A Systematic Review of Automated Construction Inspection and Progress Monitoring (ACIPM): Applications, Challenges, and Future Directions

Abstract

1. Introduction

2. Review Methodology

2.1. Significance of Work (Originality)

2.2. Frame Research Questions (RQs)

- 1.

- What are the different application areas of ACIPM?

- 2.

- What is the frequency based on construction domain and structure?

- 3.

- What are the tools and techniques that enable ACIPM?

- 4.

- What are the challenges of implementing ACIPM in construction projects?

- 5.

- What are the future directions to improve the application of ACIPM in construction projects?

2.3. Identify Related Keywords

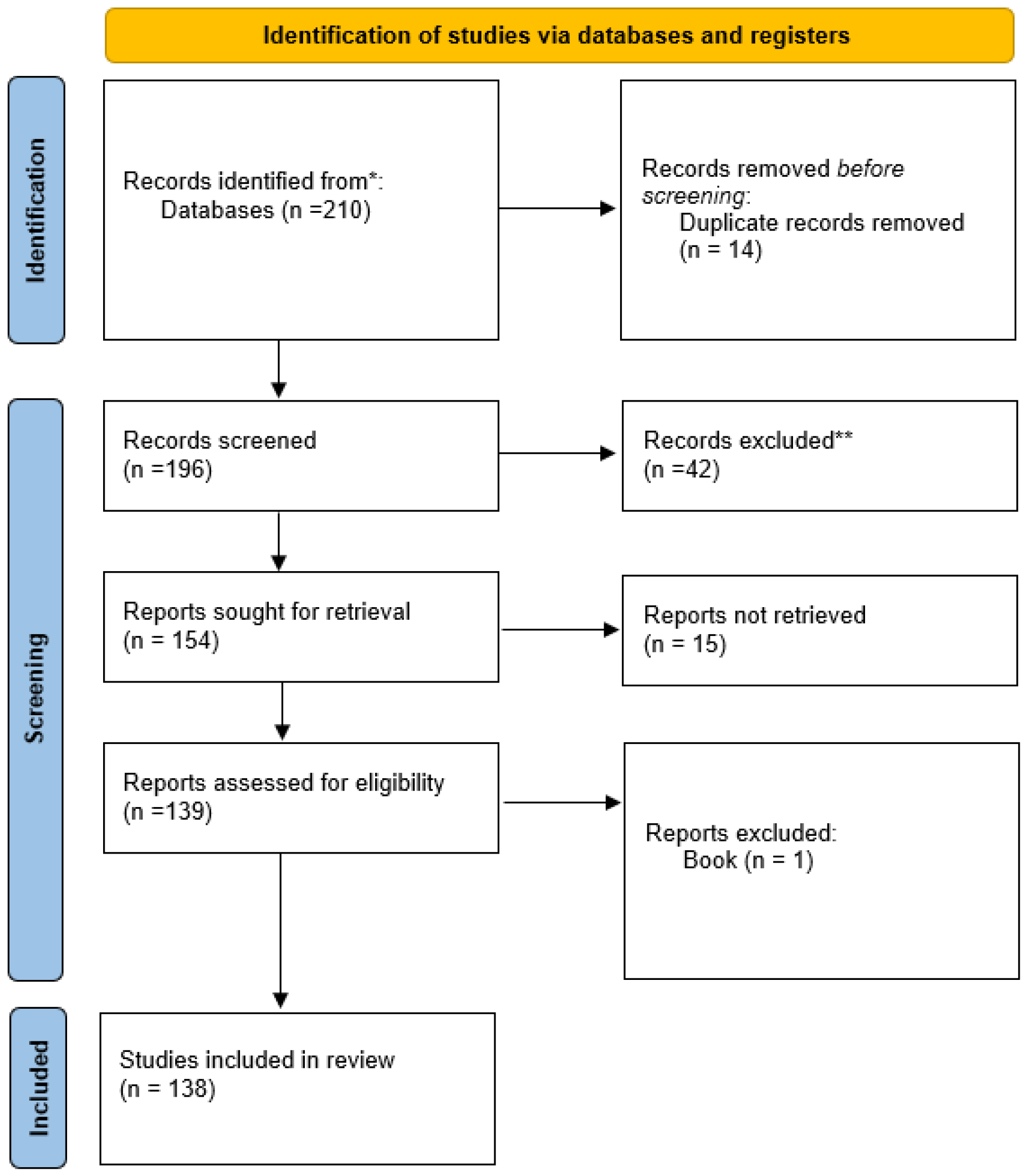

2.4. Collect, Store, and Filter Articles

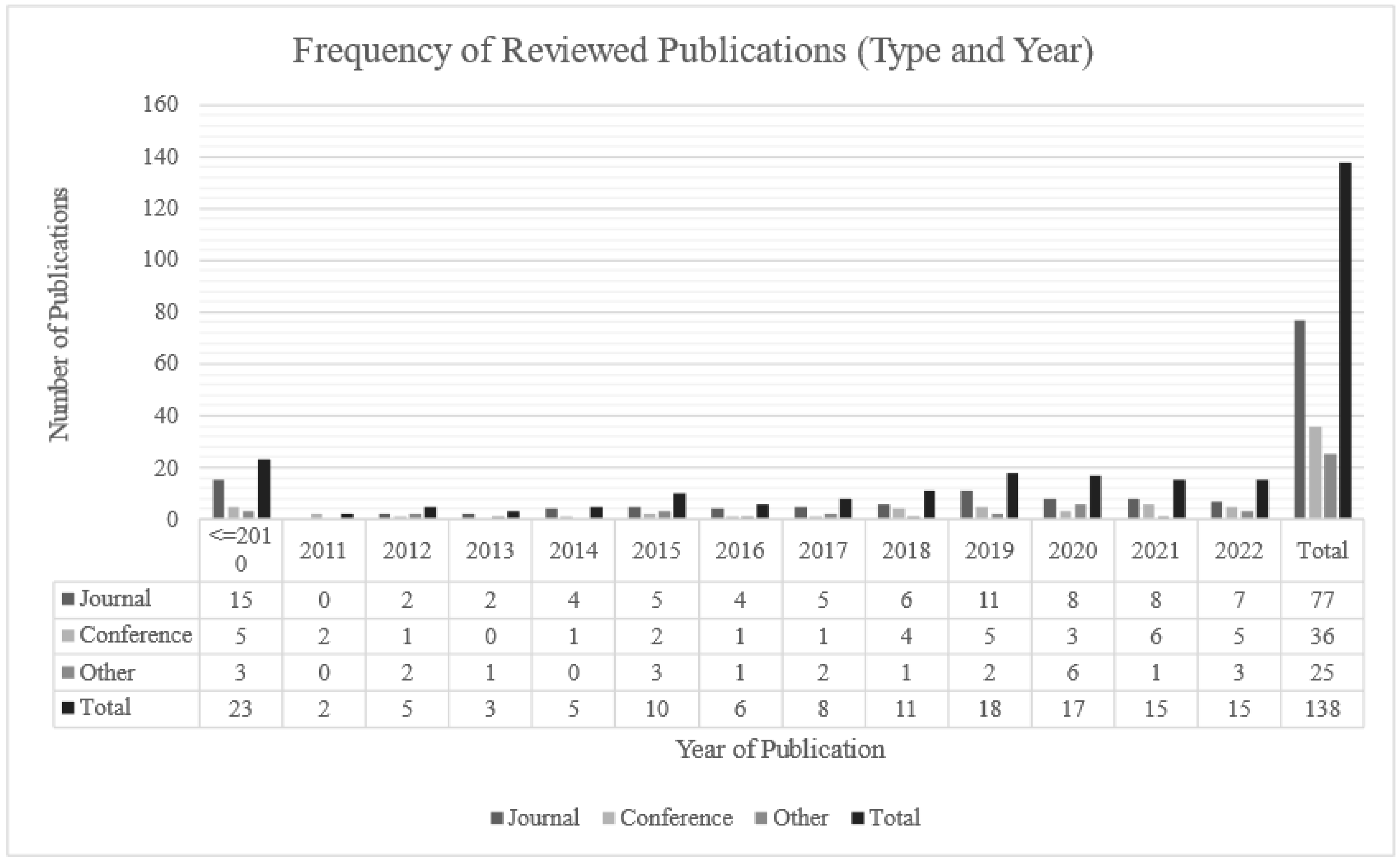

2.5. Analyze the Data

3. RQ1: What Are the Different Application Areas of ACIPM?

3.1. Automated Inspection in Transportation Domain

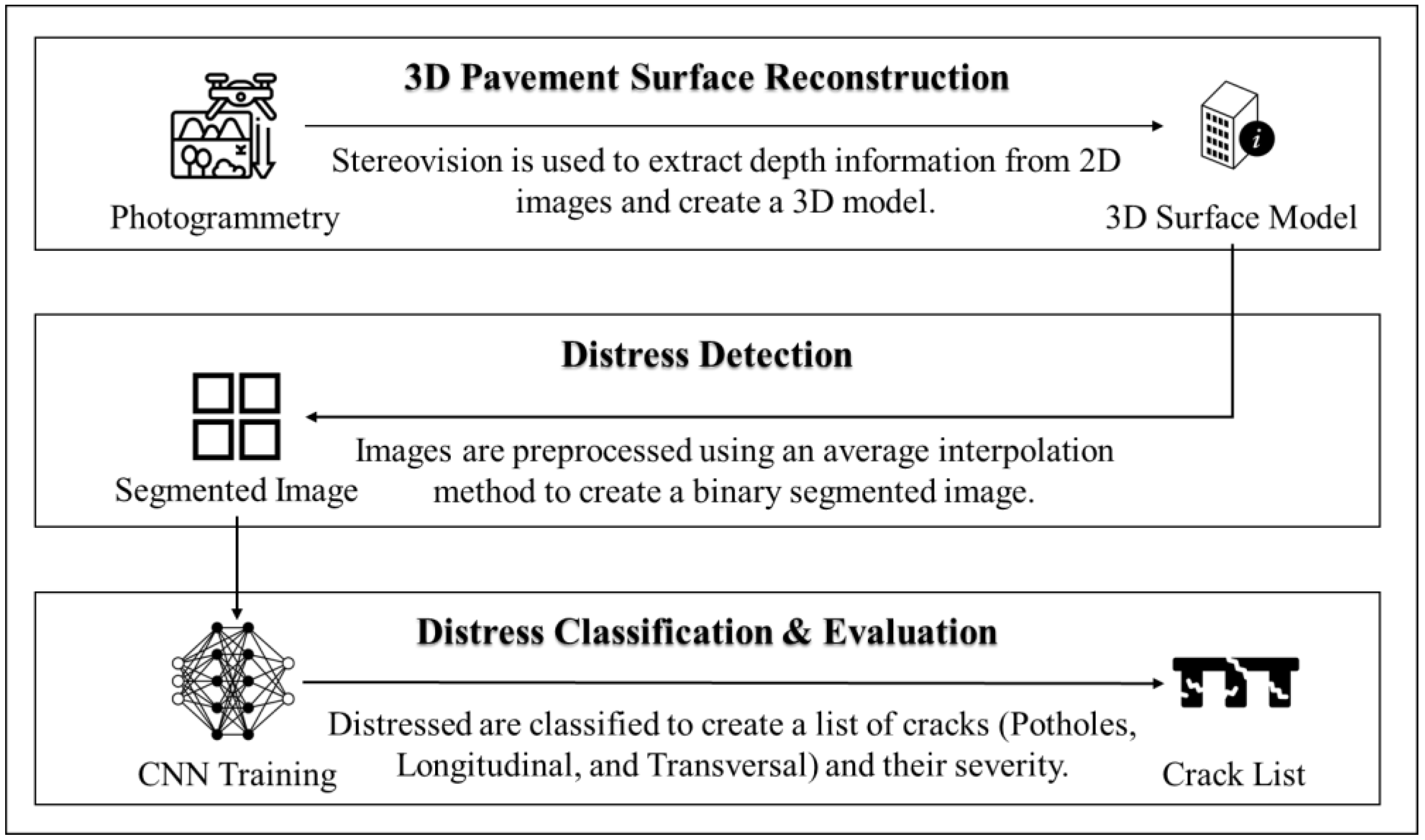

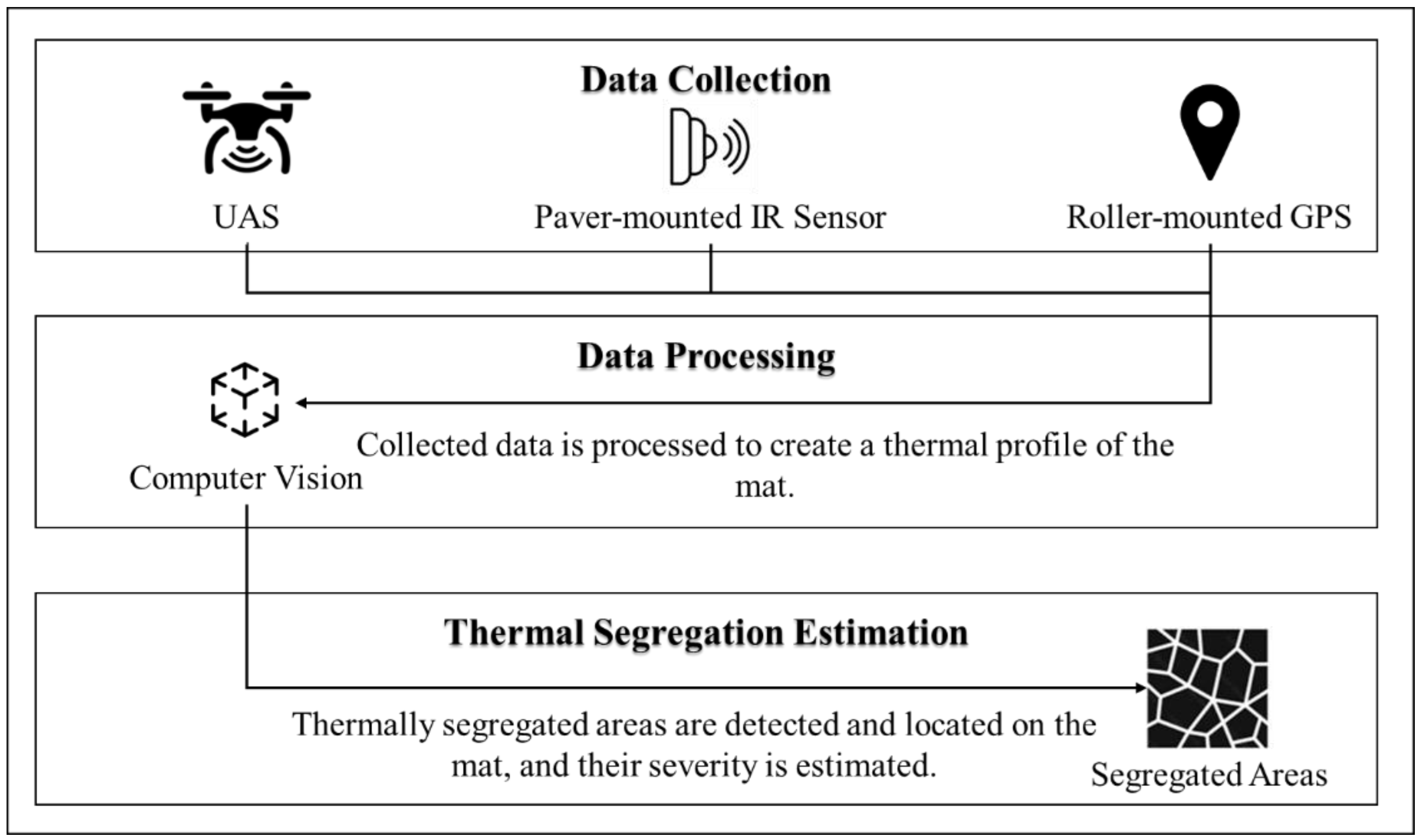

3.1.1. Pavement Inspection

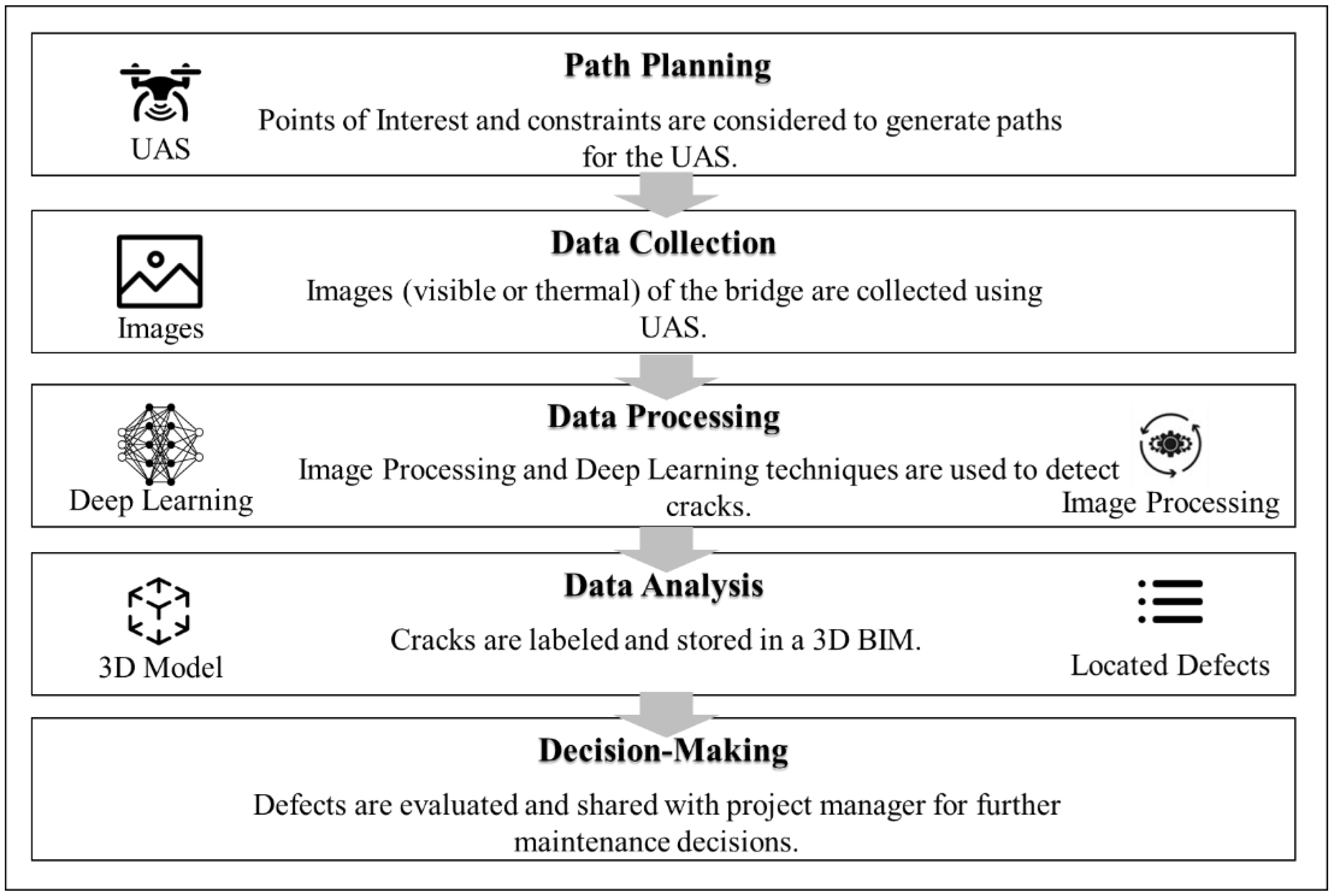

3.1.2. Bridge Inspection

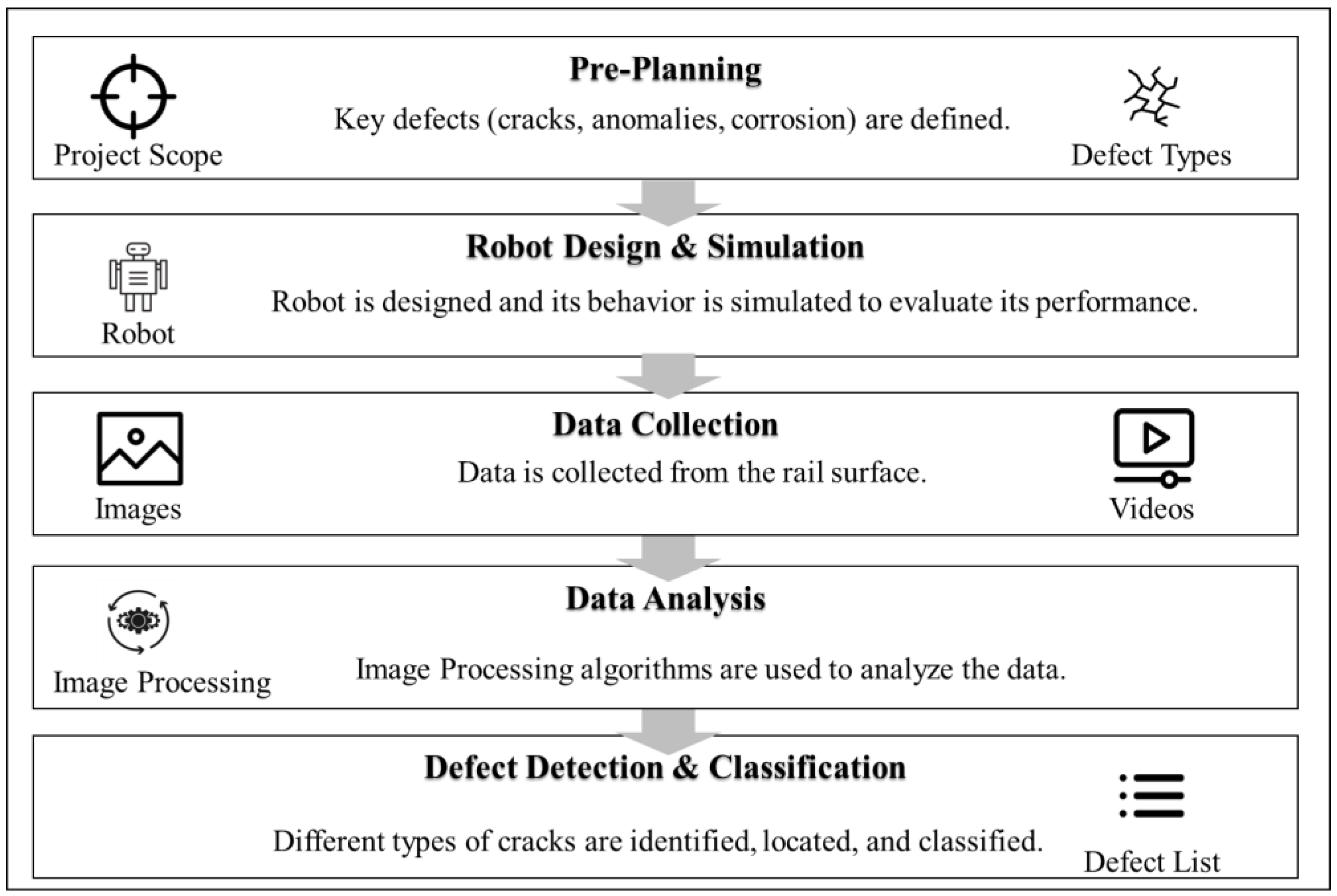

3.1.3. Railway Inspection

3.2. Automated Inspection in Building Domain

3.2.1. Progress Monitoring

3.2.2. Façade Inspection

3.2.3. Quality Control

3.2.4. Falsework Inspection

3.2.5. Energy Assessment

3.2.6. Occupancy Authorization

4. RQ2: What Is the Frequency Based on Construction Domain and Structure?

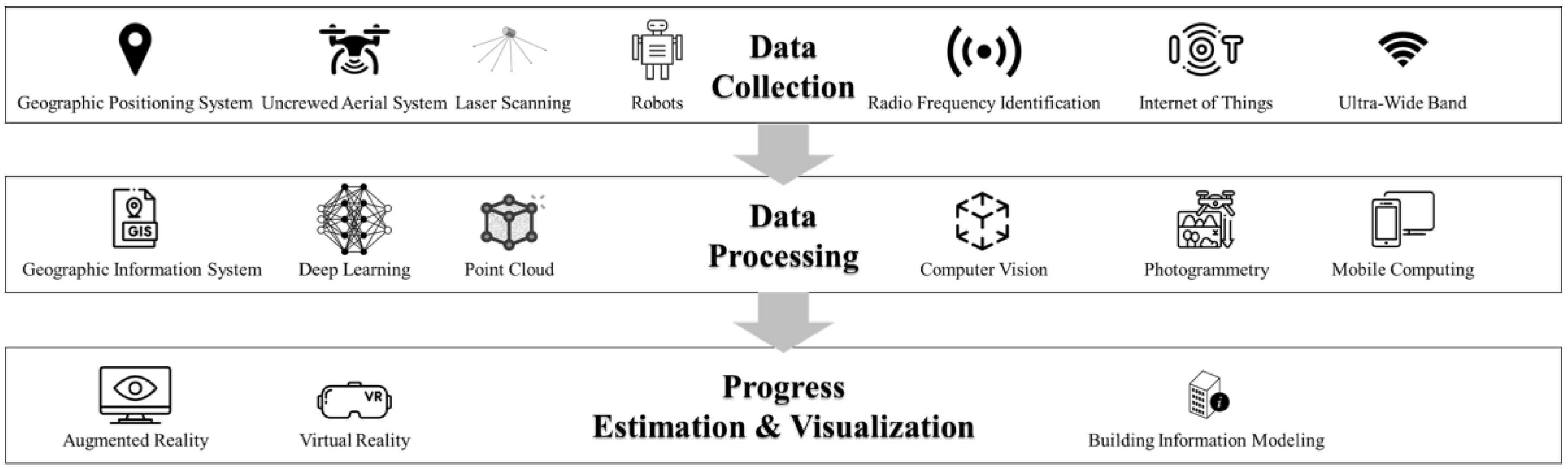

5. RQ3: What Are Data Collection and Processing Tools and Techniques?

6. RQ4: What Are the Challenges?

7. RQ5: What Are the Future Directions?

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Prieto, S.A.; Giakoumidis, N.; de Soto, B.G. AutoCIS: An Automated Construction Inspection System for Quality Inspection of Buildings. In ISARC. Proceedings of the International Symposium on Automation and Robotics in Construction; IAARC Publications: Cambridge, UK, 2021; pp. 669–676. [Google Scholar]

- Yeum, C.M.; Dyke, S.J. Vision-based automated crack detection for bridge inspection. Comput. Civ. Infrastruct. Eng. 2015, 30, 759–770. [Google Scholar] [CrossRef]

- Charron, N.; McLaughlin, E.; Phillips, S.; Goorts, K.; Narasimhan, S.; Waslander, S.L. Automated bridge inspection using mobile ground robotics. J. Struct. Eng. 2019, 145, 04019137. [Google Scholar] [CrossRef]

- Elbeheri, A.; Zayed, T. Automated steel bridge coating inspection using neural network trained image processing. In Maintenance, Safety, Risk, Management and Life-Cycle Performance of Bridges; CRC Press: Boca Raton, FL, USA, 2018; pp. 2545–2551. [Google Scholar]

- Wang, D.; Zhang, Y.; Pan, Y.; Peng, B.; Liu, H.; Ma, R. An automated inspection method for the steel box girder bottom of long-span bridges based on deep learning. IEEE Access 2020, 8, 94010–94023. [Google Scholar] [CrossRef]

- Won, J.; Park, J.-W.; Shim, C.; Park, M.-W. Bridge-surface panoramic-image generation for automated bridge-inspection using deepmatching. Struct. Health Monit. 2021, 20, 1689–1703. [Google Scholar] [CrossRef]

- Newcomer, C.; Withrow, J.; Sturgill, R.E.; Dadi, G.B. Towards an automated asphalt paving construction inspection operation. In Advances in Informatics and Computing in Civil and Construction Engineering: Proceedings of the 35th CIB W78 2018 Conference: IT in Design, Construction, and Management; Springer International Publishing: Cham, Switzerland, 2019; pp. 593–600. [Google Scholar]

- Costin, A.; Adibfar, A.; Hu, H.; Chen, S.S. Building Information Modeling (BIM) for transportation infrastructure–Literature review, applications, challenges, and recommendations. Autom. Constr. 2018, 94, 257–281. [Google Scholar] [CrossRef]

- Zhang, C.; Shen, W.; Ye, Z. Technical feasibility analysis on applying ultra-wide band technology in construction progress monitoring. Int. J. Constr. Manag. 2022, 22, 2951–2965. [Google Scholar] [CrossRef]

- Salari, E.; Bao, G. Automated pavement distress inspection based on 2D and 3D information. In Proceedings of the 2011 IEEE International Conference On Electro/Information Technology, Mankato, MN, USA, 15–17 May 2011; pp. 1–4. [Google Scholar]

- Guralnick, S.A.; Suen, E.S.; Zoruba, S. Development of automated road inspection vehicle for nondestructive evaluation of road surface condition. Transp. Res. Rec. 1996, 1536, 125–129. [Google Scholar] [CrossRef]

- Mandal, V.; Uong, L.; Adu-Gyamfi, Y. Automated road crack detection using deep convolutional neural networks. In Proceedings of the 2018 IEEE International Conference on Big Data (Big Data), Seattle, WA, USA, 10–13 December 2018; pp. 5212–5215. [Google Scholar]

- Basavaraju, A.; Du, J.; Zhou, F.; Ji, J. A machine learning approach to road surface anomaly assessment using smartphone sensors. IEEE Sens. J. 2019, 20, 2635–2647. [Google Scholar] [CrossRef]

- Ho, M.C.; Lin, J.D.; Huang, C.F. Automatic image recognition of pavement distress for improving pavement inspection. GEOMATE J. 2020, 19, 242–249. [Google Scholar] [CrossRef]

- Laurent, J.; Hébert, J.F.; Lefebvre, D.; Savard, Y. Using 3D laser profiling sensors for the automated measurement of road surface conditions. In 7th RILEM International Conference on Cracking in Pavements: Mechanisms, Modeling, Testing, Detection and Prevention Case Histories; Springer: Cham, Switzerland, 2012; pp. 157–167. [Google Scholar]

- Zhu, S.; Li, X.; Wang, H.; Yu, D. Development of an automated remote asphalt paving quality control system. Transp. Res. Rec. 2018, 2672, 28–39. [Google Scholar] [CrossRef]

- Zakeri, H.; Nejad, F.M.; Fahimifar, A. Rahbin: A quadcopter unmanned aerial vehicle based on a systematic image processing approach toward an automated asphalt pavement inspection. Autom. Constr. 2016, 72, 211–235. [Google Scholar] [CrossRef]

- Samsami, R.; Mukherjee, A.; Brooks, C.N. Mapping Unmanned Aerial System Data onto Building Information Modeling Parameters for Highway Construction Progress Monitoring. Transp. Res. Rec. 2022, 2676, 669–682. [Google Scholar] [CrossRef]

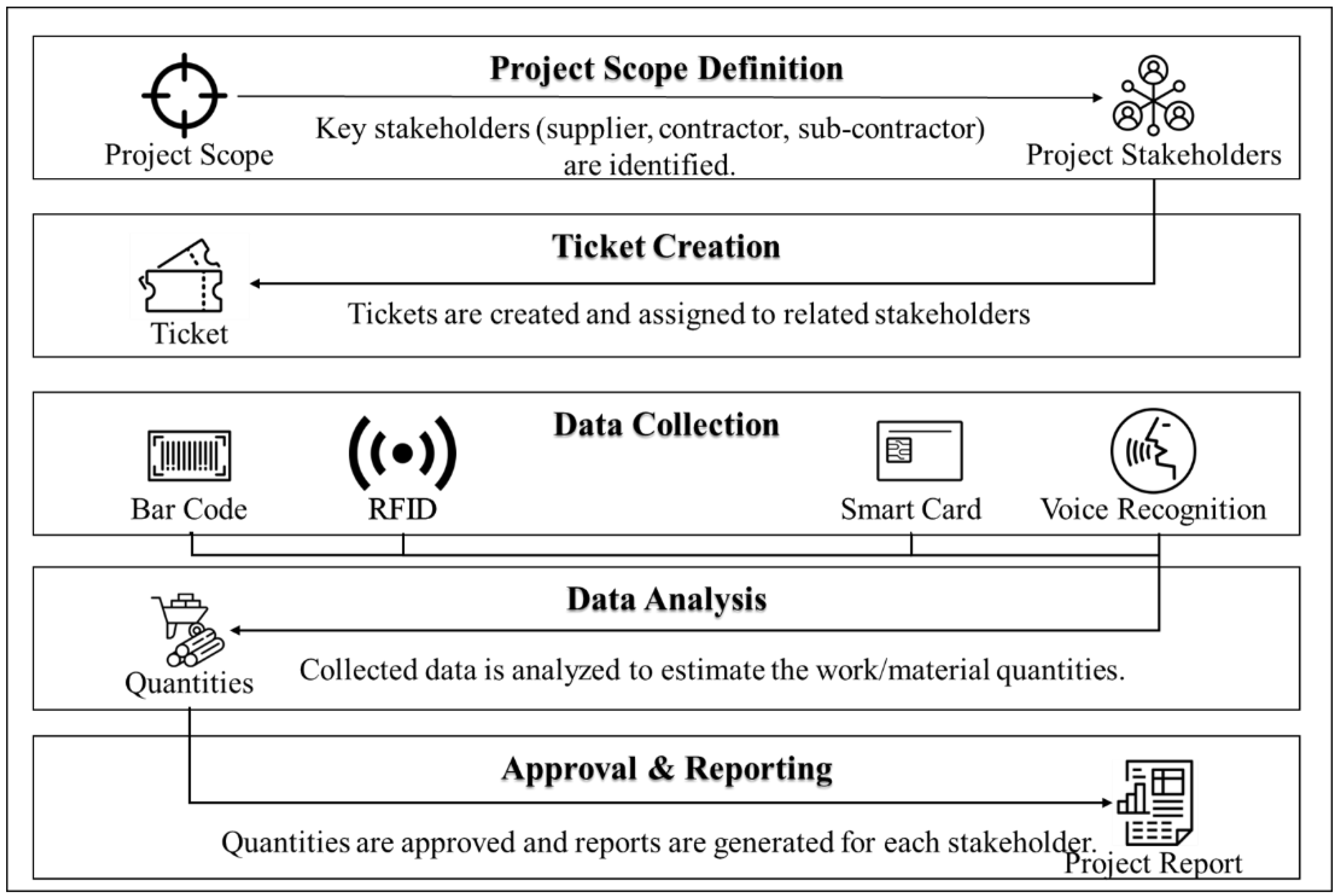

- Nipa, T.J.; Rouhanizadeh, B.; Kermanshachi, S. Utilization and implementation of the E-ticketing technology to electronically track the delivery of construction materials. In Proceedings of the CSCE Annual Conference, Montreal, QC, Canada, 12–15 June 2019. [Google Scholar]

- ASCE. ASCE Infrastructure Report Card; ASCE: Washington, DC, USA, 2021. [Google Scholar]

- Zhu, Z.; German, S.; Brilakis, I. Detection of large-scale concrete columns for automated bridge inspection. Autom. Constr. 2010, 19, 1047–1055. [Google Scholar] [CrossRef]

- FHWA. National Bridge Inspection Standard by FHWA; FHWA: Washington, DC, USA, 2022. [Google Scholar]

- Bolourian, N.; Soltani, M.M.; Albahria, A.H.; Hammad, A. High level framework for bridge inspection using LiDAR-equipped UAV. In ISARC. Proceedings of the International Symposium on Automation and Robotics in Construction; IAARC Publications: Cambridge, UK, 2017. [Google Scholar]

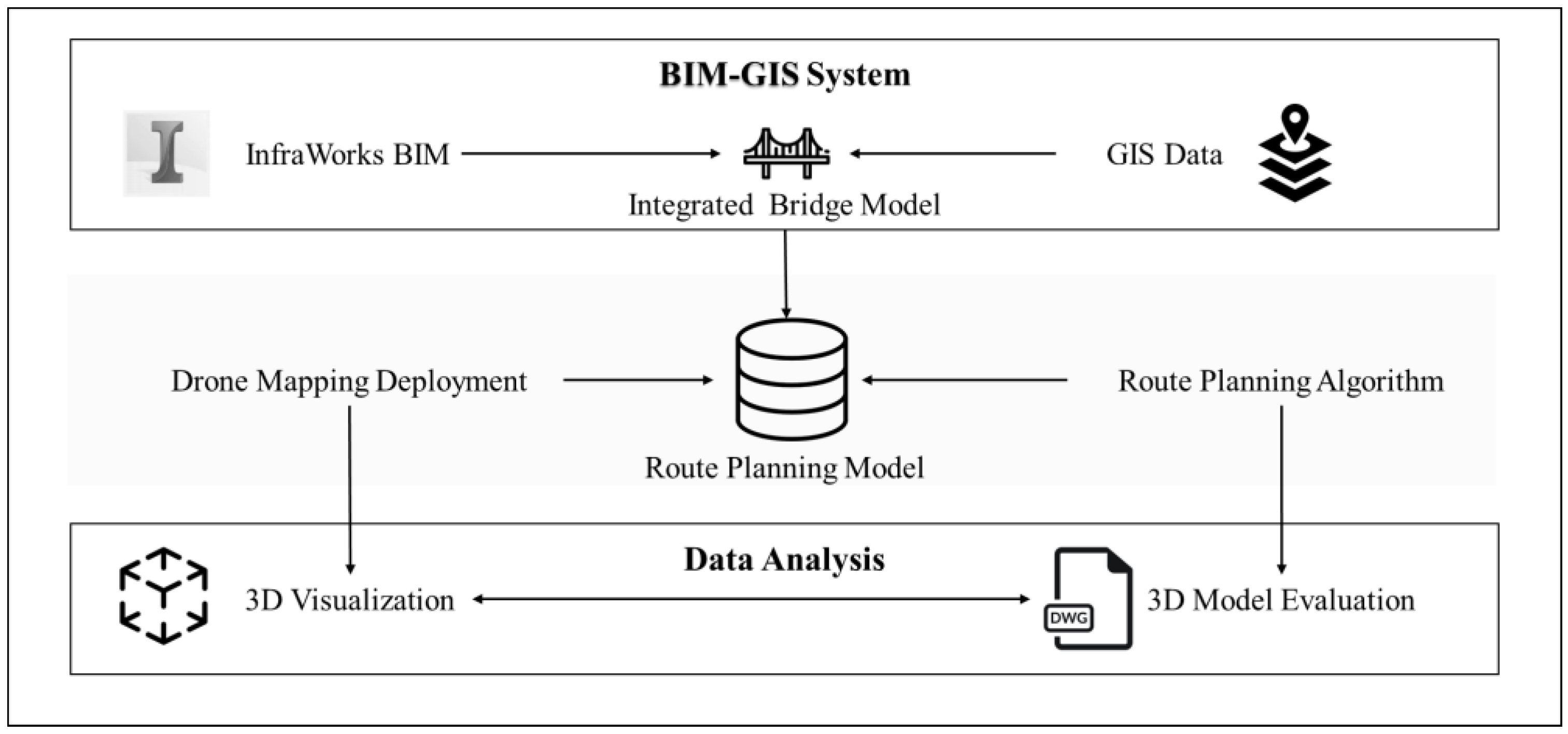

- Zou, Y.; Barati, M.; Castillo, E.R.; Amor, R. Automated UAV route planning for bridge inspection using BIM-GIS data. In Proceedings of the Conference: 4th International Conference on Civil and Building Engineering Informatics, Sendai, Japan, 7–8 November 2019; pp. 384–391. [Google Scholar]

- Wang, R.; Kawamura, Y. An automated sensing system for steel bridge inspection using GMR sensor array and magnetic wheels of climbing robot. J. Sens. 2016, 2016, 8121678. [Google Scholar] [CrossRef]

- McCrea, A.; Chamberlain, D.; Navon, R. Automated inspection and restoration of steel bridges—A critical review of methods and enabling technologies. Autom. Constr. 2002, 11, 351–373. [Google Scholar] [CrossRef]

- Zhang, C.; Zou, Y.; Wang, F.; del Rey Castillo, E.; Dimyadi, J.; Chen, L. Towards fully automated unmanned aerial vehicle-enabled bridge inspection: Where are we at? Constr. Build. Mater. 2022, 347, 128543. [Google Scholar] [CrossRef]

- Leonidas, E.; Xu, Y. The development of an automatic inspection system used for the maintenance of rail tunnels. In Proceedings of the 2018 24th International Conference on Automation and Computing (ICAC), Newcastle Upon Tyne, UK, 6–7 September 2018; pp. 1–6. [Google Scholar]

- Singh, M.; Singh, S.; Jaiswal, J.; Hempshall, J. Autonomous rail track inspection using vision based system. In Proceedings of the 2006 IEEE International Conference on Computational Intelligence for Homeland Security and Personal Safety, Alexandria, VA, USA, 16–17 October 2006; pp. 56–59. [Google Scholar]

- Gabara, G.; Sawicki, P. A new approach for inspection of selected geometric parameters of a railway track using image-based point clouds. Sensors 2018, 18, 791. [Google Scholar] [CrossRef]

- Panella, F.; Roecklinger, N.; Vojnovic, L.; Loo, Y.; Boehm, J. Cost-benefit analysis of rail tunnel inspection for photogrammetry and laser scanning. In International Archives of the Photogrammetry, Remote Sensing and Spatial Information Sciences-ISPRS Archives; ISPRS: Hannover, Germany, 2020; pp. 1137–1144. [Google Scholar]

- Ko, P.; Prieto, S.A.; de Soto, B.G. ABECIS: An automated building exterior crack inspection system using UAVs, open-source deep learning and photogrammetry. In ISARC. Proceedings of the International Symposium on Automation and Robotics in Construction; IAARC Publications: Cambridge, UK, 2021; pp. 637–644. [Google Scholar]

- Kopsida, M.; Brilakis, I. BIM registration methods for mobile augmented reality-based inspection. In eWork and eBusiness in Architecture, Engineering and Construction; CRC Press: Boca Raton, FL, USA, 2017; pp. 201–208. [Google Scholar]

- El-Omari, S.; Moselhi, O. Integrating 3D laser scanning and photogrammetry for progress measurement of construction work. Autom. Constr. 2008, 18, 1–9. [Google Scholar] [CrossRef]

- Liu, Y.; Lin, Y.; Yeoh, J.K.; Chua, D.K.; Wong, L.W.; Ang, M.H.; Chew, M.Y. Framework for Automated UAV-Based Inspection of External Building Façades. In Automating Cities: Design, Construction, Operation and Future Impact; Springer: Berlin/Heidelberg, Germany, 2021; pp. 173–194. [Google Scholar]

- Yiqing, L.I.U. Automated building façade crack inspection system using unmanned aerial vehicles. PhD. Thesis, National University of Singapore, Singapore, May 2021. [Google Scholar]

- Chen, K.; Reichard, G.; Xu, X.; Akanmu, A. Automated crack segmentation in close-range building façade inspection images using deep learning techniques. J. Build. Eng. 2021, 43, 102913. [Google Scholar] [CrossRef]

- Bouzan, G.B.; Fazzioni, P.F.; Faisca, R.G.; Soares, C.A. Building facade inspection: A system based on automated data acquisition, machine learning, and deep learning image classification methods. ARPN J. Eng. Appl. Sci. 2021, 16, 1516. [Google Scholar]

- Ko, P.; Prieto, S.A.; de Soto, B.G. Developing a Free and Open-source Automated Building Exterior Crack Inspection Software for Construction and Facility Managers. arXiv 2022, arXiv:2206.09742. [Google Scholar] [CrossRef]

- Boukamp, F.; Akinci, B. Automated processing of construction specifications to support inspection and quality control. Autom. Constr. 2007, 17, 90–106. [Google Scholar] [CrossRef]

- Lee, S.J.; Kwon, S.W.; Jeong, M.K.; Hasan, S.M.; Kim, A. Automated On-Site Quality Inspection and Reporting Technology for Off-Site Construction (OSC)-based Precast Concrete Members. In ISARC. Proceedings of the International Symposium on Automation and Robotics in Construction; IAARC Publications: Cambridge, UK, 2020; pp. 1152–1159. [Google Scholar]

- Chen, L.; Luo, H. A BIM-based construction quality management model and its applications. Autom. Constr. 2014, 46, 64–73. [Google Scholar] [CrossRef]

- Atherinis, D.; Bakowski, B.; Velcek, M.; Moon, S. Developing and laboratory testing a smart system for automated falsework inspection in construction. J. Constr. Eng. Manag. 2018, 144, 04017119. [Google Scholar] [CrossRef]

- Patiño-Cambeiro, F.; Bastos, G.; Armesto, J.; Patiño-Barbeito, F. Multidisciplinary energy assessment of tertiary buildings: Automated geomatic inspection, building information modeling reconstruction and building performance simulation. Energies 2017, 10, 1032. [Google Scholar] [CrossRef]

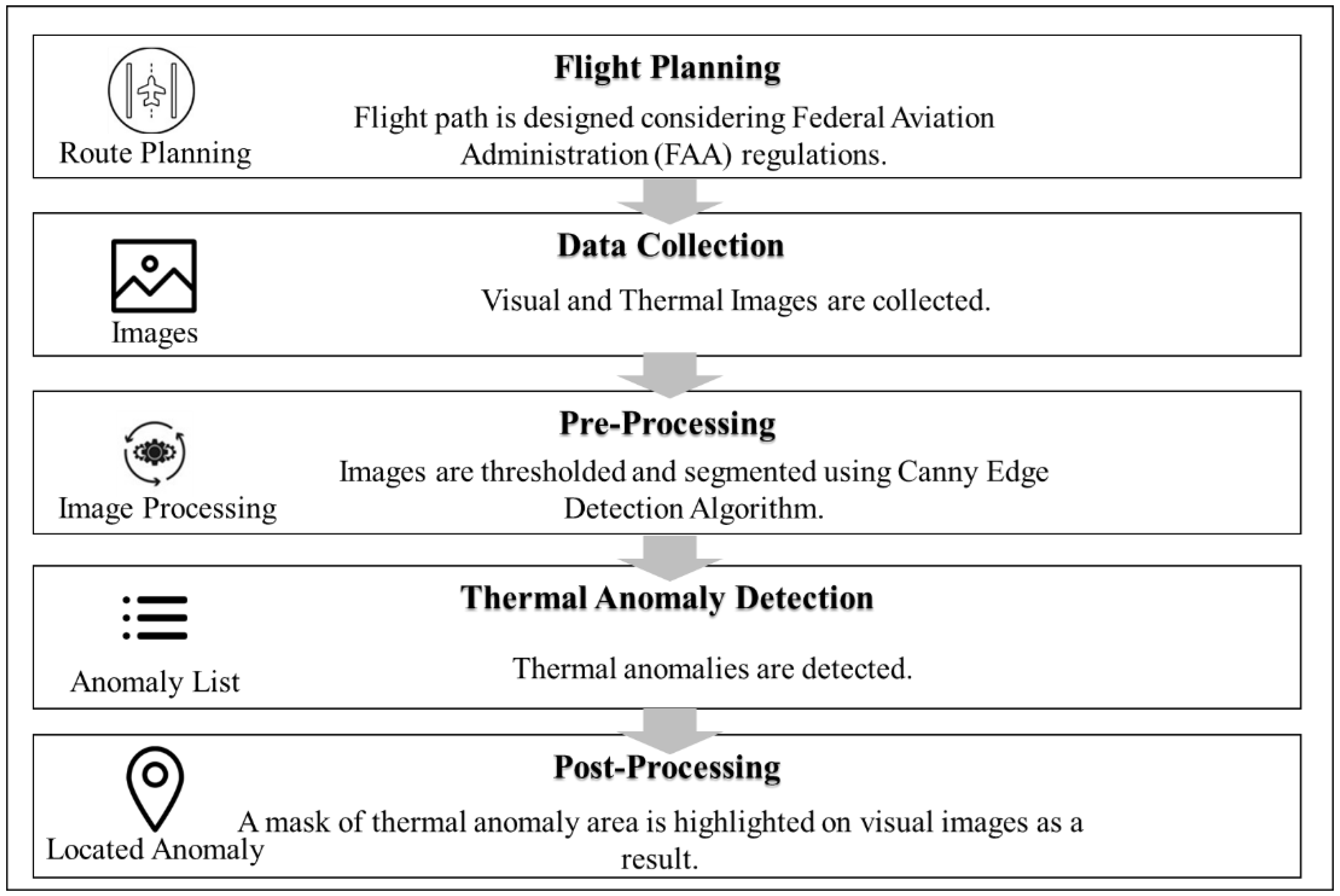

- Mirzabeigi, S.; Razkenari, M. Automated vision-based building inspection using drone thermography. Constr. Res. Congr. 2022, 2022, 737–746. [Google Scholar]

- Lee, S.H.; Ryu, J.R.; Choo, S.Y. A Study on Utilization of Unmanned Aerial Vehicle for Automated Inspection for Building Occupancy Authorization. Korean J. Comput. Des. Eng. 2017, 22, 44–58. [Google Scholar] [CrossRef]

- Li, T.; Harris, D. Automated construction of bridge condition inventory using natural language processing and historical inspection reports. In Nondestructive Characterization and Monitoring of Advanced Materials, Aerospace, Civil Infrastructure, and Transportation XIII.; SPIE: Bellingham, WA, USA, 2019; pp. 206–213. [Google Scholar]

- Yeum, C.M.; Dyke, S.J. Automated region-of-interest localization and classification for vision-based visual assessment of civil infrastructure. Struct. Health Monit. 2019, 18, 675–689. [Google Scholar] [CrossRef]

- Yin, Z.; Mao, Y.; Seto, C. Develop a UAV Platform for Automated Bridge Inspection; Mid-America Transportation Center: Washington, DC, USA, 2015. [Google Scholar]

- Elzarka, H.M.; Bell, L.C.; Floyd, R.L. Automated data acquisition for bridge inspection. J. Bridge Eng. 1999, 4, 258–262. [Google Scholar] [CrossRef][Green Version]

- Lee, J.S.; Hwang, I.; Hong, S.H.; Lee, H.S. Advanced robot system for automated bridge inspection and monitoring. In Proceedings of the IABSE Symposium: Sustainable Infrastructure-Environment Friendly, Safe and Resource Efficient, Bangkok, Thailand, 9–11 September 2009; pp. 45–52. [Google Scholar]

- Harris, N.; Liu, S.; Louis, S.J.; La, J.H. A genetic algorithm for multi-robot routing in automated bridge inspection. In Proceedings of the Genetic and Evolutionary Computation Conference Companion, Prague, Czech Republic, 13–17 July 2019; pp. 369–370. [Google Scholar]

- Giberti, H.; Zanoni, A.; Mauri, M.; Gammino, M. Preliminary study on automated concrete bridge inspection. In Engineering Systems Design and Analysis; American Society of Mechanical Engineers: New York, NY, USA, 2014; p. V003T15A011. [Google Scholar]

- Nguyen, S.T.; La, H. Climbing Robots with Automated Deployment of Sensors and NDE Devices for Steel Bridge Inspection. J. Intell. Robot. Syst. 2021, 102, 75. [Google Scholar] [CrossRef]

- Chehri, A.; Saeidi, A. IoT and deep learning solutions for an automated crack detection for the inspection of concrete bridge structures. In Human Centred Intelligent Systems: Proceedings of KES-HCIS 2021 Conference; Springer: Singapore, 2021; pp. 110–119. [Google Scholar]

- Larsen, J.L.; McElderry, J.; Baxter, J.S.; Guthrie, W.S.; Mazzeo, B.A. Automated sounding for concrete bridge deck inspection through a multi-channel, continuously moving platform. NDT E Int. 2020, 109, 102177. [Google Scholar] [CrossRef]

- Sheng, W.; Ge, J.; Ley, T.; Emerson, R. Automated and Accurate Bridge Deck Crack Inspection and Mapping; Oklahoma Transportation Center: Oklahoma City, OK, USA, 2012. [Google Scholar]

- Kuo, S.S.; Davidson, T.E.; Fiji, L.M. Development of computer automated bridge inspection process. In Computing in Civil Engineering and Geographic Information Systems Symposium; ASCE: Washington, DC, USA, 1992; pp. 794–801. [Google Scholar]

- Kim, H.; Yoon, J.; Sim, S. Automated bridge component recognition from point clouds using deep learning. Struct. Control Health Monit. 2020, 27, e2591. [Google Scholar] [CrossRef]

- O’Connor, S.M.; Zhang, Y.; Lynch, J.; Ettouney, M.; van der Linden, G. Automated analysis of long-term bridge behavior and health using a cyber-enabled wireless monitoring system. In Nondestructive Characterization for Composite Materials, Aerospace Engineering, Civil Infrastructure, and Homeland Security 2014; SPIE: Bellingham, WA, USA, 2014; pp. 223–233. [Google Scholar]

- Abdel-Qader, I.; Abudayyeh, O.; Kelly, M.E. Analysis of edge-detection techniques for crack identification in bridges. J. Comput. Civ. Eng. 2003, 17, 255–263. [Google Scholar] [CrossRef]

- Brackenbury, D.; Brilakis, I.; DeJong, M. Automated defect detection for masonry arch bridges. In International Conference on Smart Infrastructure and Construction 2019 (ICSIC) Driving Data-Informed Decision-Making; ICE Publishing: London, UK, 2019; pp. 3–9. [Google Scholar]

- Ayele, Y.Z.; Aliyari, M.; Griffiths, D.; Droguett, E.L. Automatic crack segmentation for UAV-assisted bridge inspection. Energies 2020, 13, 6250. [Google Scholar] [CrossRef]

- Nasrollahi, M. Automated Bridge Inspection for Concrete Surface Defect Detection Using Deep Neural Network Based on LiDAR Scanning. Ph.D. Thesis, Concordia University, Montreal, QC, Canada, 2019. [Google Scholar]

- Fan, R.; Guo, S.; Wang, L.; Bocus, M.J. Computer-aided road inspection: Systems and algorithms. In Recent Advances in Computer Vision Applications Using Parallel Processing; Springer International Publishing: Cham, Switzerland, 2023; pp. 13–39. [Google Scholar]

- Medina, R.; Gómez-García-Bermejo, J.; Zalama, E. Automated visual inspection of road surface cracks. In International Symposium on Automation and Robotics in Construction (ISARC); Citeseer: Online, 2010. [Google Scholar]

- Garbowski, T.; Gajewski, T. Semi-automatic inspection tool of pavement condition from three-dimensional profile scans. Procedia Eng. 2017, 172, 310–318. [Google Scholar] [CrossRef]

- Zhang, C.; Nateghinia, E.; Miranda-Moreno, L.F.; Sun, L. Pavement distress detection using convolutional neural network (CNN): A case study in Montreal, Canada. Int. J. Transp. Sci. Technol. 2022, 11, 298–309. [Google Scholar] [CrossRef]

- Samsami, R.; Mukherjee, A.; Brooks, C.N. Automated Pavement Construction Inspection Using Uncrewed Aerial Systems (UAS)—Hot Mixed Asphalt (HMA) Temperature Segregation. Drones 2023, 7, 419. [Google Scholar] [CrossRef]

- Hsie, M. Automated Inspection Planning through CAD Modeling for Steel Bridge Painting Construction. In Proceedings of the 13th International Symposium on Automation and Robotics in Construction, Tokyo, Japan, 11–13 June 1996; pp. 431–440. [Google Scholar]

- Behnam, A.; Wickramasinghe, D.C.; Ghaffar, M.A.A.; Vu, T.T.; Tang, Y.H.; Isa, H.B.M. Automated progress monitoring system for linear infrastructure projects using satellite remote sensing. Autom. Constr. 2016, 68, 114–127. [Google Scholar] [CrossRef]

- Behnam, A. A Study on the Application of Location-Based Management and Automated Progress Monitoring for Linear Construction Projects. Unpublished MPhil Thesis, University of Nottingham Malaysia Campus, Semenyih, Malaysia, 2015. [Google Scholar]

- Lesiak, P. Inspection and maintenance of railway infrastructure with the use of unmanned aerial vehicles. Probl. Kolejnictwa 2020, 188, 115–127. [Google Scholar] [CrossRef]

- Yang, H.; Wang, Y.; Hu, J.; He, J.; Yao, Z.; Bi, Q. Deep learning and machine vision-based inspection of rail surface defects. IEEE Trans. Instrum. Meas. 2021, 71, 1–14. [Google Scholar] [CrossRef]

- Zhou, H.; Xu, C.; Tang, X.; Wang, S.; Zhang, Z. A Review of Vision-Laser-Based Civil Infrastructure Inspection and Monitoring. Sensors 2022, 22, 5882. [Google Scholar] [CrossRef]

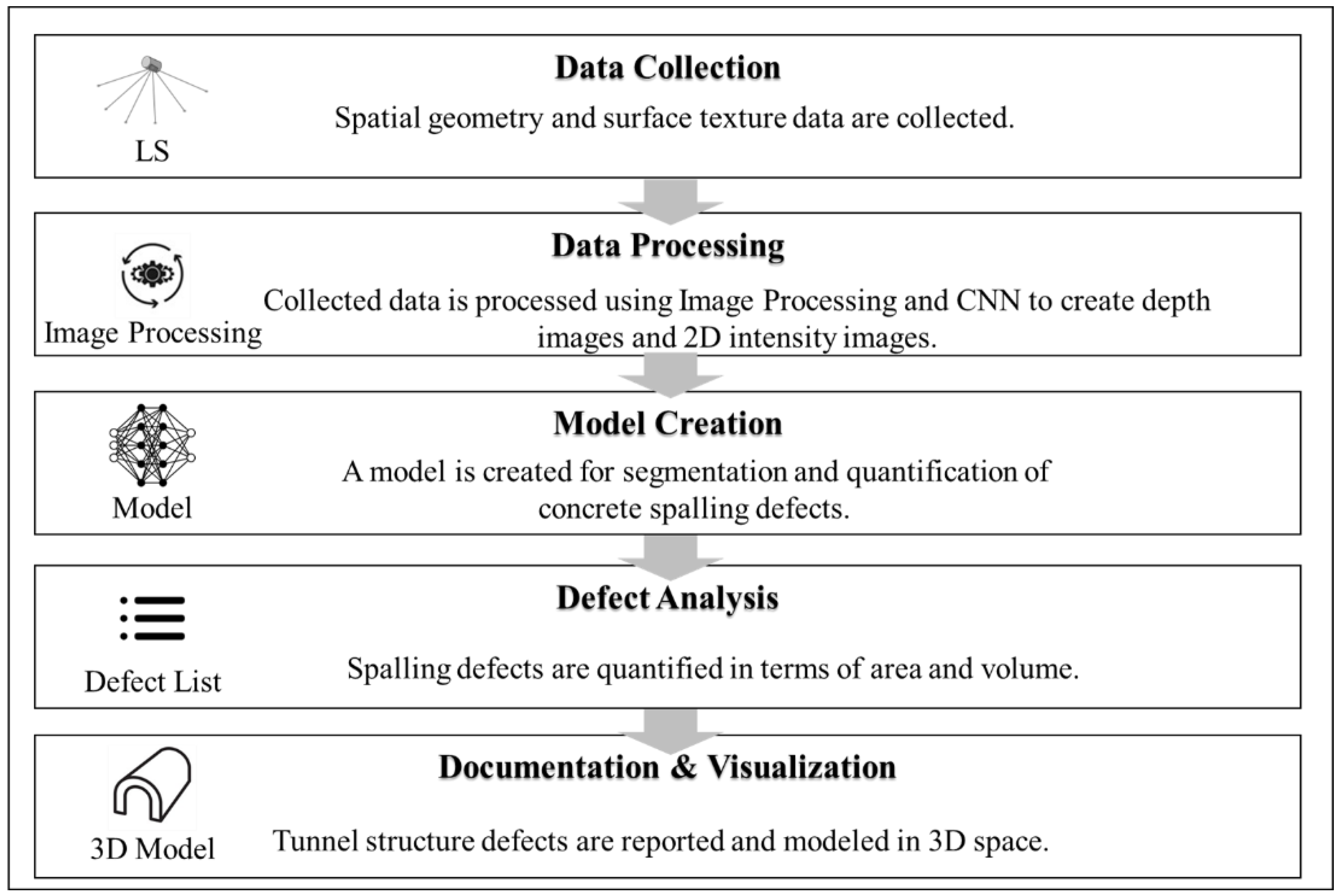

- Zhou, M.; Cheng, W.; Huang, H.; Chen, J. A novel approach to automated 3d spalling defects inspection in railway tunnel linings using laser intensity and depth information. Sensors 2021, 21, 5725. [Google Scholar] [CrossRef]

- Montero, R.; Victores, J.G.; Martinez, S.; Jardón, A.; Balaguer, C. Past, present and future of robotic tunnel inspection. Autom. Constr. 2015, 59, 99–112. [Google Scholar] [CrossRef]

- Jing, G.; Qin, X.; Wang, H.; Deng, C. Developments, challenges, and perspectives of railway inspection robots. Autom. Constr. 2022, 138, 104242. [Google Scholar] [CrossRef]

- Zhuang, L.; Wang, L.; Zhang, Z.; Tsui, K.L. Automated vision inspection of rail surface cracks: A double-layer data-driven framework. Transp. Res. Part C Emerg. Technol. 2018, 92, 258–277. [Google Scholar] [CrossRef]

- Kim, C.; Son, H.; Kim, C. Fully automated registration of 3D data to a 3D CAD model for project progress monitoring. Autom. Constr. 2013, 35, 587–594. [Google Scholar] [CrossRef]

- Golparvar-Fard, M.; Pena-Mora, F.; Savarese, S. Automated progress monitoring using unordered daily construction photographs and IFC-based building information models. J. Comput. Civ. Eng. 2015, 29, 04014025. [Google Scholar] [CrossRef]

- Lin, J.J.; Han, K.K.; Golparvar-Fard, M. A framework for model-driven acquisition and analytics of visual data using UAVs for automated construction progress monitoring. Comput. Civ. Eng. 2015, 2015, 156–164. [Google Scholar]

- Mahami, H.; Nasirzadeh, F.; Ahmadabadian, A.H.; Nahavandi, S. Automated progress controlling and monitoring using daily site images and building information modelling. Buildings 2019, 9, 70. [Google Scholar] [CrossRef]

- Braun, A.; Tuttas, S.; Borrmann, A.; Stilla, U. Automated progress monitoring based on photogrammetric point clouds and precedence relationship graphs. In ISARC. Proceedings of the International Symposium on Automation and Robotics in Construction; IAARC Publications: Cambridge, UK, 2015; p. 1. [Google Scholar]

- Dimitrov, A.; Golparvar-Fard, M. Vision-based material recognition for automated monitoring of construction progress and generating building information modeling from unordered site image collections. Adv. Eng. Inform. 2014, 28, 37–49. [Google Scholar] [CrossRef]

- Braun, A.; Tuttas, S.; Borrmann, A.; Stilla, U. A concept for automated construction progress monitoring using bim-based geometric constraints and photogrammetric point clouds. J. Inf. Technol. Constr. 2015, 20, 68–79. [Google Scholar]

- Pučko, Z.; Šuman, N.; Rebolj, D. Automated continuous construction progress monitoring using multiple workplace real time 3D scans. Adv. Eng. Inform. 2018, 38, 27–40. [Google Scholar] [CrossRef]

- Rebolj, D.; Pučko, Z.; Babič, N.Č.; Bizjak, M.; Mongus, D. Point cloud quality requirements for Scan-vs-BIM based automated construction progress monitoring. Autom. Constr. 2017, 84, 323–334. [Google Scholar] [CrossRef]

- Braun, A.; Tuttas, S.; Stilla, U.; Borrmann, A.; Center, L.O. Incorporating knowledge on construction methods into automated progress monitoring techniques. In Proceedings of the 23rd International Workshop of the European Group for Intelligent Computing in Engineering, Kraków, Poland, 29 June–1 July 2016. [Google Scholar]

- Xue, J.; Hou, X.; Zeng, Y. Review of image-based 3D reconstruction of building for automated construction progress monitoring. Appl. Sci. 2021, 11, 7840. [Google Scholar] [CrossRef]

- Lin, J.J.; Lee, J.Y.; Golparvar-Fard, M. Exploring the potential of image-based 3D geometry and appearance reasoning for automated construction progress monitoring. In Computing in Civil Engineering 2019: Data, Sensing, and Analytics; American Society of Civil Engineers: Reston, VA, USA, 2019; pp. 162–170. [Google Scholar]

- Rehman, M.S.U.; Shafiq, M.T.; Ullah, F. Automated Computer Vision-Based Construction Progress Monitoring: A Systematic Review. Buildings 2022, 12, 1037. [Google Scholar] [CrossRef]

- Wei, W.; Lu, Y.; Zhong, T.; Li, P.; Liu, B. Integrated vision-based automated progress monitoring of indoor construction using mask region-based convolutional neural networks and BIM. Autom. Constr. 2022, 140, 104327. [Google Scholar] [CrossRef]

- Mahami, H.; Nasirzadeh, F.; Ahmadabadian, A.H.; Esmaeili, F.; Nahavandi, S. Imaging network design to improve the automated construction progress monitoring process. Constr. Innov. 2019, 19, 386–404. [Google Scholar] [CrossRef]

- Pushkar, A.; Senthilvel, M.; Varghese, K. Automated progress monitoring of masonry activity using photogrammetric point cloud. In ISARC. Proceedings of the International Symposium on Automation and Robotics in Construction; IAARC Publications: Cambridge, UK, 2018; pp. 1–7. [Google Scholar]

- Guven, G.; Ergen, E. A rule-based methodology for automated progress monitoring of construction activities: A case for masonry work. J. Inf. Technol. Constr. 2019, 24, 188–208. [Google Scholar]

- Greeshma, A.S.; Edayadiyil, J.B. Automated progress monitoring of construction projects using Machine learning and image processing approach. Mater. Today Proc. 2022, 65, 554–563. [Google Scholar]

- Maalek, R.; Lichti, D.; Ruwanpura, J. Development of an automated 3D/4D as-built model generation system for construction progress monitoring and quality control. In Proceedings of the ICSC15: The Canadian Society for Civil Engineering 5th International/11th Construction Specialty Conference, Vancouver, DC, Canada, 7–10 June 2015. [Google Scholar]

- Hassan, M.U. An intelligent bim-based automated progress monitoring system using self-navigating robots for data acquisition. PhD Thesis, Middle East Technical University, Ankara, Turkey, 2018. [Google Scholar]

- Senthilvel, M. Automated Construction Progress Monitoring Using Range Imaging. Master’s Thesis, Indian Institute Of Technology Madras, Tamil Nadu, India, 2017. [Google Scholar]

- Ghassemi, N.; Mahami, H.; Tayarani Darbandi, M.; Shoeibi, A.; Hussain, S.; Nasirzadeh, F.; Alizadehsani, R.; Nahavandi, D.; Khosravi, A.; Nahavandi, S. Material Recognition for Automated Progress Monitoring using Deep Learning Methods. arXiv 2006, arXiv:2006.16344. [Google Scholar]

- Malekmohammadi, N. Analysis of implementing automated progress monitoring on UAE construction sites through integrated BIM-drone technologies. 2021. [Google Scholar]

- Rebolj, D.; Babič, N.Č.; Magdič, A.; Podbreznik, P.; Pšunder, M. Automated construction activity monitoring system. Adv. Eng. Inform. 2008, 22, 493–503. [Google Scholar] [CrossRef]

- Turkan, Y. Automated construction progress tracking using 3D sensing technologies. PhD Thesis, University of Waterloo, Waterloo, ON, Canada, January 2012. [Google Scholar]

- Turkan, Y.; Bosche, F.; Haas, C.T.; Haas, R. Automated progress tracking using 4D schedule and 3D sensing technologies. Autom. Constr. 2012, 22, 414–421. [Google Scholar] [CrossRef]

- Kim, H.; Kano, N. Comparison of construction photograph and VR image in construction progress. Autom. Constr. 2008, 17, 137–143. [Google Scholar] [CrossRef]

- Bosche, F.; Haas, C.T.; Murray, P. Performance of automated project progress tracking with 3D data fusion. In Proceedings of the CSCE 2008 Annual Conference, Quebec, QC, Canada, 10–13 June 2008. [Google Scholar]

- Braun, A.; Borrmann, A. Combining inverse photogrammetry and BIM for automated labeling of construction site images for machine learning. Autom. Constr. 2019, 106, 102879. [Google Scholar] [CrossRef]

- Ibrahim, Y.M.; Lukins, T.C.; Zhang, X.; Trucco, E.; Kaka, A.P. Towards automated progress assessment of workpackage components in construction projects using computer vision. Adv. Eng. Inform. 2009, 23, 93–103. [Google Scholar] [CrossRef]

- Lin, Z.Y.; Petzold, F.; Ma, Z.L. A real-time 4D augmented reality system for modular construction progress monitoring. In ISARC. Proceedings of the International Symposium on Automation and Robotics in Construction; IAARC Publications: Cambridge, UK, 2019; pp. 743–748. [Google Scholar]

- Prieto, S.A.; de Soto, B.G.; Adan, A. A methodology to monitor construction progress using autonomous robots. In ISARC. Proceedings of the International Symposium on Automation and Robotics in Construction; IAARC Publications: Cambridge, UK, 2020; pp. 1515–1522. [Google Scholar]

- Alizadehsalehi, S.; Yitmen, I. The impact of field data capturing technologies on automated construction project progress monitoring. Procedia Eng. 2016, 161, 97–103. [Google Scholar] [CrossRef]

- Maalek, R.; Ruwanpura, J.; Ranaweera, K. Evaluation of the state-of-the-art automated construction progress monitoring and control systems. In Proceedings of the Construction Research Congress 2014: Construction in a Global Network, Atlanta, Georgia, 19–21 May 2014; pp. 1023–1032. [Google Scholar]

- Kopsida, M.; Brilakis, I.; Vela, P.A. A review of automated construction progress monitoring and inspection methods. In Proceedings of the 32nd CIB W78 Conference 2015, Eindhoven, The Netherlands, 27–29 October 2015; pp. 421–431. [Google Scholar]

- Alizadehsalehi, S.; Yitmen, I. A concept for automated construction progress monitoring: Technologies adoption for benchmarking project performance control. Arab. J. Sci. Eng. 2019, 44, 4993–5008. [Google Scholar] [CrossRef]

- Qureshi, A.H.; Alaloul, W.S.; Wing, W.K.; Saad, S.; Ammad, S.; Musarat, M.A. Factors impacting the implementation process of automated construction progress monitoring. Ain. Shams Eng. J. 2022, 13, 101808. [Google Scholar] [CrossRef]

- Qureshi, A.H.; Alaloul, W.S.; Manzoor, B.; Saad, S.; Alawag, A.M.; Alzubi, K.M. Implementation Challenges of Automated Construction Progress Monitoring Under Industry 4.0 Framework Towards Sustainable Construction. In Proceedings of the 2021 Third International Sustainability and Resilience Conference: Climate Change, Virtual, 15–17 November 2021; pp. 322–326. [Google Scholar]

- Reja, V.K.; Pradeep, M.S.; Varghese, K. A Systematic Classification and Evaluation of Automated Progress Monitoring Technologies in Construction. In ISARC. Proceedings of the International Symposium on Automation and Robotics in Construction; IAARC Publications: Cambridge, UK, 2022; pp. 120–127. [Google Scholar]

- Panahi, R.; Louis, J.; Podder, A.; Swanson, C. Tracking Volumetric Units in Modular Factories for Automated Progress Monitoring Using Computer Vision. Constr. Res. Congr. 2022, 2022, 822–829. [Google Scholar]

- Li, C.; Chen, L.; Wang, J.; Xia, T. A Method for Image Big Data Utilization: Automated Progress Monitoring Based on Image Data for Large Construction Site. In Big Data and Security: Second International Conference, ICBDS 2020, Singapore, 20–22 December 2020, Revised Selected Papers 2; Springer: Singapore, 2021; pp. 299–313. [Google Scholar]

- Rehman, M.S.U.; Shafiq, M.T. Automated Construction Progress Monitoring–Industry Perspective. In International Conference on Construction in the 21st Century; East Carolina University: Greenville, NC, USA, 2022. [Google Scholar]

- Rehman, M.S.U.; Shafiq, M.T. Identifying the Process for Automated Vision-based Construction Progress Monitoring. In Proceedings of the 8th Zero Energy Mass Custom Home International Conference, ZEMCH 2021, ZEMCH Network, Dubai, United Arab Emirates, 26–28 October 2021; pp. 740–746. [Google Scholar]

- Hecht, H. A GPU Based Approach for As-Planned versus As-Built Comparison in the Scope of Automated BIM Based Construction Progress Monitoring. Bachelor’s Thesis, Technische Universität München, München, Germany, 2016. [Google Scholar]

- Rasheed, S.H. Cyber-Adaptive Physical Systems for Automated Construction Progress Monitoring and Asset Tracking. Master’s Thesis, Western Michigan University, Kalamazoo, MI, USA, 2013. [Google Scholar]

- Barbarosoglu, B.V. EVM-3664 Evolving Technological Trends for Automated Construction Progress Monitoring. Available online: https://www.academia.edu/49349872/Evolving_Technological_Trends_for_Automated_Construction_Progress_Monitoring (accessed on 30 November 2023).

- Aikala, A.; Khalid, M.; Seppänen, O.; Singh, V. Crane camera image preparation for automated monitoring of formwork and rebar progress. In Proceedings of the 36th CIB W78 Conference, Newcastle-Upon-Tyne, UK, 18 September 2019. [Google Scholar]

- Kielhauser, C.; Manzano, R.R.; Hoffman, J.J.; Adey, B.T. Automated construction progress and quality monitoring for commercial buildings with unmanned aerial systems: An application study from Switzerland. Infrastructures 2020, 5, 98. [Google Scholar] [CrossRef]

- Maalek, R.; Lichti, D.D.; Ruwanpura, J.Y. Automatic recognition of common structural elements from point clouds for automated progress monitoring and dimensional quality control in reinforced concrete construction. Remote Sens. 2019, 11, 1102. [Google Scholar] [CrossRef]

- Braun, A. Automated BIM-Based Construction Progress Monitoring by Processing and Matching Semantic and Geometric Data. Ph.D. Dissertation, Technical University of Munich, München, Germany, 2020. [Google Scholar]

- Tsige, G. Scan-vs-BIM Automated Registration Using Columns Segmented by Deep Learning for Construction Progress Monitoring. Master’s Thesis, University of Twente, Enschede, The Netherlands, 2022. [Google Scholar]

- Halder, S.; Afsari, K.; Serdakowski, J.; DeVito, S. A Methodology for BIM-enabled Automated Reality Capture in Construction Inspection with Quadruped Robots. In ISARC. Proceedings of the International Symposium on Automation and Robotics in Construction; IAARC Publications: Cambridge, UK, 2021; pp. 17–24. [Google Scholar]

- Bosché, F. Automated recognition of 3D CAD model objects in laser scans and calculation of as-built dimensions for dimensional compliance control in construction. Adv. Eng. Inform. 2010, 24, 107–118. [Google Scholar] [CrossRef]

- Gordon, C.; Akinci, B.; Garrett, J.H. Automated planning support for on-site construction inspection. Autom. Constr. 2008, 17, 705–718. [Google Scholar] [CrossRef]

- Besada, J.A.; Bergesio, L.; Campaña, I.; Vaquero-Melchor, D.; López-Araquistain, J.; Bernardos, A.M.; Casar, J.R. Drone mission definition and implementation for automated infrastructure inspection using airborne sensors. Sensors 2018, 18, 1170. [Google Scholar] [CrossRef] [PubMed]

- Zheng, X.; Wang, H.; Chen, J.; Kong, Y.; Zheng, S. A generic semi-supervised deep learning-based approach for automated surface inspection. IEEE Access 2020, 8, 114088–114099. [Google Scholar] [CrossRef]

- Chow, J.K.; Liu, K.-F.; Tan, P.S.; Su, Z.; Wu, J.; Li, Z.; Wang, Y.-H. Automated defect inspection of concrete structures. Autom. Constr. 2021, 132, 103959. [Google Scholar] [CrossRef]

- Kim, J.J.; Kim, A.-R.; Lee, S.-W. Artificial neural network-based automated crack detection and analysis for the inspection of concrete structures. Appl. Sci. 2020, 10, 8105. [Google Scholar] [CrossRef]

- Zhong, B.T.; Ding, L.Y.; Luo, H.B.; Zhou, Y.; Hu, Y.Z.; Hu, H.M. Ontology-based semantic modeling of regulation constraint for automated construction quality compliance checking. Autom. Constr. 2012, 28, 58–70. [Google Scholar] [CrossRef]

- Nasab, A.H.; Sardroud, J.M.; Limbachiya, M.C. Improving construction quality control and management using automated data collection technologies. In Proceedings of the 2nd International Multi-Conference on Complexity, Informatics and Cybernetics (IMCIC 2011), Orlando, FL, USA, 27–30 March 2011. [Google Scholar]

- Klein, M.B.; Ansari, H. Automated Laser Ultrasonic Inspection of Hybrid Laser Arc Welding for Pipeline Construction. Int. Pipeline Conf. 2010, 44212, 817–822. [Google Scholar]

| Research Area | Total Number | Journal/Conference Title | Publisher | Frequency |

|---|---|---|---|---|

| Applications of Automation, Robotics, and Digital Technologies | 31 | Automation in Construction | Elsevier | 21 |

| Proceedings of the ISARC | ISARC | 10 | ||

| Construction Engineering and Management | 6 | CRC International Conference | CRC | 6 |

| Advancement of Technology and Engineering Fields | 5 | IEEE International Conference | IEEE | 5 |

| Application of Advanced Information and Communication Technologies | 5 | Advanced Engineering Informatics | Elsevier | 5 |

| Application of Computing, Information Technology, and Digital Innovations | 5 | Computing in Civil Engineering | ASCE | 3 |

| Journal of Computing in Civil Engineering | ASCE | 2 | ||

| Engineering and Computer Science | 4 | Procedia Engineering | Elsevier | 2 |

| IEEE Access | IEEE | 2 | ||

| Science and Technology of Sensors and Sensing Systems | 4 | Sensors | MDPI | 4 |

| Applied Sciences | 2 | Applied Sciences | MDPI | 2 |

| Built Environment | 2 | Buildings | MDPI | 2 |

| Energy Science | 2 | Energies | MDPI | 2 |

| Transportation Engineering | 2 | Transportation Research Record | SAGE | 2 |

| Domain | Sub-Domain (Structure) | Frequency | Publications |

|---|---|---|---|

| Transportation (Total Reviewed: 58) | Bridge Inspection | 31 | [2,3,4,5,6,21,23,24,25,26,27,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64] |

| Highway Inspection | 13 | [7,10,11,12,13,14,15,16,17,65,66,67,68,69] | |

| Railway Inspection | 14 | [28,29,30,31,70,71,72,73,74,75,76,77,78,79] | |

| Building (Total Reviewed: 70) | Progress Monitoring | 52 | [18,80,81,82,83,84,85,86,87,88,89,90,91,92,93,94,95,96,97,98,99,100,101,102,103,104,105,106,107,108,109,110,111,112,113,114,115,116,117,118,119,120,121,122,123,124,125,126,127,128,129,130] |

| Quality Inspection | 9 | [1,40,41,42,45,127,128,131,132], | |

| Façade Inspection | 5 | [25,26,27,28,38] | |

| Crack Inspection | 3 | [32,37,39] | |

| Energy Assessment | 1 | [44] | |

| Falsework Inspection | 1 | [43] | |

| Occupancy Authorization | 1 | [46] | |

| Others (Related to both Domains) | 8 | [133,134,135,136,137,138,139,140] | |

| Total Reviewed | 138 | ||

| Tools and Techniques | Description | Frequency |

|---|---|---|

| Handheld Cameras | A traditional camera to capture optical images and videos from jobsite. | 39 |

| Laser Scanning (LS) | A technology that uses laser light to digitally capture the exact size and shape of a target object. | 31 |

| Augmented Reality (AR) | A computer technology to add visual, auditory, haptic, and somatosensory data on top of the current real world. | 28 |

| Computer Vision (CV) | An interdisciplinary tool for processing and analyzing visual data (digital images/video). This tool seeks to simulate, an interpreting process performed by a human visual system. | 24 |

| Deep Learning | Subset of machine learning that uses artificial neural networks with multiple layers to process and analyze complex patterns in data. | 24 |

| Uncrewed Aerial System (UAS) | An aircraft without a human pilot on board. A system consisting of a UAV, a ground-based controller, and a communication system between these is called an Unmanned Aerial System (UAS). Cameras and sensors are mountable on a UAS to capture different types of data. | 23 |

| Building Information Modeling (BIM) | A process that integrates different tools and technologies to generate visual/functional models of a built asset/facility. | 21 |

| Robots | Mechanical or virtual devices that perform tasks autonomously or semi-autonomously and are often able to mimic human actions. | 14 |

| Radio Frequency Identification (RFID) | RFID is a system consisting of a radio transponder, a radio receiver, and a transmitter. This system utilizes electromagnetic fields to detect and track the tags/smart labels attached to the target objects. | 8 |

| Geographic Information System (GIS) | Technology to captures, analyzes, and visualizes spatial data to understand patterns, relationships, and make informed decisions about the real world. | 5 |

| Geographic Positioning System (GPS) | Satellite-based navigation system to provide positioning data. GPS is one of global navigation satellite systems (GNSS) to provide geo-location and time information to a GPS receiver. | 4 |

| Point Cloud | Collection of 3D data points in space, typically obtained through laser scanning or 3D imaging techniques. | 3 |

| Photogrammetry | Technique for processing and interpreting the visual data collected using different data collection technologies, such as aerial images collected with UAS. It allows 2D/3D digital model generation of a target object. | 3 |

| Paver Mounted Thermal Profiler | Device mounted on a paver to capture temperature profiles of the asphalt pavement during construction to ensure proper quality and compaction. | 1 |

| Smartphone | Mobile device that combines the functionalities of a cellular phone with advanced features such as internet connectivity, touchscreen interface, multimedia capabilities, and a wide range of applications for various tasks | 1 |

| Internet of Things (IoT) | Network of interconnected physical devices, vehicles, appliances, and other objects embedded with sensors, software, and connectivity capabilities, to remotely collect and exchange data. | 1 |

| Mobile Computing | Using portable computing devices, such as smartphones, tablets, and laptops, to access and process information, perform tasks, and communicate while moving. | 1 |

| Virtual Reality (VR) | A computer technology that uses software to produce images /sound and create the sensation of presence at a target place. | 1 |

| Ultra-Wide Band (UWB) | Radio communication technology for target sensor data collection and tracking and precision locating. UWB consumes low level of energy, and creates short-range, high-bandwidth communication data. | 1 |

| Category | Frequency | Challenge | Publications |

|---|---|---|---|

| Limited Generalization and Adaptability | 9 | Models might lack generalization. | [17,35,37,38,39,41,59,63,76] |

| Data Quality and Variability | 8 | Data formats and quality are inconsistent across construction projects. | [7,12,24,39] |

| Data accuracy is affected by different factors, including lighting and weather conditions. | [5,43] | ||

| There are no standardized data collection methods. | [27,39] | ||

| Integration and Compatibility | 7 | It is difficult to integrate ACI systems with existing construction processes and technologies. | [27,40] |

| Different ACI platforms might not be compatible or interoperable with each other. | [7] | ||

| Real-time Data Analysis | 4 | It is challenging to capture and analyze the data in real time. | [5,35,39,42] |

| Complex Construction Contexts | 2 | Complexity due to dynamic and diverse construction, as well as irregularity in geometry and design environment needs to be studied. | [39,43] |

| Cost and Efficiency | 2 | Cost–benefit and efficiency analysis need to be studied, especially for smaller project. | [24,43] |

| Human-Technology Interface | 1 | It is challenging for construction personnel to operate the ACIPM tools. | [7] |

| Computation Optimization | 1 | Computation burden is high for the developed ACI models. | [6] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samsami, R. A Systematic Review of Automated Construction Inspection and Progress Monitoring (ACIPM): Applications, Challenges, and Future Directions. CivilEng 2024, 5, 265-287. https://doi.org/10.3390/civileng5010014

Samsami R. A Systematic Review of Automated Construction Inspection and Progress Monitoring (ACIPM): Applications, Challenges, and Future Directions. CivilEng. 2024; 5(1):265-287. https://doi.org/10.3390/civileng5010014

Chicago/Turabian StyleSamsami, Reihaneh. 2024. "A Systematic Review of Automated Construction Inspection and Progress Monitoring (ACIPM): Applications, Challenges, and Future Directions" CivilEng 5, no. 1: 265-287. https://doi.org/10.3390/civileng5010014

APA StyleSamsami, R. (2024). A Systematic Review of Automated Construction Inspection and Progress Monitoring (ACIPM): Applications, Challenges, and Future Directions. CivilEng, 5(1), 265-287. https://doi.org/10.3390/civileng5010014