Abstract

Geopolymer materials, alternatives to cement that are synthesized using industrial byproducts, have emerged as some of the leading champion materials due to their environmentally friendly attributes. They can significantly reduce pollution by utilizing a plethora of waste products and conserving natural resources that would otherwise be used in the production of conventional cement. Much work is being carried out to study geopolymers’ characteristics under different conditions. Here, a geopolymer derived from fly ash (FA) was synthesized using a combination of sodium silicate and potassium hydroxide (KOH) (2.5:1 ratio) as an alkali activator (AA) liquid. The FA/AA ratios were optimized, resulting in distinct geopolymer samples with ratios of 1.00, 1.25, 1.50, and 1.75. By adjusting the contribution of alkaline liquid, we investigated the impacts of subtle changes in the FA/AA ratio on the morphology and microstructure using X-ray diffraction (XRD) and field emission scanning electron microscopy (FESEM) techniques. The FESEM analysis illustrated a mixed matrix and morphology, with the sample with a ratio of 1.00 displaying consistently fused and homogenous morphology. The XRD results revealed the prevalent amorphous nature of geopolymer with a few crystalline phases of quartz, sodalite, hematite, and mullite. An electrical study confirmed the insulating nature of the geopolymer samples. Insulating geopolymers can provide energy-efficient buildings and resistance to fire, hurricanes, and tornadoes. Additionally, using KOH as a part of the alkali activator introduced a less-explored aspect compared to conventional sodium hydroxide-based activators, highlighting the novelty in the synthesis process.

1. Introduction

The cement industry significantly contributes to pollution and carbon dioxide emissions, and its resource-intensive nature raises sustainability concerns. Researchers are increasingly concerned about the environmental impact of traditional binders such as lime and cement, leading to a focus on replacement materials or eco-friendly alternatives such as alkali-activated materials to reduce energy consumption and carbon emissions while also mitigating waste disposal issues [1].

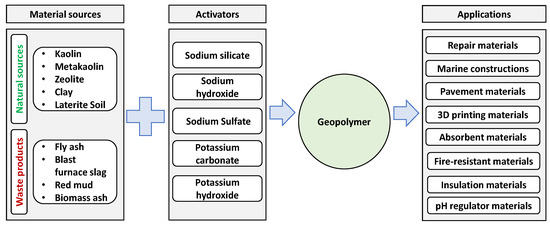

One promising approach for replacement is the use of ceramic waste powder as a partial replacement for sustainable cement. By repurposing ceramic waste that would otherwise pollute water, air, and soil, environmental impact can be reduced [2]. Waste paper sludge ash can also be used with concrete as a partial replacement material [3,4]. Eco-friendly alternatives include alkali-activated materials, known as geopolymers, which belong to a distinct category of inorganic cement-free substances. They combine latent hydraulic materials (such as metakaolin, slag, and fly ash) with an appropriate alkali activator [5]. These activator liquids typically contain sodium and potassium compounds and soluble alkali metals, particularly silicates or hydroxides [6]. The outcome of the activation process is the formation of hydraulic binders that, when mixed with water, can be utilized to create geopolymer binders that exhibit excellent properties, such as temperature resistance [7], durability [8], and mechanical strength [9]. Geopolymers’ usage presents undeniable economic and ecological advantages, as they use secondary raw materials—notably, substantial quantities of byproducts originating from the energy and metallurgical sectors. Since the dawn of the 1980s, geopolymer materials have been recognized as viable substitutes for ordinary Portland cement (OPC), driven primarily by their capacity to lower carbon dioxide emissions and offer superior performance [10]. Furthermore, they find general applications in various fields such as repair materials [11], marine construction [12], and pavement base materials [13]. Functional applications of geopolymers include insulation materials [14], high-temperature and fire-resistant materials [15], adsorbent materials [16], pH regulator materials [17], catalysts [18], and electrical materials [19]. The details of the material sources, activators, and diverse applications of geopolymers are shown in Figure 1.

Figure 1.

Raw material sources, activators, and diverse applications of geopolymers.

Recently, there has been a worldwide call for sustainable development, emphasizing the imperative to minimize our reliance on natural resources. As modernization advances, the release of harmful solid industrial waste, encompassing materials such as red mud (RM), slag, and fly ash (FA), along with concerns about pollution from dyes, heavy metals, and pharmaceuticals, has become a focal point of public apprehension [20]. Fly ash (FA), a byproduct resulting from the combustion process in coal plants, is rich in alumina and silica and is typically disposed of in landfills or ash ponds [21]. The leaching of harmful substances from fly ash into water or soil and the emission of particles into the air present significant environmental hazards. Therefore, utilizing fly ash as an alumino-silicate precursor for geopolymers offers a safe and beneficial approach to managing this hazardous solid waste [22]. Castillo et al. discussed how calcium content in fly ash affects the geopolymerization process, with the impact varying based on the solution’s alkalinity. Their findings indicate that low alkalinity conditions with moderate calcium levels produce high compressive strength, while high alkalinity leads to lower strength. The presence of small amounts of calcium is advantageous, as it forms beneficial C-A-S-H and N-A-S-H gels, but excessive calcium content can negatively impact the compressive strength of geopolymers. Therefore, Class F fly ash (low calcium content) is more suitable for highly alkaline environments [23]. The preparation of geopolymer binders is conducted at normal or slightly elevated temperatures, eliminating the need for high-temperature firing of raw materials (as in the case of Portland clinker) or consolidation through sintering (which generates CO2 from combustion processes). Geopolymer binders are formulated at ambient or slightly elevated temperatures, eliminating the need to subject raw materials to high-temperature firing (commonly seen in manufacturing Portland clinker), and they are blended through sintering, generating CO2 emissions through combustion processes.

Moreover, alkali-activated materials offer the advantage of accommodating a wide range of non-standard fillers in concrete production [24]. Nevertheless, these materials have seldom been found to have an application in electronics. Due to their sinter-free characteristics, uncomplicated fabrication process, and cost-effectiveness, geopolymers hold promising potential for diverse electronic applications.

Recently, a vast number of studies have been carried out on geopolymer binders; however, most of these studies have investigated mostly sodium-/NaOH-based geopolymers for their durability, compressive strength, and mechanical strength [11,25,26]. Lee et al. studied the setting time and mechanical properties of NaOH-activated fly ash/slag-based geopolymer [20]. Barreto et al. studied the mechanical properties of geopolymer synthesized with KOH using kaolinitic clays [9]. Majidi et al. studied the mechanical performance of geopolymer mortar developed using ground granulated blast furnace slag and fly ash mixed with potassium silicate [27]. Researchers are looking into using microporous materials such as zeolite to enhance ionic conductivity by moving extra framework cations and studying their electrical properties for potential applications [28]. Geopolymers, with a molecular structure closely resembling zeolite, have emerged as a strong candidate for electrical applications. Thus, the rapid expansion of knowledge has led to numerous modification methods to enhance the properties and performance of fly ash geopolymers substantially.

Geopolymer binders, as aluminosilicate materials, typically exhibit high electrical insulating properties. However, the inclusion of alkali cations and water within the matrix porosities tends to enhance their electrical conductivity [29]. A limited number of studies have been conducted on the electrical properties of geopolymers as a construction material. To the best of the knowledge of the authors, a few studies have been conducted by Malkawi et al., Zeng et al., Jumrat et al., and Hanjitsuwan et al. focused on the electrical properties of sodium-based alkali geopolymer [30,31,32,33]. Table 1 identifies various properties investigated for geopolymers synthesized from different types of precursors and alkaline media. By scanning through the existing literature, it can be inferred that there is a gap in studies regarding KOH-based geopolymers, and so far, the literature reporting electrical studies of KOH-based geopolymers is very scarce.

Table 1.

Literature review of the types of precursors and alkaline media for the synthesis of geopolymers and their properties.

In summary, this investigation involved formulating a range of geopolymers based on fly ash (FA), incorporating different proportions of fly ash/alkaline activator (FA/AA). The synthesis utilized a sodium silicate and potassium hydroxide alkali activator in a fixed ratio of 2.5:1. The primary objective of this research was to thoroughly explore the influences of different FA/AA ratios on the microstructure, morphology, dielectric properties, and electrical properties of geopolymers. Characterization involved various techniques, including FESEM and XRD. The dielectric and electrical characteristics were methodically investigated over a frequency spectrum from 20 Hz to 1 MHz.

2. Materials and Methods

2.1. Materials

Low-calcium-content Class F fly ash (Figure 2, SiO2 = 40.5%, Al2O3 = 31.1%, and CaO = 1.06%) was procured from NTPC (National Thermal Power Corporation Limited), Uttar Pradesh, India. Oxide components found in fly ash were analyzed through XRF, and the results are presented in Table 2. Analytical-grade sodium silicate (Na2SiO3) solution (SiO2: 70.5–72.5%, Na2O: 27.5–29.5%) and KOH with 99% purity were utilized for alkali activation.

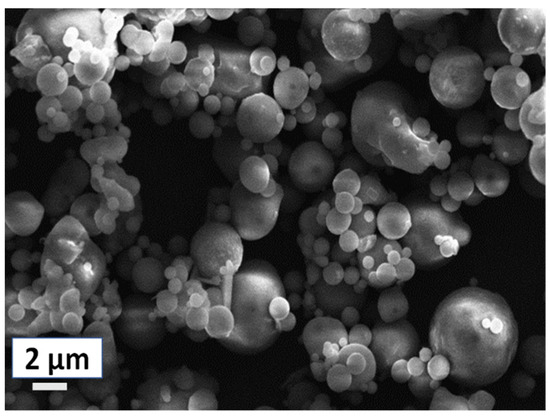

Figure 2.

Surface morphology of fly ash.

Table 2.

Chemical composition of Class F fly ash according to X-ray fluorescence.

2.2. Preparation of Geopolymers

KOH (12 M) solution was formulated by dissolving potassium hydroxide pellets in deionized water as part of the preparation process. The Na2SiO3 and KOH activator solution was allowed to sit for no less than 24 h before use to establish thorough blending and homogeneity before being stocked at ambient temperature for further utilization. The activator solution (Na2SiO3 to KOH) ratio was maintained at 2.5. The fly ash and alkali activator solution quantities were varied in a range from 1 to 1.75 during preparation to realize the effects of minute changes on geopolymerization and the associated properties. The necessary amount of water was added to achieve the desired workability of the samples. Table 3 provides specific details regarding the proportions of the geopolymer mixtures. The synthesized geopolymer samples are G1, G2, G3, and G4.

Table 3.

Mixture proportions of the geopolymers.

2.3. Characterization

Fly ash underwent X-ray fluorescence (XRF) spectroscopy analysis using a Rigaku ZSX Primus instrument to identify chemical composition. The chemical composition of the fly ash underwent analysis. The instrument covered elemental analysis from 4Be through 92U and featured a 3 kW Rh-anode X-ray tube, a spectrometer with 48 positions, and a standard sample changer, all housed in a vacuum environment. Analysis of fly ash and geopolymer samples was conducted with a Rigaku-Ultima IV powder X-ray diffractometer. The instrument was outfitted with a variable receiving slit option (Maximum 20 mm width), was sealed from 20 to 60 kV, and had a CuKα X-ray tube. Analysis was performed in a 2-theta range from 5° to 70° with a maximum sample rotation speed set to 120 rpm. FESEM was conducted with a TESCAN MAGNA analytical tool outfitted with an energy-dispersive X-ray spectrometer to investigate the microstructure and morphology of the fly ash and geopolymer samples. Before examination, the samples underwent gold coating using a sputter coater machine. Conductivity, relative permittivity, and dissipation factor measurements were conducted in a frequency range from 20 Hz to 1 MHz at ambient temperature (25 °C). The analysis used a Wayne Kerr-6540A Impedance/Grain phase analyzer with an oscillation voltage set to 1 V.

3. Results

3.1. Microstructure Analysis through Scanning Electron Microscopy

The morphology of the fly ash and geopolymer samples was elucidated with SEM images (Figure 2 and Figure 3). Figure 2 reveals spherical fly ash particles of varying sizes, spanning from 1 μm to 6 μm. Fly ash is derived from coal in an aluminum–silicon/silicon matrix from a combustion process, as is evident from the smooth spheres of fly ash.

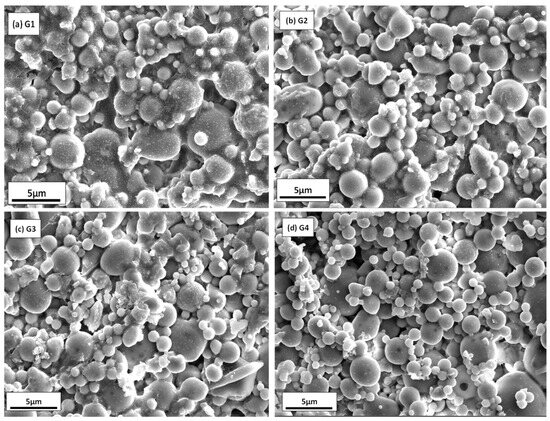

Figure 3.

SEM images of fly ash KOH-based geopolymers prepared with different ratios of FA/AA: (a) 1.00 (G1), (b) 1.25 (G2), (c) 1.50 (G3), and (d) 1.75 (G4).

The SEM images illustrating fly ash KOH-based geopolymer in Figure 3a–d demonstrate the reactions and dissolution of fly ash particles due to alkali activation in the aluminosilicate matrix. Aluminum and silicon are released, forming a uniform polymeric matrix. Despite dissolution in an alkaline medium, a few non-reacted fly ash particles are visible on the geopolymer surface, lacking full coverage by the gel. In Figure 3a, sample G1 (FA/AA = 1.00) exhibits dense spherical fly ash particles that are integrated and fused with an alkaline activator, contrasting with the G2, G3, and G4 samples (Figure 3b–d). As the FA/AA ratio increases from 1.25 to 1.75, more fly ash particles are visible in the matrix. This is attributed to an insufficient alkaline solution volume, hindering the complete polymerization of fly ash and impeding aluminosilicate geopolymer gel formation. The low alkali activator content leads to visible unreacted fly ash particles in the geopolymer samples (Figure 3b–d).

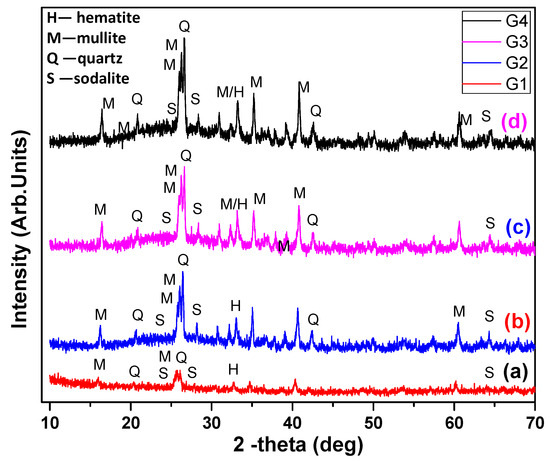

Geopolymer sample G1, exhibiting denser morphology than that of samples G2, G3, and G4, demonstrates a marked reduction in XRD pattern intensity (Figure 4 and Figure 5) relative to that of raw fly ash. Specifically, the intensity of sample G1 significantly decreases to 400 from the fly ash baseline of 3000. In contrast, samples G2, G3, and G4 display comparable intensities (1100, 1100, and 1400, respectively), all of which are still lower than that of fly ash. Despite G2, G3, and G4 possessing similar morphologies, which differ from that of raw fly ash, they indicate partial alkali activation. This observation suggests that the alkaline medium has more effectively activated sample G1 compared to the other samples [19]. In conclusion, the data indicate that sample G1, with an FA/AA ratio of 1.00, exhibits a dense morphology with a uniformly formed gel matrix, rendering it more suitable for comprehensive geopolymerization than the other samples.

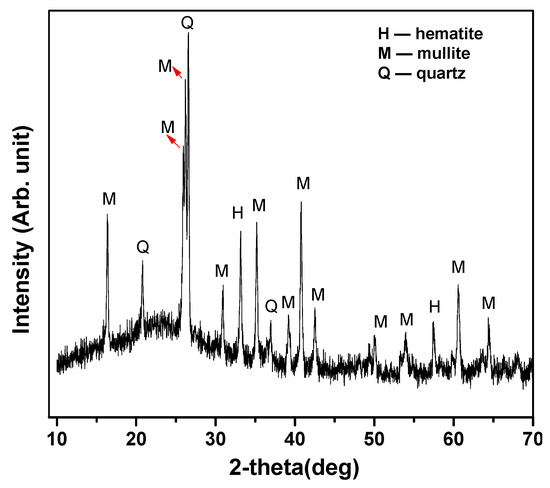

Figure 4.

XRD spectra of fly ash.

Figure 5.

XRD spectra of the fly ash KOH-based geopolymers prepared with different ratios of FA/AA: (a) 1.00 (G1), (b) 1.25 (G2), (c) 1.50 (G3), and (d) 1.75 (G4).

3.2. XRD Fly Ash and G1–4

Figure 4 and Figure 5 showcase the patterns of X-ray diffraction (XRD) for the fly ash and KOH-based geopolymers. Analysis of the fly ash XRD pattern reveals the predominant crystalline phases to be mullite (JCPDS# 01-074-4143) and quartz (SiO2) (JCPDS# 01-074-1811). Also, the aluminosilicate glassy phase (mullite, Al4.44Si1.56O9.78) is primarily attributed to the swift cooling process at elevated temperatures. In addition to crystalline phases in fly ash, the XRD pattern indicates other crystalline phases, including hematite (Fe2O3) (JCPDS #01-071-5088). In the 2-theta range of 10°–40°, a broad hump is noticeable, suggesting the presence of amorphous phases in fly ash, which constitute over 50% of the total mass. The labels H, Q, and M represent the crystalline phases of hematite, quartz, and mullite, respectively.

It is evident in the XRD analysis of the geopolymers (Figure 5) prepared at various FA/AA ratios that the predominant amorphous nature is retained, featuring crystalline peaks in the diffraction patterns; these can be ascribed to the raw material (fly ash). Notably, substantial differences are observed in the patterns of XRD between fly ash and geopolymer samples. The small hump in the 2-theta range of ~15°–~30° significantly decreased from the geopolymer samples G1–4 compared to the fly ash XRD spectra, indicating the formation of aluminosilicate gel and, hence, geopolymerization. Moreover, for geopolymer sample G1, the hump is almost flattened, suggesting the good activation of fly ash by an alkaline activator. Similar observations were made by Das et al. [36].

In Figure 5, the geopolymers display crystalline phases that were identified as quartz, sodalite (JCPDS# 04-014-6611), hematite, and mullite, and each is appropriately labeled. Notably, the sodalite phase in the XRD pattern is a product of the geopolymerization process due to the inclusion of sodium silicate. At the same time, mullite and quartz are derived from residual unprocessed fly ash. Following the activation of geopolymerization by the alkaline activator, noticeable alterations occur in the XRD pattern of fly ash (Class F). This is evident in the decrease in intensity observed in the diffractogram of geopolymer samples compared to fly ash, as depicted in Figure 4 and Figure 5. Das et al. reported comparable findings for geopolymers, where the peak intensity in the XRD pattern decreased as a result of geopolymerization processes [36].

3.3. Electrical Properties

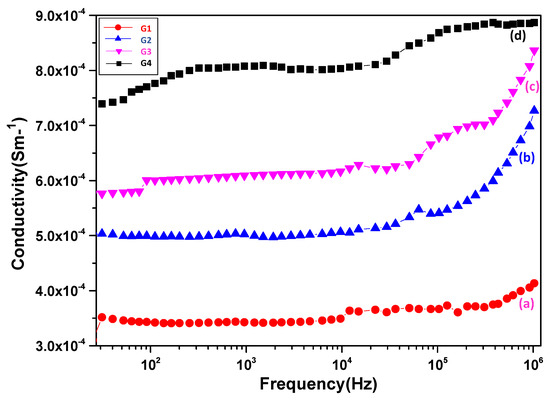

The variation in electrical conductivity for fly ash KOH-based geopolymer at different ratios of fly ash to alkaline activator (FA/AA) with frequency is depicted in Figure 6. The conductivity values exhibit a rising pattern with increasing frequency. Notably, within the frequency range of 101–103 Hz, the rate of the increment in conductivity is somewhat less evident than that in the range of 104–106 Hz. Remarkably, the geopolymer with a ratio of FA/AA equal to 1.75 showcases superior electrical conductivity at higher frequencies in contrast to the other geopolymer samples with varying ratios of FA/AA. In contrast, conductivity regularly maintains diminished values at an FA/AA ratio of 1.00, approaching zero within the examined frequency range (101–106 Hz). Therefore, it can be inferred that the fly ash KOH-based geopolymer with a ratio of FA/AA of 1.00, distinguished by a matrix exhibiting remarkable uniformity, produces reduced values of conductivity when evaluated against samples of geopolymers with FA/AA ratios of 1.25, 1.50, and 1.75.

Figure 6.

Conductivity versus frequency plot of geopolymers prepared with different ratios of FA/AA: (a) 1.00 (G1), (b) 1.25 (G2), (c) 1.50 (G3), and (d) 1.75 (G4).

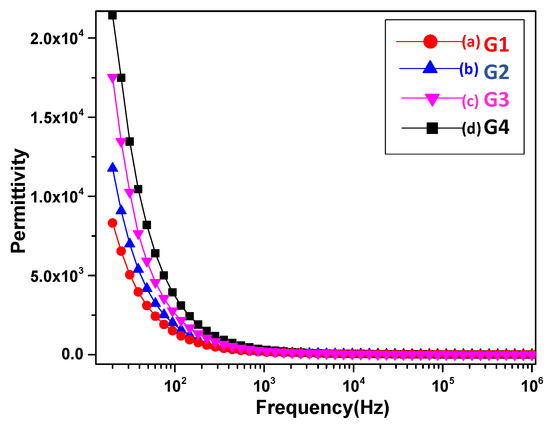

As the frequency escalates within the investigated range of 101–106 Hz, the conductivity ascends, whereas the permittivity (dielectric constant) diminishes, approaching a plateau. Figure 7 illustrates the correlation between permittivity (dielectric constant) and frequency in the geopolymer samples prepared at different ratios of FA/AA.

Figure 7.

Plot of the permittivity/dielectric constant versus frequency of geopolymers prepared with different ratios of FA/AA: (a) 1.00 (G1), (b) 1.25 (G2), (c) 1.50 (G3), and (d) 1.75 (G4).

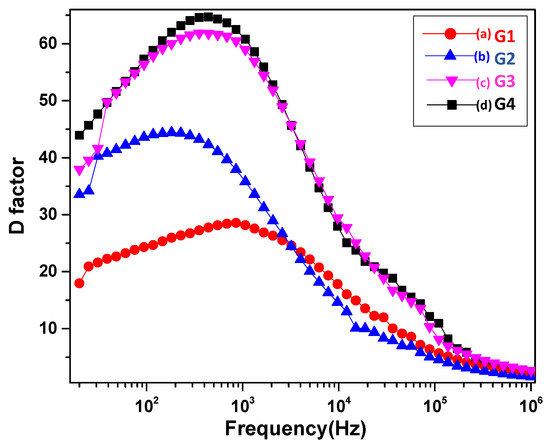

Figure 8 depicts the variation in the D factor (tangent loss) versus frequency for fly ash KOH-based geopolymer with different ratios of FA/AA. The D factor plots for all samples exhibit noticeable peak formations, which can be attributed to the reorientation of dipoles within the geopolymer matrix in the applied frequency range. Pradhan et al. reported similar peak formations for tangent loss owing to relaxing dipoles [37]. Moreover, the D factor is related to the relative permittivity. As seen in Figure 7 and Figure 8, samples exhibiting higher permittivity also showcased increased tangent loss (D factor). Hanjitsuwan et al. observed similar results in which geopolymer samples with high dielectric constants also displayed high tangent loss [35].

Figure 8.

Plot of the D factor versus frequency of fly ash KOH-based geopolymers prepared with different ratios of FA/AA: (a) 1.00 (G1), (b) 1.25 (G2), (c) 1.50 (G3), and (d) 1.75 (G4).

More explicitly, geopolymer sample G4, featuring an FA/AA ratio of 1.75, displays higher relative permittivity (dielectric constant) along with an increased tangent loss (D factor). In contrast, geopolymer sample G1, with a ratio of FA/AA of 1.00, marked by the lowest relative permittivity, shows the least pronounced peak in the D factor (tangent loss) within the examined frequency range. To summarize, all parameters (tangent loss, dielectric constant, and electrical conductivity) of the fly ash KOH-based geopolymer samples are influenced by both the FA/AA ratios and the frequency range, as evidenced by the findings of this study. In conclusion, the geopolymer sample G1, with a ratio of FA/AA of 1.00, demonstrates the least conductive properties/superior insulating properties in contrast to the geopolymers with other ratios of FA/AA.

4. Conclusions

In this study, geopolymers were synthesized by utilizing fly ash, which was activated through a combination of sodium silicate and a potassium hydroxide solution (2.5 M) with different proportions of fly ash to alkaline activator (FA/AA). X-ray fluorescence (XRF) analysis verifies that fly ash belongs to the F Class, with a composition of SiO2 + Al2O3 + Fe2O3 summing up to ~85% and a calcium oxide (CaO) content of 1.6%, making it appropriate for geopolymerization. X-ray diffraction (XRD) of the geopolymer indicates high amorphousness with a few crystalline phases of quartz, mullite, hematite, and sodalite.

- Scanning electron microscopy (SEM) images of the FA geopolymer samples confirm that structures with a lower FA/AA ratio of 1.00 display a more highly uniform structure than that of those with higher ratios (1.25, 1.50, and 1.75). Elevating the FA/AA ratio decelerates the geopolymerization kinetics, leading to a more compact morphology, as observed in the G1 sample. In contrast, G4 displays morphology similar to that of fly ash, which is attributed to insufficient activation by alkali.

- The electrical conductivity, dielectric constant, and dielectric loss of fly ash KOH-based geopolymer pastes vary depending on the frequency range and ratio of FA/AA. The conductivity increases across all samples (G1 to G4) within frequencies ranging from 101 to 106 Hz. The overall order of conductivity across all samples is G1 < G2 < G3 < G4. The geopolymer with FA/AA = 1.00 exhibits significantly lower electrical conductivity than that with FA/AA = 1.75.

- The electric conductivity increases with an increase in frequency, but the dielectric constant decreases with an increase in frequency in the order G4 > G3 > G2 > G1, with an FA/AA ratio of 1.75 demonstrating a relatively high dielectric constant and an FA/AA ratio of 1.00 showing a lower dielectric constant.

- The D factor/tangent loss shows an increase, indicated by a hump in the graph within the frequency range of 101–104 Hz owing to relaxing dipoles, then decreases in the frequency range of 104–106 Hz. The D factor/tangent loss is in the order G4 > G3 > G2 > G1, indicating that the geopolymer samples with high dielectric constants also displayed high tangent loss.

Overall, based on the observations of this study, G1 with an Na2SiO3/KOH ratio of 2.5 and an FA/AA ratio of 1.00 is deemed optimal for preparing geopolymers with dense morphology, low conductivity, and lower dielectric parameters than those of the G2, G3, and G4 samples. The samples with low dielectric parameters are less polarizable and are expected to be well suited for use in dielectric applications and insulators by acting as excellent barriers to electrical conductivity. Future work should examine more variations in the composition of fly ash KOH-based geopolymers for dielectric applications.

Author Contributions

M.Y.: writing—original draft preparation, methodology, conceptualization, and literature survey; N.S. and L.K.: data interpretation and methodology; V.N.S.: manuscript review and analysis; K.J.: XRD analysis and manuscript review; V.E.: conceptualization, supervision, and manuscript writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

No funding was acquired for this research publication.

Data Availability Statement

All data generated and analyzed during this study are included in this article.

Acknowledgments

The authors thank the Director of CSIR-NPL for permitting them to publish this work. The authors would like to express their appreciation and thanks to the Chemical and Food section (BND) of CSIR National Physical Laboratory. The authors would like to express their appreciation and thanks to Jai S. Tawale for the FESEM analysis, Sumit Mohan for the XRD analysis, and Ashok M. Biradar, S.P. Singh, and Neha Yadav for the impedance analyzer. The authors M.Y., N.S. and L.K. thank CSIR for providing senior research fellowships.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Kravchenko, E.; Lazorenko, G.; Jiang, X.; Leng, Z. Alkali-activated materials made of construction and demolition waste as precursors: A review. Sustain. Mater. Technol. 2024, 39, e00829. [Google Scholar] [CrossRef]

- Umar, T.; Tahir, A.; Egbu, C.; Honnurvali, M.S.; Saidani, M.; Al-Bayati, A.J. Developing a Sustainable Concrete Using Ceramic Waste Powder. In Collaboration and Integration in Construction, Engineering, Management and Technology; Ahmed, S.M., Hampton, P., Azhar, S., Saul, A.D., Eds.; Advances in Science, Technology & Innovation; Springer International Publishing: Cham, Switzerland, 2021; pp. 157–162. [Google Scholar] [CrossRef]

- Umar, T.; Tahir, A.; Umeokafor, N.; Nawarathna, A.; Zia, A.; Vali, M.S.H. An Experimental Investigation on Strength Characteristics of Concrete Using Wastepaper Sludge Ash (WPSA). In Proceedings of the Twelth International Conference on Construction in the 21st Century (CITC-12), Amman, Jordan, 16–19 May 2022; Available online: https://researchonline.ljmu.ac.uk/id/eprint/16966 (accessed on 1 June 2024).

- Ingale, S.D.; Nemade, P.D. Effect of paper sludge ash on properties of cement concrete: A review. Mater. Today Proc. 2023, 492. [Google Scholar] [CrossRef]

- Narani, S.S.; Siddiqua, S.; Perumal, P. Wood fly ash and blast furnace slag management by alkali-activation: Trace elements solidification and composite application. J. Environ. Manag. 2024, 354, 120341. [Google Scholar] [CrossRef]

- Cong, P.; Cheng, Y. Advances in geopolymer materials: A comprehensive review. J. Traffic Transp. Eng. Engl. Ed. 2021, 8, 283–314. [Google Scholar] [CrossRef]

- Bai, B.; Bai, F.; Nie, Q.; Jia, X. A high-strength red mud–fly ash geopolymer and the implications of curing temperature. Powder Technol. 2023, 416, 118242. [Google Scholar] [CrossRef]

- Amran, M.; Debbarma, S.; Ozbakkaloglu, T. Fly ash-based eco-friendly geopolymer concrete: A critical review of the long-term durability properties. Constr. Build. Mater. 2021, 270, 121857. [Google Scholar] [CrossRef]

- Barreto, I.A.R.; Da Costa, M.L. Synthesis of geopolymer with KOH by two kaolinitic clays from the Amazon: Influence of different synthesis parameters on the compressive strength. Mater. Chem. Phys. 2022, 287, 126330. [Google Scholar] [CrossRef]

- Abbas, R.; Abdelzaher, M.A.; Shehata, N.; Tantawy, M.A. Production, characterization and performance of green geopolymer modified with industrial by-products. Sci. Rep. 2024, 14, 5104. [Google Scholar] [CrossRef]

- Ahmad Zailani, W.W.; Bouaissi, A.; Abdullah, M.M.A.B.; Abd Razak, R.; Yoriya, S.; Mohd Salleh, M.A.A.; M.A.Z., M.R.; Fansuri, H. Bonding Strength Characteristics of FA-Based Geopolymer Paste as a Repair Material When Applied on OPC Substrate. Appl. Sci. 2020, 10, 3321. [Google Scholar] [CrossRef]

- Alzeebaree, R.; Çevik, A.; Mohammedameen, A.; Niş, A.; Gülşan, M.E. Mechanical performance of FRP-confined geopolymer concrete under seawater attack. Adv. Struct. Eng. 2020, 23, 1055–1073. [Google Scholar] [CrossRef]

- Sun, Z.; Lin, X.; Liu, P.; Wang, D.; Vollpracht, A.; Oeser, M. Study of alkali activated slag as alternative pavement binder. Constr. Build. Mater. 2018, 186, 626–634. [Google Scholar] [CrossRef]

- Gao, H.; Liu, H.; Liao, L.; Mei, L.; Zhang, F.; Zhang, L.; Li, S.; Lv, G. A bifunctional hierarchical porous kaolinite geopolymer with good performance in thermal and sound insulation. Constr. Build. Mater. 2020, 251, 118888. [Google Scholar] [CrossRef]

- Shuai, Q.; Xu, Z.; Yao, Z.; Chen, X.; Jiang, Z.; Peng, X.; An, R.; Li, Y.; Jiang, X.; Li, H. Fire resistance of phosphoric acid-based geopolymer foams fabricated from metakaolin and hydrogen peroxide. Mater. Lett. 2020, 263, 127228. [Google Scholar] [CrossRef]

- Xu, J.; Li, M.; Zhao, D.; Zhong, G.; Sun, Y.; Hu, X.; Sun, J.; Li, X.; Zhu, W.; Li, M.; et al. “Research and Application Progress of Geopolymers in Adsorption: A Review. Nanomaterials 2022, 12, 3002. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Rattanasak, U. Synthesis of porous alkali-activated materials for high-acidic wastewater treatment. J. Water Process Eng. 2020, 33, 101118. [Google Scholar] [CrossRef]

- Sanalkumar, K.U.A.; Yang, E.-H. Self-cleaning performance of nano-TiO2 modified metakaolin-based geopolymers. Cem. Concr. Compos. 2021, 115, 103847. [Google Scholar] [CrossRef]

- Yadav, M.; Kumar, L.; Yadav, V.; Jagannathan, K.; Singh, V.N.; Singh, S.P.; Ezhilselvi, V. Optimizing the Fly Ash/Activator Ratio for a Fly Ash-Based Geopolymer through a Study of Microstructure, Thermal Stability, and Electrical Properties. Ceramics 2023, 6, 2352–2366. [Google Scholar] [CrossRef]

- Lee, N.K.; Lee, H.K. Setting and mechanical properties of alkali-activated fly ash/slag concrete manufactured at room temperature. Constr. Build. Mater. 2013, 47, 1201–1209. [Google Scholar] [CrossRef]

- Matsimbe, J.; Dinka, M.; Olukanni, D.; Musonda, I. Geopolymer: A Systematic Review of Methodologies. Materials 2022, 15, 6852. [Google Scholar] [CrossRef]

- Zhang, L. Production of bricks from waste materials—A review. Constr. Build. Mater. 2013, 47, 643–655. [Google Scholar] [CrossRef]

- Castillo, H.; Collado, H.; Droguett, T.; Sánchez, S.; Vesely, M.; Garrido, P.; Palma, S. Factors Affecting the Compressive Strength of Geopolymers: A Review. Minerals 2021, 11, 1317. [Google Scholar] [CrossRef]

- De Moraes, M.J.B.; Nagata, E.Y.; Duran, A.J.F.P.; Rossignolo, J.A. Alkali activated materials applied in 3D printing construction: A review. Heliyon 2024, 10, e26696. [Google Scholar] [CrossRef]

- Pratap, B.; Mondal, S.; Rao, B.H. NaOH molarity influence on mechanical and durability properties of geopolymer concrete made with fly ash and phosphogypsum. Structures 2023, 56, 105035. [Google Scholar] [CrossRef]

- Gultekin, A.; Ramyar, K. Effect of curing type on microstructure and compressive strength of geopolymer mortars. Ceram. Int. 2022, 48, 16156–16172. [Google Scholar] [CrossRef]

- Al-Majidi, M.H.; Lampropoulos, A.; Cundy, A.; Meikle, S. Development of geopolymer mortar under ambient temperature for in situ applications. Constr. Build. Mater. 2016, 120, 198–211. [Google Scholar] [CrossRef]

- Swain, D.; Row, T.N.G. Structure, Ionic Conduction and Dielectric Relaxation in a Novel Fast Ion Conductor, Na2Cd(SO4)2. Chem. Mater. 2007, 19, 347–349. [Google Scholar] [CrossRef]

- MacKenzie, K.J.D. Innovative applications of inorganic polymers (geopolymers). In Handbook of Alkali-Activated Cements, Mortars and Concretes; Elsevier: Amsterdam, The Netherlands, 2015; pp. 777–805. [Google Scholar] [CrossRef]

- Malkawi, A.B.; Al-Mattarneh, H.; Achara, B.E.; Mohammed, B.S.; Nuruddin, M.F. Dielectric properties for characterization of fly ash-based geopolymer binders. Constr. Build. Mater. 2018, 189, 19–32. [Google Scholar] [CrossRef]

- Zeng, S.; Wang, J. Characterization of mechanical and electric properties of geopolymers synthesized using four locally available fly ashes. Constr. Build. Mater. 2016, 121, 386–399. [Google Scholar] [CrossRef]

- Jumrat, S.; Chatveera, B.; Rattanadecho, P. Dielectric properties and temperature profile of fly ash-based geopolymer mortar. Int. Commun. Heat Mass Transf. 2011, 38, 242–248. [Google Scholar] [CrossRef]

- Hanjitsuwan, S.; Hunpratub, S.; Thongbai, P.; Maensiri, S.; Sata, V.; Chindaprasirt, P. Effects of NaOH concentrations on physical and electrical properties of high calcium fly ash geopolymer paste. Cem. Concr. Compos. 2014, 45, 9–14. [Google Scholar] [CrossRef]

- Bakthavatchalam, K.; Rajendran, M. An experimental investigation on potassium activator based geopolymer concrete incorporated with hybrid fibers. Mater. Today Proc. 2021, 46, 8494–8501. [Google Scholar] [CrossRef]

- Hanjitsuwan, S.; Chindaprasirt, P.; Pimraksa, K. Electrical conductivity and dielectric property of fly ash geopolymer pastes. Int. J. Miner. Metall. Mater. 2011, 18, 94–99. [Google Scholar] [CrossRef]

- Das, D.; Rout, P.K. Synthesis, Characterization and Properties of Fly Ash Based Geopolymer Materials. J. Mater. Eng. Perform. 2021, 30, 3213–3231. [Google Scholar] [CrossRef]

- Pradhan, D.K.; Choudhary, R.N.P.; Samantaray, B.K. Studies of Dielectric Relaxation and AC Conductivity Behavior of Plasticized Polymer Nanocomposite Electrolytes. Int. J. Electrochem. Sci. 2008, 3, 597–608. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).