Alternative Products Selling Sustainability? A Brazilian Case Study on Materials and Processes to Produce Plant-Based Hamburger Patties

Abstract

:1. Introduction

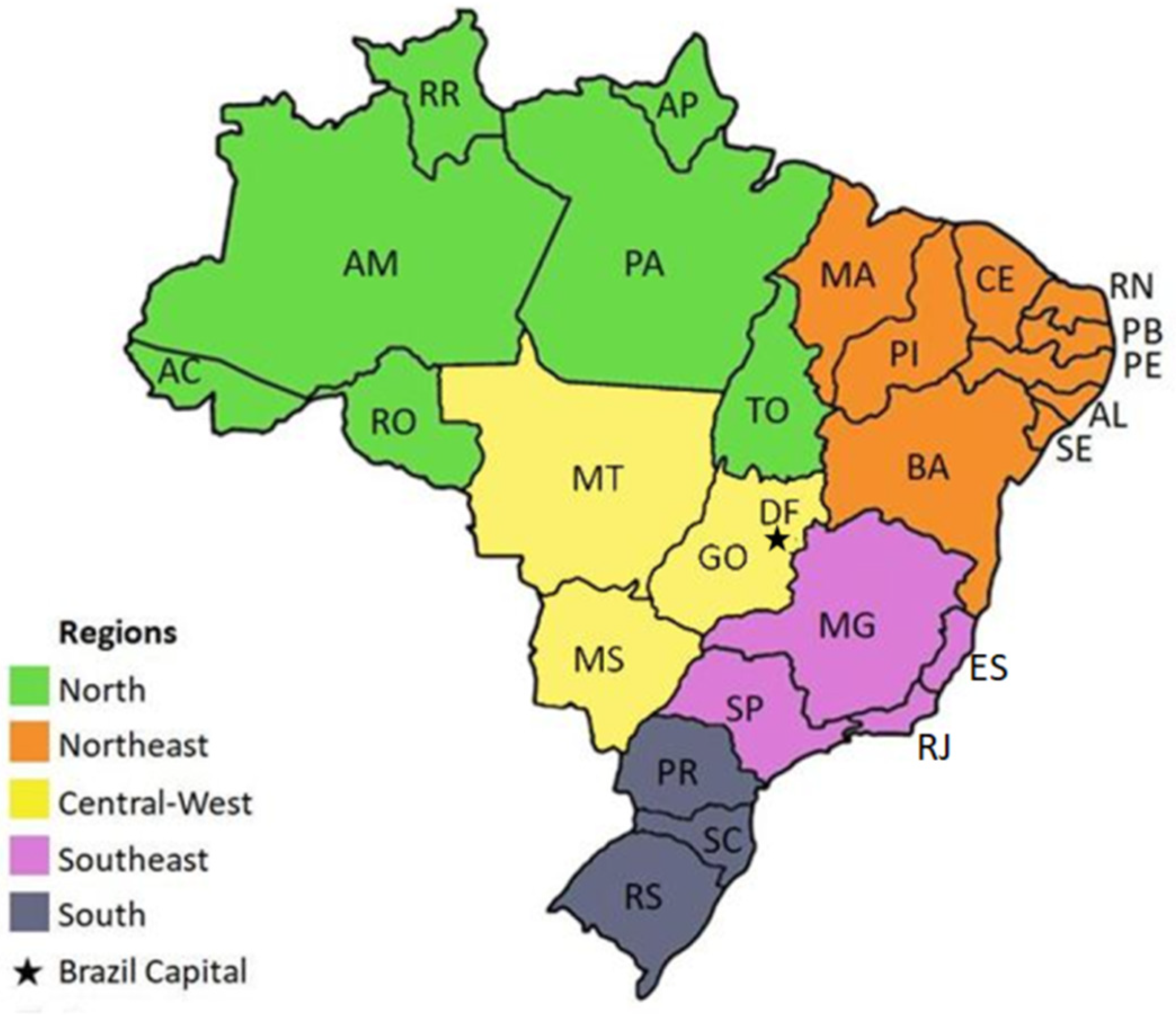

2. Brazilian Scene

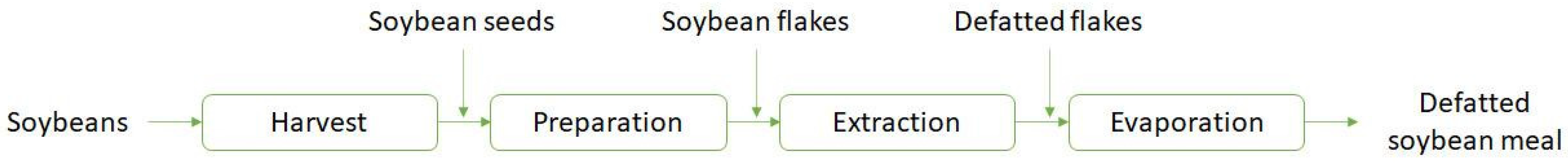

3. Soybean Protein Products and Their Industrial Processing Steps

Impacts of Products and Processes Involved in Soybean Processing

4. Case Study: Unpacking Burgers in Chemistry Curricula

5. Conclusions and Perspectives

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ANVISA | Brazilian Health Regulatory Agency |

| DSM | defatted soy meal |

| EFSA | European Food Safety Authority |

| EPA | Environmental Protection Agency |

| EU | European Union |

| FDA | Food and Drug Administration |

| GC | Green Chemistry |

| GHG | Greenhouse gas |

| IBGE | Brazilian Institute of Geography and Statistics |

| LCA | Life Cycle Assessment |

| MT | Mato Grosso |

| PBMA | plant-based meat analogs |

| RS | Rio Grande do Sul |

| SC | Sustainable Chemistry |

| SDGs | Sustainable Development Goals |

| SP | São Paulo |

| SPC | soy protein concentrate |

| SPI | soy protein isolate |

| STP | soy textured protein |

| UN | United Nations |

References

- UN Department of Economic and Social Affairs. Sustainable Development—The 17 Goals. Available online: https://sdgs.un.org/goals (accessed on 28 June 2022).

- Zuin, V.G. Circularity in Green Chemical Products, Processes and Services: Innovative Routes Based on Integrated Eco-Design and Solution Systems. Curr. Opin. Green Sustain. Chem. 2016, 2, 40–44. [Google Scholar] [CrossRef]

- Perlatti, B.; Forim, M.R.; Zuin, V.G. Green Chemistry, Sustainable Agriculture and Processing Systems: A Brazilian Overview. Chem. Biol. Technol. Agric. 2014, 1, 5. [Google Scholar] [CrossRef]

- European Commission. Communication from the Commission—The European Green Deal. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52019DC0640 (accessed on 28 June 2022).

- European Commission. Farm to Fork Strategy. Available online: https://ec.europa.eu/food/horizontal-topics/farm-fork-strategy_en (accessed on 28 June 2022).

- Poore, J.; Nemecek, T. Reducing Food’s Environmental Impacts through Producers and Consumers. Science. 2018, 360, 987–992. [Google Scholar] [CrossRef] [PubMed]

- IPES FOOD. The Politics of Protein. Available online: https://www.ipes-food.org/pages/politicsofprotein (accessed on 28 June 2022).

- FAIRR. Plant-Based Profits: Investment Risks and Opportunities in Sustainable Food Systems. Available online: https://www.fairr.org/article/plant-based-profits-investment-risks-opportunities-sustainable-food-systems/ (accessed on 28 June 2022).

- IBOPE. Pesquisa de Opinião Pública sobre Vegetarianismo. Available online: https://www.svb.org.br/images/Documentos/JOB_0416_VEGETARIANISMO.pdf (accessed on 27 June 2022).

- Elliott, C. Eatertainment and the (Re)Classification of Children’s Foods. Food Cult. Soc. 2010, 13, 539–553. [Google Scholar] [CrossRef]

- Mejia, M.; Fresán, U.; Harwatt, H.; Oda, K.; Uriegas-Mejia, G.; Sabaté, J. Life Cycle Assessment of the Production of a Large Variety of Meat Analogs by Three Diverse Factories. J. Hunger Environ. Nutr. 2020, 15, 699–711. [Google Scholar] [CrossRef]

- Bicudo Da Silva, R.F.; Batistella, M.; Moran, E.; Celidonio, O.L.D.M.; Millington, J.D.A. The Soybean Trap: Challenges and Risks for Brazilian Producers. Front. Sustain. Food Syst. 2020, 4, 12. [Google Scholar] [CrossRef]

- Strassburg, B.B.N.; Brooks, T.; Feltran-Barbieri, R.; Iribarrem, A.; Crouzeilles, R.; Loyola, R.; Latawiec, A.E.; Oliveira Filho, F.J.B.; Scaramuzza, C.A.d.M.; Scarano, F.R.; et al. Moment of Truth for the Cerrado Hotspot. Nat. Ecol. Evol. 2017, 1, 99. [Google Scholar] [CrossRef]

- Ritchie, H.; Roser, M.; Rosado, P. CO₂ and Greenhouse Gas Emissions. Available online: https://ourworldindata.org/co2-and-other-greenhouse-gas-emissions (accessed on 28 June 2022).

- Rekow, L. Socio-Ecological Implications of Soy in the Brazilian Cerrado. Chall. Sustain. 2019, 7, 7–29. [Google Scholar] [CrossRef]

- Rajão, R.; Soares-Filho, B.; Nunes, F.; Börner, J.; Machado, L.; Assis, D.; Oliveira, A.; Pinto, L.; Ribeiro, V.; Rausch, L.; et al. The Rotten Apples of Brazil’s Agribusiness. Science 2020, 369, 246–248. [Google Scholar] [CrossRef]

- Zanotti, K.; Stahl, A.M.; Segatto, M.L.; Zuin, V.G. Green and Sustainable Extraction of High-Value Compounds. In Sustainable Separation Engineering; Szekely, G., Zhao, D., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2022; pp. 63–104. ISBN 978-1-119-74011-7. [Google Scholar]

- Messina, M.; Sievenpiper, J.L.; Williamson, P.; Kiel, J.; Erdman, J.W., Jr. Perspective: Soy-Based Meat and Dairy Alternatives, Despite Classification as Ultra-Processed Foods, Deliver High-Quality Nutrition on Par with Unprocessed or Minimally Processed Animal-Based Counterparts. Adv. Nutr. 2022, 13, 726–738. [Google Scholar] [CrossRef]

- FAO. Adapting Agriculture to Climate Change. Available online: https://www.fao.org/3/i6398e/i6398e.pdf (accessed on 22 April 2022).

- Ritchie, H.; Roser, M. Environmental Impacts of Food Production. Available online: https://ourworldindata.org/environmental-impacts-of-food (accessed on 29 June 2022).

- FAO. FAOSTAT. Available online: https://www.fao.org/faostat/en/#data (accessed on 13 April 2022).

- EMBRAPA. Visão 2030: O Futuro Da Agricultura Brasileira. Available online: https://www.embrapa.br/visao/o-futuro-da-agricultura-brasileira (accessed on 29 June 2022).

- Comex Stat. Estatísticas de Comércio Exterior Em Dados Abertos. Available online: https://www.gov.br/produtividade-e-comercio-exterior/pt-br/assuntos/comercio-exterior/estatisticas/base-de-dados-bruta (accessed on 22 April 2022).

- WITS. Brazil Protein; Concentrates and Textured Protein Substances Imports by Country—2019. Available online: https://wits.worldbank.org/trade/comtrade/en/country/BRA/year/2019/tradeflow/Imports/partner/ALL/product/210610 (accessed on 29 June 2022).

- CONAB. Safra Brasileira de Grãos. Available online: https://www.conab.gov.br/info-agro/safras/graos (accessed on 27 June 2022).

- FAOSTAT. Pesticides Use, Pesticides Trade and Pesticides Indicators—Global, Regional and Country Trends, 1990–2019; FAOSTAT Analytical Briefs: Rome, Italy, 2022; p. 23.

- ABRASCO. Dossiê ABRASCO: Um Alerta Sobre Os Impactos Dos Agrotóxicos Na Saúde. Available online: https://www.abrasco.org.br/dossieagrotoxicos/wp-content/uploads/2013/10/DossieAbrasco_2015_web.pdf (accessed on 27 June 2022).

- ANVISA. Programa de Análise de Resíduos de Agrotóxicos Em Alimentos—PARA: Plano Plurianual 2017–2020—Resultados Do 1o Ciclo 2017–2018. Available online: https://www.gov.br/anvisa/pt-br/assuntos/agrotoxicos/programa-de-analise-de-residuos-em-alimentos/arquivos/3772json-file-1 (accessed on 27 June 2022).

- Karp, S.G.; Porto de Souza Vandenberghe, L.; Binder Pagnoncelli, M.G.; Sarmiento Vásquez, Z.; Martínez-Burgos, W.J.; Prado, F.; Wedderhoff Herrmann, L.; Letti, L.A.J.; Mezzalira, F.; Soccol, C.R. Integrated Processing of Soybean in a Circular Bioeconomy. In Biomass, Biofuels, Biochemicals—Circular Bioeconomy: Technologies for Biofuels and Biochemicals; Varjani, S., Pandey, A., Bhaskar, T., Mohan, S.V., Tsang, D.C.W., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 189–216. ISBN 978-0-323-89855-3. [Google Scholar]

- van Dam, J.; Faaij, A.P.C.; Hilbert, J.; Petruzzi, H.; Turkenburg, W.C. Large-Scale Bioenergy Production from Soybeans and Switchgrass in Argentina: Part B. Environmental and Socio-Economic Impacts on a Regional Level. Renew. Sustain. Energy Rev. 2009, 13, 1679–1709. [Google Scholar] [CrossRef]

- IBGE. Censo Agropecuário: Resultados Definitivos. Available online: https://censoagro2017.ibge.gov.br/templates/censo_agro/resultadosagro/index.html (accessed on 28 June 2022).

- IBGE. Censo Agropecuário: Brasil Grandes Regiões e Unidades de Federação. Available online: https://biblioteca.ibge.gov.br/pt/biblioteca-catalogo?view=detalhes&id=261914 (accessed on 28 June 2022).

- Zhang, T.; Dou, W.; Zhang, X.; Zhao, Y.; Zhang, Y.; Jiang, L.; Sui, X. The Development History and Recent Updates on Soy Protein-Based Meat Alternatives. Trends Food Sci. Technol. 2021, 109, 702–710. [Google Scholar] [CrossRef]

- De Pretto, C.; Giordano, R.d.L.C.; Tardioli, P.W.; Costa, C.B.B. Possibilities for Producing Energy, Fuels, and Chemicals from Soybean: A Biorefinery Concept. Waste Biomass Valorization 2018, 9, 1703–1730. [Google Scholar] [CrossRef]

- Araújo, D.J.C.; Machado, A.V.; Vilarinho, M.C.L.G. Availability and Suitability of Agroindustrial Residues as Feedstock for Cellulose-Based Materials: Brazil Case Study. Waste Biomass Valorization 2019, 10, 2863–2878. [Google Scholar] [CrossRef]

- Kumar, P.; Chatli, M.K.; Mehta, N.; Singh, P.; Malav, O.P.; Verma, A.K. Meat Analogues: Health Promising Sustainable Meat Substitutes. Crit. Rev. Food Sci. Nutr. 2017, 57, 923–932. [Google Scholar] [CrossRef] [PubMed]

- Steel, C.J.; Leoro, M.G.V.; Schmiele, M.; Ferreira, R.E.; Chang, Y.K. Thermoplastic Extrusion in Food Processing. In Thermoplastic Elastomers; El-Sonbati, A., Ed.; IntechOpen: Rijeka, Croatia, 2012; pp. 265–290. [Google Scholar]

- Endres, J.G. Soy Protein Products: Characteristics, Nutritional Aspects, and Utilization; AOCS Publishing: New York, NY, USA, 2001; ISBN 978-1-00-304055-2. [Google Scholar]

- Guo, M. Soy Food Products and Their Health Benefits. In Functional Foods; Guo, M., Ed.; Woodhead Publishing Series in Food Science, Technology and Nutrition; Woodhead Publishing: Sawston, UK, 2009; pp. 237–277. ISBN 978-1-84569-592-7. [Google Scholar]

- Brazil. Available online: https://www.gov.br/anvisa/pt-br/assuntos/noticias-anvisa/2020/aprovada-norma-sobre-rotulagem-nutricional (accessed on 27 June 2022).

- Byrne, F.P.; Jin, S.; Paggiola, G.; Petchey, T.H.M.; Clark, J.H.; Farmer, T.J.; Hunt, A.J.; Robert McElroy, C.; Sherwood, J. Tools and Techniques for Solvent Selection: Green Solvent Selection Guides. Sustain. Chem. Process. 2016, 4, 7. [Google Scholar] [CrossRef]

- Prat, D.; Wells, A.; Hayler, J.; Sneddon, H.; McElroy, C.R.; Abou-Shehada, S.; Dunn, P.J. CHEM21 Selection Guide of Classical- and Less Classical-Solvents. Green Chem. 2016, 18, 288–296. [Google Scholar] [CrossRef]

- Clough, S.R. Hexane. In Encyclopedia of Toxicology, 3rd ed.; Wexler, P., Ed.; Academic Press: Oxford, UK, 2014; pp. 900–904. ISBN 978-0-12-386455-0. [Google Scholar]

- Committee on Acute Exposure Guideline Levels; Committee on Acute Exposure Guideline Levels; Committee on Toxicology; Board on Environmental Studies and Toxicology; Division on Earth and Life Studies; National Research Council. Acute Exposure Guideline Levels for Selected Airborne Chemicals; National Academies Press: Washington, DC, USA, 2013; Volume 14.

- EPA. Hexane. Available online: https://www.epa.gov/sites/default/files/2016-09/documents/hexane.pdf (accessed on 24 June 2022).

- ANVISA. Resolução de Diretoria Colegiada—RDC No 466, de 10 de fevereiro de 2021. Available online: https://portal.in.gov.br/web/dou (accessed on 24 June 2022).

- FDA. CFR—Code of Federal Regulations Title 21. Available online: https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?fr=173.270 (accessed on 22 June 2022).

- Cheng, M.-H.; Sekhon, J.J.K.; Rosentrater, K.A.; Wang, T.; Jung, S.; Johnson, L.A. Environmental Impact Assessment of Soybean Oil Production: Extruding-Expelling Process, Hexane Extraction and Aqueous Extraction. Food Bioprod. Process. 2018, 108, 58–68. [Google Scholar] [CrossRef]

- WWF. The Soy Saga—The Journey from Brazil. Available online: https://panda.maps.arcgis.com/apps/Cascade/index.html?appid=dc3bded33f934cf4a4ccdc3f6ab3e377 (accessed on 23 June 2022).

- Ahmed, H. Principles and Reactions of Protein Extraction, Purification, and Characterization; CRC Press: Boca Raton, FL, USA, 2017; ISBN 978-0-429-21142-3. [Google Scholar]

- Wittek, P.; Zeiler, N.; Karbstein, H.P.; Emin, M.A. High Moisture Extrusion of Soy Protein: Investigations on the Formation of Anisotropic Product Structure. Foods 2021, 10, 102. [Google Scholar] [CrossRef]

- CETESB. Available online: https://produtosquimicos.cetesb.sp.gov.br/ficha/produto/19 (accessed on 24 June 2022).

- Aboissa Commodity Brokers. Brazilian SPC Production is Considered Innovative. Available online: https://www.aboissa.com.br/en/news/latest-news/2716-brazilian-spc-production-is-considered-innovative (accessed on 24 June 2022).

- Freitas, M.L.F.; Albano, K.M.; Telis, V.R.N. Characterization of Biopolymers and Soy Protein Isolate-High-Methoxyl Pectin Complex. Polímeros 2017, 27, 62–67. [Google Scholar] [CrossRef]

- Henderson, R.K.; Hill, A.P.; Redman, A.M.; Sneddon, H.F. Development of GSK’s Acid and Base Selection Guides. Green Chem. 2015, 17, 945–949. [Google Scholar] [CrossRef]

- Garcia-Garcia, G.; Azanedo, L.; Rahimifard, S. Embedding Sustainability Analysis in New Food Product Development. Trends Food Sci. Technol. 2021, 108, 236–244. [Google Scholar] [CrossRef]

- Vieira, J.G.; Rodrigues Filho, G.; Meireles, C.d.S.; Faria, F.A.C.; Gomide, D.D.; Pasquini, D.; Cruz, S.F.d.; de Assunção, R.M.N.; Motta, L.A.d.C. Synthesis and Characterization of Methylcellulose from Cellulose Extracted from Mango Seeds for Use as a Mortar Additive. Polímeros. 2012, 22, 80–87. [Google Scholar] [CrossRef]

- Committee on Acute Exposure Guideline Levels; Committee on Toxicology; Board on Environmental Studies and Toxicology; Division on Earth and Life Studies; National Research Council. Methyl Chloride: Acute Exposure Guideline Levels; National Academies Press: Washington, DC, USA, 2012; Volume 12.

- Arts, J.; Kellert, M.; Pottenger, L.; Theuns-van Vliet, J. Evaluation of Developmental Toxicity of Methyl Chloride (Chloromethane) in Rats, Mice, and Rabbits. Regul. Toxicol. Pharmacol. 2019, 103, 274–281. [Google Scholar] [CrossRef]

- Brasil. Portal de Legislação. Available online: https://www.diariodasleis.com.br/legislacao/federal/163269-aprova-a-inclusuo-dos-aditivos-ins-461-metilcelulose-e-ins-464-hidroxipropil-metilcelulose-na-legislauuo-brasileira-nas-funues-espessante-e-estabilizante-de-acordo-com-as-condiues-abaixo-mencionada.html (accessed on 23 June 2022).

- Hamilton, J.W.; Wagner, J.; Burdick, B.B.; Bass, P. Clinical Evaluation of Methylcellulose as a Bulk Laxative. Dig. Dis. Sci. 1988, 33, 993–998. [Google Scholar] [CrossRef] [PubMed]

- FEEDAP; Bampidis, V.; Azimonti, G.; Bastos, M.d.L.; Christensen, H.; Dusemund, B.; Kos Durjava, M.; Kouba, M.; López-Alonso, M.; López Puente, S.; et al. Safety and Efficacy of Methyl Cellulose for All Animal Species. EFSA J. 2020, 18, e06212. [Google Scholar] [CrossRef]

- Bakhsh, A.; Lee, S.-J.; Lee, E.-Y.; Sabikun, N.; Hwang, Y.-H.; Joo, S.-T. A Novel Approach for Tuning the Physicochemical, Textural, and Sensory Characteristics of Plant-Based Meat Analogs with Different Levels of Methylcellulose Concentration. Foods 2021, 10, 560. [Google Scholar] [CrossRef]

- Sjöström, J.; Eilks, I.; Zuin, V.G. Towards Eco-Reflexive Science Education—A Critical Reflection About Educational Implications of Green Chemistry. Sci. Educ. 2016, 25, 321–341. [Google Scholar] [CrossRef]

- Eilks, I.; Zuin, V.G. Green and Sustainable Chemistry Education (GSCE): Lessons to Be Learnt for a Safer, Healthier and Fairer World Today and Tomorrow. Curr. Opin. Green Sustain. Chem. 2018, 13, A4–A6. [Google Scholar] [CrossRef]

- Zuin, V.G.; Kümmerer, K. Towards more sustainable curricula. Nat. Rev. Chem. 2021, 5, 76–77. [Google Scholar] [CrossRef]

- Zuin, V.G.; Eilks, I.; Elschami, M.; Kummerer, K. Education in Green Chemistry and in Sustainable Chemistry: Perspectives towards sustainability. Green Chem. 2021, 23, 1594–1608. [Google Scholar] [CrossRef]

- Segatto, M.L.; Stahl, A.M.; Zanotti, K.; Zuin, V.G. Green and Sustainable Extraction of Proteins from Agro-industrial Waste: An Overview and a Closer Look to Latin America. Curr. Opin. Green Sustain. Chem. 2022, 37, 100661. [Google Scholar] [CrossRef]

| Region | Area Harvested (ha) | Relative to Region Area (%) | Relative to Brazilian Area (%) |

|---|---|---|---|

| North | 2,333,100 | 0.6 | 0.3 |

| Northeast | 3,544,300 | 2 | 0.4 |

| Central-West | 17,612,200 | 11 | 2 |

| Southeast | 3,061,300 | 3 | 0.4 |

| South | 12,375,300 | 21 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zuin, V.G.; Araripe, E.; Zanotti, K.; Stahl, A.M.; Gomes, C.J.C. Alternative Products Selling Sustainability? A Brazilian Case Study on Materials and Processes to Produce Plant-Based Hamburger Patties. Sustain. Chem. 2022, 3, 415-429. https://doi.org/10.3390/suschem3030026

Zuin VG, Araripe E, Zanotti K, Stahl AM, Gomes CJC. Alternative Products Selling Sustainability? A Brazilian Case Study on Materials and Processes to Produce Plant-Based Hamburger Patties. Sustainable Chemistry. 2022; 3(3):415-429. https://doi.org/10.3390/suschem3030026

Chicago/Turabian StyleZuin, Vânia G., Evelyn Araripe, Karine Zanotti, Aylon M. Stahl, and Caroindes J. C. Gomes. 2022. "Alternative Products Selling Sustainability? A Brazilian Case Study on Materials and Processes to Produce Plant-Based Hamburger Patties" Sustainable Chemistry 3, no. 3: 415-429. https://doi.org/10.3390/suschem3030026