.01 | - | - | - | 0.03 | 0.14 | - | 1.35 |

| Expanded perlite [28] | 74.93 | 12.88 | 0.70 | 4.42 | 0.04 | 0.70 | 3.85 | 0.01 | 0.02 | - | 0.07 | 0.07 | 2.06 |

| Coconut shell [129] | 20.70 | 5.75 | 2.5 | 0.15 | 1.89 | 63.11 | 0.60 | 0.05 | 2.75 | - | - | 0.20 | 2.30 |

| Bottom ash [71] | 31.80 | 12.10 | 18.00 | 2.50 | 2.40 | 25.30 | - | 0.30 | 3.70 | - | 0.50 | - | 3.20 |

| Expanded vermiculite [103] | 41.00 | 10.00 | 9.50 | 7.00 | 24.00 | 5.00 | - | - | - | - | 1.50 | - | - |

| Physical Properties | Specific Gravity | Water Absorption (%) | Bulk Density (kg/m3) | Dry Density (kg/m3) | Fineness Modulus | Porosity (%) |

|---|---|---|---|---|---|---|

| Palm oil clinker [79] | 1.92 | 3.30 | - | - | 3.52 | - |

| Palm oil clinker [102] | 1.87 | 14.65 (24h) | - | 1096 | - | - |

| Coconut shell [129] | 1.15 | 10.02 | 695 | - | 6.11 | 38 |

| Artificial aggregates [87] | 1.63 | 11.50 | - | 773 | - | - |

| Artificial aggregates [73] | 1.63 | 11.50 | - | 769 | - | - |

| Recycled lightweight concrete aggregates [70] | 1.42 | 76.00 | 360 | - | 5.75 | - |

| Bottom ash [71] | 2.47 | 3.32 | 1116 | - | 6.00 | - |

| Composition | SiO2 | Al2O3 | Fe2O3 | K2O | MgO | CaO | Na2O | P2O5 | SO3 | SrO | TiO2 | MnO | Others | LOI |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [105] | 62 | 18 | 7 | 4 | 3 | 3 | 2 | 1.36 | ||||||

| [106] | 66.05 | 16.57 | 7.1 | 2.69 | 1.99 | 2.46 | 0.69 | 0.21 | 0.03 | 0.84 | ||||

| [57] | 58 | 27 | 1 | 2.3 | 0.4 | 0.2 | 0.3 | 1.3 | ||||||

| [107] | 53.3 | 16.6 | 6.2 | 2.8 | 2 | |||||||||

| [108] | 61.67 | 18.51 | 6.14 | 3.18 | 3.97 | 3.5 | 1.54 | 0.19 | 0.23 | 0.13 | 0.65 | |||

| [109] | 61.05 | 15.74 | 6.1 | 2.67 | 2.52 | 3.92 | 5.62 | 0.21 | 0.03 | 0.84 | 0.75 | |||

| [4] | 66.05 | 16.57 | 7.1 | 2.69 | 1.99 | 2.46 | 0.69 | |||||||

| [110] | 66.2 | 16 | 6.4 | 4 | 1.8 | 1.8 | 0.1 | 2.7 | 0.1 | |||||

| [111] | 60.1 | 17.7 | 7.85 | 4 | 2.95 | 2.1 | 1.75 | 0.2 | 0.55 | 0.9 | 0.1 | 1.8 | ||

| [112] | 64.83 | 15.05 | 7.45 | 2.55 | 3.67 | 2.98 | 1.1 | 0.13 | 0.63 | 0.13 | 1.37 |

| Properties | Specific Gravity | Water Absorption (%) | Bulk Density (kg/m3) | Dry Density (kg/m3) | Fineness Modulus | Porosity (%) |

|---|---|---|---|---|---|---|

| [113] | - | 24.1 (24 h) | 279 | 503 | - | - |

| [105] | - | - | 750 | 1600 | - | - |

| [114] | 1.23 | 40 (4 h) | 650 | 600 | - | - |

| [115] | - | 15.8 (24 h) | 624 | 1076 | - | 40.7 (24 h) |

| [116] | - | 12.3 (24 h) | 613 | 1068 | - | 60 total |

| [117] | - | 12.3 (24 h) | 613 | 1068 | - | 60 total |

| [118] | - | 26.2 | 358 | - | 5.77 | - |

| [119] | - | 23.2 (24 h) | 681 | 1092 | - | - |

| [120] | - | - | 562 | 1060 | - | 59 total |

| [121] | 2.65 | - | 1442 | - | 7.16 | - |

| [6] | 0.80 | 27 (24 h) | - | - | - | - |

| [122] | 0.44 | 10 | 357 | - | 5.99 | - |

| [123] | 0.66 | 26.5 (24 h) | 273 | - | 5.96 | - |

| [52] | 2.1 | - | 560 | - | - | - |

| Previous Research and Studies | FA/AAS Ratio | Na2SiO3/NaOH Ratio |

|---|---|---|

| [77] | 2.22–3.33 | - |

| [72] | 2.83 | 2.50 |

| [96] | 2.83 | 2.50 |

| [84] | 2.83 | 2.50 |

| [95] | 2.50–3.33 | 1.50–2.50 |

| [98] | 2.00 | 1.00 |

| [132] | 2.00 | 2.50 |

| [133] | 1.81 | 1.00–2.50 |

| [134] | 2.00–2.80 | 1.00–3.00 |

| Refs. | Lightweight Aggregates | Age, Day | Compressive Strength, MPa |

|---|---|---|---|

| [86] | Porous glass | 28 | 10 |

| [99] | Expanded perlite | 28 | 50 |

| [28] | Expanded perlite | 28 | 1.38 |

| [79] | Palm oil clinker | 28 | 53 |

| [129] | Coconut shell | 28 | 40.4 |

| [73] | Artificial aggregates | 28 | 35.8 |

| [70] | Recycled lightweight concrete aggregates | 28 | 17.5 |

| [71] | Bottom ash | 28 | 18.1 |

| [103] | Expanded vermiculite | 28 | 2.0 |

| [52] | LECA | 28 | 48 |

| [75] | LECA | 28 | 60.4 |

| [168] | LECA | 28 | 23.53 |

| Refs | Mean Compressive Strength, MPa | Age, Day | Modulus of Elasticity, GPa |

|---|---|---|---|

| [84] | 89 | 90 | 30.8 |

| [84] | 68 | 90 | 27.3 |

| [84] | 55 | 90 | 26.1 |

| [84] | 44 | 90 | 23.0 |

| [95] | 57 | 91 | 27.2 |

| [95] | 59 | 91 | 28.0 |

| [95] | 63 | 91 | 26.8 |

| [170] | 60 | 28 | 18.4 |

| [170] | 55 | 28 | 11.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, S.Q.; Lim, N.H.A.S.; Saleh, A.T.; Wei, K.E.L.; Samadi, M.; Huseien, G.F. A Bibliometric Review of Lightweight Aggregate Geopolymer Concrete. CivilEng 2024, 5, 892-927. https://doi.org/10.3390/civileng5040046

Tan SQ, Lim NHAS, Saleh AT, Wei KEL, Samadi M, Huseien GF. A Bibliometric Review of Lightweight Aggregate Geopolymer Concrete. CivilEng. 2024; 5(4):892-927. https://doi.org/10.3390/civileng5040046

Chicago/Turabian StyleTan, Shea Qin, Nor Hasanah Abdul Shukor Lim, Ali Taha Saleh, Kenneth Ee Li Wei, Mostafa Samadi, and Ghasan Fahim Huseien. 2024. "A Bibliometric Review of Lightweight Aggregate Geopolymer Concrete" CivilEng 5, no. 4: 892-927. https://doi.org/10.3390/civileng5040046

APA StyleTan, S. Q., Lim, N. H. A. S., Saleh, A. T., Wei, K. E. L., Samadi, M., & Huseien, G. F. (2024). A Bibliometric Review of Lightweight Aggregate Geopolymer Concrete. CivilEng, 5(4), 892-927. https://doi.org/10.3390/civileng5040046