Energy-Environmental Impact Assessment of Greenhouse Grown Tomato: A Case Study in Almeria (Spain)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Goal and Scope of the Study

2.2. System Boundaries and Assumptions

- Production and processing stage (aka materials and manufacturing)

- −

- Daytime temperature between 20 and 25 °C;

- −

- Night temperature between 15 and 18 °C;

- −

- Relative humidity between 60 and 80%;

- −

- Sun exposure of between 8 and 16 h per day;

- −

- CO2 concentration of ca. 335 ppm with open windows and 650 ppm with closed windows.

- −

- Nitrogen, N: 3.11 kg;

- −

- Phosphorous, P: 0.6 kg;

- −

- Potassium, K: 4.21 kg;

- −

- Calcium, Ca: 2.26 kg;

- −

- Magnesium, Mg: 1.08 kg.

- b.

- Transportation stage

- c.

- Use stage

- d.

- Disposal stage

2.3. Calculations

3. Results

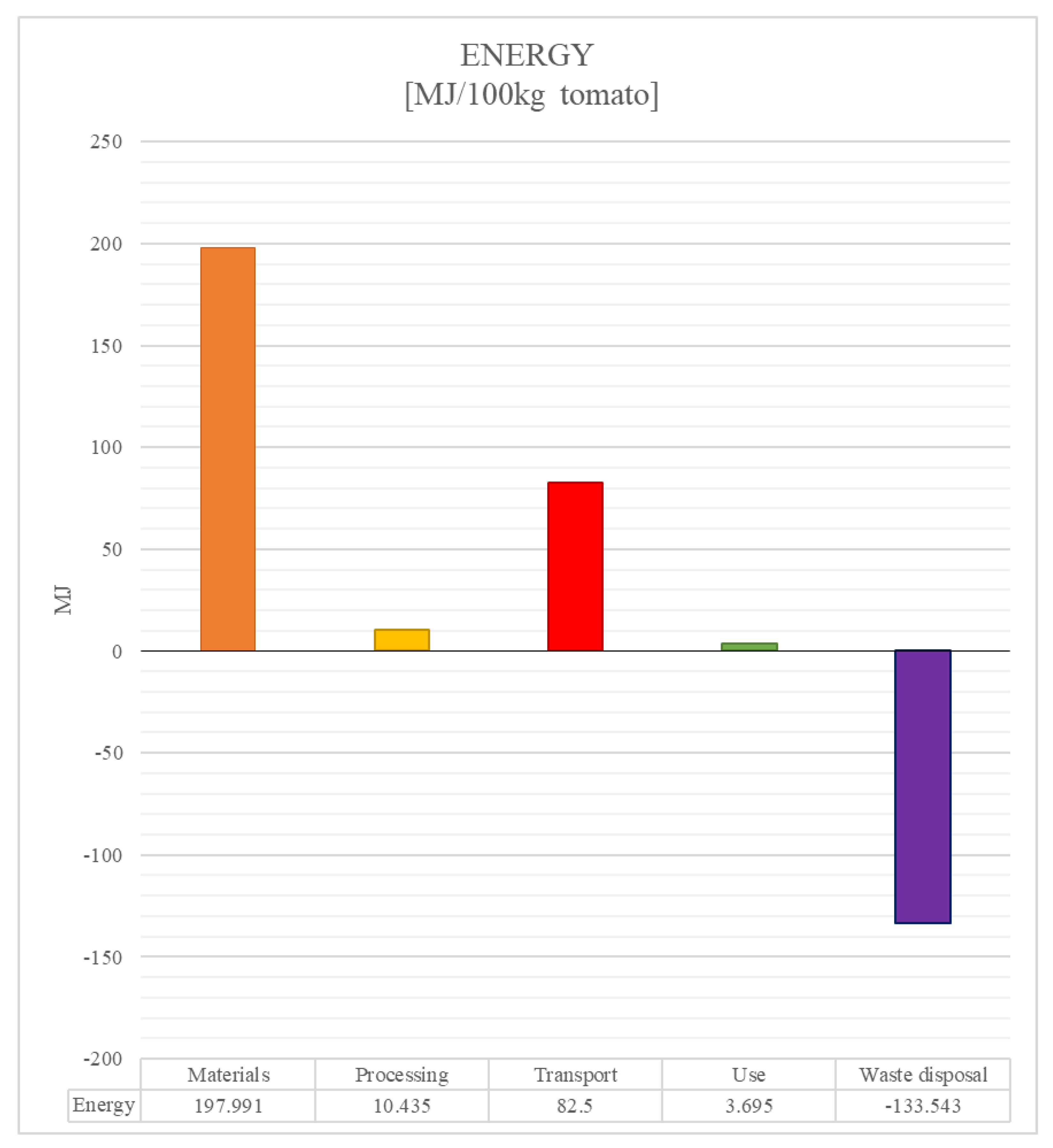

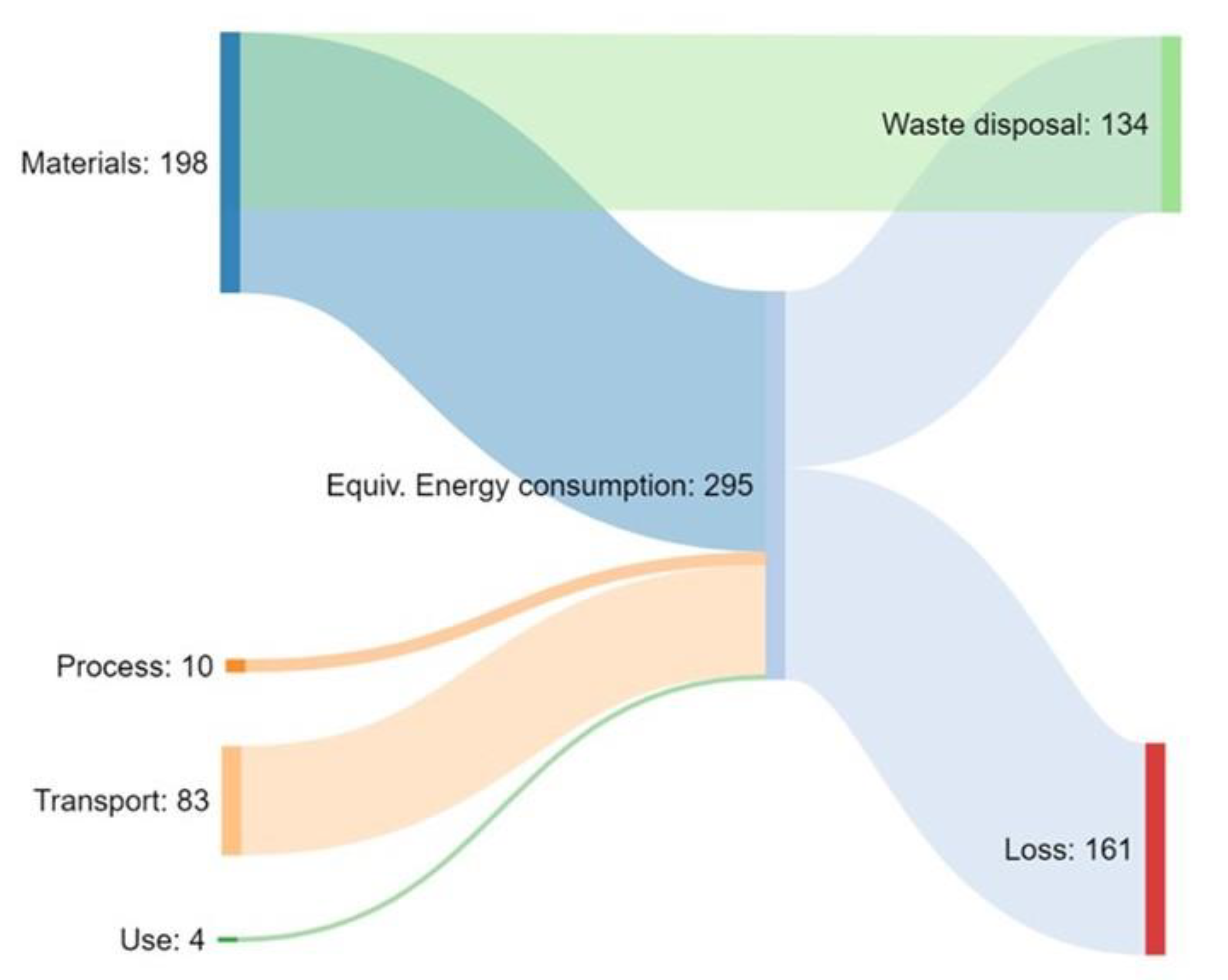

3.1. Energy Consumption

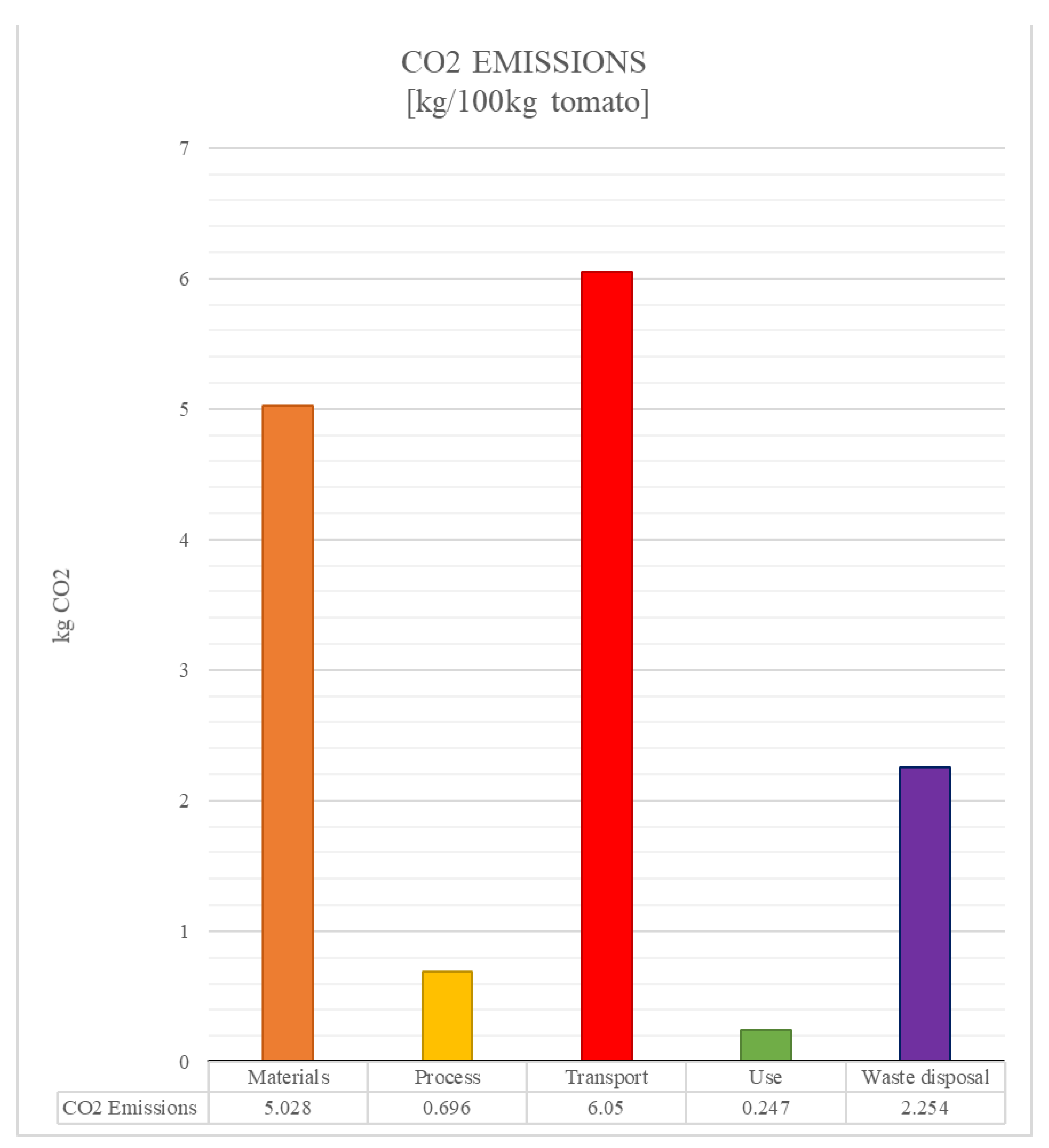

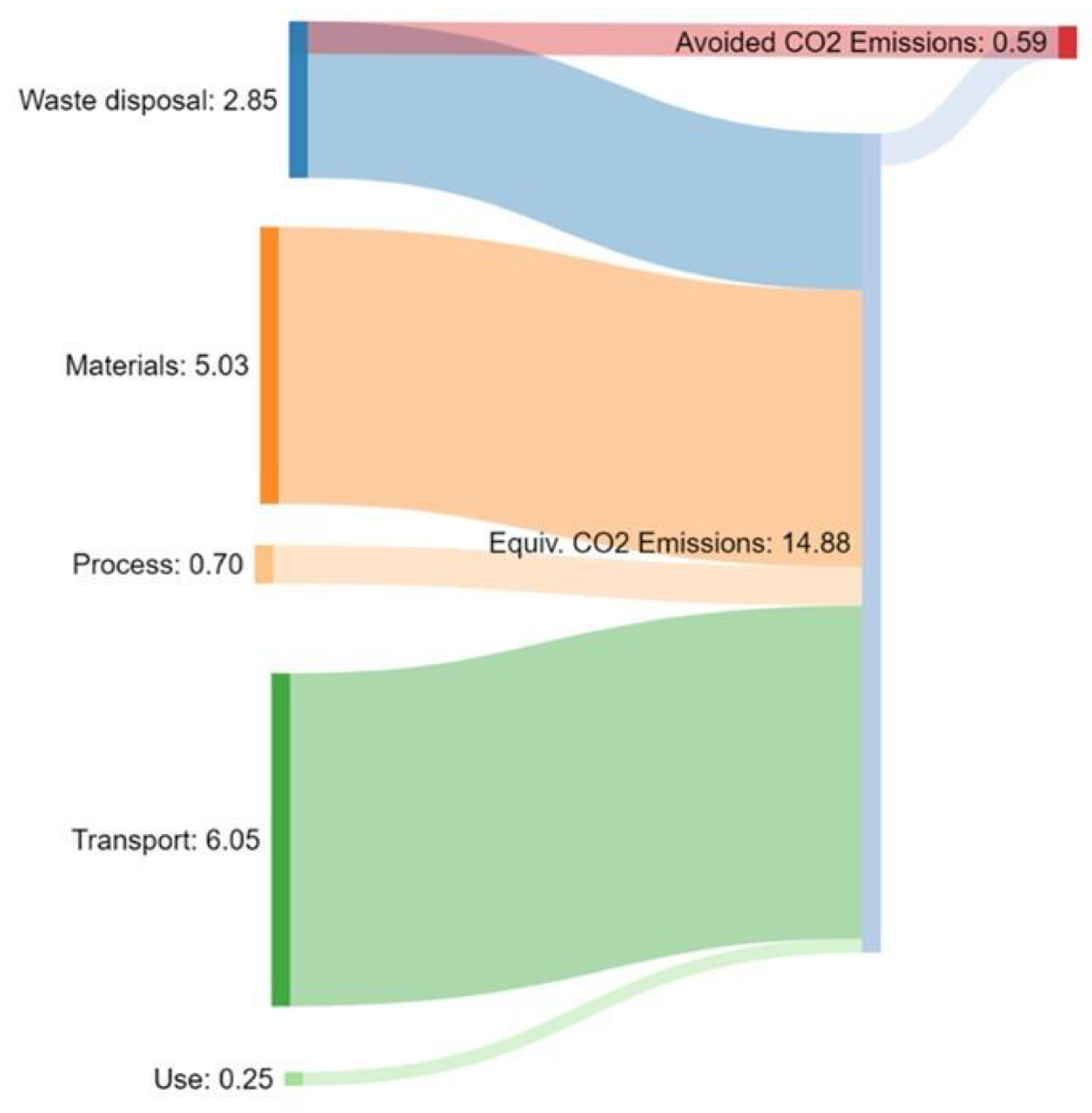

3.2. CO2 Emissions

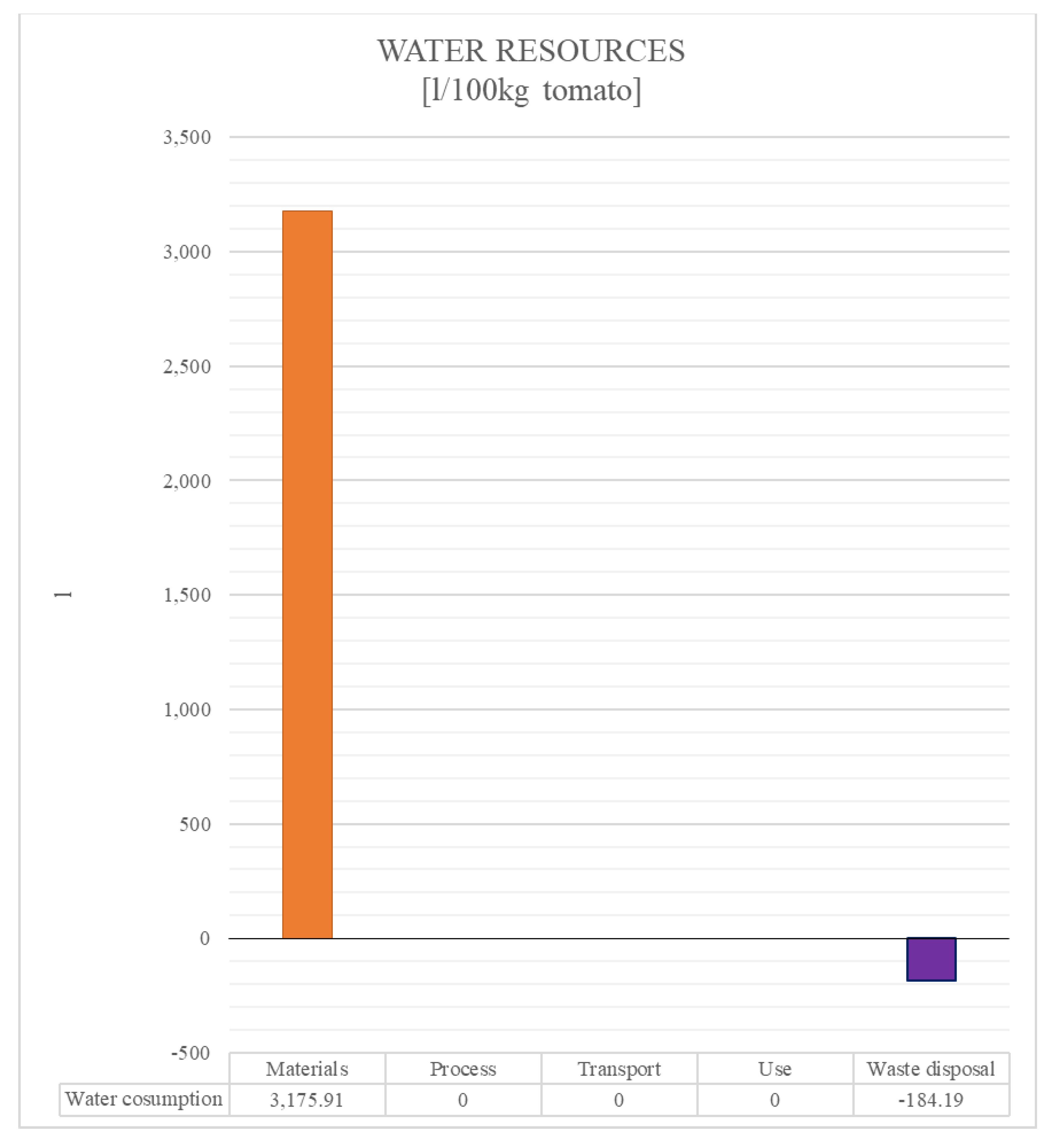

3.3. Water Consumption

3.4. The Role of Food Losses on the Environmental Impact of Tomatoes

4. Discussion

4.1. Energy Alternatives

4.2. Reducing CO2 Emissions

4.3. Reducing Water Consumption

4.4. Considerations on Food Loss

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Morone, P.; Koutinas, A.; Gathergood, N.; Arshadi, M.; Matharu, A. Food Waste: Challenges and Opportunities for Enhancing the Emerging Bio-Economy. J. Clean Prod. 2019, 221, 10–16. [Google Scholar] [CrossRef]

- Gustafsson, J.; Cederberg, C.; Sonesson, U. The Methodology of the FAO Study: Global Food Losses and Food Waste-Extent, Causes and Prevention-FAO, 2011; SIK Institutet för Livsmedel och Bioteknik: Göteborg, Sweden, 2013. [Google Scholar]

- Teigiserova, D.A.; Hamelin, L.; Thomsen, M. Towards Transparent Valorization of Food Surplus, Waste and Loss: Clarifying Definitions, Food Waste Hierarchy, and Role in the Circular Economy. Sci. Total Environ. 2020, 706, 136033. [Google Scholar] [CrossRef]

- World Resources Institute. Creating a Sustainable Food Future: A Menu of Solutions. Available online: https://www.wri.org/research/creating-sustainable-food-future (accessed on 9 August 2021).

- IPCC Summary for Policy Makers. Climate Change 2014 Impacts, Adaptation Vulnerability—Contribution of Working Group II to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2014; pp. 1–32. [Google Scholar] [CrossRef]

- Xue, L.; Liu, G.; Parfitt, J.; Liu, X.; Herpen, E.; Van Stenmarck, Å.; O’Connor, C.; Östergren, K.; Cheng, S. Missing Food, Missing Data? A Critical Review of Global Food Losses and Food Waste Data. Environ. Sci. Technol. 2017, 51, 6618–6633. [Google Scholar] [CrossRef] [PubMed]

- Canali, M.; Amani, P.; Aramyan, L.; Gheoldus, M.; Moates, G.; Östergren, K.; Silvennoinen, K.; Waldron, K.; Vittuari, M. Food Waste Drivers in Europe, from Identification to Possible Interventions. Sustainability 2016, 9, 37. [Google Scholar] [CrossRef] [Green Version]

- Vittuari, M.; Politano, A.; Gaiani, S.; Canali, M.; Elander, M. Review of EU Legislation and Policies with Implications on Food Waste; European Union: Brussels, Belgium, 2015. [Google Scholar]

- Ilgin, M.A.; Gupta, S.M. Environmentally Conscious Manufacturing and Product Recovery (ECMPRO): A Review of the State of the Art. J. Environ. Manag. 2010, 91, 563–591. [Google Scholar] [CrossRef]

- Scherhaufer, S.; Moates, G.; Hartikainen, H.; Waldron, K.; Obersteiner, G. Environmental Impacts of Food Waste in Europe. Waste Manag. 2018, 77, 98–113. [Google Scholar] [CrossRef] [PubMed]

- Mondello, G.; Salomone, R.; Ioppolo, G.; Saija, G.; Sparacia, S.; Lucchetti, M.C. Comparative LCA of Alternative Scenarios for Waste Treatment: The Case of Food Waste Production by the Mass-Retail Sector. Sustainability 2017, 9, 827. [Google Scholar] [CrossRef] [Green Version]

- Beretta, C.; Hellweg, S. Potential Environmental Benefits from Food Waste Prevention in the Food Service Sector. Resour. Conserv. Recycl. 2019, 147, 169–178. [Google Scholar] [CrossRef]

- Wikström, F.; Williams, H.; Venkatesh, G. The Influence of Packaging Attributes on Recycling and Food Waste Behaviour—An Environmental Comparison of Two Packaging Alternatives. J. Clean Prod. 2016, 137, 895–902. [Google Scholar] [CrossRef] [Green Version]

- Rigamonti, L.; Grosso, M.; Giugliano, M. Life Cycle Assessment of Sub-Units Composing a MSW Management System. J. Clean Prod. 2010, 18, 1652–1662. [Google Scholar] [CrossRef]

- Saer, A.; Lansing, S.; Davitt, N.H.; Graves, R.E. Life Cycle Assessment of a Food Waste Composting System: Environmental Impact Hotspots. J. Clean Prod. 2013, 52, 234–244. [Google Scholar] [CrossRef]

- Yeo, J.; Chopra, S.S.; Zhang, L.; An, A.K. Life Cycle Assessment (LCA) of Food Waste Treatment in Hong Kong: On-Site Fermentation Methodology. J. Environ. Manag. 2019, 240, 343–351. [Google Scholar] [CrossRef]

- Andersson, K.; Ohlsson, T.; Olsson, P. Screening Life Cycle Assessment (LCA) of Tomato Ketchup: A Case Study. J. Clean Prod. 1998, 6, 277–288. [Google Scholar] [CrossRef]

- Gasol, C.M.; Salvia, J.; Serra, J.; Antón, A.; Sevigne, E.; Rieradevall, J.; Gabarrell, X. A Life Cycle Assessment of Biodiesel Production from Winter Rape Grown in Southern Europe. Biomass Bioenergy 2012, 40, 71–81. [Google Scholar] [CrossRef]

- Denny, G.M. Urban agriculture and seasonal food footprints: An LCA study of tomato production and consumption in the UK. In Sustainable Food Planning: Evolving Theory and Practice; Chapter 27; Wageningen Academic Publishers: Wageningen, The Netherlands, 2012; pp. 323–336. [Google Scholar] [CrossRef]

- Torrellas, M.; Antón, A.; López, J.C.; Baeza, E.J.; Parra, J.P.; Muñoz, P.; Montero, J.I. LCA of a Tomato Crop in a Multi-Tunnel Greenhouse in Almeria. Int. J. Life Cycle Assess. 2012, 17, 863–875. [Google Scholar] [CrossRef]

- Bernstad Saraiva Schott, A.; Andersson, T. Food Waste Minimization from a Life-Cycle Perspective. J. Environ. Manag. 2015, 147, 219–226. [Google Scholar] [CrossRef] [PubMed]

- Zarei, M.J.; Kazemi, N.; Marzban, A. Life Cycle Environmental Impacts of Cucumber and Tomato Production in Open-Field and Greenhouse. J. Saudi Soc. Agric. Sci. 2019, 18, 249–255. [Google Scholar] [CrossRef]

- Canaj, K.; Mehmeti, A.; Cantore, V.; Todorović, M. LCA of Tomato Greenhouse Production Using Spatially Differentiated Life Cycle Impact Assessment Indicators: An Albanian Case Study. Environ. Sci. Pollut. Res. 2020, 27, 6960–6970. [Google Scholar] [CrossRef]

- Benedetti, B.; De Toso, D.; Baldo, G.L.; Rollino, S. EcoAudit: A Renewed Simplified Procedure to Facilitate the Environmentally Informed Material Choice Orienting the Further Life Cycle Analysis for Ecodesigners. Mater. Trans. 2010, 51, 832–837. [Google Scholar] [CrossRef] [Green Version]

- European Commission. Life Cycle Indicators Framework: Development of Life Cycle Based Macro-Level Monitoring Indicators for Resources, Products and Waste for the EU-27; Institute for Environment and Sustainability: Luxembourg, 2012. [Google Scholar]

- The CES EduPack Eco Audit Tool? A White Paper—MAELabs UCSD. Available online: https://www.yumpu.com/en/document/view/18639559/the-ces-edupack-eco-audit-tool-a-white-paper-maelabs-ucsd (accessed on 29 July 2021).

- González, R. Evaluación del Impacto Energético-Ambiental Asociado a la Pérdida y el Desperdicio de Alimentos en España; Comillas Pontifical University: Madrid, Spain, 2021. [Google Scholar]

- Lipińska, M.; Tomaszewska, M.; Kołożyn-Krajewska, D. Identifying Factors Associated with Food Losses during Transportation: Potentials for Social Purposes. Sustainability 2019, 11, 2046. [Google Scholar] [CrossRef] [Green Version]

- Bani, R.J.; Josiah, M.N.; Kra, E.Y. Postharvest Losses of Tomatoes in Transit; University of Ghana: Accra, Ghana, 2006. [Google Scholar]

- Singh, J.; Shani, A.B.R.; Femal, H.; Deif, A. Packaging’s Role in Sustainability: Reusable Plastic Containers in the Agricultural-Food Supply Chains. Organ. Sustain. Eff. 2016, 5, 175–204. [Google Scholar] [CrossRef]

- Lo-Iacono-Ferreira, V.; Viñoles-Cebolla, R.; Bastante-Ceca, M.; Capuz-Rizo, S. Carbon Footprint Comparative Analysis of Cardboard and Plastic Containers Used for the International Transport of Spanish Tomatoes. Sustainability 2021, 13, 2552. [Google Scholar] [CrossRef]

- Chonhenchob, V.; Singh, S.P. A Comparison of Corrugated Boxes and Reusable Plastic Containers for Mango Distribution. Packag. Technol. Sci. 2003, 16, 231–237. [Google Scholar] [CrossRef]

- Edwards-Jones, G. Does Eating Local Food Reduce the Environmental Impact of Food Production and Enhance Consumer Health? Proc. Nutr. Soc. 2010, 69, 582–591. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pérez-Martínez, P.J.; Sorba, I.A. Energy Consumption of Passenger Land Transport Modes. Energy Environ. 2010, 21, 577–600. [Google Scholar] [CrossRef]

- Ministerio de Transportes, Movilidad y Agenda Urbana. Report of the Technical-Scientific Commission for the Study of Improvements in the Railway Sector. Available online: https://www.mitma.gob.es/ferrocarriles/informe-para-el-estudio-de-mejoras-en-sector-ferroviario/english-version (accessed on 28 July 2021).

- McKinnon, A.C. Green Logistics: Improving the Environmental Sustainability of Logistics; Kogan Page: London, UK, 2010; p. 372. [Google Scholar]

- Gerçek, S.; Demirkaya, M.; Işik, D. Water Pillow Irrigation versus Drip Irrigation with Regard to Growth and Yield of Tomato Grown under Greenhouse Conditions in a Semi-Arid Region. Agric. Water Manag. 2017, 180, 172–177. [Google Scholar] [CrossRef]

- Valenzano, V.; Parente, A.; Serio, F.; Santamaria, P. Effect of Growing System and Cultivar on Yield and Water-Use Efficiency of Greenhouse-Grown Tomato. J. Hortic. Sci. Biotechnol. 2008, 83, 71–75. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, H.; Zhu, H. CRISPR Technology Is Revolutionizing the Improvement of Tomato and Other Fruit Crops. Hortic. Res. 2019, 6, 77. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cheng, J.; Shearin, T.E.; Peet, M.M.; Willits, D.H. Utilization of Treated Swine Wastewater for Greenhouse Tomato Production. Water Sci. Technol. 2004, 50, 77–82. [Google Scholar] [CrossRef]

- Løvdal, T.; Droogenbroeck, B.; Van Eroglu, E.C.; Kaniszewski, S.; Agati, G.; Verheul, M.; Skipnes, D. Valorization of Tomato Surplus and Waste Fractions: A Case Study Using Norway, Belgium, Poland, and Turkey as Examples. Foods 2019, 8, 229. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Global Food Losses and Food Waste. Available online: http://www.fao.org/3/mb060e/mb060e00.htm (accessed on 28 July 2021).

- Beretta, C.; Stoessel, F.; Baier, U.; Hellweg, S. Quantifying Food Losses and the Potential for Reduction in Switzerland. Waste Manag. 2013, 33, 764–773. [Google Scholar] [CrossRef] [Green Version]

- Ribeiro, I.; Sobral, P.; Peças, P.; Henriques, E. A Sustainable Business Model to Fight Food Waste. J. Clean Prod. 2018, 177, 262–275. [Google Scholar] [CrossRef]

- Mookerjee, S.; Cornil, Y.; Hoegg, J. From Waste to Taste: How “Ugly” Labels Can Increase Purchase of Unattractive Produce. J. Mark. 2021, 85, 62–77. [Google Scholar] [CrossRef]

- Porter, S.D.; Reay, D.S.; Bomberg, E.; Higgins, P. Avoidable Food Losses and Associated Production-Phase Greenhouse Gas Emissions Arising from Application of Cosmetic Standards to Fresh Fruit and Vegetables in Europe and the UK. J. Clean Prod. 2018, 201, 869–878. [Google Scholar] [CrossRef] [Green Version]

- Bernstad, A.K.; Cánovas, A.; Valle, R. Consideration of Food Wastage along the Supply Chain in Lifecycle Assessments: A Mini-Review Based on the Case of Tomatoes. Waste Manag. Res. 2017, 35, 29–39. [Google Scholar] [CrossRef]

- Benítez, J.J.; Castillo, P.M.; Del Río, J.C.; León-Camacho, M.; Domínguez, E.; Heredia, A.; Guzmán-Puyol, S.; Athanassiou, A.; Heredia-Guerrero, J.A. Valorization of Tomato Processing by-Products: Fatty Acid Extraction and Production of Bio-Based Materials. Materials 2018, 11, 2211. [Google Scholar] [CrossRef] [Green Version]

- Benoît, C.; Parent, J.; Kuenzi, I.; Revéret, J.-P. Corporate social responsibilities. In Developing a Methodology for Social Life Cycle Assessment: The North American Tomato’s CSR Case, Proceedings of the Governance and Life Cycle Analysis Opportunities for Going Beyond ISO-LCA, Brussels, Belgium, 27–28 September 2007; CIRAIG: Montréal, QC, Canada, 2007. [Google Scholar]

- Bouzid, A.; Padilla, M. Analysis of Social Performance of the Industrial Tomatoes Food Chain in Algeria. New Medit 2014, 13, 60–66. [Google Scholar]

- Petti, L.; Sanchez Ramirez, P.K.; Traverso, M.; Ugaya, C.M.L. An Italian Tomato “Cuore Di Bue” Case Study: Challenges and Benefits Using Subcategory Assessment Method for Social Life Cycle Assessment. Int. J. Life Cycle Assess. 2018, 23, 569–580. [Google Scholar] [CrossRef]

- Gillman, A.; Campbell, D.C.; Spang, E.S. Does On-Farm Food Loss Prevent Waste? Insights from California Produce Growers. Resour. Conserv. Recycl. 2019, 150, 104408. [Google Scholar] [CrossRef] [Green Version]

- Goossens, Y.; Wegner, A.; Schmidt, T. Sustainability Assessment of Food Waste Prevention Measures: Review of Existing Evaluation Practices. Front. Sustain. Food Syst. 2019, 3, 90. [Google Scholar] [CrossRef]

- Hebrok, M.; Boks, C. Household Food Waste: Drivers and Potential Intervention Points for Design—An Extensive Review. J. Clean Prod. 2017, 151, 380–392. [Google Scholar] [CrossRef]

| Life Cycle Stage | System Boundaries | Energy | CO2-e Emissions | Water | |

|---|---|---|---|---|---|

| Materials | LDPE | 0.4131 kg | 81 MJ/kg | 2.8 kg CO2/kg | 58 L/kg |

| Water | 2850 L | Embedded in fruit | - | 1 L/kg | |

| Nutrients | 4.6125 kg | Embedded in fruit | - | See water | |

| Cardboard | 3.226 kg | 51 MJ/kg | 1.2 kg CO2/kg | 93.6 L/kg | |

| Processing | Greenhouse | N/A | 11.594 kWh…0.9 MJ/kWh 1 | 0.06 CO2/kWh | - |

| Packaging | N/A | Manual work | - | - | |

| Transportation | Diesel 14 t truck | 550 km | 1.5 MJ/km/t | 0.11 kg CO2/Km/t | - |

| Use | Consumed | 3 d in fridge | 3.4768 kWh…0.9 MJ/kWh 1 | 0.06 CO2/kWh | - |

| Discarded | 7 d in fridge | 6.7881 kWh…0.9 MJ/kWh 1 | 0.06 CO2/kWh | - | |

| Disposal (tomatoes) | Losses at greenhouse | 0.5498 kg | - | - | - |

| Losses at packaging | 2 kg | - | - | - | |

| Losses at distribution | 9.8 kg | - | - | - | |

| Losses in households (compost) | 16.8 kg (33%) | −1.33 MJ/kg | - | - | |

| Disposal (other) | Combustion fresh residue (plant parts) | 0.5498 kg | −15.194 MJ/kg 2 | - | - |

| Recycling LDPE | 8.44% | −27.3 MJ/kg 2 | −1.02 kg CO2/kg 2 | - | |

| Combustion LDPE | 91.66% | −45.1 MJ/kg 2 | 3.14 kg CO2/kg | - | |

| Recycling cardboard | 72% | −18.85 MJ/kg 2 | −0.973 kg CO2/kg 2 | −61% 2 | |

| Combustion cardboard | 28% | −19.7 MJ/kg | 1.835 kg CO2/kg | - | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hueso-Kortekaas, K.; Romero, J.C.; González-Felipe, R. Energy-Environmental Impact Assessment of Greenhouse Grown Tomato: A Case Study in Almeria (Spain). World 2021, 2, 425-441. https://doi.org/10.3390/world2030027

Hueso-Kortekaas K, Romero JC, González-Felipe R. Energy-Environmental Impact Assessment of Greenhouse Grown Tomato: A Case Study in Almeria (Spain). World. 2021; 2(3):425-441. https://doi.org/10.3390/world2030027

Chicago/Turabian StyleHueso-Kortekaas, Katia, José C. Romero, and Raquel González-Felipe. 2021. "Energy-Environmental Impact Assessment of Greenhouse Grown Tomato: A Case Study in Almeria (Spain)" World 2, no. 3: 425-441. https://doi.org/10.3390/world2030027

APA StyleHueso-Kortekaas, K., Romero, J. C., & González-Felipe, R. (2021). Energy-Environmental Impact Assessment of Greenhouse Grown Tomato: A Case Study in Almeria (Spain). World, 2(3), 425-441. https://doi.org/10.3390/world2030027