Circular Economy Development in the Construction Sector in Japan

Abstract

:1. Introduction

1.1. Circular Economy Development in the Construction Sector in Japan

1.2. Pre-Study Survey

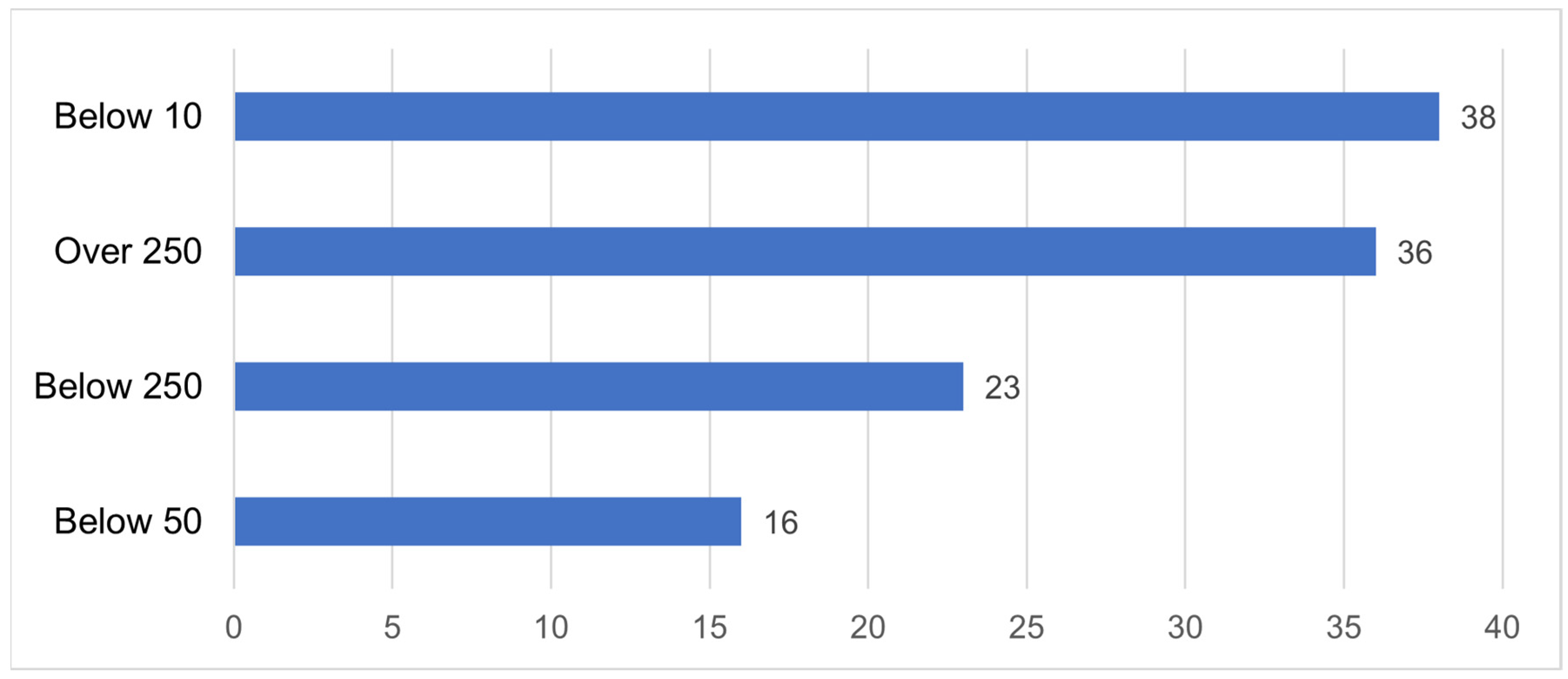

2. Materials and Methods

3. Results and Discussion

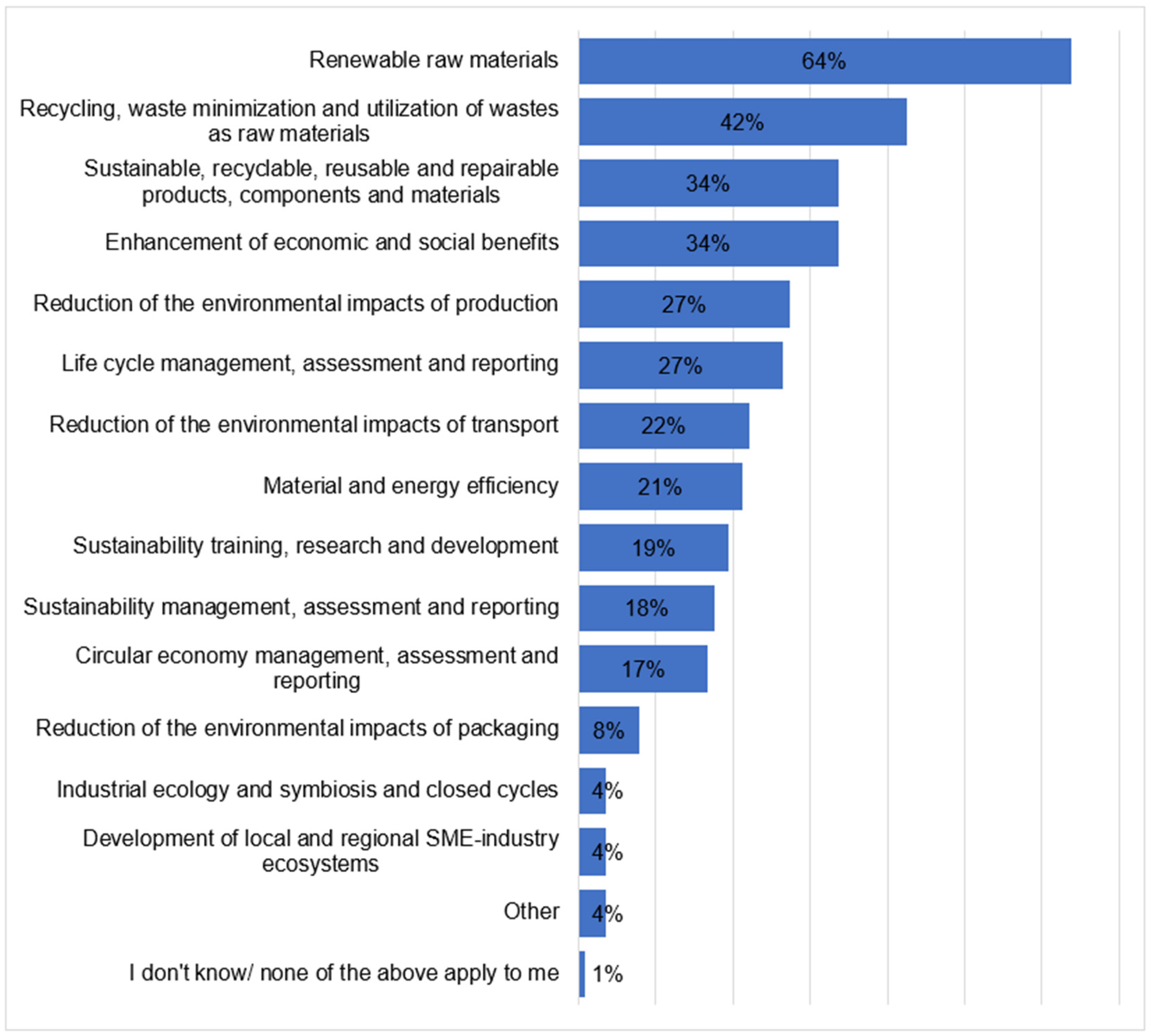

3.1. Sustainable Production

3.2. Sustainable Consumption

3.3. Value Creation and Maintenance

3.4. Innovations

3.5. Material and Energy Use

3.6. Barriers

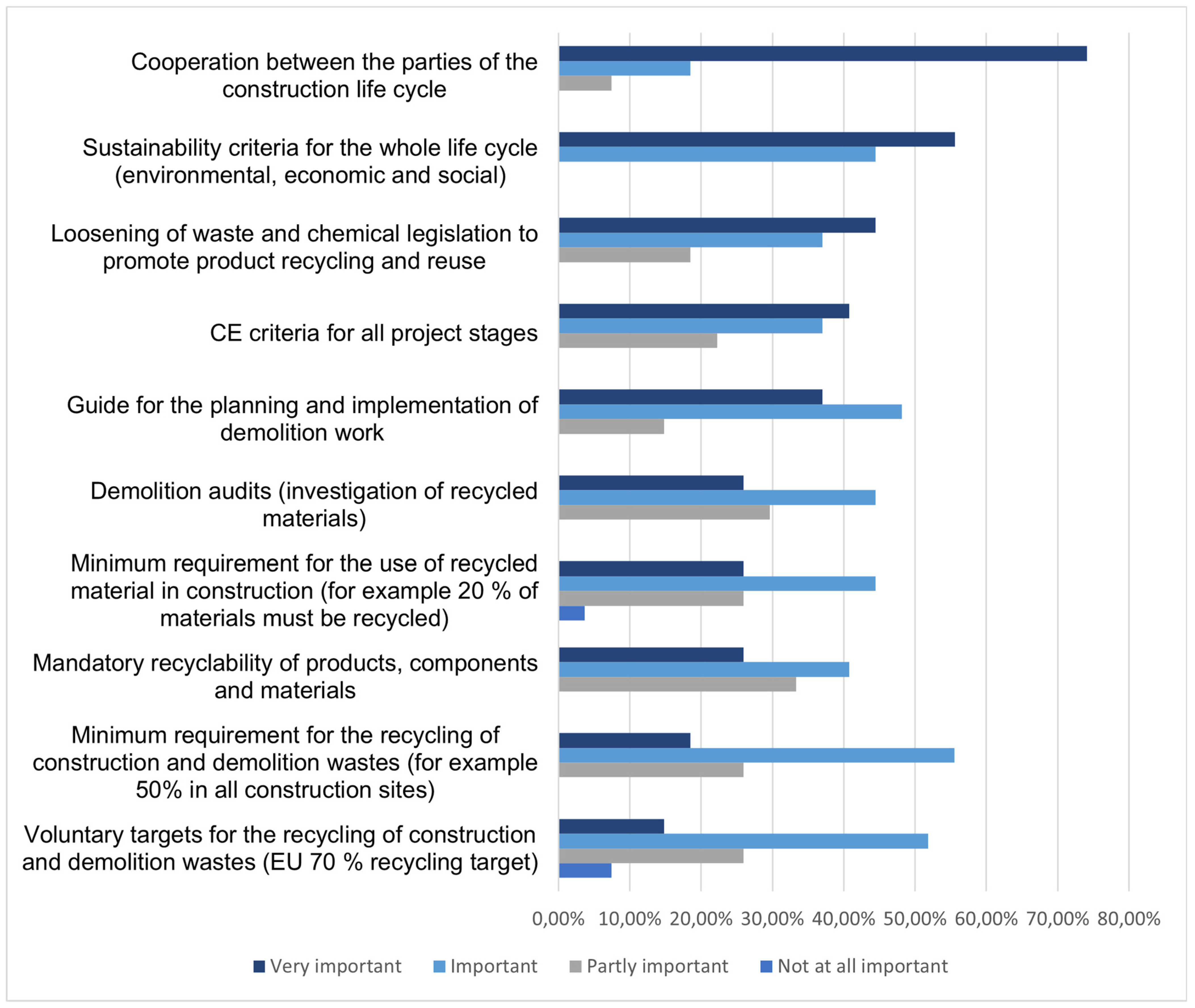

3.7. Guidance

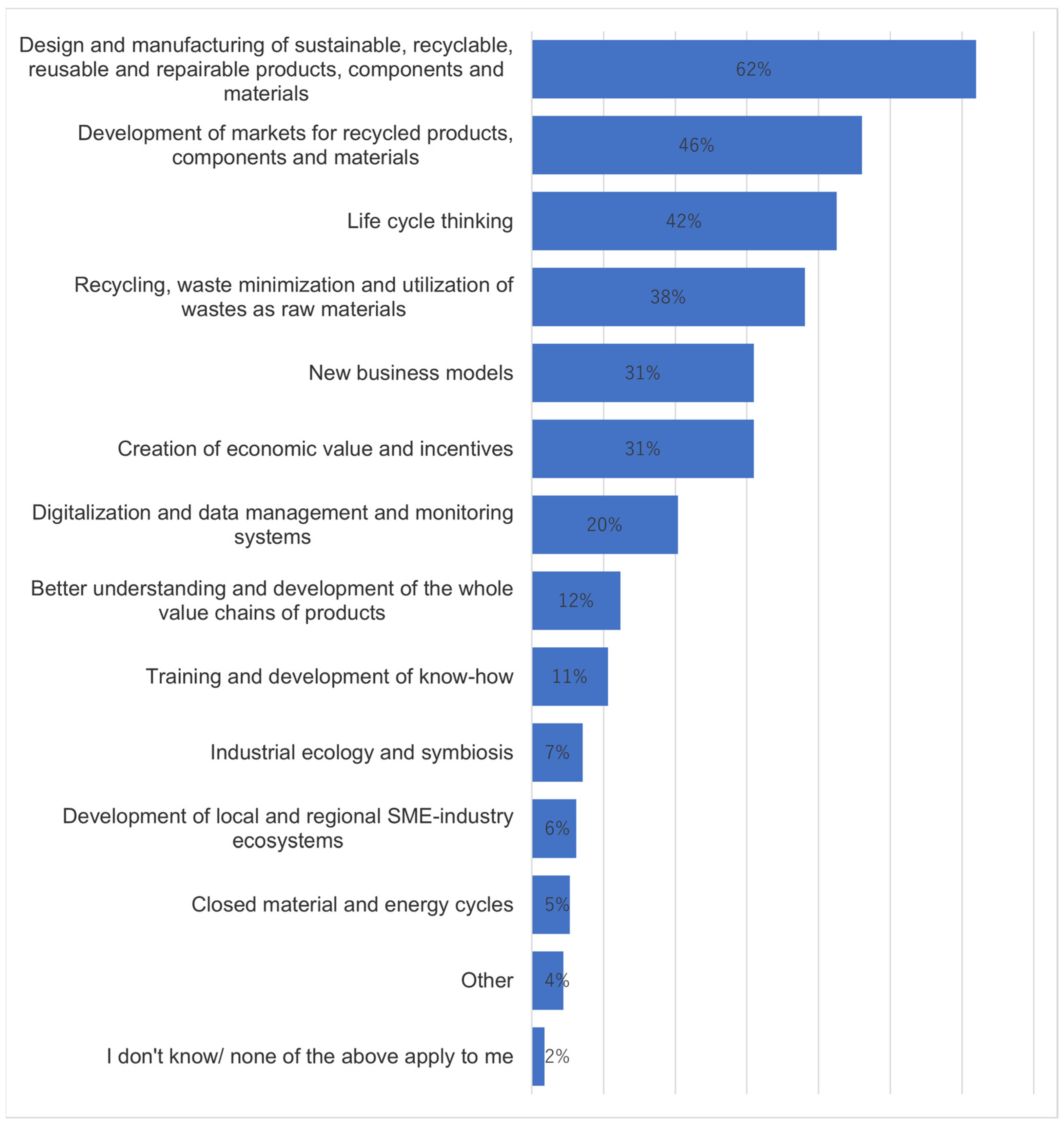

3.8. Circular Economy Development

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ellen McArthur Foundation. Towards a Circular Economy: Business Rationale for an Accelerated Transition. Available online: https://emf.thirdlight.com/link/ip2fh05h21it-6nvypm (accessed on 19 October 2021).

- Eberhardt, L.C.M.; Birkved, M.; Birgisdottir, H. Building design and construction strategies for a circular economy. Archit. Eng. Des. Manag. 2020, 225, 12055. [Google Scholar] [CrossRef]

- Pomponi, F.; Moncaster, A. Circular economy for the built environment: A research framework. J. Clean. Prod. 2017, 143, 710–718. [Google Scholar] [CrossRef] [Green Version]

- Joensuu, T.; Edelman, H.; Saari, A. Circular economy practices in the built environment. J. Clean. Prod. 2020, 276, 124215. [Google Scholar] [CrossRef]

- Eberhardt, L.C.M.; Birgisdottir, H.; Birkved, M. Potential of Circular Economy in Sustainable Buildings. IOP Conf. Ser. Mater. Sci. Eng. 2019, 471, 92051. [Google Scholar] [CrossRef]

- Andrews, D. The Circular Economy, Design Thinking and Education for Sustainability. Local Econ. 2015, 30, 305–315. [Google Scholar] [CrossRef]

- Díaz-López, C.; Bonoli, A.; Martín-Morales, M.; Zamorano, M. Analysis of the Scientific Evolution of the Circular Economy Applied to Construction and Demolition Waste. Sustainability 2021, 13, 9416. [Google Scholar] [CrossRef]

- Wijewickrama, M.K.C.S.; Rameezdeen, R.; Chileshe, N. Information brokerage for circular economy in the construction industry: A systematic literature review. J. Clean. Prod. 2021, 313, 127938. [Google Scholar] [CrossRef]

- Karhu, J.; Linkola, L. Circular economy in the built environment in finland—A case example of collaboration. IOP Conf. Ser. Earth Environ. Sci. 2019, 297, 12024. [Google Scholar] [CrossRef]

- Hossain, M.U.; Ng, S.T.; Antwi-Afari, P.; Amor, B. Circular economy and the construction industry: Existing trends, challenges and prospective framework for sustainable construction. Renew. Sustain. Energy Rev. 2020, 130, 109948. [Google Scholar] [CrossRef]

- Sitra. Summary of Closing Remarks from the WCEF 2018 Hosts. Available online: https://www.sitra.fi/en/articles/summary-of-closing-remarks-from-wcef-2018-hosts/ (accessed on 2 December 2021).

- Sitra. WCEF2018 Report. Available online: https://media.sitra.fi/2018/11/20141120/sitramoejwcef2018report.pdf (accessed on 7 December 2021).

- Ministry of Economy, Trade and Industry of Japan. Circular Economy Vision 2020. Available online: https://www.meti.go.jp/english/press/2020/0522_003.html#:~:text=Aiming%20to%20present%20basic%20future,abroad%20and%20analyzed%20the%20results (accessed on 6 December 2021).

- Ogunmakinde, O.E. A Review of Circular Economy Development Models in China, Germany and Japan. Recycling 2019, 4, 27. [Google Scholar] [CrossRef] [Green Version]

- Umeda, Y.; Takata, S.; Matsumoto, M. Technical Committee for Life Cycle Engineering: Life Cycle Engineering in the Era of Circular Economy. J. Jpn. Soc. Precis. Eng. 2019, 85, 817–820. [Google Scholar] [CrossRef]

- Teramoto, H. An Inquiry into the Influence Plastic giving to the Economic Society―Transition from Linear Economy to Circular Economy. Aichi Gakuin Econ. Rev. 2020, 8, 83–97. [Google Scholar]

- Wuyts, W.; Miatto, A.; Sedlitzky, R.; Tanikawa, H. Extending or ending the life of residential buildings in Japan: A social circular economy approach to the problem of short-lived constructions. J. Clean. Prod. 2019, 231, 660–670. [Google Scholar] [CrossRef]

- Japan’s Circularity. A Panorama of Japansese Policy, Innovation, Technology and Industry Contributions towards Achieving the Paris Agreement. EU-Japan Centre for Industrial Cooperation. Available online: https://www.eu-japan.eu/sites/default/files/publications/docs/japans_circularity_-_helene_bangert_-_11.12.2020.pdf (accessed on 6 December 2021).

- Hosoda, E. Recent Developments in Circular Economies: A Comparative Study of the EU and Japan. Mater. Cycles Waste Manag. Res. 2015, 26, 253–260. [Google Scholar] [CrossRef]

- Benton, D.; Hazell, J. The Circular Economy in Japan. 2015. Available online: https://www.the-ies.org/analysis/circular-economy-japan (accessed on 2 December 2021).

- Kasuga, H. The Dawn of Reiwa Modernism: “Circular Economy” Adopted Emotional Feelings. Int. J. Affect. Eng. 2021, 19, 23–28. [Google Scholar] [CrossRef]

- Saldana, J. Fundamentals of Qualitative Research; Oxford University Press: Oxford, UK, 2011; pp. 3–30. ISBN -10:0199737959. [Google Scholar]

- Patten, M.L. Questionnaire Research: A Practical Guide, 4th ed.; Routledge: New York, NY, USA, 2014. [Google Scholar] [CrossRef]

- Gillham, B. Developing a Questionnaire, 2nd ed.; Continuum International Publishing Group: London, UK, 2007; ISBN 10:0826496318. [Google Scholar]

- Hirsjärvi, H.; Remes, P.; Sajavaara, P. Tutki ja Kirjoita, 13th ed.; Tammi: Helsinki, Finland, 2007; ISBN 978-951-26-5635-6. [Google Scholar]

- Birmingham, P.; Wilkinson, D. Using Research Instruments: A Guide for Researchers; Taylor & Francis Group: Abingdon-on-Thames, UK, 2003; ISBN 9780415272797. [Google Scholar]

- Fink, A. How to Conduct Surveys: A Step-By-Step Guide, 4th ed.; Sage: Newcastle upon Tyne, UK, 2009; ISBN 10:141296668X. [Google Scholar]

- Oppenheim, A.N. Questionnaire Design, Interviewing and Attitude Measurement; Pinter: London, UK; Washington, DC, USA, 1997; ISBN 10:0826451764. [Google Scholar]

- Saris, W.E.; Gallhofer, I.N. Design, Evaluation, and Analysis of Questionnaires for Survey Research; John Wiley & Sons: Hoboken, NJ, USA, 2007; ISBN 10:0470114959. [Google Scholar]

- Sudman, S.; Bradbrun, N.M. Asking Questions: A Practical Guide to Questionnaire Design; The Jossey-Bass Series in Social and Behavioural Sciences; Jossey-Bass Publishers: Hoboken, NJ, USA, 1982; ISBN 9780985895464. [Google Scholar]

- Peterson, R.A. Constructing Effective Questionnaires; SAGE Publications: Thousand Oaks, CA, USA, 2000. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K. Life cycle performance of modular buildings: A critical review. Renew. Sustain. Energy Rev. 2016, 62, 1171–1183. [Google Scholar] [CrossRef]

- Braganca, L.; Mateus, R.; Koukkari, H. Perspectives of building sustainability assessment. In Portugal SB07. Sustainable Construction, Materials and Practices: Challenge of the Industry for the New Millennium; Braganca, L., Pinheiro, M.D., Jalali, S., Mateus, R., Amoeda, R., Guedes, M.C., Eds.; IOS Press: Amsterdam, The Netherlands, 2007; pp. 356–365. ISBN 9781586037857. [Google Scholar]

- Nuñez-Cacho, P.; Górecki, J.; Molina-Moreno, V.; Corpas-Iglesias, F.A. What Gets Measured, Gets Done: Development of a Circular Economy Measurement Scale for Building Industry. Sustainability 2018, 10, 2340. [Google Scholar] [CrossRef] [Green Version]

- Akadiri, P.O.; Chinyio, E.A.; Olomolaiye, P.O. Design of A Sustainable Building: A Conceptual Framework for Implementing Sustainability in the Building Sector. Buildings 2012, 2, 126–152. [Google Scholar] [CrossRef] [Green Version]

- Foster, G. Circular economy strategies for adaptive reuse of cultural heritage buildings to reduce environmental impacts. Resour. Conserv. Recycl. 2020, 152, 104507. [Google Scholar] [CrossRef]

- Saidani, M.; Yannou, B.; Leroy, Y.; Cluzel, F. How to Assess Product Performance in the Circular Economy? Proposed Requirements for the Design of a Circularity Measurement Framework. Recycling 2017, 2, 6. [Google Scholar] [CrossRef] [Green Version]

- Papastamoulis, V.; London, K.; Feng, Y.; Zhang, P.; Crocker, R.; Patias, P. Conceptualising the Circular Economy Potential of Construction and Demolition Waste: An Integrative Literature Review. Recycling 2021, 6, 61. [Google Scholar] [CrossRef]

- Jarre, M.; Petit-Boix, A.; Priefer, C.; Meyer, R.; Leipold, S. Transforming the bio-based sector towards a circular economy—What can we learn from wood cascading? For. Policy Econ. 2020, 110, 101872. [Google Scholar] [CrossRef]

- Niu, Y.; Rasi, K.; Hughes, M.; Halme, M.; Fink, G. Prolonging life cycles of construction materials and combating climate change by cascading: The case of reusing timber in Finland. Resour. Conserv. Recycl. 2021, 170, 105555. [Google Scholar] [CrossRef]

- Murray, A.; Skene, K.; Haynes, K. The circular economy: An interdisciplinary exploration of the concept and application in a global context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef] [Green Version]

- Hossain, M.U.; Ng, S.T. Critical consideration of buildings’ environmental impact assessment towards adoption of circular economy: An analytical review. J. Clean. Prod. 2018, 205, 763–780. [Google Scholar] [CrossRef]

- Ginga, C.P.; Ongpeng, J.M.C.; Daly, M.K.M. Circular Economy on Construction and Demolition Waste: A Literature Review on Material Recovery and Production. Materials 2020, 13, 2970. [Google Scholar] [CrossRef]

- Xue, K.; Hossain, M.U.; Liu, M.; Ma, M.; Zhang, Y.; Hu, M.; Chen, X.; Cao, G. BIM Integrated LCA for Promoting Circular Economy towards Sustainable Construction: An Analytical Review. Sustainability 2021, 13, 1310. [Google Scholar] [CrossRef]

- Tomaszewska, J. Polish Transition towards Circular Economy: Materials Management and Implications for the Construction Sector. Materials 2020, 13, 5228. [Google Scholar] [CrossRef]

- De los Rios, I.C.; Charnley, F.J.S. Skills and capabilities for a sustainable and circular economy: The changing role of design. J. Clean. Prod. 2017, 160, 109–122. [Google Scholar] [CrossRef]

- Ghisellini, P.; Ripa, M.; Ulgiati, S. Exploring environmental and economic costs and benefits of a circular economy approach to the construction and demolition sector. A literature review. J. Clean. Prod. 2018, 178, 618–643. [Google Scholar] [CrossRef]

- Rahla, K.M.; Mateus, R.; Bragança, L. Selection Criteria for Building Materials and Components in Line with the Circular Economy Principles in the Built Environment—A Review of Current Trends. Infrastructures 2021, 6, 49. [Google Scholar] [CrossRef]

- Mercader-Moyano, P.; Porras-Pereira, P.; Levinton, C. Circular Economy and Regenerative Sustainability in Emergency Housing: Eco-Efficient Prototype Design for Subaşi Refugee Camp in Turkey. Sustainability 2021, 13, 8100. [Google Scholar] [CrossRef]

- Jensen, J.O.; Jørgensen, M.S.; Lauridsen, M.E.; Lauridsen, E.H. Has social sustainability left the building? The recent conceptualization of “sustainability” in Danish buildings. Sustain. Sci. Pract. Policy 2012, 8, 94–105. [Google Scholar] [CrossRef]

- van Dam, K.; Simeone, L.; Keskin, D.; Baldassarre, B.; Niero, M.; Morelli, N. Circular Economy in Industrial Design Research: A Review. Sustainability 2020, 12, 10279. [Google Scholar] [CrossRef]

- Sakaguchi, D.; Takano, A.; Hughes, M. The potential for cascading wood from demolished buildings: Potential flows and possible applications through a case study in Finland. Int. Wood Prod. J. 2017, 8, 208–215. [Google Scholar] [CrossRef]

- Mehr, J.; Vadenbo, C.; Steubing, B.; Hellweg, S. Environmentally optimal wood use in Switzerland—Investigating the relevance of material cascades. Resour. Conserv. Recycl. 2018, 131, 181–191. [Google Scholar] [CrossRef]

- Höglmeier, K.; Steubing, B.; Weber-Blaschke, G.; Richter, K. LCA-based optimization of wood utilization under special consideration of a cascading use of wood. J. Environ. Manag. 2015, 152, 158–170. [Google Scholar] [CrossRef]

- Dahlbo, H.; Bacher, J.; Lahtinen, K.; Jouttijärvi, T.; Suoheimo, P.; Mattila, T.; Sironen, S.; Myllymaa, T.; Saramaki, K. Construction and demolition waste management e a holistic evaluation of environmental performance. J. Clean. Prod. 2015, 107, 333–341. [Google Scholar] [CrossRef]

- Sakaguchi, D.; Takano, A.; Hughes, M. The potential for cascading wood from demolished buildings: The condition of recovered wood through a case study in Finland. Int. Wood Prod. J. 2016, 7, 137–143. [Google Scholar] [CrossRef]

- Husgafvel, R.; Linkosalmi, L.; Hughes, M.; Kanerva, J.; Dahl, O. Forest sector circular economy in Finland: A regional study on sustainability driven competitive advantage and an assessment of the potential for cascading recovered solid wood. J. Clean. Prod. 2018, 181, 483–497. [Google Scholar] [CrossRef]

- Ruiz, L.A.L.; Ramón, X.R.; Domingo, S.G. The circular economy in the construction and demolition waste sector—A review and an integrative model approach. J. Clean. Prod. 2020, 248, 119238. [Google Scholar] [CrossRef]

- Bertino, G.; Kisser, J.; Zeilinger, J.; Langergraber, G.; Fischer, T.; Österreicher, D. Fundamentals of Building Deconstruction as a Circular Economy Strategy for the Reuse of Construction Materials. Appl. Sci. 2021, 11, 939. [Google Scholar] [CrossRef]

- Sumter, D.; de Koning, J.; Bakker, C.; Balkenende, R. Key Competencies for Design in a Circular Economy: Exploring Gaps in Design Knowledge and Skills for a Circular Economy. Sustainability 2021, 13, 776. [Google Scholar] [CrossRef]

- Sumter, D.; de Koning, J.; Bakker, C.; Balkenende, R. Circular Economy Competencies for Design. Sustainability 2020, 12, 1561. [Google Scholar] [CrossRef] [Green Version]

- Munaro, M.R.; Tavares, S.F.; Bragança, L. Towards circular and more sustainable buildings: A systematic literature review on the circular economy in the built environment. J. Clean. Prod. 2020, 260, 121134. [Google Scholar] [CrossRef]

- Ellen McArthur Foundation. Circular Design. Available online: https://archive.ellenmacarthurfoundation.org/explore/circular-design (accessed on 15 October 2021).

- zu Castell-Rüdenhausen, M.; Wahlström, M.; Astrup, T.F.; Jensen, C.; Oberender, A.; Johansson, P.; Waerner, E.R. Policies as Drivers for Circular Economy in the Construction Sector in the Nordics. Sustainability 2021, 13, 9350. [Google Scholar] [CrossRef]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L.; Colling, M. Strategies for Applying the Circular Economy to Prefabricated Buildings. Buildings 2018, 8, 125. [Google Scholar] [CrossRef] [Green Version]

- Ghaffar, S.H.; Burman, M.; Braimah, N. Pathways to circular construction: An integrated management of construction and demolition waste for resource recovery. J. Clean. Prod. 2020, 244, 118710. [Google Scholar] [CrossRef]

- Leising, E.; Quist, J.; Bocken, N. Circular Economy in the building sector: Three cases and a collaboration tool. J. Clean. Prod. 2018, 176, 976–989. [Google Scholar] [CrossRef]

- Tserng, H.-P.; Chou, C.-M.; Chang, Y.-T. The Key Strategies to Implement Circular Economy in Building Projects—A Case Study of Taiwan. Sustainability 2021, 13, 754. [Google Scholar] [CrossRef]

- Mahpour, A. Prioritizing barriers to adopt circular economy in construction and demolition waste management. Resour. Conserv. Recycl. 2018, 134, 216–227. [Google Scholar] [CrossRef]

- Guerra, B.C.; Leite, F. Circular economy in the construction industry: An overview of United States stakeholders’ awareness, major challenges, and enablers. Resour. Conserv. Recycl. 2021, 170, 105617. [Google Scholar] [CrossRef]

- Hartley, K.; van Santen, R.; Kirchherr, J. Policies for transitioning towards a circular econ-omy: Expectations from the European Union (EU). Resour. Conserv. Recycl. 2020, 155, 104634. [Google Scholar] [CrossRef]

- Torres-Guevara, L.E.; Prieto-Sandoval, V.; Mejia-Villa, A. Success Drivers for Implementing Circular Economy: A Case Study from the Building Sector in Colombia. Sustainability 2021, 13, 1350. [Google Scholar] [CrossRef]

- Morseletto, P. Targets for a circular economy. Resour. Conserv. Recycl. 2020, 153, 104553. [Google Scholar] [CrossRef]

- Jones, P.; Comfort, D. The construction industry and the circular economy. Int. J. Manag. Cases 2018, 20, 4–15. Available online: http://eprints.glos.ac.uk/id/eprint/5562 (accessed on 22 October 2021).

- Velenturf, A.P.M.; Jensen, P.D.; Purnell, P.; Jopson, J.; Ebner, N. A Call to Integrate Economic, Social and Environmental Motives into Guidance for Business Support for the Transition to a Circular Economy. Adm. Sci. 2019, 9, 92. [Google Scholar] [CrossRef] [Green Version]

- Giannoccaro, I.; Ceccarelli, G.; Fraccascia, L. Features of the Higher Education for the Circular Economy: The Case of Italy. Sustainability 2021, 13, 11338. [Google Scholar] [CrossRef]

- Husgafvel, R.; Linkosalmi, L.; Sakaguchi, D.; Hughes, M. How to advance sustainable and circular economy oriented public procurement?—A review of the operational environment and a case study from the Kymenlaakso region in Finland. In Circular Economy and Sustainability, Volume 1: Management and Policy; Elsevier: Amsterdam, The Netherlands, 2022; pp. 227–277. [Google Scholar] [CrossRef]

- Benachio, G.L.F.; Freitas, M.C.D.; Tavares, S.F. Circular economy in the construction industry: A systematic literature review. J. Clean. Prod. 2020, 260, 121046. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Husgafvel, R.; Sakaguchi, D. Circular Economy Development in the Construction Sector in Japan. World 2022, 3, 1-26. https://doi.org/10.3390/world3010001

Husgafvel R, Sakaguchi D. Circular Economy Development in the Construction Sector in Japan. World. 2022; 3(1):1-26. https://doi.org/10.3390/world3010001

Chicago/Turabian StyleHusgafvel, Roope, and Daishi Sakaguchi. 2022. "Circular Economy Development in the Construction Sector in Japan" World 3, no. 1: 1-26. https://doi.org/10.3390/world3010001

APA StyleHusgafvel, R., & Sakaguchi, D. (2022). Circular Economy Development in the Construction Sector in Japan. World, 3(1), 1-26. https://doi.org/10.3390/world3010001