Abstract

Growing demand for road infrastructures and accompanying environmental footprint calls for the replacement of pavement materials with recycled options. The complexities in real-world usability are dependent upon project-specific characteristics and are affected by budgetary constraints of local governmental agencies, material applicability, and climatical conditions. This study conducts a comprehensive lifecycle cost analysis (LCCA) of an urban highway section “E10” in the hot Middle Eastern climate of Abu Dhabi, where virgin asphalt usage is dominant, using actual cost data under multiple scenarios and recycled construction waste (RCW) usage across aggregate layers and recycled asphalt pavement (RAP) across wearing, binder, and asphalt base courses. Blast furnace slag as partial cement replacement for road concrete works is also analysed. Impacts across all lifecycle stages from initial earthworks and construction to routine maintenance and operation were compared. Results found that cost of sustainable construction is lower. Cost reduction was highest for RAP and RCW usage, particularly when the usage was accumulated. The optimum cost scenario used 25% RCW in the sub-base, 80% RCW in the unbound base, 25% warm-mix asphalt (WMA) RAP in the asphalt base, 15% warm-mix RAP in the binder and wearing courses, and 65% slag for concrete roadworks and resulted in USD 2.6 million (15%) cost reduction over 30 years from 2015 to 2045.

1. Introduction

Roads are a critical part of urban settlements, and their construction, maintenance, and rehabilitation (M&R) activities are often assessed by the extent of the capital available for execution, while public agencies base it on the cost of raising capital against meeting the public road demand trade-off, exemplified by municipal transport agencies in the study by Rahman and Vanier [1]. International Road Forum [2] notes that the construction, operation, and M&R of pavements alone constitute a global investment of USD 400 billion per annum. Increasing global focus on sustainability implementation for road and pavement works has shifted the debate from just cost–benefit analyses to performance across the overall sustainability triple-bottom-line cost ( environmental and social factors), with the environmental parameter given considerably higher weight by experts, but this has yet to reach large-scale application because of lack of accompanying economic analyses [3,4]. On the industry side, pavement works still begin initially with the economic feasibility of the construction endeavour and then the cost evaluation of alternate options. Thus, a detailed cost assessment of recycled/greener pavement materials using real-world data from large-scale worldwide projects is still needed when promoting practical applications because of their influence on the successful management of road transport assets [5,6].

In a study by Rahman and Vanier [1] surveying owners and managers on the management practices involved in Canadian infrastructures, it was found that the majority of the respondents (91%) asserted the need for a decision-support tool for infrastructure asset management, whereas 70% identified lifecycle cost analysis (LCCA) as an effective tool to ensure timely maintenance. The studies conducted on the potential application of LCCA generally focus on the design phase; however, its application during construction and maintenance phases has also been researched. LCCA can be implemented as a standalone process without its complementary component of lifecycle analysis (LCA), an environmental and social aspect assessment approach discussed in pavement research [7,8].

However, the practical usage of LCCA beyond research is dependent upon addressing uncertainty in collected data as well as the need for an easy to use “knowledge-based dataset”. The identified LCCA models need uncertainty and reliability evaluations beyond the feasibility phase toward identifying the optimal decision based on durability, functionality, and economic efficiency. Probabilistic and deterministic LCCAs are examples of traditional LCCA models; where the former approach acknowledges the uncertainties in the values of input variables in terms of probability distributions, the latter disregards them in favour of deterministic input variables [9,10].

Frameworks based upon probability powered LCCA performance, durability, and cost parameters have been proposed to varying degrees of success within the domain of infrastructure design and management [1,11,12,13,14,15,16], and the limitations of probabilistic analysis during infrastructure investment decision making have also been recognised. For example, Walls and Smith [11] highlight that in order to compensate for the deterministic inputs provided for various parameters in an LCCA model, the impact of the variability of the values on the obtained results is assessed through sensitivity analysis which might fail to acknowledge certain aspects of uncertainties that can be critical and, therefore, affect the “trueness” of the alternative with the lowest LCC.

On the other hand, in an effort to reduce the considerable environmental footprint associated with the usage of virgin materials in the construction and M&R of roadworks and pavements, recycled asphalt pavement (RAP), warm-mix asphalt (WMA), and other alternate material options for asphalt and concrete works have been explored [17,18]. These studies [18,19,20,21] have indicated that recycled and alternate material production technology usage has shown a significant drop in energy consumption and global warming potential of road construction and rehabilitation projects without comprising the durability and structural performance of pavements. Other studies [22] have noted that adding stabilised crumb rubber in RAP-based asphalt pavements provides adequate structural performance and durability by up to 50% RAP content. Thus, the use of recycled or alternate materials offers an opportunity to reduce the overall environmental burden of construction endeavours without compromising structural performance. However, because of the lack of comprehensive assessment methodology across all pavement components, including pavement cross sections and roadside concrete works (foundations for road lights, carriageway barriers, curbs, etc.), an environmentally optimal pavement alternative might not be identifiable [3,23].

Conversely, assessing environmental needs from a comprehensive approach merits different alternatives; the decisive criteria are usually based on the initial economic (design–build) and other client-end cost factors. Waheed et al. [24] proposed that the costs occurring at various stages in the lifecycle of any road transport system project are a vital part of the design and management process to assess all the probable costs occurring within its expected service life. If the operational and long-term costs are neglected while selecting an option, the chosen alternative may have a lower upfront cost but can be more expensive over the life cycle of a civil engineering structure. The issue is more prevalent in regions and large-scale road pavement projects where the lack of accurate data collection from primary data sources and verification of the quality of the collected data for an LCCA evaluation may influence the reliability of results. Additionally, the existing research on pavement LCCA, as covered above, had only focused on a limited number of components of a pavement by assessing either the cross section, surface/wearing courses, or structural members. Some studies only focused on the deterioration and M&R of roads and pavements.

In the current study, based on the pavement LCA literature on the different environmental impacts reducing the alternate pavement cases, a holistic LCCA methodology is presented, which analyses the cost benefits of alternate materials for pavement cross-section (RAP and WMA) and road concrete works (ground granulated blast furnace slag or GGBFS) in a unified assessment approach for the entire pavement lifecycle. A case study large-scale pavement project from Abu Dhabi city in the United Arab Emirates (UAE) is selected. Over the last two decades, the region has seen unprecedented growth with the commencement of ambitious infrastructure development projects with multi-million-dollar high-profile road projects constantly being constructed. There have been some studies analysing the lifecycle environmental impact of using recycled or alternate materials for roadworks [7,25]; however, the feasibility evaluation of these solutions remains limited from a cost perspective.

In the UAE, road projects are valued at USD 122.6 billion [26]. To support its anticipated economic growth, the country is expected to spend another USD 354 billion from 2019 to 2038 for developing roads and other infrastructures, representing an annual expenditure of approximately USD 18 billion [27]. However, a study [28] on infrastructure projects in Abu Dhabi found average cost overruns of approximately USD 10 million (adjusted for inflation). The study identified improper estimation and lack of LCCA approach as the main reason for cost overruns due to unfamiliarity with lifecycle costs, which provides an evaluation opportunity that has been explored in this study. To that end, this study applied the LCCA methodology for calculating the cost of recycled materials against the conventional materials approach for roadworks, including pavement cross section and roadside concrete works. Actual field data for the road section using virgin materials and traditional asphalt production mix for pavement works and Portland cement concrete for the complete concrete works are used as the baseline “B1” case. For sub-base and base courses, virgin unbound granular aggregates are used; virgin HMA asphalt concrete is used in the second base course and binder and wearing courses. Additionally, HMA emulsion prime coat on top of the u-base course and tack coat on top of the asphalt base course and asphalt binder course at a rate of 0.5 kg/m2 are also applied on the case study road section as the baseline case. The impact of using RAP and WMA, recycled construction waste (RCW), and GGBFS is then analysed as alternate cases.

The input material and unit cost dataset were coordinated with the relevant local government agencies and the local material suppliers in the case study location to determine the initial agency costs for both approaches (virgin and recycled materials), including the cost of initial designs, rental of equipment and vehicles for site work, and labour costs. The proposed methodology can then be extended to alternate pavement materials assessment for any road transport system decision-making process using the developed decision criteria based on the potential initial economic, discounted operation, maintenance, and end-of-life (EOL) costs. It can also serve as a potential case study for launching an investigation into the real-world cost of implementing sustainable practices and materials for roadworks in developing countries where a large percentage of projects still rely on conventional materials for construction projects [7].

2. Methodology

2.1 Goal and Scope

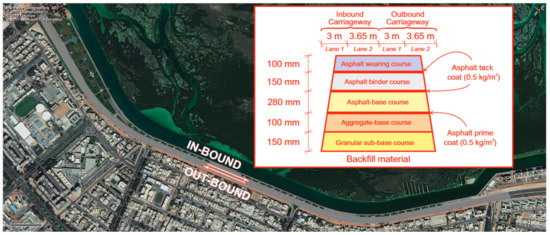

This research is based on the asset management case study of actual roadworks in the UAE and aims to focus on two aspects: initial construction of a pavement and lifecycle management of the built asset after procurement of new projects. LCCA approach is applied for this purpose to calculate the environmental impacts of a 3.5 km-long asphalt dual carriageway section case study in Abu Dhabi, shown in Figure 1.

Figure 1.

Case study of the asphalt pavement section.

System Boundary, Alternate Scenarios, and Lifecycle Inventory

According to ISO 14040 guidelines for estimating lifecycle impacts, the system boundary of this study is extended across all lifecycle stages, starting from preconstruction activities. The following lifecycle stages are considered: raw material extraction and processing, material and equipment transport to the construction site, initial construction, routine maintenance, and rehabilitation after every five years by milling and repaving. Wearing course (<4.5 cm depth) is analysed assuming a 30-year lifetime. In this study, a regular mill and inlay every five years for the top 4.5 cm of wearing course have been considered based on the actual field practice and consultation with the local experts. This periodic mill and inlay of top layers of the wearing course, in addition to the minor surficial repairs, is a commonly recommended practice in many parts of the world for high traffic and major roads/highways due to rutting (~3.5 cm deep) and fatigue, etc. For example, Giani et al. [29] chose a periodic five-year mill and inlay of wearing course, Scheving [30] proposed a 5–6-year periodic mill and inlay of 4.5 cm of wearing course with AADT ≥ 12,000 (case study has same traffic level), and Celauro et al. [31] evaluated periodic four-year mill and inlay of wearing course as a cost-environment-technical balanced option. The lifecycles assumed in these studies and others for the pavement section facing similar daily traffic are 30 years [29], 50 years [32], and 100 years [33], which is similar to or longer than the pavement lifetime assumed in the current study (30 years). Similar to these studies and the expert practices in the case study region, major rehabilitation or extension work is assumed at the end of the 30-year lifecycle.

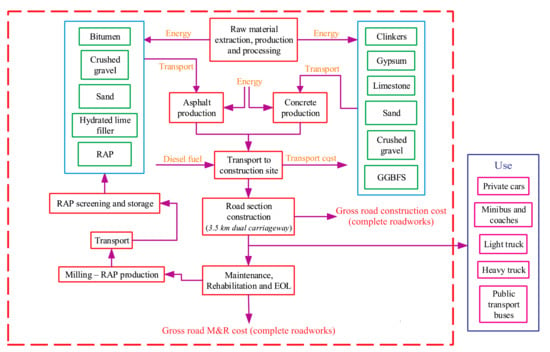

The base year selected is 2015, as per the most recent cost and construction data for the selected road project. The operation and usage stage costs of vehicles are not modelled as they are usually attributed to the road users and vehicle usage [34] and are dependent on large-scale policies related to traffic management and user mode choice behaviour [35,36]. Routine maintenance, minor pavement patchworks, and wear-and-tear costs are modelled as part of the M&R costs. Similarly, the EOL stage is not modelled because of the lack of data, and it can also be reasonably assumed that the salvage value could be offset at the EOL by replacement costs by adopting a conservative approach. Figure 2 illustrates the modelled system boundary for this study.

Figure 2.

System boundary considered for the studied pavement section.

In the virgin material-based scenario, virgin crushed stone and sand sub-base and unbound-base courses, virgin hot-mix asphalt (HMA) base, binder and wearing courses, and 100% ordinary Portland cement (OPC) are used for performing the pavement and concrete works. Different alternate material techniques are applied, as stated earlier, constituting RCW, RAP, and WMA for pavement cross section and GGBFS for the concrete components. The most cost-effective alternates are then combined to create an optimum performing alternative, and the whole lifecycle costs are then calculated for only this optimum alternative against the virgin material-based baseline scenario to estimate the overall cost savings.

As soil courses of different strength and compaction rates may affect the performance of the supported pavement structure, the recycled material option must carry adequate structural strength and durability. Arulrajah et al. [37] and Arulrajah et al. [38] have found that RCW generates adequate friction angle and compression and shear strength, while other studies have noted their strength and stability for soil courses while carrying a considerably lower environmental footprint [39,40]. In recycled material-based alternates, 60% replacement of virgin backfill material with RCW for earthworks, 25% replacement of sub-base aggregates with RCW, and 80% replacement of unbound virgin aggregate for the base course with RCW are analysed.

Similarly, Debbarma et al. [41] have found that pavements containing upward of 80% or more RAP content have adequate flexural strength of 3.67 MPa and compressive strength of 27.6 MPa, while WMA mixtures have been found to exhibit higher strength and durability values for asphalt pavements [42,43]. As such, we analysed five different scenarios containing 10–25% RAP content across pavement cross sections. Based on strength and durability studies on GGBFS usage, ordinary Portland cement (OPC) was partially replaced by GGBFS as an alternate cementitious material. These alternate pavement scenarios are initially tested for the initial costs, and then the optimum cost alternates are combined to create an optimum “alternate material scenario” or “A1”, which is then analysed against the baseline “B1” case for the entire 30-year (2015–2045) lifecycle cost impacts. For the M&R stage, the milled RAP content is used to replace 15% of virgin asphalt in the wearing course. Although other studies have shown using even higher RAP content during the M&R stage, an upper limit of 15% is applied in this study because of the lack of performance data.

The accuracy and transparency of the reported LCCA results for lifecycle stages of the road network assets depend upon the proper acknowledgement of the quality and extent of the material and unit cost data. The lifecycle inventory (LCI) is developed based on the data procured from local material suppliers, contractors initially used for the construction, and the local municipality (Abu Dhabi Municipality) and is shown in Table 1. It includes the expected costs for material procurement, transport to the construction site, and construction and the potential personnel and equipment costs (including repairs), as quoted and billed in the lump-sum bill of quantities charged by contractors for any real-world construction project. The future costs “Ct” occurring after “n” years are discounted to the present value “PV” based on Equation (1) [3] to provide a more realistic and common basis for comparison between different alternatives for costs occurring over the entire lifecycle of the pavement. The discount rate of 5% is used [44]:

Table 1.

Lifecycle inventory for the different pavement section alternatives considered in this study 1.

3. Results and Discussion

The lifecycle cost impact results for the applied LCCA are provided in this section. It compares the cost performances of the different alternatives coupling the benefits of recycled materials for earthworks, pavement aggregate, asphalt courses, and roadside concrete works, based on strategies for improving the sustainability performance of the case study highway section in Abu Dhabi city. It should be noted here that the cost distributions are based on the actual project costs for the studied highway section. The road network in Abu Dhabi, U.A.E., is highly developed [46], and the expansion towards desert areas in the west has increased the availability of infrastructure, material supply chain, and utilities in the desert regions [47], making the results more robust against location changes within the region.

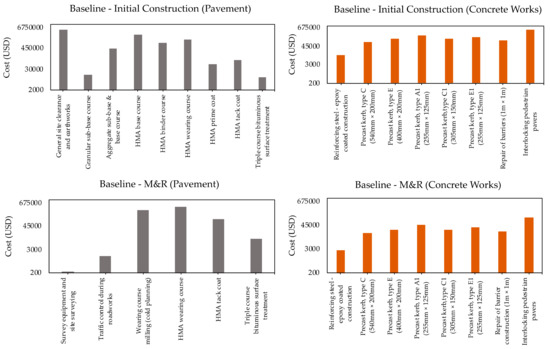

3.1. Distribution of Baseline Cost Impacts across Pavement Cross Section and Concrete Works

Figure 3 shows the lifecycle cost results for the section of the studied road, including pavement cross section and the roadside concrete works (concrete curbs, barriers, and foundation works for the traffic signs and lighting systems) in a concise work using a discount rate of 5% to include the M&R costs discounted to the year 2015 values, i.e., original year of the pavement cost data obtained from local resources; it shows that pavement cross section costs were the highest because of their discernable contribution. For initial construction, it contributed 88% (USD 10.75 million) to lifecycle costs, while concrete works constituted a 12% (USD 1.45 million) share.

Figure 3.

LCCA results for the studied road in the baseline scenario using virgin materials for included lifecycle stages.

During the M&R stage, 25% (USD 0.89 million) of costs came from concrete works, while 75% (USD 0.29 million) came from pavement cross sections over the 30-year lifecycle from 2015 to 2045. The highest costs were generated by general earthworks during initial construction at USD 5.0104 million which not only highlights its importance for reducing the overall cost but also raises an important question about previous studies not including it within the system boundary of LCCA works. Regarding pavement works, the HMA base course (USD 2.6948 millions) and HMA wearing course (USD 1.4861 millions) construction contributed the largest cost share.

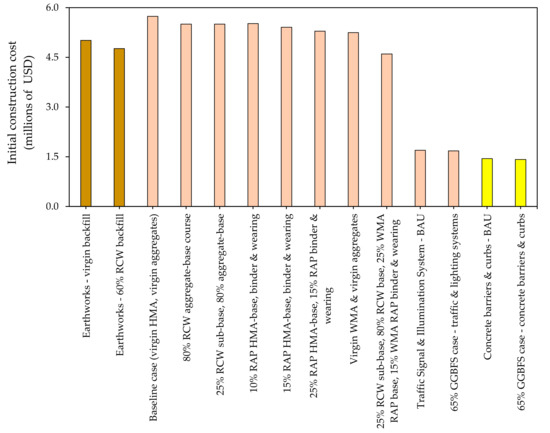

3.2. Cost Impacts of All Recycled and Alternate Material Scenarios during Initial Road Construction

Cost results for the initial construction activities have been provided in Figure 4. These results show significant cost savings across all considered scenarios. For earthworks, replacing 60% of virgin backfill with RCW reduced construction costs by USD 0.246 million (4.92%), while using 80% RCW for the unbound aggregate base course of pavement reduced the construction costs by $0.236 million (4.12%), and combining RCW usage in sub-base (at 25% replacement), and 80% in aggregate base approximately caused a reduction of USD 0.239 million (4.16%). On the other hand, replacing 10% of virgin HMA with RAP content exhibited a construction cost difference of only around USD 0.223 million (3.88%). Following this, after a 15% RAP addition in the pavement HMA courses, a higher construction stage cost reduction of USD 0.334 million (5.82%) was noted, which was further escalated by the addition of 10% RAP (totalling 25%) in the HMA base course showing a cost difference of USD 0.448 million (7.81%).

Figure 4.

Comparison of cost impacts for the studied alternate material scenarios during initial construction across pavement and concrete works components.

However, the results from Figure 4 also illustrate that the improvement in pavement asphalt mixing technology carries a far greater benefit than recycling pavement asphalt content. After using virgin WMA instead of HMA across all bituminous pavement courses, the construction cost was reduced by USD 0.494 million (8.61%). Construction costs of the alternate material option combining the optimum performing recycled materials and WMA for the pavement works in the 25% RCW sub-base, 80% RCW base, 25% WMA RAP base, and 15% WMA RAP binder and wearing courses showed a significant cost reduction of USD 1.139 million (19.85%), making it the ideal option for further evaluation across all lifecycle stages.

Regarding the usage of GGBFS as the alternate material for roadside concrete construction works, it was found from Figure 4 that to construct concrete foundations of traffic lights and illumination systems, 65% replacement of OPC with GGBFS resulted in a cost benefit of approximately USD 0.019 million (1.15%) and the same 65% GGBFS usage for the concrete curbs resulted in a higher degree of cost savings at USD 0.032 million (2.23%). These benefits are largely due to the change in raw material costs because the cost of procuring GGBFS is considerably lower than the OPC as the former is generally produced as industrial waste from steel and iron production. Yet, a high-cost difference was not noted here because of the slight difference in production costs of both types of concretes, as the supply chain in the UAE is not currently optimised for slag usage. For example, Elchalakani et al. [48] have noted that the cost of OPC concrete production in UAE is 0.17 USD/kg in a bulk batch-mixing plant, while 65% GGBFS concrete can be produced at an average price of 0.16 USD/kg.

Nonetheless, the lower cost results from this study for using GGBFS-based concrete still serve as a proof of concept for further adoption of sustainable materials for roadside concrete works in the UAE and other countries in the developing world which largely rely on OPC for large-scale infrastructure projects.

3.3. Reduction Potential of Cost Impacts across Lifecycle Stages for Optimum Recycled and Alternate Materials across All Roadwork Components

The literature review conducted in this paper has argued that the application of a cost-efficient analysis for investment decisions is not limited to the initial design and must be extended to the management, routine maintenance, rehabilitation, and other stages of a road section lifecycle to achieve true optimisation across all cost-related items. Following a cost assessment of conducting and maintaining complete roadworks (including pavement courses, roadside concrete kerbs, barriers, and foundation works for traffic signals and lighting systems) using conventional virgin materials, the lifecycle cost was calculated for the alternative recycled material contribution to road components constructions and M&R stages using the cost-wise optimum performing scenario from Section 3.2, with 25% RCW sub-base, 80% RCW base, 25% WMA RAP base, and 15% WMA RAP binder and wearing courses for construction of pavement cross section and 65% GGBFS for the roadside concrete works.

During M&R, the baseline scenario used virgin HMA for repaving the milled wearing course, while the alternate recycled material scenario used over 80% of the milled RAP content to replace the virgin bituminous material, following the local guidelines and results from previous studies [33,49,50]. The milled RAP from the pavement location is transported to a batch-mix plant as in situ recycling is not currently available in the country, and the results for structural performances and durability of in site recycled pavements from developing countries are considerably limited, which might affect the extendibility of the study results to other regions which lack such technologies for pavement works.

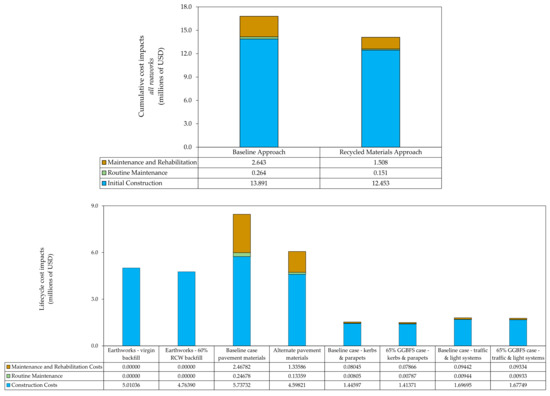

Figure 5 presents the results for the comparative analysis of lifecycle costs of this alternate recycled material scenario against the currently practised baseline scenario using 100% virgin materials for all roadwork components discounted from a 30-year lifecycle to the base year 2015 present value. It can be seen from these results that the largest share of cost impacts was contributed by construction cost, which had an 82.7% share in the baseline approach, and it increased to constitute an 88.2% share for the recycled material approach. However, this increase was offset by the reduction in routine maintenance cost, which is based on the day-to-day minor surficial repairs of the pavement cross section and the roadside concrete works, as it was reduced to 1.1% of the cost share for the recycled material scenario compared with the 1.6% share in the baseline approach.

Figure 5.

Cost impacts and reduction potential distribution across all lifecycle stages for complete roadworks.

Similarly, the periodic (every five years) M&R costs also offset the cost share for the recycled material option with a 10.7% portion claimed for the recycled material approach compared with the 15.7% allocation for the baseline approach. Despite the changes in the cost share of the different roadworks components, Figure 5 illustrates a considerable cost benefit of using recycled alternate material for the studied pavement section over the entire lifecycle as the full cost from LCCA for the baseline approach was reduced by 16% (USD 2.7 million) after using recycled pavement materials.

The majority of these cost savings were contributed by the change in lifecycle costs for pavement cross section, with a difference of approximately USD 4.77 million between the recycled and baseline options. This was followed by the lifecycle cost savings for RCW-based earthworks, which were USD 0.493 million less than the virgin backfill option. This further iterates the significance of extending the LCCA system boundary to include the preconstruction site works and earthworks and shows the benefit of introducing recycled materials for constructing this stage of pavement works. Utilising GGBFS for roadside concrete works in curbs and pedestrian pavers contributed to a lifecycle cost saving of around USD 0.069 million, while the concrete foundation works of traffic lights and illumination systems had a cost reduction of around USD 0.042 million.

It should be noted here that these cost reduction results are due to the lower cost of recycled materials, particularly the high RAP content in the asphalt base course during construction and in the wearing course during the M&R stage. However, the performance aspects, particularly rutting resistance, moisture susceptibility, and fatigue resistance of recycled material and virgin WMA mixes, are different from the conventional HMA option. However, the higher RAP is only used during the maintenance stage by in-plant recycling techniques, and only the top 4.5 cm of the wearing course is milled and recycled. The application of WMA and RAP-based recycled options during construction and M&R stages in the studied region here is novel, yet it has been applied in other regions in pavement literature. For example, Harvey et al. [51], Giani, Dotelli, Brandini and Zampori [29] and Vidal et al. [52] applied similar practices in both stages for the pavement cross section.

Considering the performance aspects of RAP and WMA mixtures, one study [42] observed that irrespective of the alternate pavement design mix, stripping resistance, moisture susceptibility, and cracking resistance were higher than conventional HMA without any RAP content. Another study [53] found deformation resistance, fatigue and stiffness for RAP-WMA mix to be comparable to HMA pavements. The current study builds upon these external studies to provide a basis for using a much conservative RAP content in construction and M&R of asphalt pavements in the studied region to provide a proof-of-concept and create precedence in terms of some cost benefits of recycled and sustainable road construction works in the Middle Eastern region where the practice is limited. Additionally, the environmental benefits of using recycled materials for the studied pavement section were not captured in this study and have been previously published by the authors under a separate study [25].

4. Conclusions

Typically, the LCCA of using recycled materials for a road section, including pavement courses and roadside concrete works, are not compared against virgin materials in sustainable construction literature. This study exhibited a comprehensive LCCA of roadwork for a case-study 3.5 km-long highway section in the United Arab Emirates over 30-year (2015–2045) lifecycle period as representative of developing countries with high virgin material demand. Results showed that the construction stage had the highest cost at 82.7%, followed by periodic M&R at 15.7% and routine maintenance at 1.6%. These results used a 5% discount rate for converting potential future costs to the base year 2015 costs.

Using recycled material for earthworks where 60% virgin backfill was replaced with adequate quality RCW reduced costs by USD 0.493 million. For pavement cross section, using a combination of RCW for aggregate courses and 15% to 25% RAP for the asphalt courses mixed in a batch-mix plant using WMA reduced lifecycle costs by USD 4.769 million. Considering 65% GGBFS as partial OPC replacement for roadside concrete works resulted in a lifecycle cost benefit of USD 0.110 million. Overall, after using recycled materials, the construction costs were reduced by 10.3%, and M&R costs were reduced by 42.9%. This generated an overall cost savings of approximately 16% (USD 2.69 million) over the lifecycle. Thus, this study shows that the benefit of recycled pavement materials is not only an environmental factor but is also supported by substantial cost benefits. An additional cost model may be added to the work here to include cost fluctuations modelling for external economic factors, such as market changes, war conflicts, price variations, etc.

Author Contributions

Conceptualization, methodology, software, funding acquisition, validation, data analysis, writing—original draft preparation, U.H.; Project administration, supervision, resources, writing—review and editing, A.W.; Data curation, resources, writing—review and editing, H.A.J.; Investigation, formal analysis, visualization, A.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research project is supported by an Australian Government Research Training Program (RTP) scholarship.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Research data and models can be made available upon request.

Acknowledgments

The authors thank the Abu Dhabi Municipality (ADM) for their assistance and support in data collection.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Rahman, S.; Vanier, D.J. Life cycle cost analysis as a decision support tool for managing municipal infrastructure. In Proceedings of the Building for the Future: The 16th CIB World Building Congress, Toronto, ON, Canada, 1–7 May 2004; Volume 2004, pp. 1–12. [Google Scholar]

- IRF. World Road Statistics 2010; International Road Federation: Geneva, Switzerland, 2010. [Google Scholar]

- Hasan, U.; Whyte, A.; Al Jassmi, H. Critical review and methodological issues in integrated life-cycle analysis on road networks. J. Clean. Prod. 2019, 206, 541–558. [Google Scholar] [CrossRef]

- Batouli, M.; Bienvenu, M.; Mostafavi, A. Putting sustainability theory into roadway design practice: Implementation of LCA and LCCA analysis for pavement type selection in real world decision making. Transp. Res. Part D Transp. Environ. 2017, 52, 289–302. [Google Scholar] [CrossRef]

- Hasan, U. Development of a Multi-Criteria Decision-Making Framework for Sustainable Road Transport Systems: Integrating Stakeholder-Cost-Environment-Energy Lifecycle Impacts; Curtin University: Perth, WA, Australia, 2019. [Google Scholar]

- Chen, S.-H.; Ni, F.M.-W. Explore pavement roughness under various funding for the Taiwan provincial highways using LCCA. Int. J. Pavement Eng. 2018, 20, 1392–1399. [Google Scholar] [CrossRef]

- Hasan, U.; Whyte, A.; Al Jassmi, H. Life cycle assessment of roadworks in United Arab Emirates: Recycled construction waste, reclaimed asphalt pavement, warm-mix asphalt and blast furnace slag use against traditional approach. J. Clean. Prod. 2020, 257, 120531. [Google Scholar] [CrossRef]

- Hasan, U.; Whyte, A.; Al Jassmi, H. Framework for delivering an AV-based mass mobility solution: Integrating government-consumer actors and life-cycle analysis of transportation systems. In Proceedings of the 46th European Transport Conference, Dublin, Ireland, 10–12 October 2018; p. 18. [Google Scholar]

- Ruparathna, R.; Hewage, K.; Sadiq, R. Multi-period maintenance planning for public buildings: A risk based approach for climate conscious operation. J. Clean. Prod. 2018, 170, 1338–1353. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Z. Deterministic and probabilistic life-cycle cost analysis of pavement overlays with different pre-overlay conditions. Road Mater. Pavement Des. 2017, 20, 58–73. [Google Scholar] [CrossRef]

- Walls, J.; Smith, M.R. Life-Cycle Cost Analysis in Pavement Design: In Search of Better Investment Decisions; FHWA-SA-98-079; Federal Highway Administration: Washington, DC, USA, 1998; p. 107. [Google Scholar]

- Bandara, N.; Gunaratne, M. Current and future pavement maintenance prioritization based on rapid visual condition evaluation. J. Transp. Eng. 2001, 127, 116–123. [Google Scholar] [CrossRef]

- Cho, H.-N.; Kim, J.-H.; Choi, Y.-M.; Lee, K.-M. Practical application of life-cycle cost effective design and rehabilitation of civil infrastructures. In Proceedings of the 3rd International Workshop on Life-Cycle Cost Analysis and Design of Civil Infrastructure Systems, Lausanne, Switzerland, 25–26 March 2003. [Google Scholar]

- Flintsch, G.W.; Chen, C. Soft computing applications in infrastructure management. J. Infrastruct. Syst. 2004, 10, 157–166. [Google Scholar] [CrossRef]

- Chen, C. Soft Computing-Based Life-Cycle Cost Analysis Tools for Transportation Infrastructure Management; Virginia Polytechnic Institute: Blacksburg, VA, USA, 2007. [Google Scholar]

- Goh, K.C.; Yang, J. Developing a life-cycle costing analysis model for sustainability enhancement in road infrastructure project. In Rethinking Sustainable Development: Planning, Infrastructure Engineering, Design and Managing Urban Infrastructure; Queensland University of Technology: Brisbane, Australia, 2009; pp. 324–331. [Google Scholar]

- Han, C.; Ma, T.; Xu, G.; Chen, S. A multi-factor analysis approach for recycled asphalt mixture stockpile center location. Transp. Res. Part D Transp. Environ. 2020, 86, 102463. [Google Scholar] [CrossRef]

- Prakash, G.; Suman, S.K. An intensive overview of warm mix asphalt (WMA) technologies towards sustainable pavement construction. Innov. Infrastruct. Solut. 2022, 7, 1–26. [Google Scholar] [CrossRef]

- Hasan, U.; Chegenizadeh, A.; Budihardjo, M.A.; Nikraz, H. Experimental evaluation of construction waste and ground granulated blast furnace slag as alternative soil stabilisers. Geotech. Geol. Eng. 2016, 34, 1707–1722. [Google Scholar] [CrossRef]

- Hasan, U.; Chegenizadeh, A.; Budihardjo, M.A.; Nikraz, H. Shear strength evaluation of bentonite stabilised with recycled materials. J. GeoEngineering 2016, 11, 59–73. [Google Scholar]

- Bressi, S.; Santos, J.; Orešković, M.; Losa, M. A comparative environmental impact analysis of asphalt mixtures containing crumb rubber and reclaimed asphalt pavement using life cycle assessment. Int. J. Pavement Eng. 2021, 22, 524–538. [Google Scholar] [CrossRef]

- Ding, X.; Chen, L.; Ma, T.; Ma, H.; Gu, L.; Chen, T.; Ma, Y. Laboratory investigation of the recycled asphalt concrete with stable crumb rubber asphalt binder. Constr. Build. Mater. 2019, 203, 552–557. [Google Scholar] [CrossRef]

- Yu, B.; Liu, Q.; Gu, X. Data quality and uncertainty assessment methodology for pavement LCA. Int. J. Pavement Eng. 2018, 19, 519–525. [Google Scholar] [CrossRef]

- Waheed, U.; Hudson, W.R.; Ralph, H. Life-Cycle Cost and Benefit Analysis. In Public Infrastructure Asset Management; McGraw Hill: New York, NY, USA, 2013; p. 544. [Google Scholar]

- Hasan, A.; Hasan, U.; Whyte, A.; Al Jassmi, H. Lifecycle analysis of recycled asphalt pavements: Case study scenario analyses of an urban highway section. CivilEng 2022, 3, 242–262. [Google Scholar] [CrossRef]

- Abbas, W. UAE Invests More in Transportation. Khaleej Times, 23 December 2017. [Google Scholar]

- John, I. $1.6t Required for GCC Infrastructure Upgrade. Khaleej Times, 21 October 2019. [Google Scholar]

- El Gergawy, Y. Life Cycle Cost Analysis as a Technique to Reduce Project’s Cost Overruns of Assets in UAE: A Case Study-Based Research; British University in Dubai: Dubai, United Arab Emirates, 2011. [Google Scholar]

- Giani, M.I.; Dotelli, G.; Brandini, N.; Zampori, L. Comparative life cycle assessment of asphalt pavements using reclaimed asphalt, warm mix technology and cold in-place recycling. Resour. Conserv. Recycl. 2015, 104, 224–238. [Google Scholar] [CrossRef]

- Scheving, A.G. Life Cycle Cost Analysis of Asphalt and Concrete Pavements; Reykjavík University: Reykjavík, Iceland, 2011. [Google Scholar]

- Celauro, C.; Corriere, F.; Guerrieri, M.; Lo Casto, B.; Rizzo, A. Environmental analysis of different construction techniques and maintenance activities for a typical local road. J. Clean. Prod. 2017, 142, 3482–3489. [Google Scholar] [CrossRef]

- Santos, J.; Ferreira, A.; Flintsch, G. A life cycle assessment model for pavement management: Road pavement construction and management in Portugal. Int. J. Pavement Eng. 2015, 16, 315–336. [Google Scholar] [CrossRef]

- Biswas, W.K. Carbon footprint and embodied energy assessment of a civil works program in a residential estate of Western Australia. Int. J. Life Cycle Assess. 2014, 19, 732–744. [Google Scholar] [CrossRef]

- Hasan, U.; Whyte, A.; Al Jassmi, H. Assessing lifecycle environmental footprint of autonomous mass-mobility for urban highways by microsimulation-modelling. SSRN Electron. J. 2021. [Google Scholar] [CrossRef]

- Hasan, U.; Whyte, A.; Al Jassmi, H. Life-cycle asset management in residential developments building on transport system critical attributes via a data-mining algorithm. Buildings 2018, 9, 1. [Google Scholar] [CrossRef] [Green Version]

- Hasan, U.; Whyte, A.; Al Jassmi, H. Public bus transport service satisfaction: Understanding its value to urban passengers towards improved uptake. Trans. Transp. Sci. 2021, 12, 25–37. [Google Scholar] [CrossRef]

- Arulrajah, A.; Piratheepan, J.; Bo, M.W.; Sivakugan, N. Geotechnical characteristics of recycled crushed brick blends for pavement sub-base applications. Can. Geotech. J. 2012, 49, 796–811. [Google Scholar] [CrossRef]

- Arulrajah, A.; Disfani, M.M.; Horpibulsuk, S.; Suksiripattanapong, C.; Prongmanee, N. Physical properties and shear strength responses of recycled construction and demolition materials in unbound pavement base/subbase applications. Constr. Build. Mater. 2014, 58, 245–257. [Google Scholar] [CrossRef]

- Hasan, U.; Chegenizadeh, A.; Budihardjo, M.; Nikraz, H. A review of the stabilisation techniques on expansive soils. Aust. J. Basic Appl. Sci. 2015, 9, 541–548. [Google Scholar]

- Hasan, U. Experimental Study on Bentonite Stabilisation Using Construction Waste and Slag; Curtin University: Perth, Australia, 2015. [Google Scholar]

- Debbarma, S.; Ransinchung, R.N.G.D.; Singh, S. Feasibility of roller compacted concrete pavement containing different fractions of reclaimed asphalt pavement. Constr. Build. Mater. 2019, 199, 508–525. [Google Scholar] [CrossRef]

- Zhao, S.; Huang, B.; Shu, X.; Woods, M. Comparative evaluation of warm mix asphalt containing high percentages of reclaimed asphalt pavement. Constr. Build. Mater. 2013, 44, 92–100. [Google Scholar] [CrossRef]

- Zhao, S.; Huang, B.; Shu, X.; Jia, X.; Woods, M. Laboratory Performance Evaluation of Warm-Mix Asphalt Containing High Percentages of Reclaimed Asphalt Pavement. Transp. Res. Rec. 2012, 2294, 98–105. [Google Scholar] [CrossRef]

- Alshamsi, K.H.; Hussin, M.R.; Azam, M. The impact of inflation and GDP per capita on foreign direct investment: The case of United Arab Emirates. Invest. Manag. Financ. Innov. 2017, 12, 132–141. [Google Scholar]

- ADM. Standard Specifications for Road and Bridge Construction. 1997, p. 652. Available online: https://jawdah.qcc.abudhabi.ae/en/Registration/QCCServices/Services/STD/ISGL/ISGL-LIST/TR-542-1.pdf (accessed on 14 March 2022).

- Salman, S.; Alaswad, S. Alleviating road network congestion: Traffic pattern optimization using Markov chain traffic assignment. Comput. Oper. Res. 2018, 99, 191–205. [Google Scholar] [CrossRef]

- Yagoub, M.M. Monitoring of urban growth of a desert city through remote sensing: Al-Ain, UAE, between 1976 and 2000. Int. J. Remote Sens. 2004, 25, 1063–1076. [Google Scholar] [CrossRef]

- Elchalakani, M.; Aly, T.; Abu-Aisheh, E. Sustainable concrete with high volume GGBFS to build Masdar City in the UAE. Case Stud. Constr. Mater. 2014, 1, 10–24. [Google Scholar] [CrossRef] [Green Version]

- Giustozzi, F.; Toraldo, E.; Crispino, M. Recycled airport pavements for achieving environmental sustainability: An Italian case study. Resour. Conserv. Recycl. 2012, 68, 67–75. [Google Scholar] [CrossRef]

- Turk, J.; Mauko Pranjić, A.; Mladenovič, A.; Cotič, Z.; Jurjavčič, P. Environmental comparison of two alternative road pavement rehabilitation techniques: Cold-in-place-recycling versus traditional reconstruction. J. Clean. Prod. 2016, 121, 45–55. [Google Scholar] [CrossRef]

- Harvey, J.; Meijer, J.; Ozer, H.; Al-Qadi, I.L.; Saboori, A.; Kendall, A. Pavement Life Cycle Assessment Framework; United States Federal Highway Administration: Urbana, IL, USA, 2016; p. 244. [Google Scholar]

- Vidal, R.; Moliner, E.; Martínez, G.; Rubio, M.C. Life cycle assessment of hot mix asphalt and zeolite-based warm mix asphalt with reclaimed asphalt pavement. Resour. Conserv. Recycl. 2013, 74, 101–114. [Google Scholar] [CrossRef]

- Jacobs, M.; van den Beemten, C.; Sluer, B.W. Successful Dutch experiences with low energy asphalt concrete. In Proceedings of the 11th International Conference on Asphalt Pavements, Nagoya, Japan, 1–6 August 2010; pp. 1459–1568. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).