Preliminary Investigation of the Mechanical and Physical Properties of Natural Hydraulic Lime Grouts with Nano-Silica

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Taguchi Method

2.3. Experimental Methods

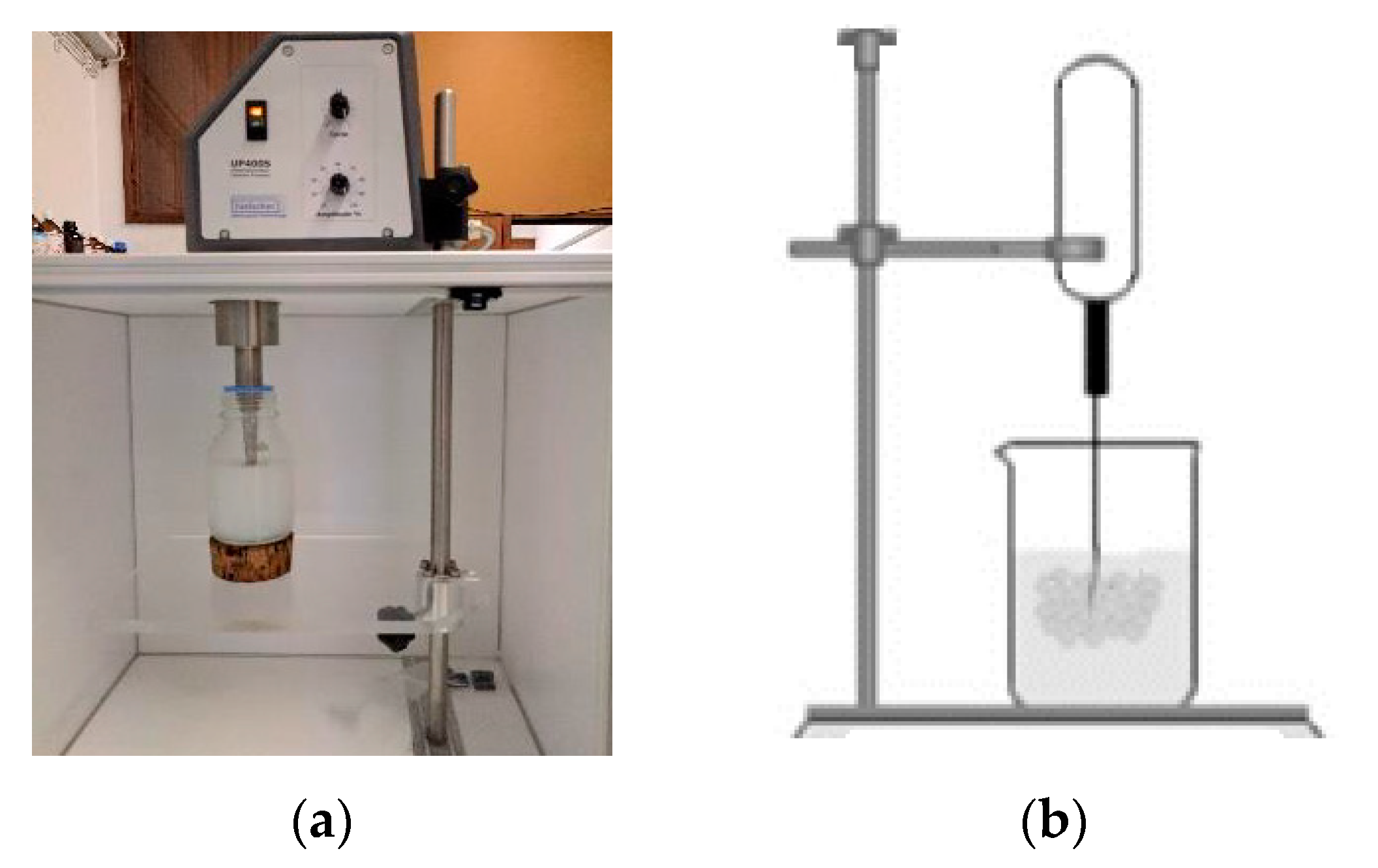

2.3.1. Grout Preparation

2.3.2. Rheological Measurements

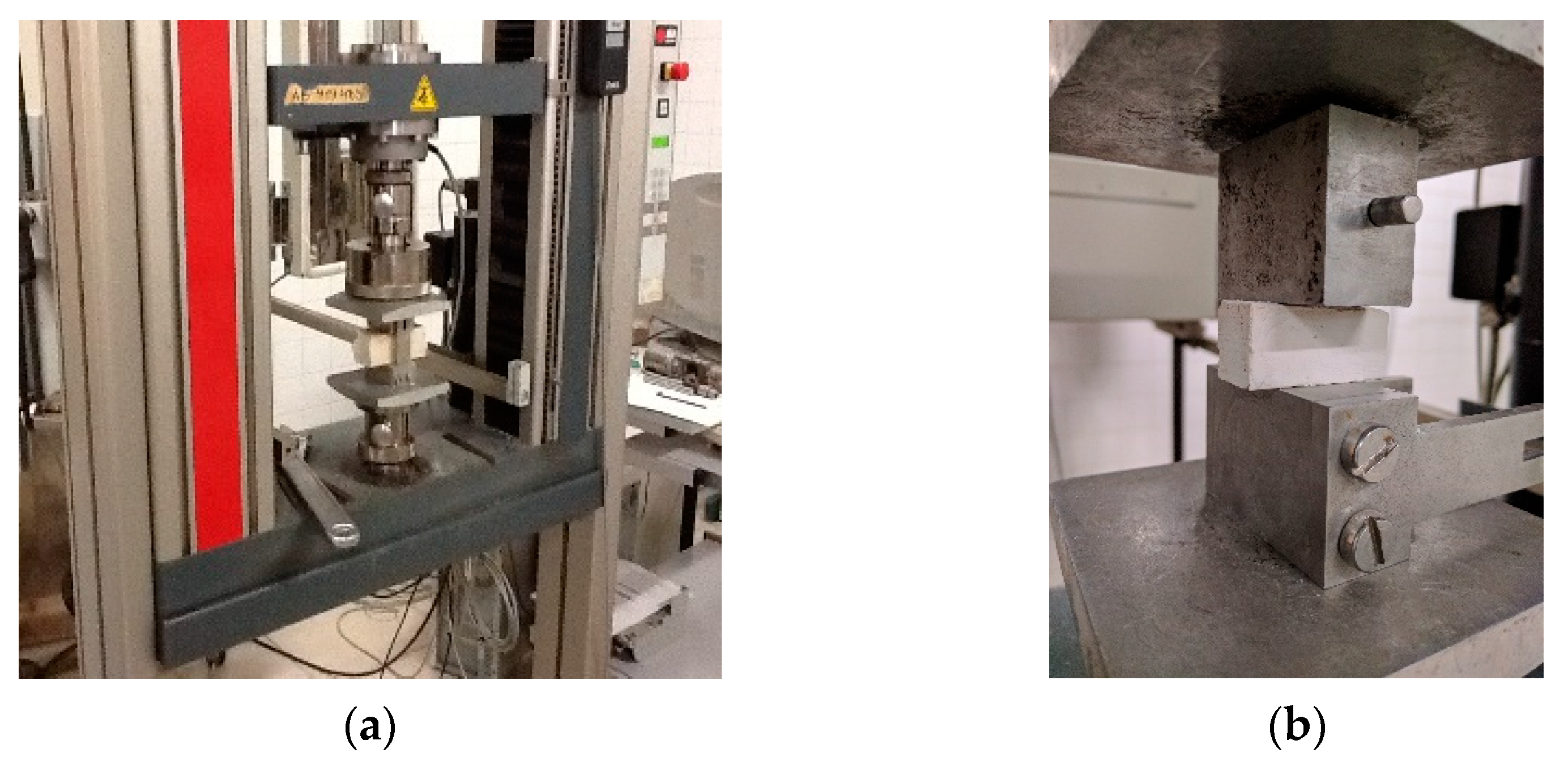

2.3.3. Compressive Strength

2.3.4. Open Porosity

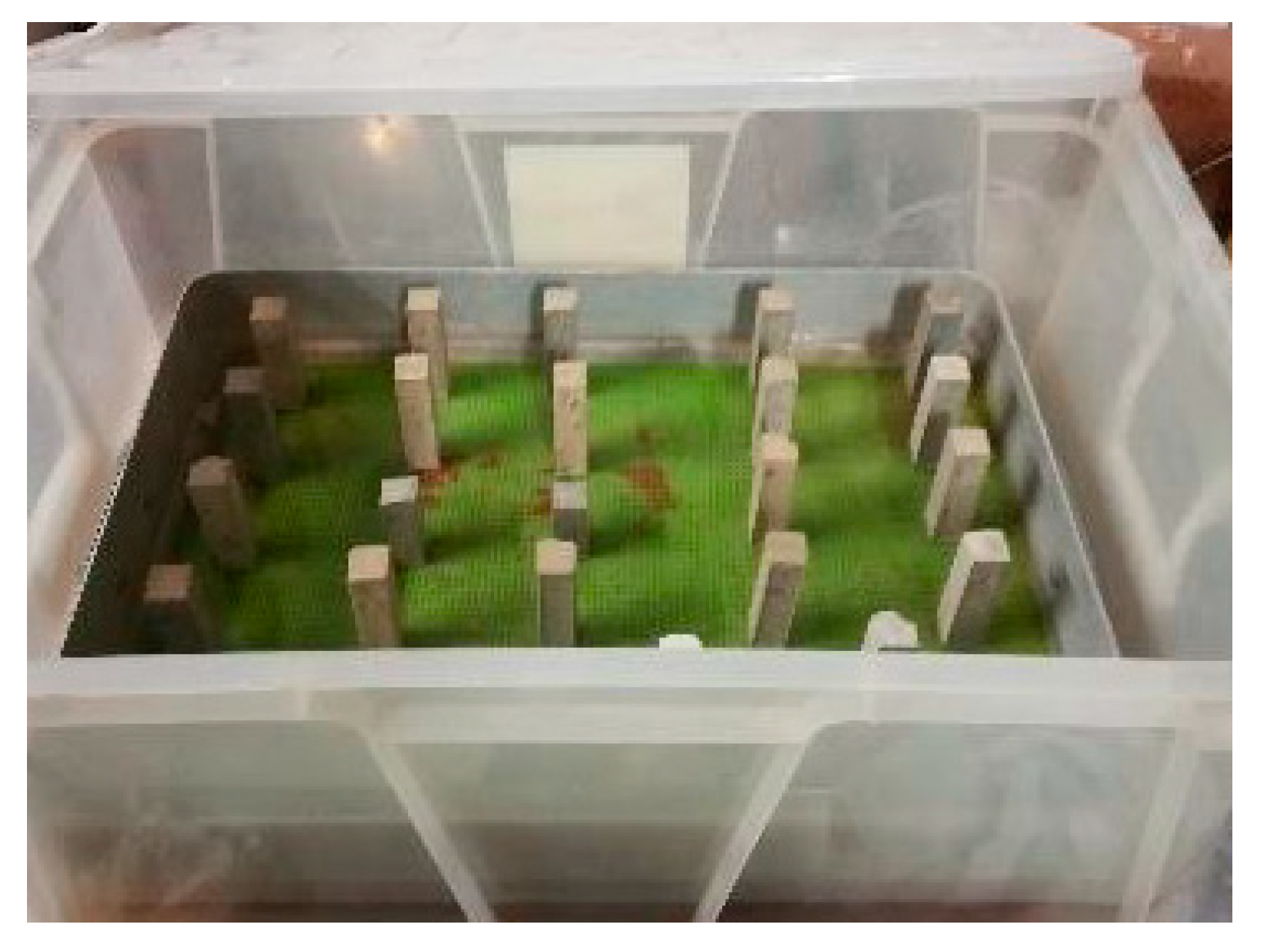

2.3.5. Water Absorption by Capillarity

2.3.6. Drying

3. Results and Discussion

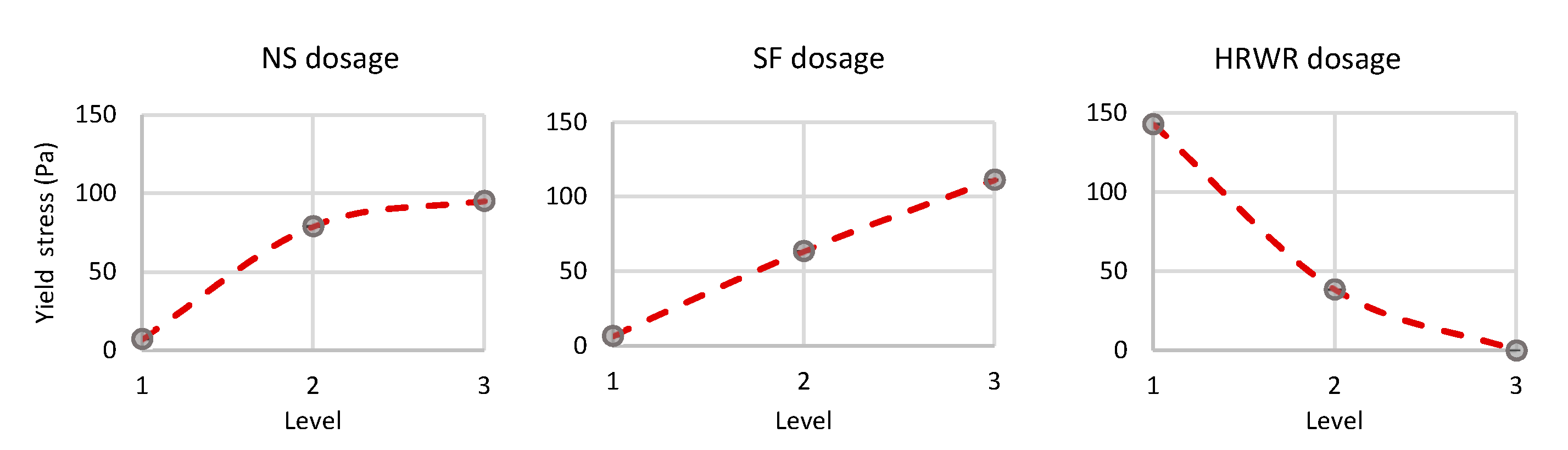

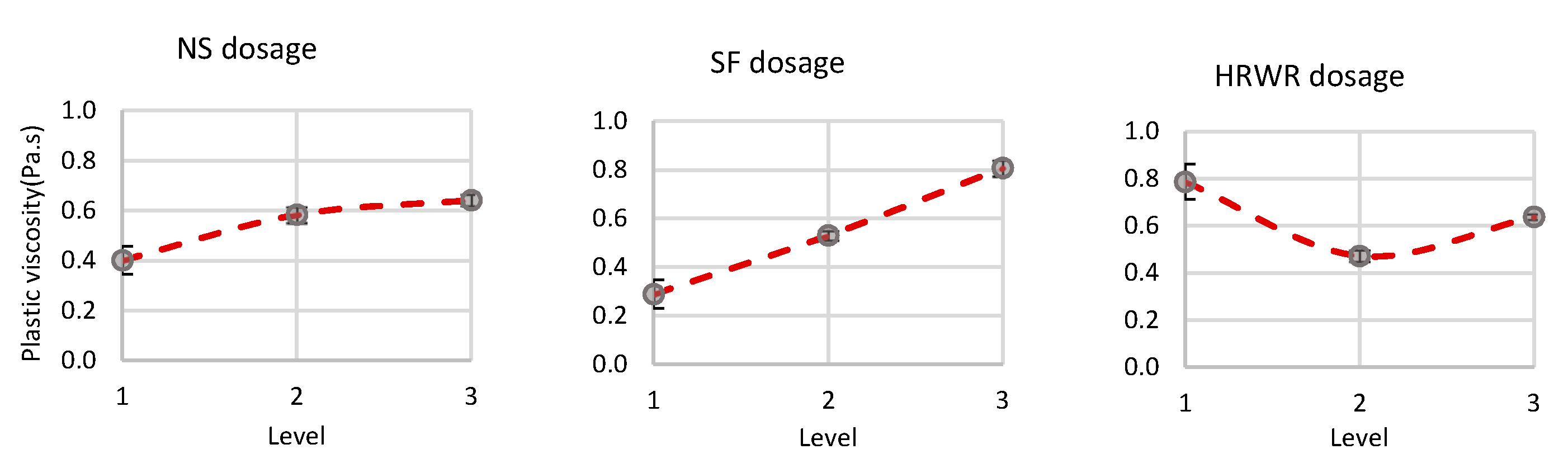

3.1. Rheological Measurements

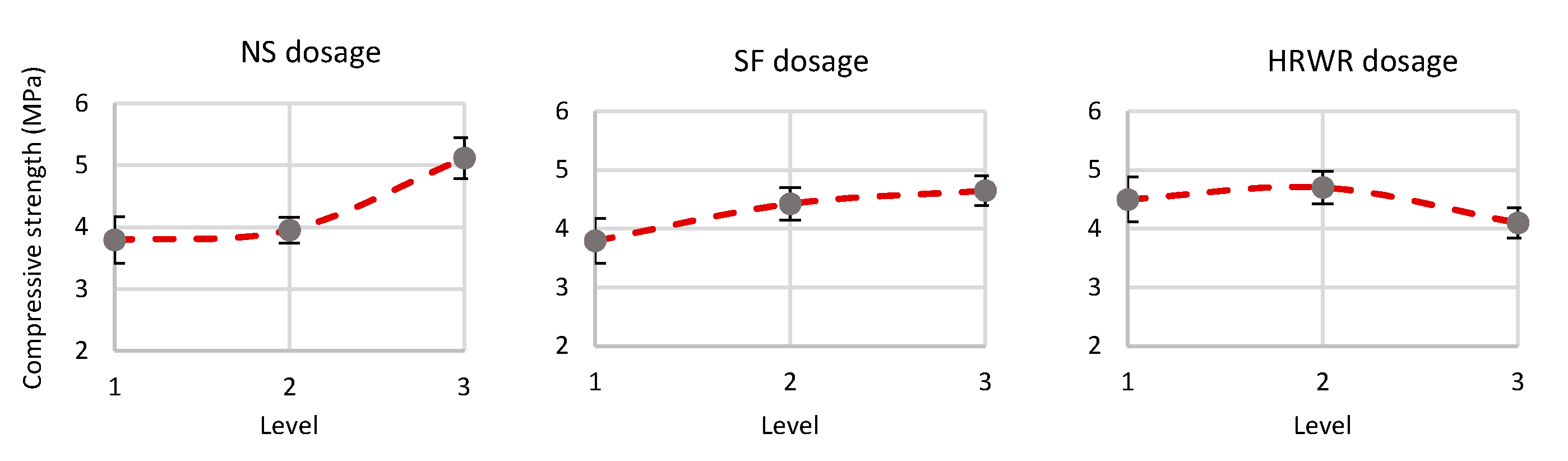

3.2. Mechanical Strenght

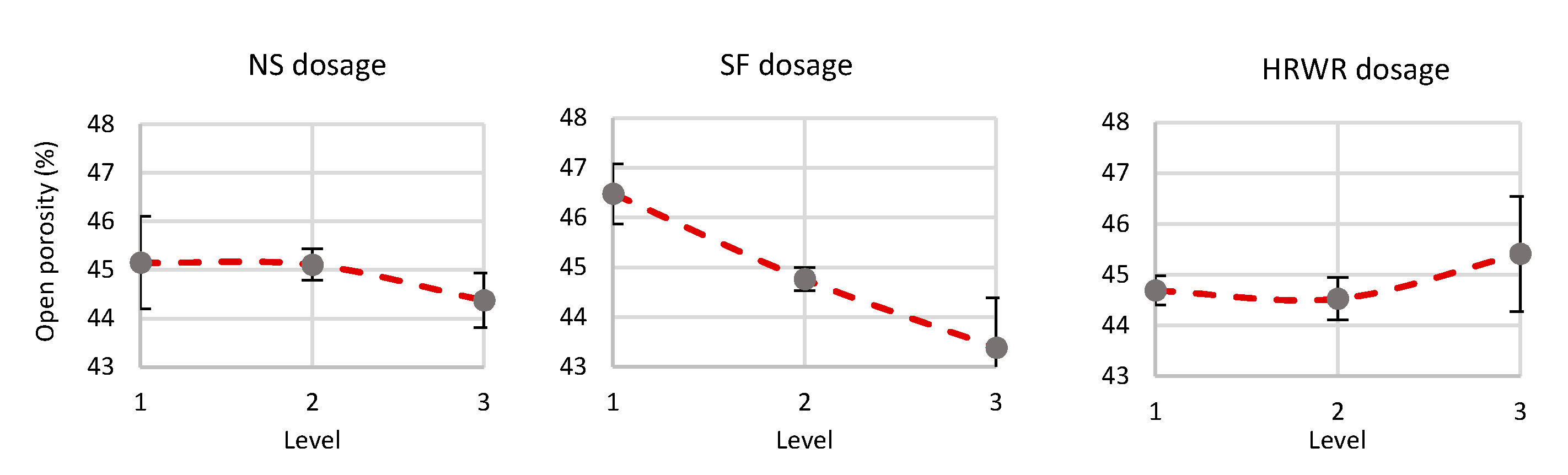

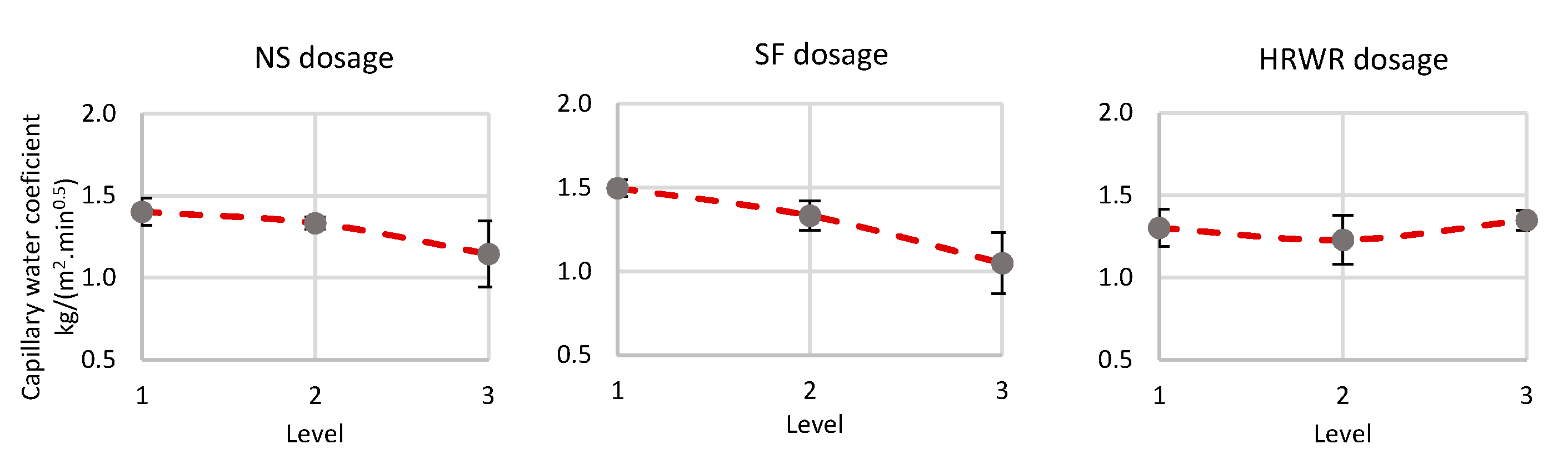

3.3. Water Absorption and Open Porosity

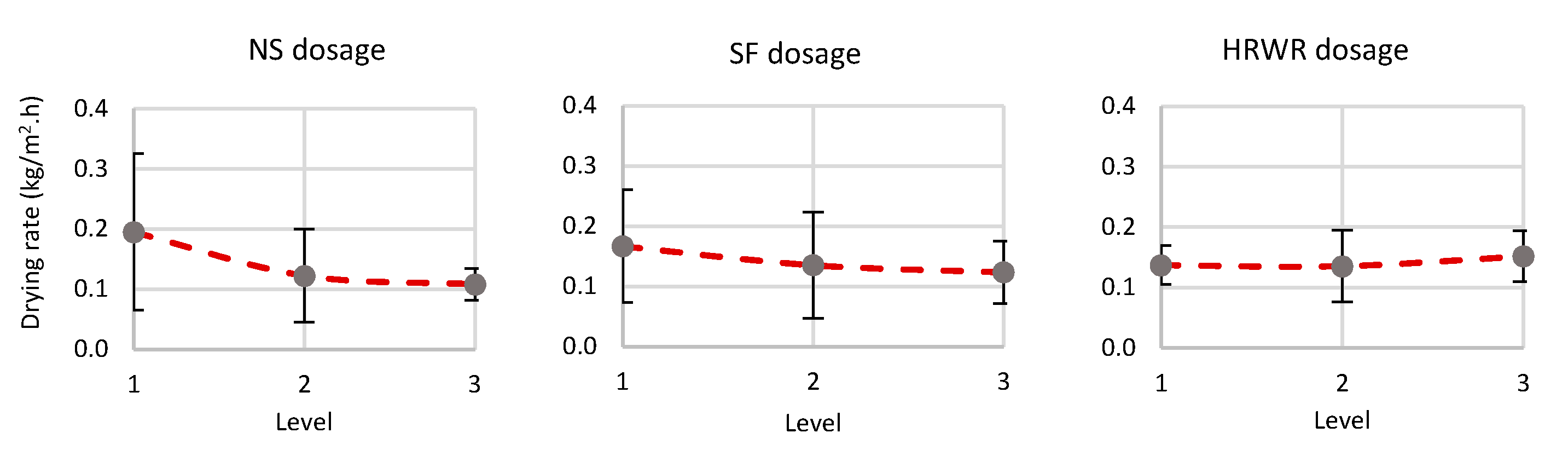

3.4. Drying

4. Conclusions

- The increase in the dosage of NS and SF promotes the increase of yield stress and plastic viscosity. NS causes a 10-fold increase in yield stress when the dosage is increased from 0 wt% to 0.5 wt%.

- The rheological results confirmed the necessity and importance of a HRWR. Moreover, HRWR dosage is the factor with the highest impact on yield stress values.

- A slight increase in plastic viscosity with the increase of HRWR between the dosage of 0.25 and 0.35 wt% was obtained, which may be due to some instability phenomena.

- The compressive strength shows a tendency to grow with an increasing dosage of NF and SF. Nevertheless, these mechanical strength values were obtained with non-standard specimens, so the direct comparison with other studies must be done carefully because the values of compressive strength may be slightly different from those that would have been obtained with standard-size specimens.

- The open porosity decreases with the increase of the NS dosage as well as increasing the dosage of SF. On the other hand, the increase of the HRWR dosage leads to the increase of the open porosity, especially for dosages above 0.25 wt%.

- The presence of NS and SF produces grouts with lower water absorption coefficients. A 40% reduction in the water absorption coefficient was obtained for an NF dosage of 1 wt%. This comes from the fact that NS and SF contribute to pore size refinement and hardened matrix densification.

- NS causes a more pronounced reduction of the drying rate compared to SF. HRWR dosages higher than 0.25 wt% lead to an increase in the drying capacity, which is believed to be due to some entrained air caused by the HRWR.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Experiment | Yield Stress (Pa) | Plastic Viscosity (Pa.s) | Compressive Strength (MPa) | Open Porosity (%) | Water Absorption Coefficient (kg/(m2.min0.5)) | Drying Rate (kg/m2.h) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Measurement 1 | Measurement 2 | Measurement 3 | Measurement 1 | Measurement 2 | Measurement 3 | Sample 1 | Sample 2 | Sample 3 | Sample 4 | Sample 1.2 | Sample 2.2 | Sample 3.2 | Sample 4.2 | Sample 5 | Sample 6 | Sample 7 | Sample 5 | Sample 6 | Sample 7 | |

| I | 14.57 | 14.29 | 14.43 | 0.40 | 0.11 | 0.25 | 3.43 | 4.22 | 2.67 | 3.44 | 46.18 | 47.12 | 46.39 | 46.17 | 1.67 | 1.73 | 1.52 | 0.12 | 0.12 | 0.24 |

| II | 7.58 | 7.53 | 7.56 | 0.45 | 0.40 | 0.42 | 4.31 | 4.76 | 3.86 | 4.31 | 44.69 | 44.52 | 44.85 | 45.21 | 1.32 | 1.38 | 1.34 | 0.12 | 0.51 | 0.11 |

| III | 0.39 | 0.35 | 0.37 | 0.53 | 0.53 | 0.52 | 3.63 | 3.47 | 3.79 | 3.63 | 45.84 | 44.96 | 41.07 | 44.81 | 1.17 | 1.14 | 1.36 | 0.14 | 0.11 | 0.29 |

| IV | 6.08 | 5.94 | 6.01 | 0.31 | 0.28 | 0.30 | 3.25 | 2.97 | 3.11 | 3.11 | 46.25 | 45.96 | 46.85 | 46.28 | 1.48 | 1.50 | 1.46 | 0.10 | 0.09 | 0.45 |

| V | 0.01 | 0.002 | 0.005 | 0.27 | 0.24 | 0.26 | 3.83 | 4.12 | 3.54 | 3.83 | 45.62 | 45.49 | 45.61 | 44.99 | 1.50 | 1.44 | 1.41 | 0.02 | 0.05 | 0.02 |

| VI | 232.28 | 231.32 | 231.80 | 1.26 | 1.14 | 1.20 | 5.26 | 4.57 | 4.93 | 4.92 | 43.59 | 43.86 | 43.65 | 43.15 | 1.10 | 1.07 | 1.03 | 0.12 | 0.13 | 0.11 |

| VII | 0.06 | 0.04 | 0.04 | 0.34 | 0.30 | 0.32 | 4.83 | 5.32 | 4.34 | 4.83 | 46.09 | 46.07 | 48.12 | 46.27 | 1.37 | 1.35 | 1.39 | 0.12 | 0.12 | 0.14 |

| VIII | 184.14 | 183.62 | 183.04 | 0.93 | 0.89 | 0.91 | 5.42 | 4.84 | 5.13 | 5.13 | 44.07 | 44.19 | 43.96 | 43.97 | 1.11 | 1.07 | 1.42 | 0.12 | 0.12 | 0.15 |

| IX | 102.90 | 102.30 | 102.60 | 0.73 | 0.66 | 0.70 | 5.39 | 4.96 | 5.82 | 5.39 | 42.66 | 42.47 | 43.00 | 41.60 | 0.89 | 0.45 | 1.24 | 0.09 | 0.11 | 0.01 |

References

- Carocci, C.F. Guidelines for the safety and preservation of historical centres in seismic areas. In Historical Constructions; Lourenço, P.B., Roca, P., Eds.; University of Minho: Guimares, Portugal, 2001; pp. 145–166. [Google Scholar]

- Miranda, L.; Milosevic, J.; Bento, R. Cyclic behaviour of stone masonry walls strengthened by grout injection. Mater. Struct. 2017, 50, 1–17. [Google Scholar] [CrossRef]

- Valluzzi, M.R.; Porto, F.; Modena, C. Behavior and modeling of strengthened three-leaf stone masonry walls. Mater. Struct. 2004, 37, 184–192. [Google Scholar] [CrossRef]

- Ferretti, F.; Incerti, A.; Tilocca, A.R.; Mazzotti, C. In-plane shear behavior of stone masonry panels strengthened through grout injection and fibre-reinforced cementitious matrices. Int. J. Archit. Herit. 2019, 1–20. [Google Scholar] [CrossRef]

- Penelis, G.; Karaveziroglou, M.; Papayanni, J. Grouts for repairing and strengthening old masonry structural. In Structural Repair and Maintenance of Historical Buildings; Brebbia, C.A., Ed.; Computational Mechanics Publications: Basel, Switzerland, 1989; pp. 79–188. [Google Scholar]

- Antonacci, E.; Aloisio, A.; Galeota, D.; Alaggio, R.; The, S. Maria di Collemaggio basilica: From vulnerability assessment to first results of SHM. J. Archit. Eng. 2020, 26, 05020007. [Google Scholar] [CrossRef]

- Miltiadou, A. Contribution à l’étude des Coulis Hydraulique pour la Réparation et le Renforcement des Structures et des Monuments Historiques en Maçonnerie. Ph.D. Thesis, ENPC Paris, Marne-la-Vallée, France, 1990. [Google Scholar]

- Vintzileou, E.; Mouzakis, C.; Adami, C.-E.; Karapitta, L. Seismic behavior of three-leaf stone masonry buildings before and after interventions: Shaking table tests on a two-storey masonry model. Bull. Earthq. Eng. 2015, 13, 3107–3133. [Google Scholar] [CrossRef]

- Collepardi, M. Degradation and restoration of masonry walls of historical buildings. Mater. Struct. 1990, 23, 81–102. [Google Scholar] [CrossRef]

- Binda, L.; Penazzi, D.; Saisi, A. Historic Masonry Buildings: Necessity of a Classification of Structures and Masonries for the Adequate Choice of Analytical Models. In Proceedings of the VI International Symposium Computer Methods in Structural Masonry-STRUMAS, Rome, Italy, 22–24 September 2003; pp. 168–173. [Google Scholar]

- Mirza, J.; Mirza, M.S.; Roy, V.; Saleh, K. Basic rheological and mechanical properties of high-volume fly ash grouts. Science 2002, 16, 353–363. [Google Scholar] [CrossRef]

- Eriksson, M.; Friedrich, M.; Vorschulze, C. Variations in the rheology and penetrability of cement-based grouts—An experimental study. Cem. Concr. Res. 2004, 34, 1111–1119. [Google Scholar] [CrossRef]

- Fernàndez-Altable, V.; Casanova, I. Influence of mixing sequence and superplasticiser dosage on the rheological response of cement pastes at different temperatures. Cem. Concr. Res. 2006, 36, 1222–1230. [Google Scholar] [CrossRef]

- Bras, A. Grout Optimization for Masonry Consolidation. Ph.D. Thesis, NOVA University of Lisbon, Lisbon, Portugal, 2011. [Google Scholar]

- Baltazar, L.G.; Henriques, F.M.A.; Cidade, M.T. Contribution to the design of hydraulic lime-based grouts for masonry consolidation. J. Civ. Eng. Manag. 2015, 21, 698–709. [Google Scholar] [CrossRef]

- Baltazar, L.G.; Henriques, F.M.A.; Cidade, M.T. Grouts with improved durability for masonry consolidation: An experimental study with non-standard specimens. Key Eng. Mater. 2017, 747, 480–487. [Google Scholar] [CrossRef]

- Binda, L.; Modena, C.; Baronio, G.; Abbaneo, S. Repair and investigation techniques for stone masonry walls. Constr. Build. Mater. 1997, 11, 133–142. [Google Scholar] [CrossRef]

- Van Rickstal, F.; Toumbakari, E.-E.; Ignoul, S.; Van Gement, D.A. Development of mineral grouts for consolidation injection. In Consolidation of Masonry, Advances in Materials Science and Restoration; Van Gemert, D., Ed.; Aedificatio: Freiburg, Germany, 2003; pp. 61–75. [Google Scholar]

- Luso, E.; Lourenço, P.-B. Experimental characterization of commercial lime based grouts for stone masonry consolidation. Constr. Build. Mater. 2016, 2, 216–225. [Google Scholar] [CrossRef] [Green Version]

- Antonovic, V.; Pundiene, I.; Stonys, R.; Cesniene, J.; Keriené, J. A review of the possible applications of nanotechnology in refractory concrete. J. Civ. Eng. Manag. 2010, 16, 595–602. [Google Scholar] [CrossRef]

- Hosseini, P. Toward green revolution in concrete industry: The role of nanotechnology (a review). Aust. J. Basic Appl. Sci. 2011, 5, 2768–2782. [Google Scholar]

- Pacheco-Torgal, F.; Miraldo, S.; Ding, Y.; Labrincha, J.A. Targeting HPC with the help of nanoparticles: An overview. Constr. Build. Mater. 2013, 38, 365–370. [Google Scholar] [CrossRef] [Green Version]

- Aleem, S.A.E.; Heikal, M.; Morsi, W.M. Hydration characteristic, thermal expansion and microstructure of cement containing nano-silica. Constr. Build. Mater. 2014, 59, 151–160. [Google Scholar] [CrossRef]

- Senff, L.; Labrincha, J.A.; Ferreira, V.M.; Hotza, D.; Repette, W.L. Effect of nano-silica on rheology and fresh properties of cement pastes and mortars. Constr. Build. Mater. 2009, 23, 2487–2491. [Google Scholar] [CrossRef]

- Berra, M.; Carassiti, F.; Mangialardi, T.; Paolini, A.E.; Sebastiani, M. Effects of nanosilica addition on workability and compressive strength of Portland cement pastes. Constr. Build. Mater. 2012, 35, 666–675. [Google Scholar] [CrossRef]

- Qing, Y.; Zenan, Z.; Deyu, K.; Rongshen, C. Influence of nano-SiO2 addition on properties of hardened cement paste as compared with silica fume. Constr. Build. Mater. 2007, 21, 539–545. [Google Scholar] [CrossRef]

- Stefanidou, M. Influence of nano-SiO2 on the Portland cement pastes. Compos. Part B Eng. 2012, 43, 2706–2710. [Google Scholar] [CrossRef]

- Luo, K.; Li, J.; Lu, J.; Jiang, J.; Niu, Y. Effect of nano-SiO2 on early hydration of natural hydraulic lime. Constr. Build. Mater. 2019, 216, 119–127. [Google Scholar] [CrossRef]

- Roy, R.K. Design of Experiments Using Taguchi Approach: 16 Steps to Product and Process Improvement; Wiley: Hoboken, NJ, USA, 2011. [Google Scholar]

- Baltazar, L.G.; Henriques, F.M.A.; Jorne, F.; Cidade, M.T. The use of rheology in the study of the composition effects on the fresh behaviour of hydraulic lime grouts for injection of masonry walls. Rheol. Acta 2013, 52, 127–138. [Google Scholar] [CrossRef]

- Binda, L.; Saisi, A.; Tedeschi, C. Compatibility of materials used for repair of masonry buildings: Research and applications. In Fracture and Failure of Natural Building Stone; Springer: Amsterdam, The Netherlands, 2006; pp. 167–182. [Google Scholar]

- EN 459–1. Building Lime. Part 1: Definitions, Specifications and Conformity Criteria; CEN, European Committee for Standardization: Brussels, Belgium, 2015. [Google Scholar]

- Prince, W.; Edwards-Lajnef, M.; Aitcin, P.C. Interaction between Ettringite and a Polynaphthalene Sulfonate Superplasticizer in a Cementitious Paste. Cem. Concr. Res. 2002, 32, 79–85. [Google Scholar] [CrossRef]

- Shannag, M.J. High strength concrete containing natural pozzolan and silica fume. Cem. Concr. Compos. 2000, 22, 399–406. [Google Scholar] [CrossRef]

- Wei-Hsing, H. Properties of cement-fly ash grout admixed with ben- tonite, silica fume, or organic fiber. Cem. Concr. Res. 1997, 27, 395–406. [Google Scholar]

- Baltazar, L.G.; Henriques, F.M.A.; Cidade, M.T. Rheological characterization of injection grouts using rotational rheometry. In Advances in Rheology Research; Nova Science Publishers: New York, NY, USA, 2017; pp. 13–42. [Google Scholar]

- Baltazar, L.G.; Henriques, F.M.A. Rheology of grouts for masonry injection. Key Eng. Mater. 2015, 624, 283–290. [Google Scholar] [CrossRef]

- EN 1015–11. Methods of Test for Mortar for Masonry. Determination of Flexural and Compressive Strength of Hardened Mortar; CEN, European Committee for Standardization: Brussels, Belgium, 2019. [Google Scholar]

- EN 1936. Natural Stone Test Methods–Determination of Real Density and Apparent Density, and of Total and Open Porosity; CEN, European Committee for Standardization: Brussels, Belgium, 2006. [Google Scholar]

- EN 1015–18. Methods of Test for Mortar for Masonry–Part 18: Determination of Water Absorption Coefficient Due to Capillary Action of Hardened Rendering Mortar; CEN, European Committee for Standardization: Brussels, Belgium, 2002. [Google Scholar]

- RILEM. Recommended tests to measure the deterioration of stone and to assess the effectiveness of treatment methods. Test no. II.5–Evaporation curve. Mater. Struct. 1980, 75, 175–253. [Google Scholar]

- Jorne, F.; Henriques, F.M.A.; Baltazar, L.G. Injection capacity of hydraulic lime grouts in different porous media. Mater. Struct. 2014, 48, 2211–2233. [Google Scholar] [CrossRef]

- Palacios, M.; Alonso, M.M.; Varga, C.; Puertas, F. Influence of the alkaline solution and temperature on the rheology and reactivity of alkali-activated fly ash pastes. Cem. Concr. Compos. 2018, 95, 277–284. [Google Scholar] [CrossRef]

- Baltazar, L.G.; Henriques, F.M.A.; Cidade, M.T. Rheology of natural hydraulic lime grouts for conservation of stone masonry-influence of compositional and processing parameters. Fluids 2019, 4, 13. [Google Scholar] [CrossRef] [Green Version]

- Jorne, F.; Henriques, F.M.A.; Baltazar, L.G. Influence of superplasticizer, temperature, resting time and injection pressure on hydraulic lime grout injectability. Correlation analysis between fresh grout parameters and grout injectability. J. Build. Eng. 2015, 4, 140–151. [Google Scholar] [CrossRef]

- Mohammed, A.S. Effect of temperature on the rheological properties with shear stress limit of iron oxide nanoparticle modified bentonite drilling muds. Egypt. J. Pet. 2017, 26, 791–802. [Google Scholar] [CrossRef] [Green Version]

- Ltifi, M.; Guefrech, A.; Mounanga, P.; Khelidj, A. Experimental study of the effect of addition of nano-silica on the behaviour of cement mortars Mounir. Procedia Eng. 2011, 10, 900–905. [Google Scholar] [CrossRef] [Green Version]

- Toumbakari, E.-E. Lime-Pozzolan-Cement Grouts and Their Structural Effects on Composite Masonry Walls. Ph.D. Thesis, Katholieke Universiteit Leuven, Leuven, Belgium, 2002. [Google Scholar]

- Assaad, J.; Daou, Y. Cementitious grouts with adapted rheological properties for injection by vacuum. Cem. Concr. Res. 2014, 59, 43–54. [Google Scholar] [CrossRef]

- Senff, L.; Ascensão, G.; Hotza, D.; Ferreira, V.M.; Labrincha, J.A. Assessment of the single and combined effect of superabsorbent particles and porogenic agents in nanotitania-containing mortars. Energy Build. 2016, 127, 980–990. [Google Scholar] [CrossRef]

- Banfill, P.F.G. Additivity effects in the rheology of fresh concrete containing water-reducing admixtures. Constr. Build. Mater. 2011, 25, 2955–2960. [Google Scholar] [CrossRef]

- Shihada, S.; Arafa, M. Effects of silica fume, ultrafine and mixing sequences on properties of ultra high performance concrete. Asian J. Mater. Sci. 2010, 2, 137–146. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Xiao, H.G.; Ou, J.P. A study on mechanical and pressure-sensitive properties ofcement mortar with nanophase materials. Cem. Concr. Res. 2004, 34, 435–438. [Google Scholar] [CrossRef]

- Jo, B.W.; Kim, C.H.; Tae, G.H.; Park, J.B. Characteristics of cement mortar with nano-SiO2 particles. Constr. Build. Mater. 2007, 21, 1351–1355. [Google Scholar] [CrossRef]

- Baltazar, L.G.; Henriques, F.M.A.; Cidade, M.T. Experimental study and modeling of rheological and mechanical properties of NHL grouts. J. Mater. Civ. Eng. 2015, 27. [Google Scholar] [CrossRef]

- Koohestani, B.; Belem, T.; Koubaa, A.; Bussière, B. Experimental investigation into the compressive strength development of cemented paste backfill containing Nano-silica. Cem. Concr. Compos. 2016, 72, 180–189. [Google Scholar] [CrossRef]

- Palla, R.; Karade, S.R.; Mishra, G.; Sharma, U.; Singh, L.P. High strength sustainable concrete using silica nanoparticles. Constr. Build. Mater. 2017, 138, 285–295. [Google Scholar] [CrossRef]

- Hall, C.; Hoff, W. Water Transportation in Brick, Stone and Concrete; Taylor and Francis: London, UK, 2002. [Google Scholar]

- Demir, I.; Baspinar, M.S. Effect of silica fume and expanded perlite addition on the technical properties of the fly ash–lime–gypsum mixture. Constr. Build. Mater. 2008, 22, 1299–1304. [Google Scholar] [CrossRef]

| Fineness | 90 µm | 24.8% |

| 200 µm | 2.9% | |

| Setting time | Start | 2 h |

| End | 6 h | |

| Specific surface area | 480 m2/kg | |

| Al2O3 | 2.00% | |

| CaO | 85.00% | |

| Fe2O3 | 2.00% | |

| MgO | 1.00% | |

| MnO | 0.03% | |

| SiO2 | 8.00% | |

| SiC | 0.01% | |

| SO3 | 1.00% | |

| SrO | 0.05% | |

| K2O | 0.70% | |

| Product Form | Undensified Powder |

|---|---|

| Colour | dark grey |

| Bulk density (g/cm3) | 2.20 |

| Specific surface area | 17.5 m2/g |

| Al2O3 | 0.15% |

| SiO2 | 97% |

| Fe2O3 | 0.03% |

| Na2O | 0.05% |

| MgO | 0.30% |

| CaO | 0.20% |

| SiC | 0.50% |

| K2O | 0.80% |

| Product Form | Powder |

|---|---|

| Colour | white |

| Specific surface area | 235 m2/g |

| Principal action | pozzolanic |

| Secondary action | filler |

| Purity | >96.3% |

| Ti | <120 ppm |

| Ca | <20 ppm |

| Na | <50 ppm |

| Fe | <200 ppm |

| Factor | Designation | Level | ||

|---|---|---|---|---|

| 1 | 2 | 3 | ||

| NS dosage (wt%) | NS | 0 | 0.5 | 1 |

| SF dosage (wt%) | SF | 0 | 5 | 10 |

| HRWR dosage (wt%) | HRWR | 0.1 | 0.25 | 0.35 |

| wt% = per weight of binder | ||||

| Experiment | Factors | ||

|---|---|---|---|

| NS | SF | HRWR | |

| I | 1 | 1 | 1 |

| II | 1 | 2 | 2 |

| III | 1 | 3 | 3 |

| IV | 2 | 1 | 2 |

| V | 2 | 2 | 3 |

| VI | 2 | 3 | 1 |

| VII | 3 | 1 | 3 |

| VIII | 3 | 2 | 1 |

| IX | 3 | 3 | 2 |

| Experiment I | Experiment IV | Experiment VII | |||

|---|---|---|---|---|---|

| NS (wt%) | 0 | NS (wt%) | 0.5 | NS (wt%) | 1 |

| SF (wt%) | 0 | SF (wt%) | 0 | SF (wt%) | 0 |

| HRWR (wt%) | 0.1 | HRWR (wt%) | 0.25 | HRWR (wt%) | 0.35 |

| Experiment II | Experiment V | Experiment VIII | |||

| NS (wt%) | 0 | NS (wt%) | 0.5 | NS (wt%) | 1 |

| SF (wt%) | 5 | SF (wt%) | 5 | SF (wt%) | 5 |

| HRWR (wt%) | 0.25 | HRWR (wt%) | 0.35 | HRWR (wt%) | 0.1 |

| Experiment III | Experiment VI | Experiment IX | |||

| NS (wt%) | 0 | NS (wt%) | 0.5 | NS (wt%) | 1 |

| SF (wt%) | 10 | SF (wt%) | 10 | SF (wt%) | 10 |

| HRWR (wt%) | 0.35 | HRWR (wt%) | 0.1 | HRWR (wt%) | 0.25 |

| Yield Stress | Plastic Viscosity | Compressive Strength | Open Porosity | Water Absorption Coefficient | Drying Rate | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S/N (dB) | (Pa) | S/N (dB) | (Pa.s) | S/N (dB) | (MPa) | S/N (dB) | (%) | S/N (dB) | kg/(m2·min0.5) | S/N (dB) | kg/m2·h | |

| I | −23.19 | 14.43 | 11.11 | 0.25 | 10.39 | 3.44 | −33.34 | 46.47 | −4.29 | 1.64 | 15.44 | 0.16 |

| II | −17.57 | 7.56 | 7.43 | 0.42 | 12.62 | 4.31 | −33.03 | 44.82 | −2.60 | 1.35 | 10.23 | 0.25 |

| III | 8.60 | 0.37 | 5.53 | 0.53 | 11.19 | 3.63 | −32.91 | 44.17 | −1.77 | 1.23 | 14.14 | 0.18 |

| IV | −15.58 | 6.01 | 10.53 | 0.30 | 9.84 | 3.25 | −33.32 | 46.34 | −3.42 | 1.48 | 11.34 | 0.22 |

| V | 46.51 | 0.0004 | 11.82 | 0.26 | 11.63 | 3.83 | −33.15 | 45.43 | −3.23 | 1.45 | 29.32 | 0.01 |

| VI | −47.30 | 231.80 | −1.58 | 1.20 | 13.81 | 5.26 | −32.78 | 43.56 | −0.57 | 1.07 | 18.32 | 0.12 |

| VII | 25.41 | 0.050 | 9.89 | 0.32 | 13.61 | 4.83 | −33.38 | 46.65 | −2.76 | 1.37 | 18.04 | 0.13 |

| VIII | −45.28 | 183.60 | 0.81 | 0.91 | 14.18 | 5.42 | −32.88 | 44.05 | −1.66 | 1.21 | 17.66 | 0.13 |

| IX | −40.22 | 102.60 | 3.14 | 0.70 | 14.59 | 5.39 | −32.55 | 42.44 | 0.76 | 0.92 | 22.01 | 0.07 |

| Factor | Degree of Freedom | Sum of Squares | Mean Squares | Contribution of Factor (%) |

|---|---|---|---|---|

| NS dosage | 2 | 1.32 104 | 6.58 103 | 21.5 |

| SF dosage | 2 | 1.65 104 | 8.25 103 | 26.6 |

| HRWR dosage | 2 | 1.32 104 | 6.58 103 | 21.5 |

| Factor | Degree of Freedom | Sum of Squares | Mean Squares | Contribution of Factor (%) |

|---|---|---|---|---|

| NS dosage | 2 | 0.094 | 0.047 | 13.3 |

| SF dosage | 2 | 0.403 | 0.202 | 48.3 |

| HRWR dosage | 2 | 0.285 | 0.142 | 38.5 |

| Factor | Degree of Freedom | Sum of Squares | Mean Squares | Contribution of Factor (%) |

|---|---|---|---|---|

| NS dosage | 2 | 3.130 | 1.565 | 50.5 |

| SF dosage | 2 | 1.175 | 0.587 | 37.0 |

| HRWR dosage | 2 | 0.241 | 0.121 | 12.5 |

| Factor | Degree of Freedom | Sum of Squares | Mean Squares | Contribution of Factor (%) |

|---|---|---|---|---|

| NS dosage | 2 | 0.107 | 0.054 | 26.8 |

| SF dosage | 2 | 0.309 | 0.154 | 60.8 |

| HRWR dosage | 2 | 0.022 | 0.011 | 12.4 |

| Factor | Degree of Freedom | Sum of Squares | Mean Squares | Contribution of Factor (%) |

|---|---|---|---|---|

| NS dosage | 2 | 0.013 | 0.007 | 29.0 |

| SF dosage | 2 | 0.003 | 0.002 | 31.7 |

| HRWR dosage | 2 | 0.006 | 0.003 | 39.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baltazar, L.G.; Cardoso, J. Preliminary Investigation of the Mechanical and Physical Properties of Natural Hydraulic Lime Grouts with Nano-Silica. CivilEng 2021, 2, 421-441. https://doi.org/10.3390/civileng2020024

Baltazar LG, Cardoso J. Preliminary Investigation of the Mechanical and Physical Properties of Natural Hydraulic Lime Grouts with Nano-Silica. CivilEng. 2021; 2(2):421-441. https://doi.org/10.3390/civileng2020024

Chicago/Turabian StyleBaltazar, Luis G., and João Cardoso. 2021. "Preliminary Investigation of the Mechanical and Physical Properties of Natural Hydraulic Lime Grouts with Nano-Silica" CivilEng 2, no. 2: 421-441. https://doi.org/10.3390/civileng2020024

APA StyleBaltazar, L. G., & Cardoso, J. (2021). Preliminary Investigation of the Mechanical and Physical Properties of Natural Hydraulic Lime Grouts with Nano-Silica. CivilEng, 2(2), 421-441. https://doi.org/10.3390/civileng2020024